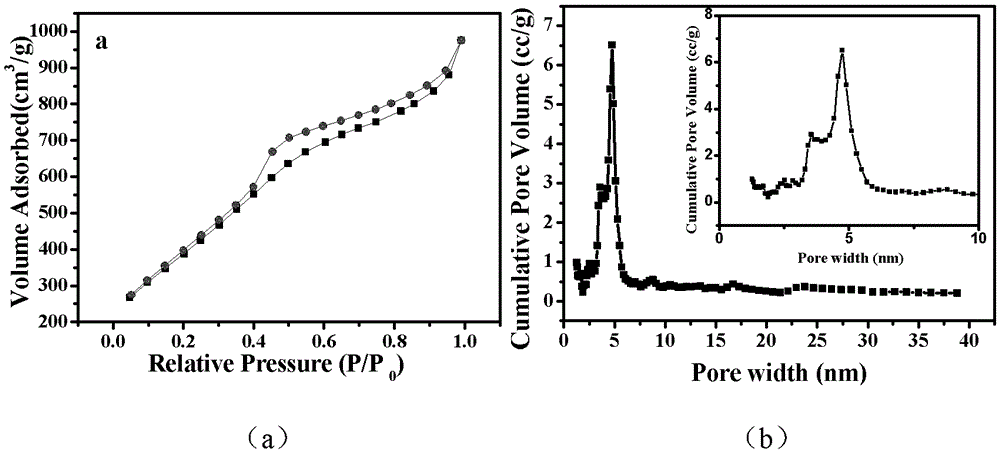

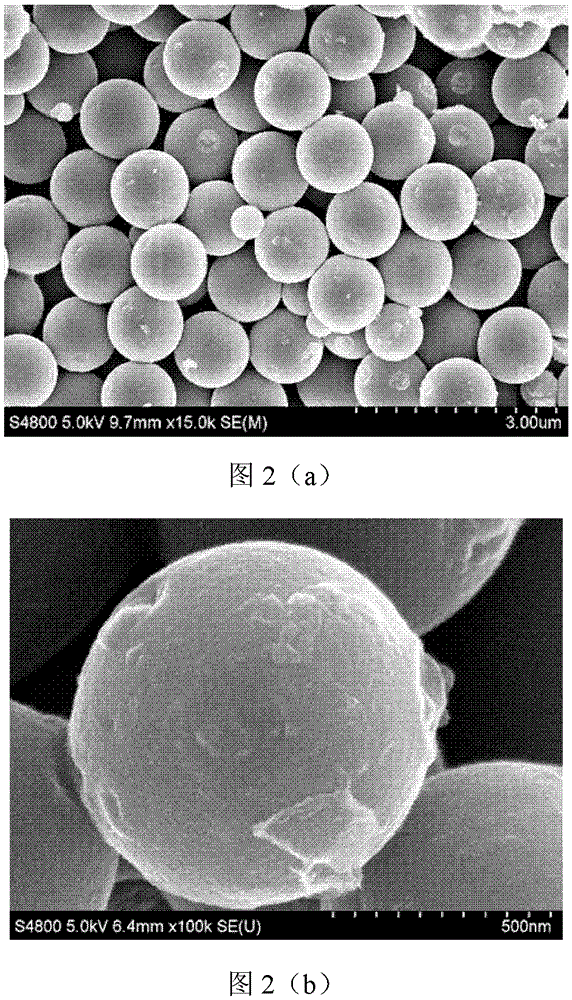

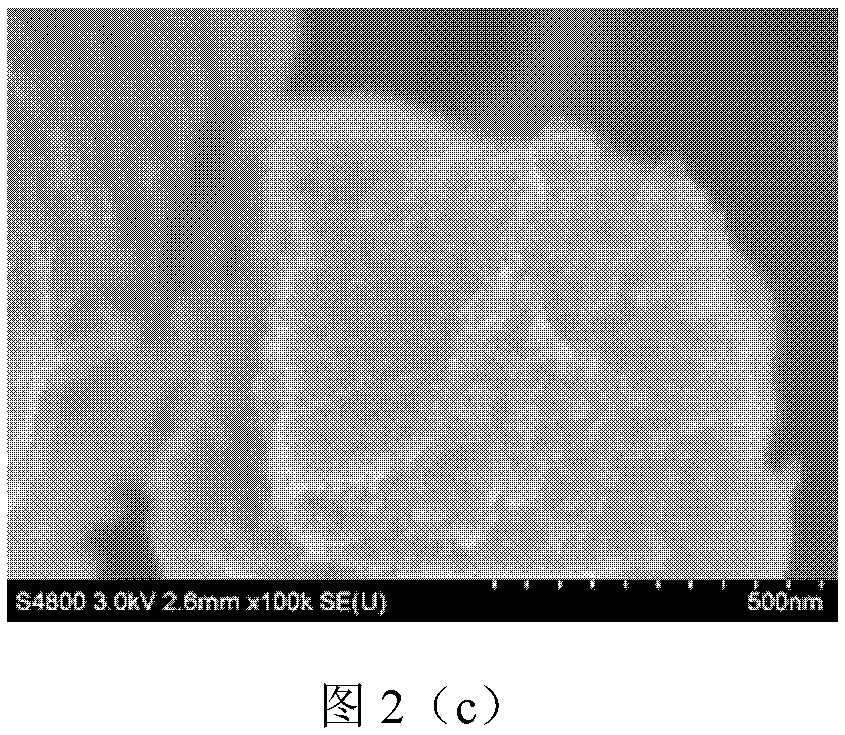

Mesopore-micropore carbon micro sphere of high specific surface area for super capacitor and preparation method of carbon micro sphere

A high specific surface area, supercapacitor technology, applied in the field of materials, can solve the problems of low specific surface area and pore volume, affect the service life of equipment, and unfavorable capacitance performance, etc., and achieve the effect of simple preparation process, improved hydrophilicity and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method for high specific surface area mesoporous-microporous carbon microspheres for supercapacitors, comprising the following steps:

[0038] (1) Dissolve 2gPVPK-30 and 2gSBA-15 in 90mL ethanol at 60-80°C to obtain solution A; dissolve 3g ammonium polyphosphate in 10mL water to obtain solution B; add solution A and solution B to the Stirrer, condenser, thermometer and vent 2 250mL four-necked flask, then 20g styrene and 0.2g initiator AIBN (azobisisobutyronitrile) were shaken and mixed evenly, and slowly dropped into the four-necked flask. Cool to room temperature to obtain an emulsion. Then carry out centrifugal sedimentation at a speed of 3500r / min, discard the supernatant, wash the microspheres in the lower layer with absolute ethanol, and after ultrasonic dispersion, centrifuge and wash again, and repeat this 5 times to remove unreacted styrene and other raw materials; Finally, it was poured into a petri dish and dried in a vacuum oven at 60° C. for...

Embodiment 2

