High-barrier spun and melted novel breathable material as well as preparation method and application thereof

A high-barrier, mixed-type technology, applied in textiles and papermaking, medical science, bandages, etc., can solve problems such as unfavorable baby health, engine oil residue, etc., and achieve high water repellency, low surface tension, and improved air permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

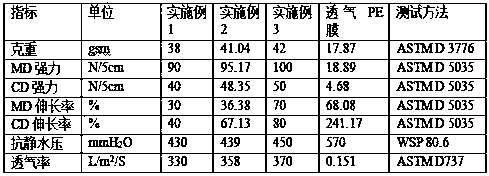

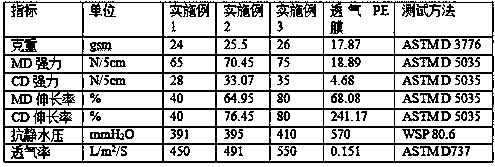

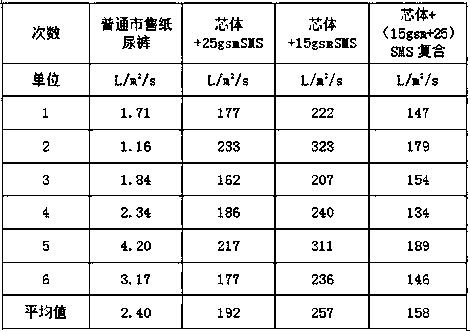

Embodiment 1

[0057] Example 1 A new high-barrier spunmelt hybrid breathable material and its preparation method

[0058] A preparation method of a high-barrier spunmelt hybrid breathable new material of the present invention comprises the following steps:

[0059] (1) Material selection:

[0060] As for the selection of materials, high-quality and differentiated raw materials are selected.

[0061] The raw materials include S-layer raw materials and M-layer raw materials;

[0062] The S-layer raw materials include spunbond PP material, high barrier masterbatch and white masterbatch;

[0063] The spunbonded PP material has an MFR range of 32-40g / 10min;

[0064] The high-barrier masterbatch is polypropylene particles with a fluorine-containing ratio in the range of 10-30%, and the MFR range is in the range of 70-105 g / 10min;

[0065] The white masterbatch is titanium dioxide TiO 2 ;

[0066] The addition ratio of the high barrier masterbatch is 1%, the addition ratio of the white maste...

Embodiment 2

[0085] Example 2 A high-barrier spunmelt hybrid breathable new material and its preparation method

[0086] A preparation method of a high-barrier spunmelt hybrid breathable new material of the present invention comprises the following steps:

[0087] (1) Material selection:

[0088] As for the selection of materials, high-quality and differentiated raw materials are selected.

[0089] The raw materials include S-layer raw materials and M-layer raw materials;

[0090] The S-layer raw materials include spunbond PP material, high barrier masterbatch and white masterbatch;

[0091] The spunbonded PP material has an MFR range of 32-40g / 10min,

[0092] The high-barrier masterbatch is polypropylene particles with a fluorine-containing ratio in the range of 10-30%, and the MFR range is in the range of 70-105 g / 10min;

[0093] The white masterbatch is titanium dioxide TiO 2 ;

[0094] The addition ratio of the high barrier masterbatch is 1.5%, the addition ratio of the white mas...

Embodiment 3

[0113] Example 3 A high-barrier spunmelt hybrid breathable new material and its preparation method

[0114] A preparation method of a high-barrier spunmelt hybrid breathable new material of the present invention comprises the following steps:

[0115] (1) Material selection:

[0116] As for the selection of materials, high-quality and differentiated raw materials are selected.

[0117] The raw materials include S-layer raw materials and M-layer raw materials;

[0118] The S-layer raw materials include spunbond PP material, high barrier masterbatch and white masterbatch;

[0119] The spunbonded PP material has an MFR range of 32-40g / 10min,

[0120] The high-barrier masterbatch is polypropylene particles with a fluorine-containing ratio in the range of 10-30%, and the MFR range is in the range of 70-105 g / 10min;

[0121] The white masterbatch is titanium dioxide TiO 2 ;

[0122] The addition ratio of the high barrier masterbatch is 10%, the addition ratio of the white mast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Air permeability | aaaaa | aaaaa |

| Powerful | aaaaa | aaaaa |

| Powerful | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com