Method of continuously producing epichlorohydrin by directly epoxidizing chloropropene

An epichlorohydrin and chloropropene technology, applied in chemical instruments and methods, chemical recovery, organic chemistry, etc., can solve the problems of unstable operation, difficult separation and recovery of catalysts, etc., and achieve the effects of stable reaction temperature and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

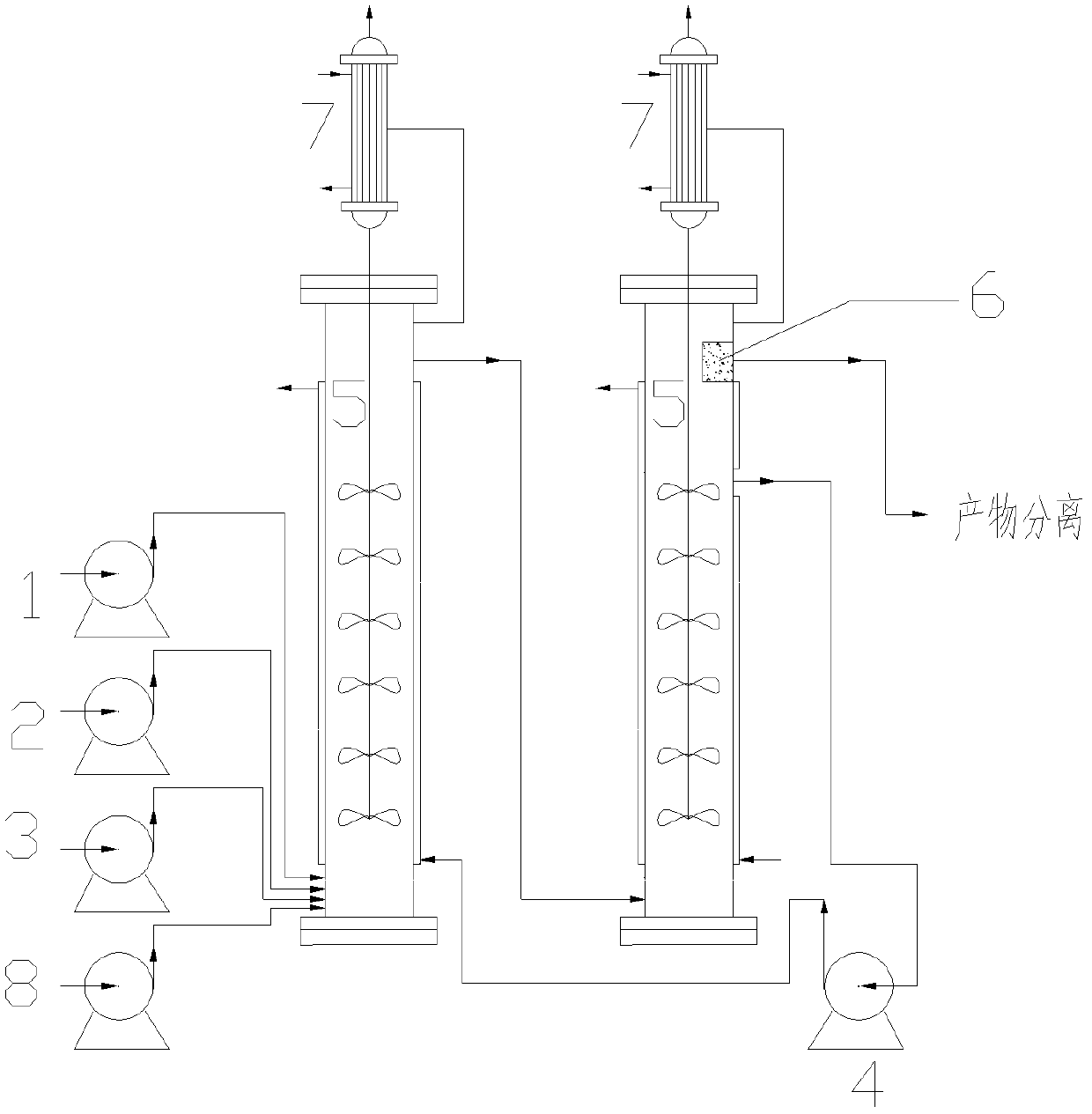

[0029] according to figure 2 Shown two reactor series epichlorohydrin production process;