[0057] (1) Dissolve 1g PVPK-30 and 5g SBA-15 in 90mL ethanol at 80°C to obtain solution A; dissolve 4g ammonium polyphosphate in 10mL water to obtain solution B; add solution A and solution B to the , condenser, thermometer and N 2 In a 250mL four-necked flask, 18g of styrene and 0.1g of initiator AIBN (azobisisobutyronitrile) were shaken and mixed evenly, and slowly dropped into the four-necked flask. Cool to room temperature to obtain an emulsion. Then carry out centrifugal sedimentation at a speed of 3500r / min, discard the supernatant, wash the lower layer of microspheres with absolute ethanol, and after ultrasonic dispersion, then centrifuge and wash, repeat this 5 times to remove unreacted substances; finally pour into the culture medium dish, and dried in a vacuum oven at 60°C for 8 hours to obtain a white powder product, namely polystyrene microspheres.

[0058] (2) Divide 50mL of n-heptane into the first part and the second part, the volume ratio of the first part an...

Embodiment 3

[0062] (1) Dissolve 3g PVPK-30 and 4g SBA-15 in 90mL ethanol at 60°C to obtain solution A; dissolve 1g ammonium polyphosphate in 10mL water to obtain solution B; add solution A and solution B to the , condenser, thermometer and N 2 In a 250mL four-necked flask, 19g of styrene and 0.3g of initiator AIBN (azobisisobutyronitrile) were shaken and mixed evenly, and slowly dropped into the four-necked flask. Cool to room temperature to obtain an emulsion. Then carry out centrifugal sedimentation at a speed of 3500r / min, discard the supernatant, wash the lower layer of microspheres with absolute ethanol, and after ultrasonic dispersion, then centrifuge and wash, repeat this 5 times to remove unreacted substances; finally pour into the culture medium dish, and dried in a vacuum oven at 60°C for 8 hours to obtain a white powder product, namely polystyrene microspheres.

[0063] (2) Divide 100mL of n-heptane into the first part and the second part, the volume ratio of the first part a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Most probable aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com