Method for fabricating high water absorption resin

A technology of super absorbent resin and manufacturing method, which is used in absorbent pads, medical science, bandages, etc., can solve the problems of high dust volume and poor recovery efficiency, and achieve the effects of stable reaction temperature, improved production quality, and improved uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] (1) First add 17.35kg of 49% sodium hydroxide aqueous solution and 30.52kg of water in a 100L reaction tank, and then slowly add 22.53kg of acrylic acid into the aqueous sodium hydroxide solution under ice bath for neutralization; at this time, the monomer Concentration 38.6wt% aqueous solution, in which 68mole% acrylic acid is partially neutralized to sodium acrylate.

[0065] (2) Add 33.80 g of glycerol polyethylene glycol triglycidyl ether (n=7) to the partially neutralized acrylic acid aqueous solution, and maintain the temperature at about 20°C.

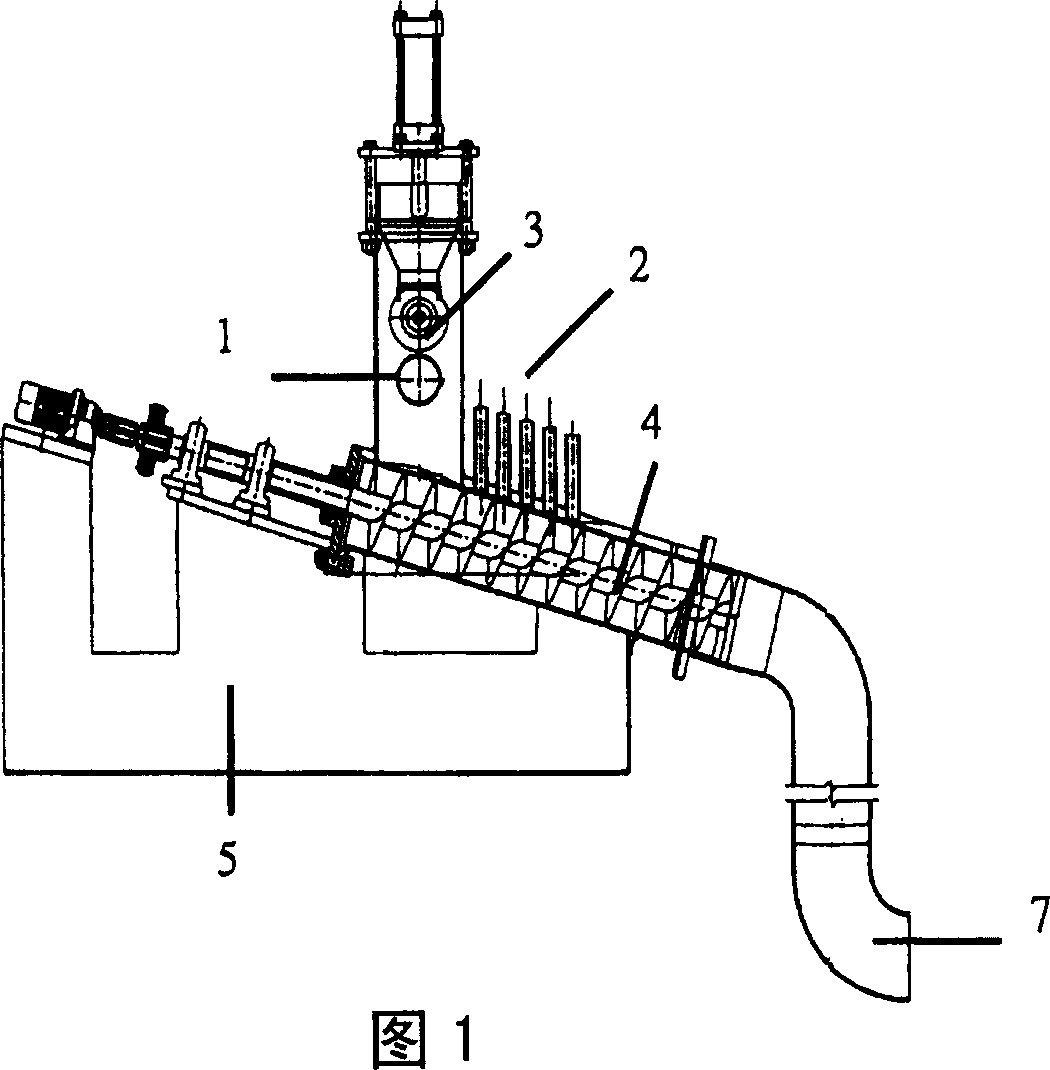

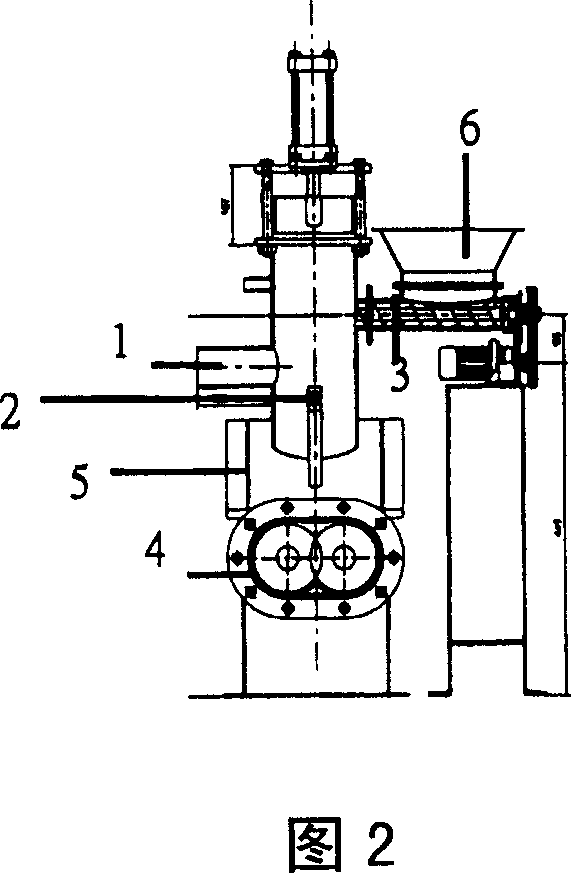

[0066] (3) Control the flow rate of the above-mentioned sodium acrylate solution to be 70.4kg / hr, and then make it enter the mixing body from 1 in Fig. 2 of the description of the present invention.

[0067] (4) Control the feeding amount of the water-absorbing resin with a particle size of less than 100 μm (hereinafter collectively referred to as fine powder) to 1.02 kg / hr, and enter the mixing body from 6. in Figure 2 o...

Embodiment 2

[0076] Repeat embodiment one, but the feeding amount of step 4 changes 1.53kg / hr into. The results showed that the reaction material and the fine powder were well mixed, the temperature of the polymerization reaction was stable, and there was no colloid formed on the screw or at the outlet elbow. The viscosity of the discharged reaction material is 7.2cP, the soluble content of the finished product is 2.51%, the absorption rate is 71.75 seconds, and 49g / cm 2 The absorption rate under pressure is 25.39g / g.

Embodiment 3

[0078] Repeat embodiment one, but the feeding amount of step 4 changes 2.04kg / hr into. The results showed that the reaction material and the fine powder were well mixed, the temperature of the polymerization reaction was stable, and there was no colloid formed on the screw or at the outlet elbow. The viscosity of the discharged reaction material is 7.8cP, the soluble content of the finished product is 2.49%, the absorption rate is 67.23 seconds, and 49g / cm 2 The absorption rate under pressure is 25.17g / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com