[0030] The secondary reactor is composed of two reactors connected in series, and the structure is as follows: a reflux condenser is provided at the top of each reactor in the secondary reactor;

[0031] A feed inlet and a slurry return inlet are provided on the lower side wall of the first-stage reactor; an overflow port is provided on the upper side wall of the first-stage reactor; on the upper side wall of the last-stage reactor A clear liquid discharge port with a built-in filter is provided, and a slurry return outlet is provided below the clear liquid discharge port and on the upper side wall of the reactor. A slurry pump is installed on the pipeline;

[0032] An overflow port is provided on the upper side wall of the first-stage reactor, and an overflow material inlet is provided on the lower side wall of the last-stage reactor. The overflow port and the overflow material inle...

Embodiment 2

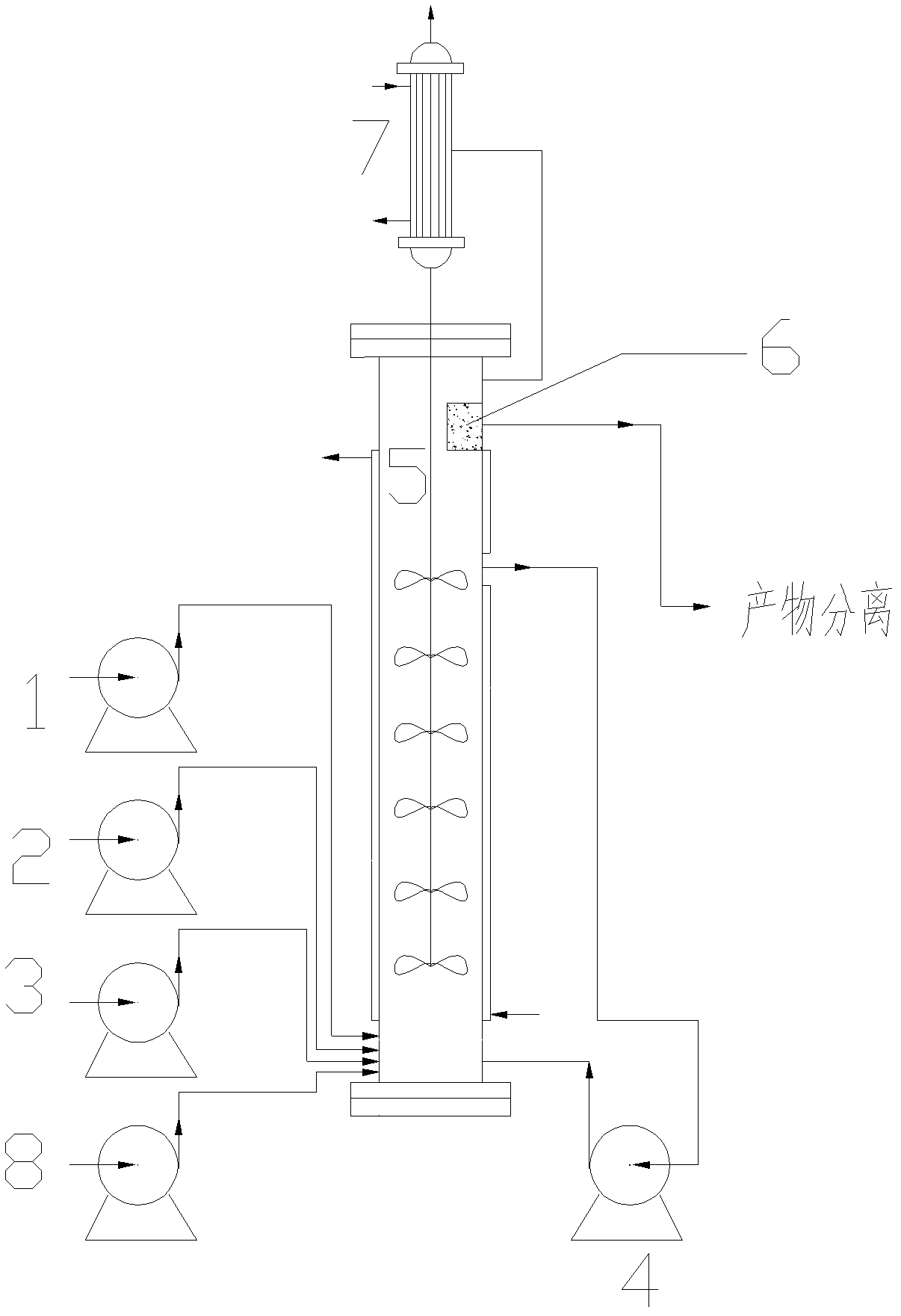

[0038] according to figure 1 The single reactor epichlorohydrin production process shown;

