Super-efficient carboxylic acid water reducer without thermal energy consumption

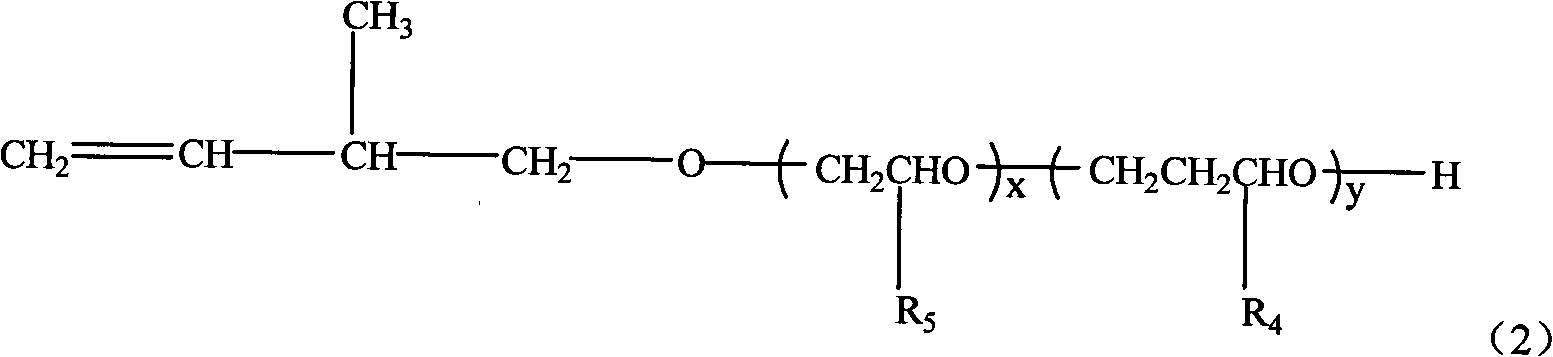

A super-efficient carboxylic acid and water-reducing agent technology, which is applied in the field of concrete admixtures, can solve the problems of poor cement adaptability, heat energy consumption, etc., and achieve high water-reducing performance, short production time, and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

