3-cyanopyridine absorption method

The technology of a cyanopyridine and an absorption tower is applied in the absorption field of 3-cyanopyridine, which can solve the problems such as easy hydrolysis of 3-cyanopyridine, and achieve the effects of reducing energy consumption, improving absorption efficiency and achieving good technical effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

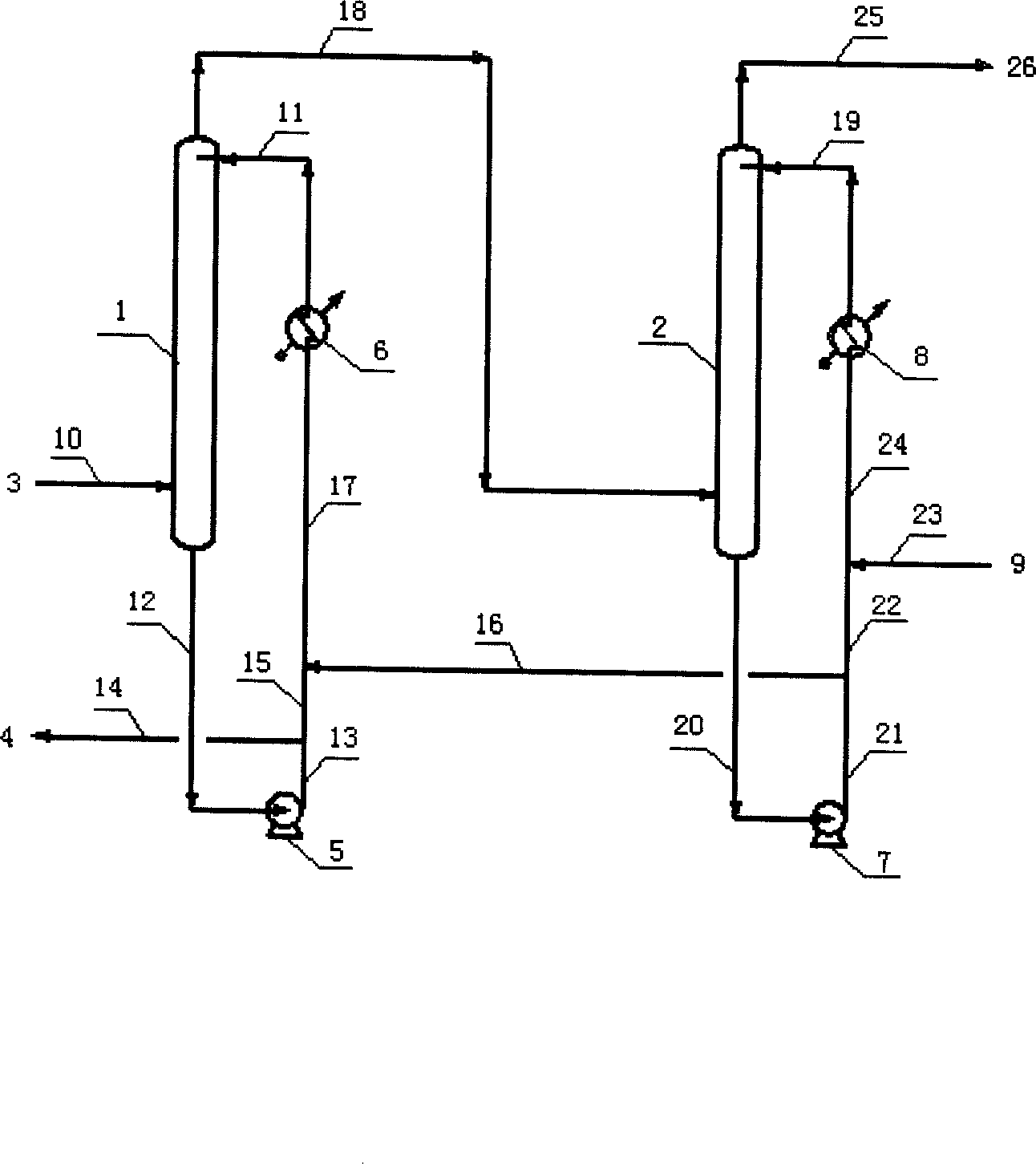

[0023]The gas-phase reaction product of 3-cyanopyridine obtained by the ammoxidation of 3-picoline is subjected to cyclic absorption in two towers, and the schematic diagram of the process flow is shown in Figure 1. The flow rate of the gaseous reaction product entering the first absorption tower is 1764.08 kg / hour, the temperature is 390°C, and the pressure is 40KPa, wherein the flow rate of 3-cyanopyridine is 152.76 kg / hour. The number of theoretical plates of the first absorption tower is 6, the pressure at the top of the tower is 30KPa, the pressure at the bottom of the tower is 35KPa, the temperature at the top of the tower is 46°C, the temperature at the bottom of the tower is 60°C, the weight ratio of liquid to gas is 10, and the temperature of the liquid circulating to the top of the tower is 45°C. The number of theoretical plates of the second absorption tower is also 6, the pressure at the top of the tower is 20KPa, the pressure at the bottom of the tower is 25KPa, th...

Embodiment 2

[0025] The absorption process conditions are the same as in Example 1, except that the concentration of 3-cyanopyridine in the bottom liquid of the first absorption tower remains 4% by weight, and the yield of 3-cyanopyridine is 96.6% by weight.

Embodiment 3

[0027] The absorption process conditions are the same as in Example 1, except that the number of theoretical plates in the first absorption tower and the second absorption tower is 12, and the yield of 3-cyanopyridine is 96.2% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com