[0039] Single reactor structure: The upper side wall of the reactor is provided with a clear liquid outlet with a built-in filter, and a slurry return outlet is provided below the clear liquid outlet and on the middle and upper side wall of the reactor. The lower side of the reactor The wall is provided with a feed inlet and a slurry return inlet, and the slurry return outlet and the slurry return inlet are connected by pipes, and a slurry pump is arranged on their connecting pipes; a reflux condenser is provided at the top of the reactor;

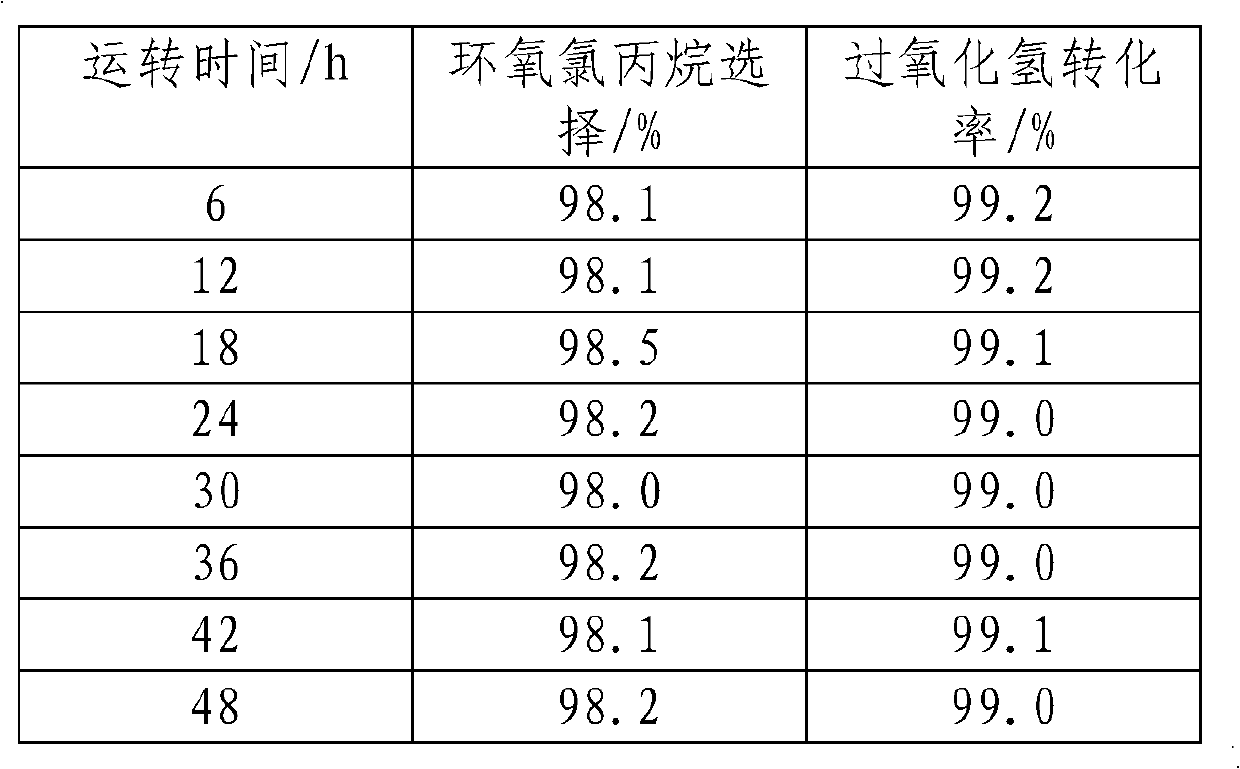

[0040] The volume of the reactor is 45L, and the total volume is 45L. Add 2.5kg of phosphotungstic heteropoly salt catalyst and 35L of chloropropene into the reactor through a metering pump in advance. When the reaction temperature is 50°C and the reaction pressure is 0.1MPa, start For continuous production, allyl chloride and hydrogen peroxide are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com