Production method of waterborne polyurethane used for artificial leather bonding resin

A technology of water-based polyurethane and bonding resin, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of polyurethane initial adhesion and durability without comprehensive consideration, and achieve low labor intensity, High solid content, good hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

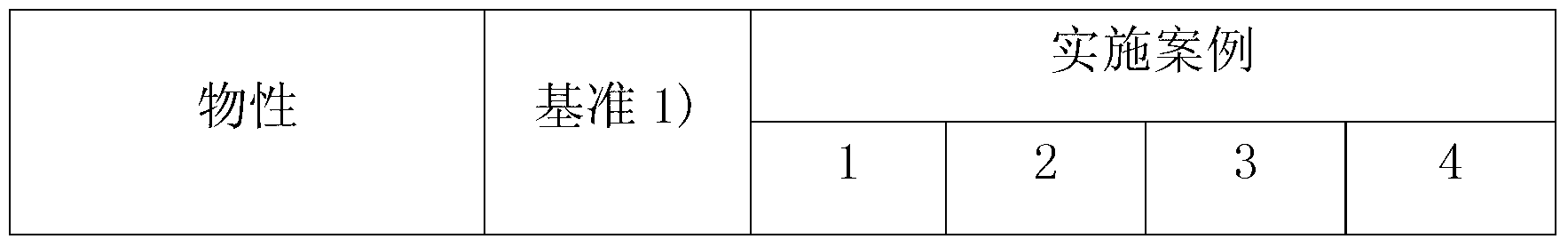

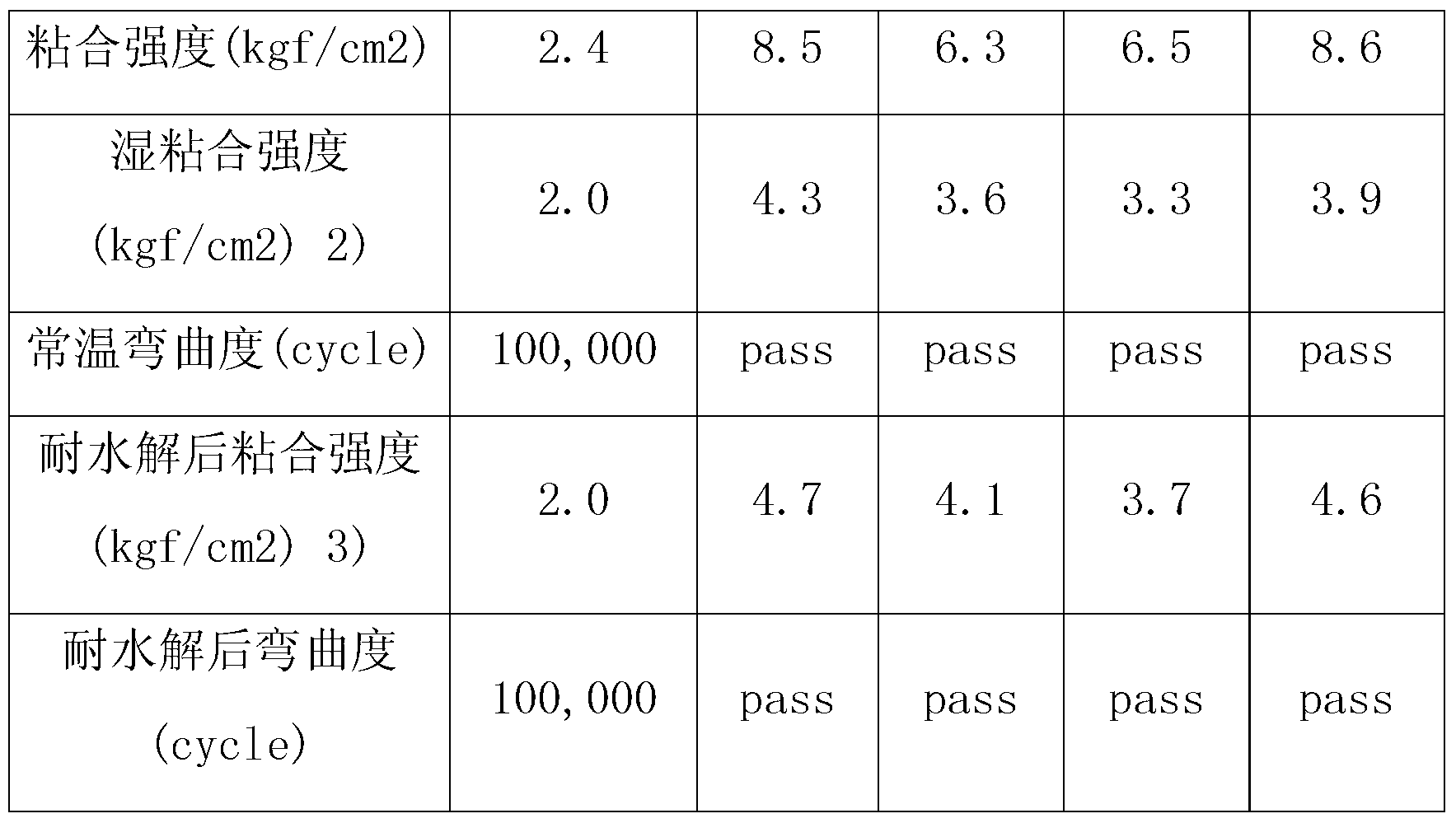

Examples

Embodiment 1

[0017] The first step, the preparation of water-based polyurethane A: put 650g of polyadipate and 1,4 butanediol ester polyol into the reactor to polymerize to obtain polyester polyol with a molecular weight of 2000, seal it, raise the temperature to 100°C, and React under 0.1MPa vacuum and pump water for 30 minutes, cool down to 80°C, put in 225.25g of isophorone diisocyanate, 24.55g of 1,4-butanediol and 80g of sulfonic acid polyether polyol, heat up to 100°C for reaction , react until the measured NCO% value is 2.01%; then cool down to 70°C, add 1500g of water at 1000 revolutions per minute, stir at high speed to disperse, reduce the speed to 200 revolutions per minute, then add 20.2g of piperazine, At 50°C, until the NCO group disappears (FT-IR measurement), the reaction is terminated after the final stirring, the solid content of the produced water-based polyurethane is 40%, and the Brookfield viscosity is 20cPs (1#, 30min / r, 25 ℃);

