Silicon-nitrile-based hybrid resin and synthesizing method thereof

A synthesis method and technology of silicon-based nitrile, which are applied in the field of organic synthetic polymer materials, can solve the problems of application difficulty and low temperature environment of liquid nitrogen, and achieve the effects of low reaction temperature, excellent mechanical properties and good thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

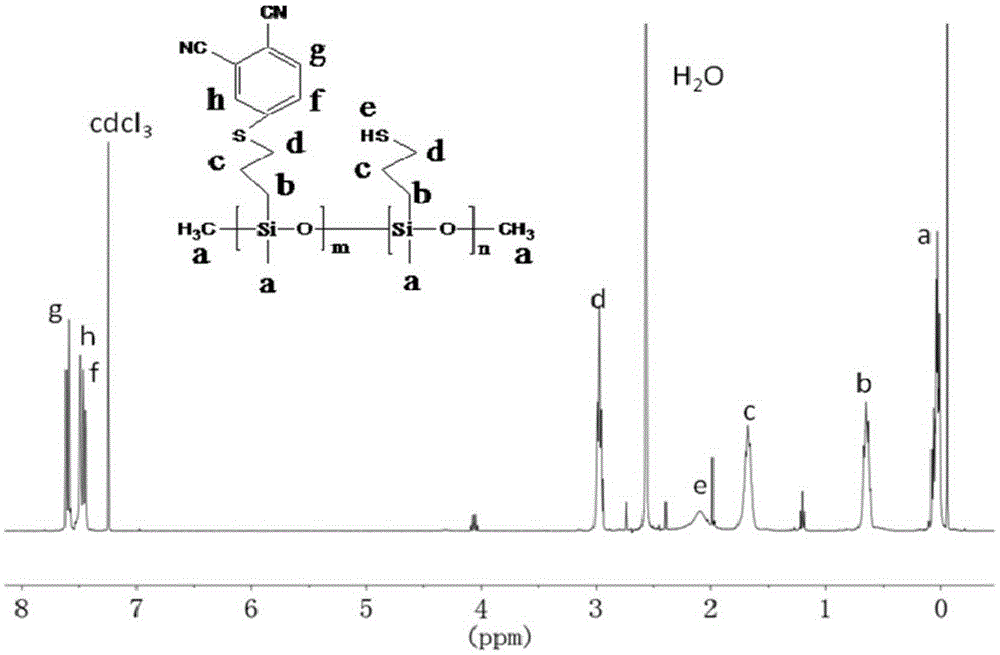

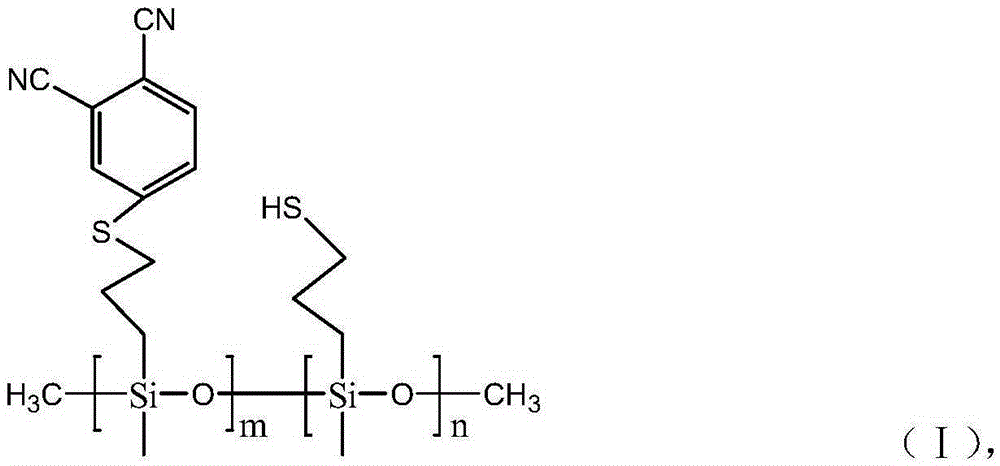

[0035] A silicon-based nitrile-based hybrid resin of the present invention has a molecular structural formula of the following formula (I):

[0036]

[0037] The number average molecular weight of the silicon-based nitrile-based hybrid resin is 7000-13000.

[0038] A kind of synthetic method of the silicon-based nitrile-based hybrid resin of above-mentioned present embodiment, comprises the following steps:

[0039] (1) Under the protection of nitrogen, mix and dissolve 0.0075mol of mercaptopropylmethylsiloxane (number average molecular weight is 4000-7000, kinematic viscosity is 75cSt~150cSt), 0.01125mol of anhydrous potassium carbonate in 20ml of dimethyl Sulfoxide DMSO (solvent), stirred at room temperature (35° C.) for 1 hour to obtain a solution containing potassium siloxane mercapto salt.

[0040] (2) Add 0.0075 mol of 4-nitrophthalonitrile to the above solution containing potassium siloxane mercapto salt, and stir at room temperature (35° C.) for 24 hours to obtain ...

Embodiment 2

[0044] A silicon-based nitrile-based hybrid resin of the present invention is the same as in Example 1.

[0045] A kind of synthetic method of the silicon-based nitrile-based hybrid resin of this embodiment, the steps are basically the same as in Example 1, the difference is only: in the step (1), the solvent used is N, N-dimethylformamide DMF, The stirring time is 2 hours; in step (2), the stirring time is 16 hours.

Embodiment 3

[0047] A silicon-based nitrile-based hybrid resin of the present invention is the same as in Example 1.

[0048] A kind of synthetic method of the silicon-based nitrile-based hybrid resin of this embodiment, the steps are basically the same as in Example 1, the difference is only: in the step (1), the solvent used is 1,4-dioxane, and the stirring time For 3 hours; in step (2), the stirring time was 22 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com