Method for producing butadiene by oxidatively dehydrogenating butene and used catalyst

An oxidative dehydrogenation, lattice oxygen catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve low energy consumption, reduced energy consumption, high Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

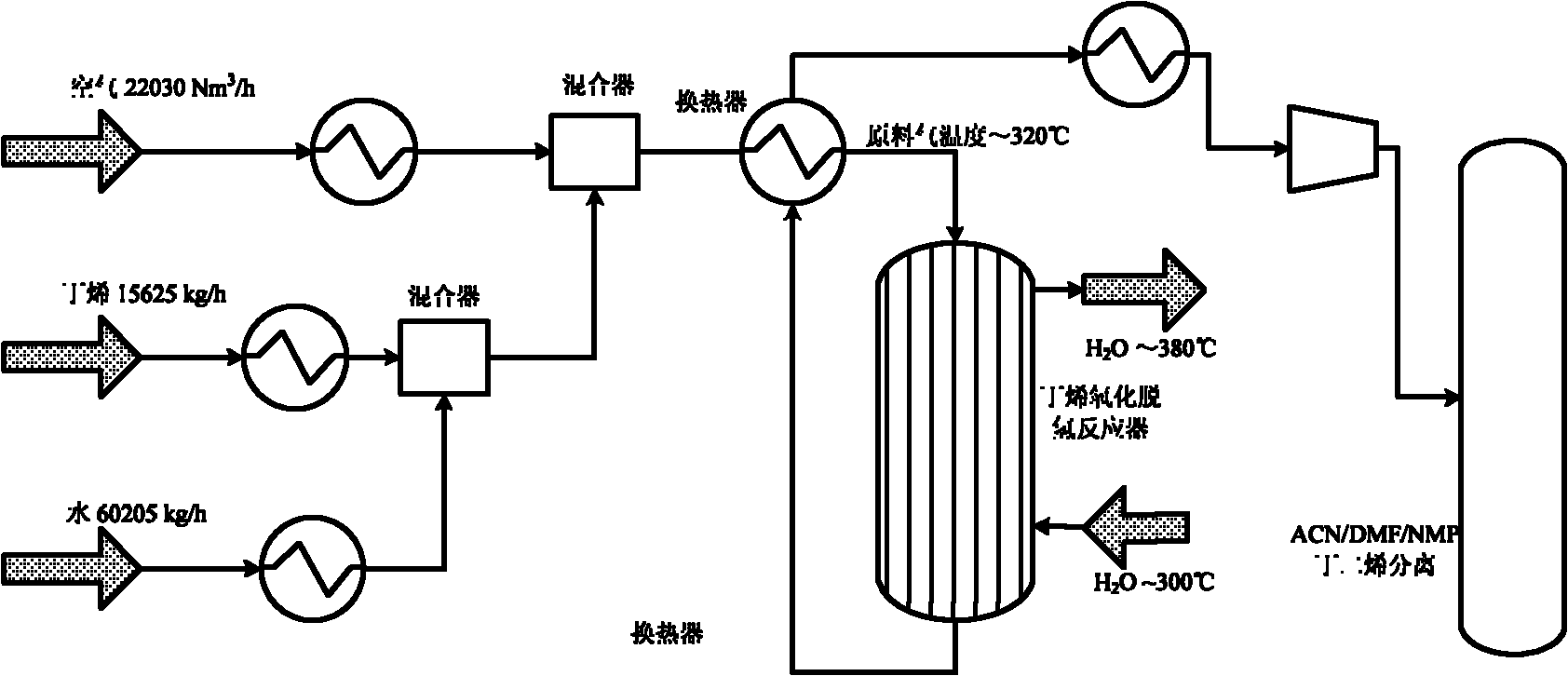

Embodiment 1

[0055] n-butene 15625kg / h, of which isobutene3 / h, preheat to 110°C, then mix butene with steam first, and then mix with oxygen. The mixed raw material gas and the product gas at 400°C are heat-exchanged and heated to react, then heat-exchanged and heated to 320°C, enter the tube reactor, and react under the action of a lattice oxygen catalyst. The temperature of the reaction gas at the outlet of the reactor is 400°C, and the heat of reaction It is removed by indirect heat exchange with water vapor, and the product gas is further cooled after heat exchange with the raw material gas. After separating a large amount of water, it is compressed and entered into the NMP process for the absorption, separation and purification of butadiene, which can produce butadiene of polymerization grade purity. olefin products. Butene single-pass conversion rate is 85%, butadiene selectivity is not less than 94%, butadiene yield is greater than 80%, and oxygen-containing compounds are less than ...

