Organosilicon acrylate compound waterproof finishing agent emulsion

A technology of silicone emulsion and silicone acrylate, which is applied in fiber treatment, textiles and papermaking, fiber types, etc., can solve the problems of poor washability and poor film fastness on the surface of fabrics, and achieve enhanced water repellency, Reduced surface tension, good film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Silicone acrylate composite waterproof finishing agent emulsion is formed by blending silicone emulsion and silicon-containing acrylate emulsion, in terms of mass percentage, 68% of silicone emulsion and 32% of silicon-containing acrylate emulsion; under stirring, the organic Slowly add silicon emulsion into silicon-containing acrylate emulsion, mix well;

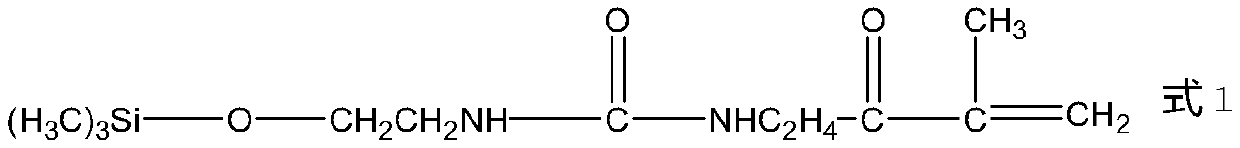

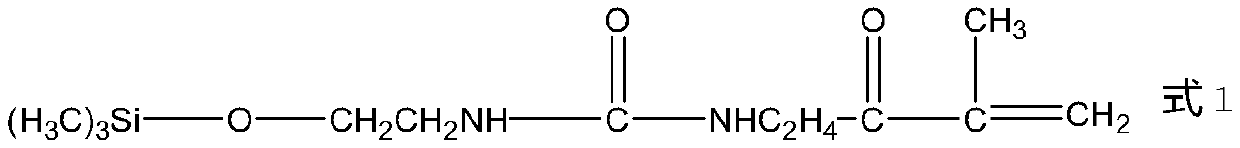

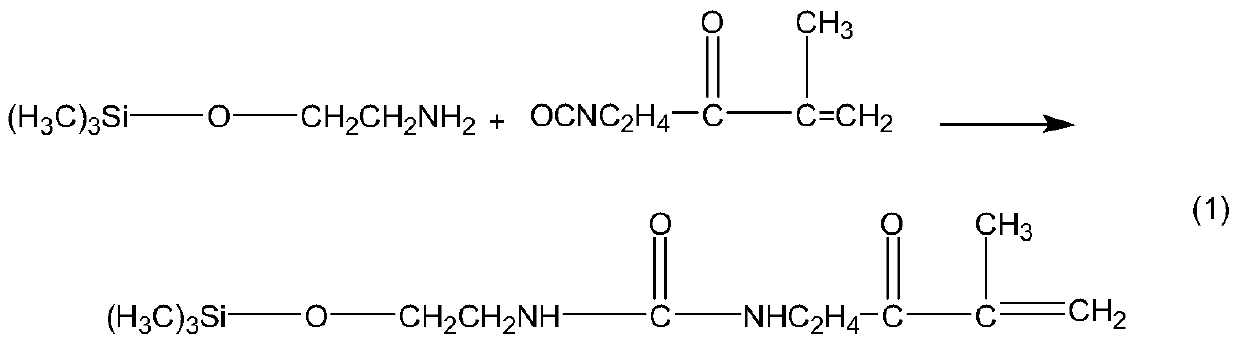

[0042] The silicone emulsion is mainly composed of vinyl nano-SiO 2 Sol, polymerizable organosilicon monomer (as shown in the above formula 1), vinyl siloxane emulsion polymerization, the preparation method is as follows:

[0043] 1) Add 80 parts of vinyl siloxane emulsion, 40 parts of water, 2 parts of AEO-9, 1 part of AEO-7 into the emulsifier, slowly add 24 parts of polymerizable silicone monomer under stirring, and keep stirring to emulsify for 0.5 h, into a pre-emulsion;

[0044] 2) 50 parts of vinyl siloxane emulsion, 14 parts of vinyl nano-SiO 2 Add sol, 50 parts of water, and 20% pre-emulsion (volume ratio) ...

Embodiment 2

[0058] Silicone acrylate composite waterproof finishing agent emulsion is formed by blending silicone emulsion and silicon-containing acrylate emulsion. In terms of mass percentage, silicone emulsion is 59%, and silicon-containing acrylate emulsion is 41%. Slowly add silicon emulsion into silicon-containing acrylate emulsion, mix well;

[0059] The silicone emulsion is mainly composed of vinyl nano-SiO 2 Sol, polymerizable organosilicon monomer (as shown in the above formula 1), vinyl siloxane emulsion polymerization, the preparation method is as follows:

[0060] 1) Add 80 parts of vinyl siloxane emulsion, 40 parts of water, 2 parts of AEO-9, 1 part of AEO-7 into the emulsifier, slowly add 24 parts of polymerizable silicone monomer under stirring, and keep stirring to emulsify for 0.5 h, into a pre-emulsion;

[0061] 2) 50 parts of vinyl siloxane emulsion, 14 parts of vinyl nano-SiO 2 Add sol, 50 parts of water, and 20% pre-emulsion (volume ratio) into the reactor, stir an...

Embodiment 3

[0075] Silicone acrylate composite waterproof finishing agent emulsion is formed by blending silicone emulsion and silicon-containing acrylate emulsion, in terms of mass percentage, 52% of silicone emulsion and 48% of silicon-containing acrylate emulsion; under stirring, the organic Slowly add silicon emulsion into silicon-containing acrylate emulsion, mix well;

[0076] The silicone emulsion is mainly composed of vinyl nano-SiO 2 Sol, polymerizable organosilicon monomer (as shown in the above formula 1), vinyl siloxane emulsion polymerization, the preparation method is as follows:

[0077] 1) Add 80 parts of vinyl siloxane emulsion, 40 parts of water, 2 parts of AEO-9, 1 part of AEO-7 into the emulsifier, slowly add 24 parts of polymerizable silicone monomer under stirring, and keep stirring to emulsify for 0.5 h, into a pre-emulsion;

[0078] 2) 50 parts of vinyl siloxane emulsion, 14 parts of vinyl nano-SiO 2 Add sol, 50 parts of water, and 20% pre-emulsion (volume ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com