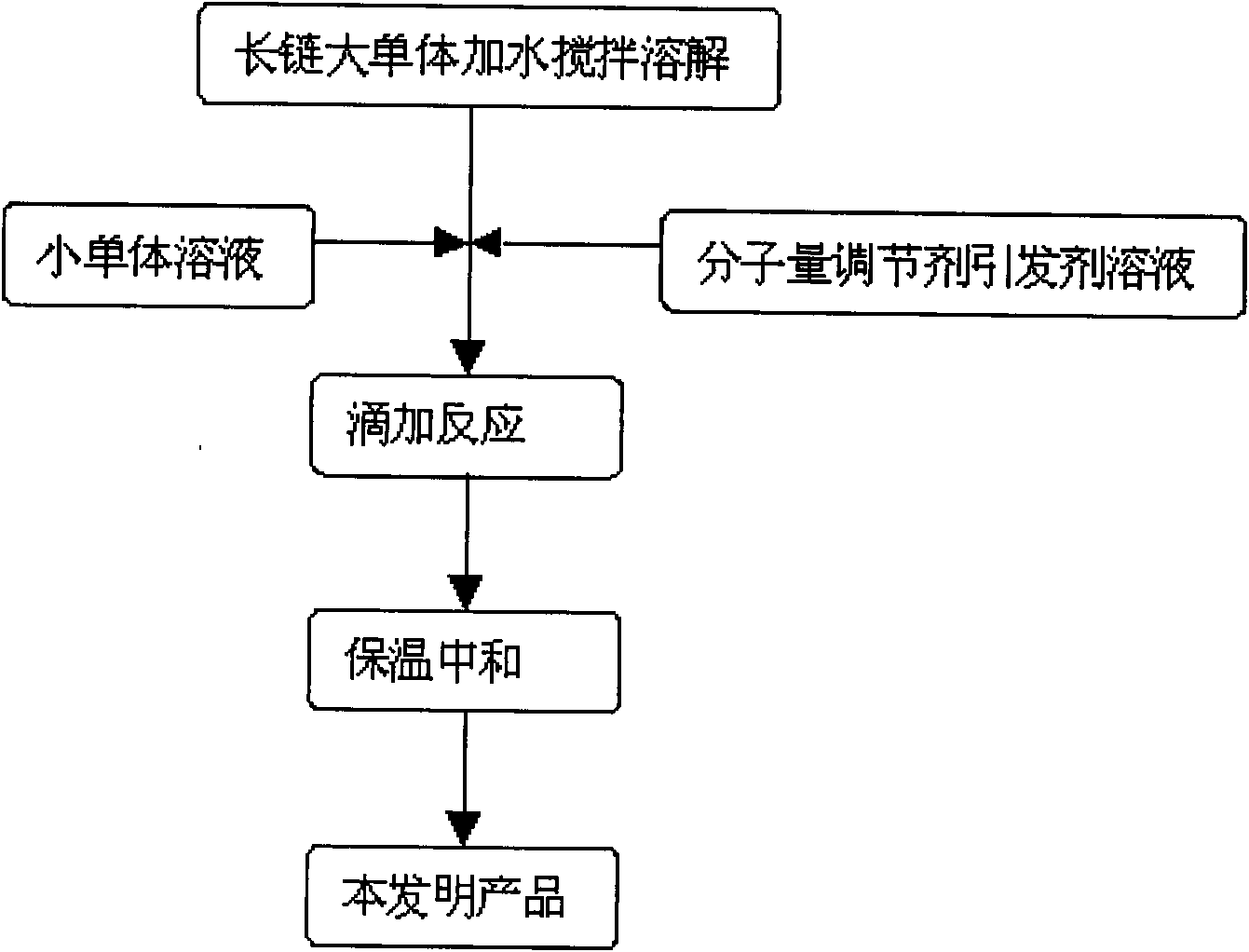

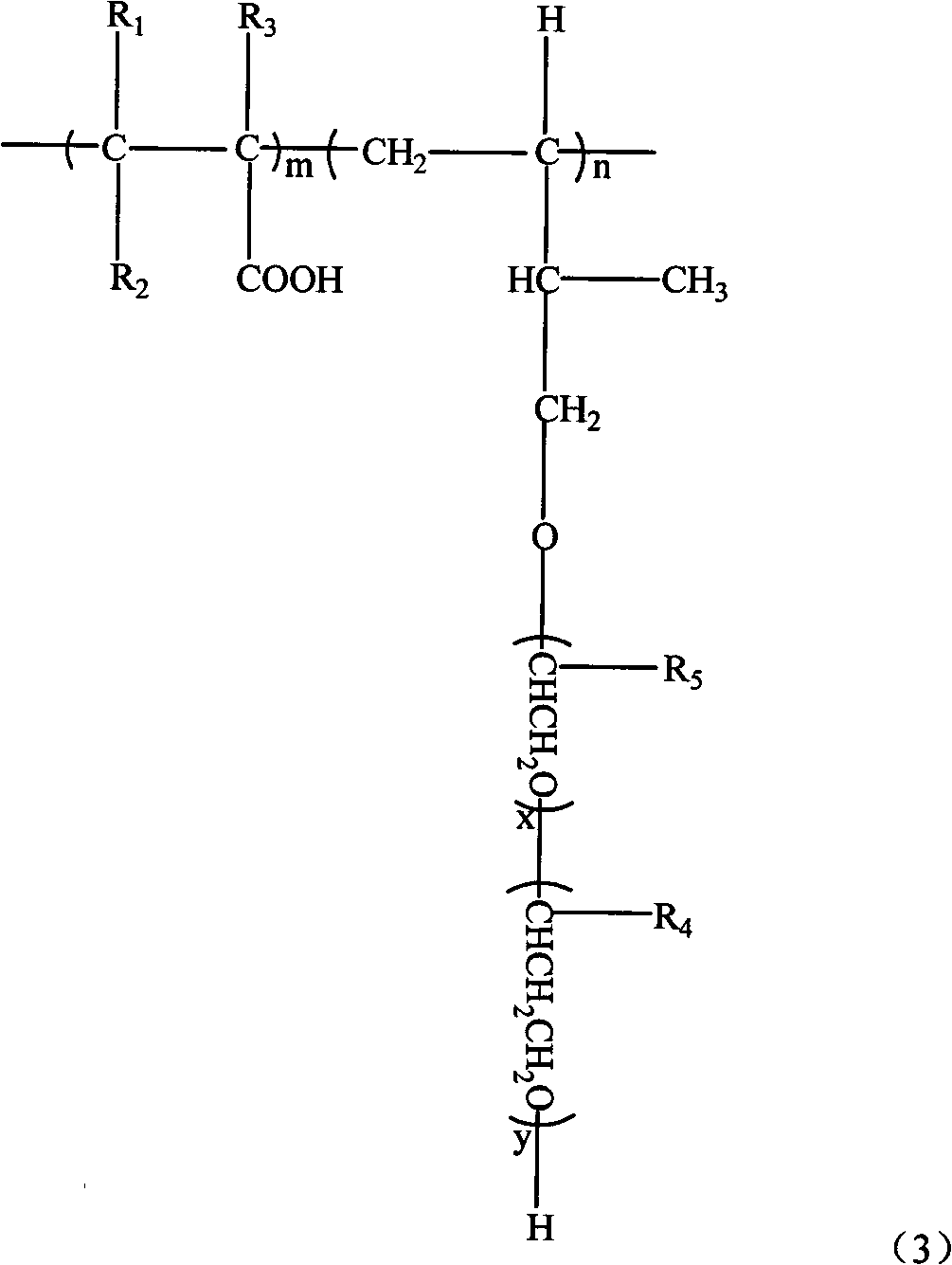

[0030] Embodiment 1 Preparation of water reducer of the present invention

[0031] Preparing the base material: Stir and dissolve the isopentenyl polyether and water together to prepare 220 g of a 60% aqueous solution.

[0032] Preparation of material B: pre-mix acrylic acid and water into 27g of 77% aqueous solution;

[0033] Preparation of material A: the initiator ammonium persulfate is preformulated into 30 g of an aqueous solution with a concentration of 0.15%, and then 0.1-0.3 g of a molecular weight modifier vinyl acetate and 0.3-0.5 g of hydrogen peroxide (30%) are added in sequence and stirred evenly.

[0034] At 30°C (temperature fluctuation is controlled within ±1°C), add material A and material B dropwise to the bottom material at the same time, the dropping time of material A is controlled at 1.5 hours, and the dropping time of material B is controlled at 1.0 hour; material A After the dropwise addition, keep warm for 0.5-1.0 hours, then add water and stir evenly...

Embodiment 2

[0035] Embodiment 2 Preparation of water reducer of the present invention

[0036] Preparing the base material: First, stir and dissolve the isopentenyl polyether and water together to prepare 264 g of a 50% aqueous solution.

[0037] Preparation of material B: 29.7g of a 70% aqueous solution was pre-formulated with acrylic acid and water;