[0018] In the second step, the prepa...

Embodiment 2

[0020]The first step, the preparation of water-based polyurethane A: put 650g of polyadipate and 1,4 butanediol ester polyol into the reactor to polymerize to obtain polyester polyol with a molecular weight of 2000, seal it, raise the temperature to 100°C, and React under 0.1MPa vacuum and pump water for 30 minutes, cool down to 70°C, put in 207.36g of 1,6-hexamethylene diisocyanate, 26.82g of 1,4-butanediol and 70g of sulfonic polyether polyol, heat up to 90°C for reaction , react until the measured NCO% value is 2.37%; then cool down to 70°C, add 2757g of water at 1000 rpm, and stir at high speed to disperse. In the prepolymer, a total of 45.83g of isophorone diamine (IPDA) needs to be added, diluted with 100g of water, and isophorone diamine (IPDA) is slowly added within 10 minutes. Then cool down to 50°C until the NCO group disappears, and the reaction is terminated after stirring at last;

[0021] The solid content of the produced waterborne polyurethane is 35%, Brookfie...

Embodiment 3

[0025] The same steps as in Example 1 were used to obtain water-based polyurethane resin A and water-based polyurethane resin B.

[0026] Prepare according to the proportion of 60% water-based polyurethane A and 40% water-based polyurethane B.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brookfield viscosity | aaaaa | aaaaa |

| Brookfield viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com