Embodiment 2

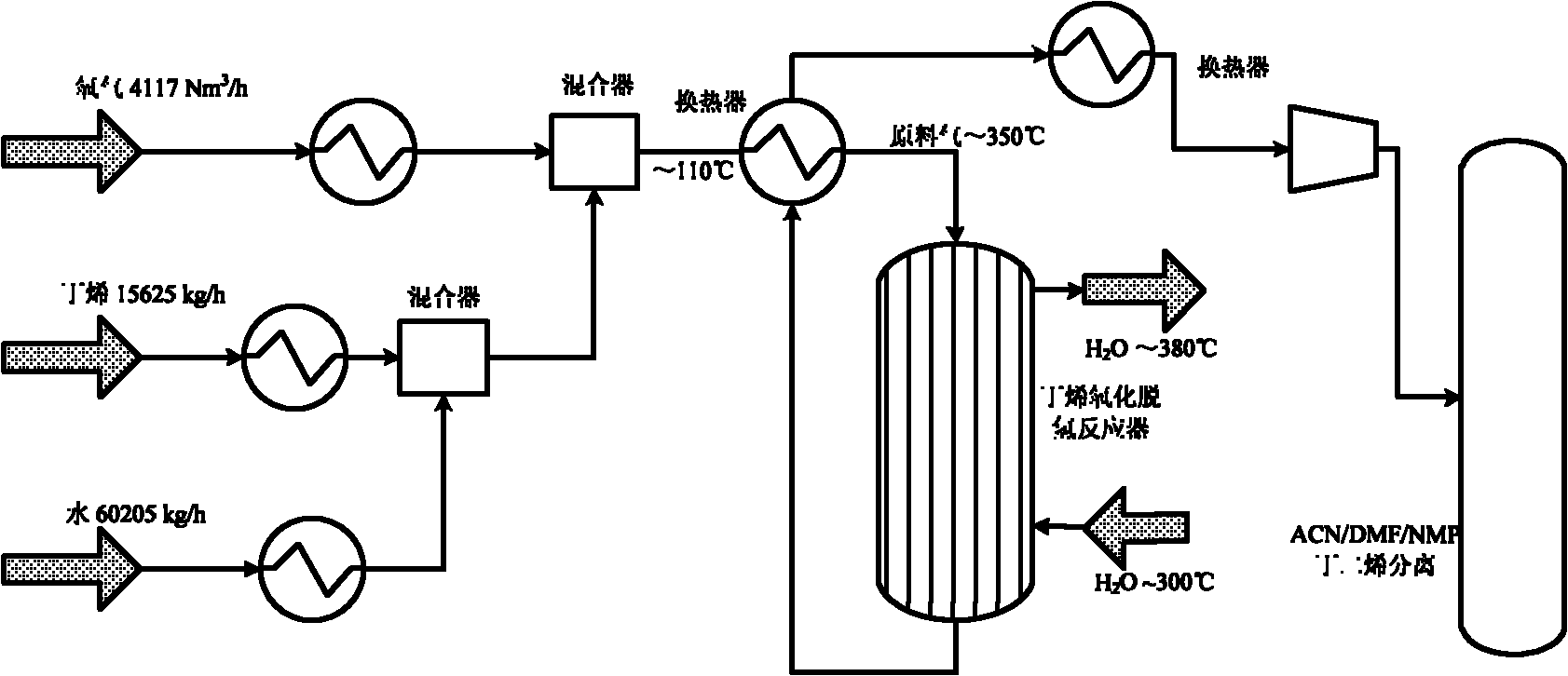

[0057] N-butene 15625kg / h, of which isobutene3 / h, preheated to 110°C. Butene is mixed with steam first and then with oxygen. The mixed raw material gas and the product gas at 390°C are heated up to react, and then the temperature is raised to above 300°C, and enter the tube reactor, where the reaction is carried out under the action of a lattice oxygen catalyst. The temperature of the reaction gas at the outlet of the reactor is 390°C, and the reaction The heat is removed by indirect heat exchange with water vapor, and the product gas that comes out is further cooled after heat exchange with the raw material gas. After a large amount of water is separated, it is compressed and entered into the ACN process for butadiene absorption separation and refining system, which can be produced to meet the polymerization grade standard. Butadiene products. Butene per-pass conversion rate is 90%, butadiene selectivity is 93%, butadiene yield is ~83%, and oxygen-containing compounds are 3...

Embodiment 3

[0059] n-butene 8000kg / h, of which isobutene3 / h, preheat to 110°C, then mix butene with steam first, and then mix with oxygen. The mixed raw material gas and the product gas at 410°C are heat-exchanged and heated to react, then heat-exchanged and heated to 330°C, enter the tube reactor, and react under the action of a lattice oxygen catalyst. The temperature of the reaction gas at the outlet of the reactor is 410°C, and the heat of reaction It is removed by indirect heat exchange with water vapor, and the product gas is further cooled after heat exchange with raw material gas. After separating a large amount of water, it is compressed and enters the DMF process to absorb, separate and refine butadiene to obtain butadiene of polymerization grade purity. product. Butene single-pass conversion rate is 91%, butadiene selectivity is 93.5%, butadiene yield is 85%, and oxygen-containing compound is less than 0.6%. Use 10m 3 Lattice Oxygen Catalysts, Catalysts in Composite Oxides o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com