Narrow-distribution middle-low-molecular-weight sodium polyacrylate preparation method

A sodium polyacrylate, low molecular weight technology, applied in the field of preparation of water-soluble electrolytes, can solve the problem of reaction temperature, monomer concentration initiator amount, feeding mode stirring speed, reaction time not strictly controlled, average relative molecular weight out of control, lack of products Unique performance and other issues, to achieve the effect of good heat dissipation, low manufacturing cost and high equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

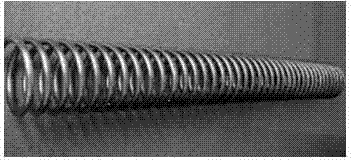

Image

Examples

Embodiment 1

[0023] Implementation example 1: The preparation method of sodium polyacrylate (Mn=20900) of the present invention comprises the following steps:

[0024] In the first step, at room temperature, add 31.36 kg of acrylic acid monomer and 32 L of water into the material kettle, stir evenly, add 0.32 kg of n-dodecanethiol and 0.47 kg of potassium persulfate, and fully stir evenly;

[0025] In the second step, the coiled tube reactor is placed in a constant temperature water bath at 60°C, and the temperature of the constant temperature water bath is controlled at 60±3°C; use a metering pump for the uniformly mixed material in the first step, and adjust the output flow of the metering pump to 62L / h, so that the time for the material to circulate and react in the tube is 6h; after cooling the output material to room temperature, adjust the pH=7 to 8 with 30% sodium hydroxide solution;

[0026] In the third step, after the reaction, wash and dry to obtain sodium polyacrylate (Mn=20...

Embodiment 2

[0027] Implementation example 2: The preparation method of sodium polyacrylate (Mn=5750) of the present invention comprises the following steps:

[0028] In the first step, at room temperature, add 28.56kg of acrylic acid monomer and 34L of water into the material kettle, after stirring evenly, add 0.48kg of n-dodecanethiol and 0.47kg of potassium persulfate, and fully stir evenly;

[0029] In the second step, the tubular reactor is placed in a constant temperature water bath at 70°C, and the temperature of the constant temperature water bath is controlled at 70±3°C; use a metering pump to adjust the output flow of the metering pump to 60L / h for the uniformly mixed material in the first step, The reaction time of the material in the tube is 5h; after cooling the output material to room temperature, adjust the pH=7~8 with 30% sodium hydroxide solution;

[0030] In the third step, after the reaction, wash and dry to obtain sodium polyacrylate (Mn=5750, Mw=9260, PDI=1.61, solid...

Embodiment 3

[0031] Implementation example 3: The preparation method of sodium polyacrylate (Mn=5010) of the present invention comprises the following steps:

[0032] In the first step, at room temperature, add 20.68kg of acrylic acid monomer and 22L of water into the material kettle, stir evenly, add 28.6L of isopropanol and 0.48kg of potassium persulfate, and stir well;

[0033] In the second step, the tubular reactor is placed in a constant temperature water bath at 70°C, and the temperature of the constant temperature water bath is controlled at 70±3°C; use a metering pump for the uniformly mixed material in the first step, and adjust the output flow of the metering pump to 65L / h. The reaction time of the material in the tube is 5h; after cooling the output material to room temperature, adjust the pH=7~8 with 30% sodium hydroxide solution;

[0034] In the third step, after the reaction, wash and dry to obtain sodium polyacrylate (Mn=5010, Mw=9930, PDI=1.98, solid content 49%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com