[0038] Prepare material A: preformulate the initiator ammonium persulfate into 30 g of an aqueous solution with a concentration of 0.2%, and then add 0.1 to 0.3 g of the molecular weight regulator mercaptopropionic acid and 0.2 to 0.4 g of hydrogen peroxide (30%) in sequence, and stir evenly.

[0039] At 25°C (temperature fluctuation is controlled within ±1°C), material A and material B are added dropwise to the bottom material at the same time, the dropping time of material A is controlled at 3.5 hours, the dropping time of material B is controlled at 3.0 hours, and the dropping time of material A is controlled at 3.0 hours. After the dr...

Embodiment 3

[0040] Embodiment 3 Preparation of water reducer of the present invention

[0041] Preparing the base material: Stir and dissolve the isopentenyl polyether and water together to prepare 240 g of a 55% aqueous solution.

[0042] Preparation of material B: pre-mix acrylic acid and water into 26g of 80% aqueous solution;

[0043] Preparation of material A: The initiator ammonium persulfate is pre-formulated into 30g of an aqueous solution with a concentration of 0.18%, and then sequentially add 0.3-0.6g of molecular weight modifier sodium methacrylate sulfonate, 0.15-0.45g of hydrogen peroxide (30%), and stir well .

[0044] At 20°C (the temperature fluctuation is controlled within ±1°C), add material A and material B dropwise to the bottom material at the same time, the dropping time of material A is controlled at 3.5 hours, the dropping time of material B is controlled at 3.0 hours, and the dropping time of material A is controlled at 3.0 hours. After the dropwise addition, k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com