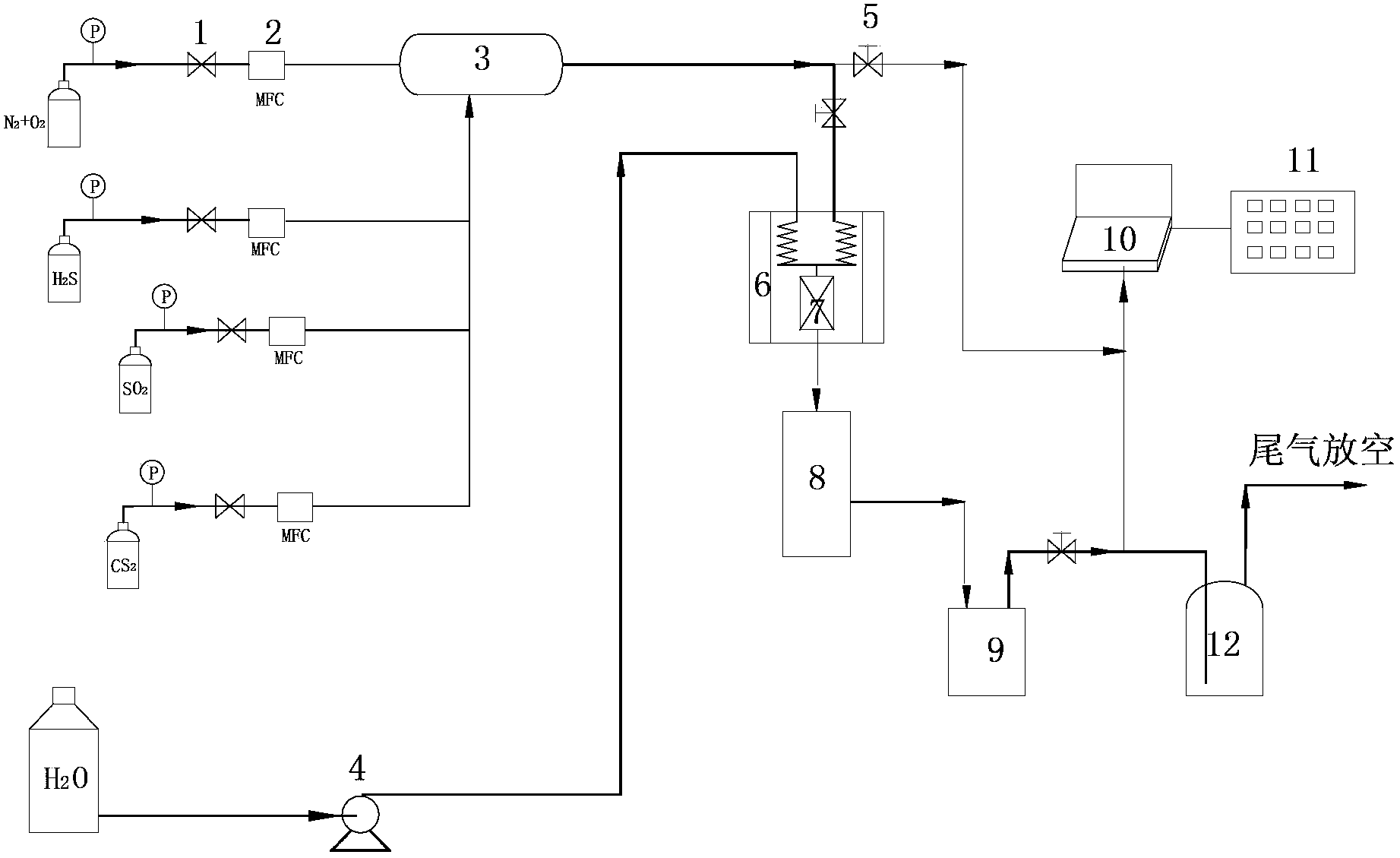

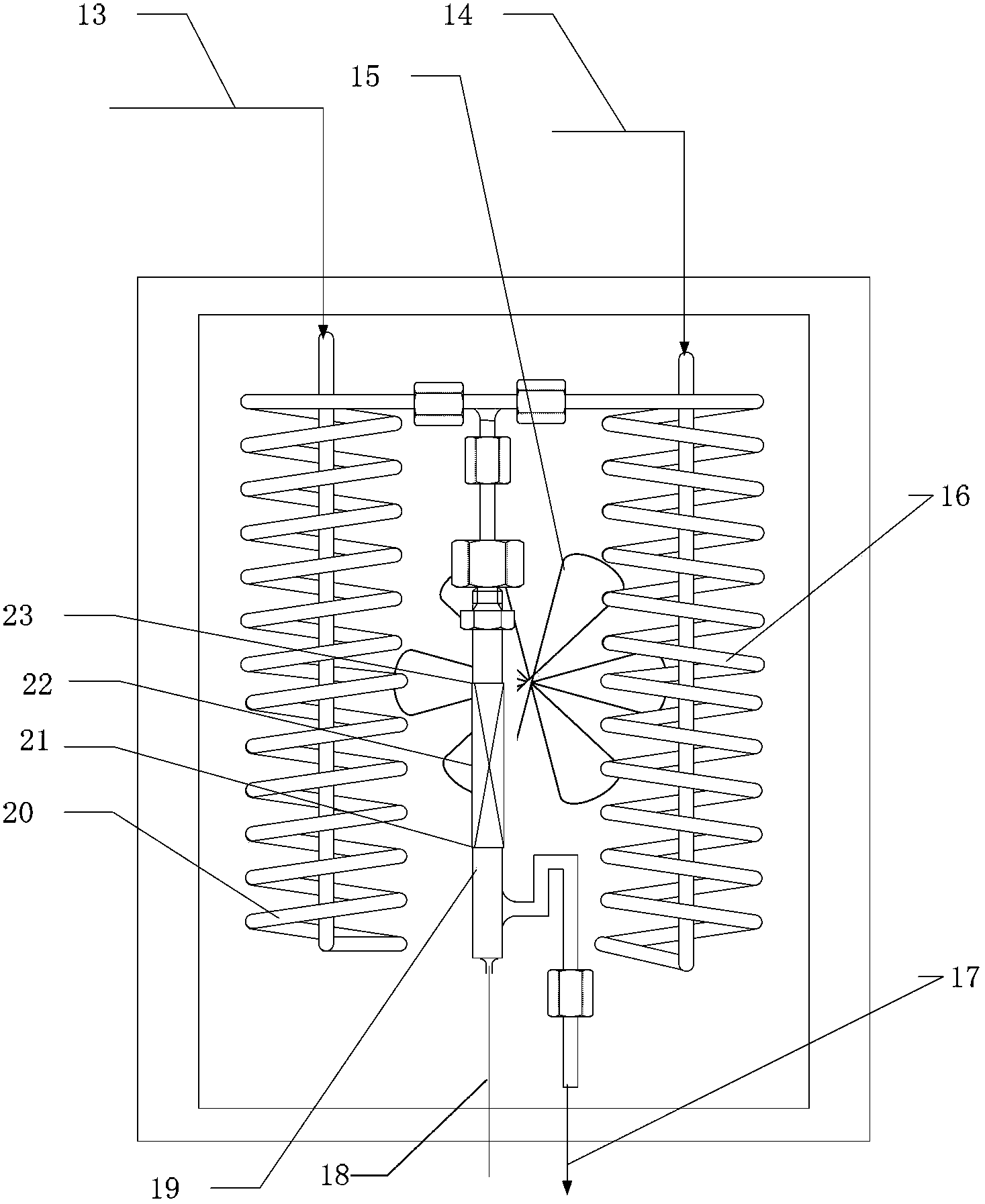

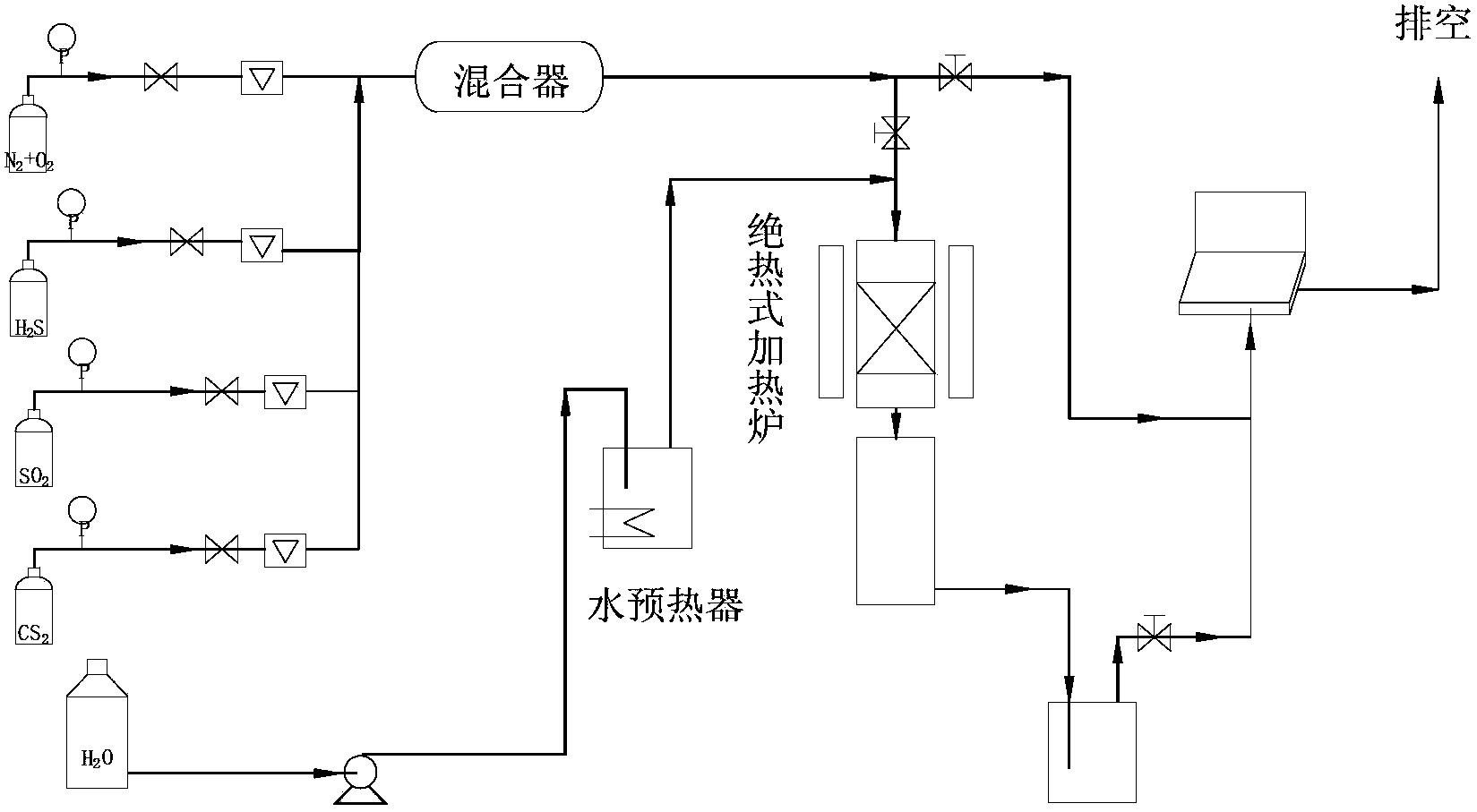

Sulfur recovery catalyst activity evaluating device and test method

A technology for evaluating devices and catalysts, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of easy sulfur formation in system equipment, large error in test data, and high sulfur content in raw gas, and achieve accurate and reliable test data and constant reaction temperature. , the effect of small bed temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] On the micro-reaction activity evaluation device of the present invention, the temperature control measurement under different temperatures has been carried out, and the temperatures of the upper, middle and lower temperature measuring points of the catalyst bed are as shown in Table 1.

[0053] Table 1 Temperature control measurement data at different temperatures

[0054] Catalyst bed upper temperature / °C

[0055] Catalyst bed temperature difference / °C

[0056] It can be seen from Table 1 that the temperature difference of the catalyst bed is in the range of 0.2-0.6°C, all of which are less than 1°C.

Embodiment 2

[0058] On the micro-reaction activity evaluation device of the present invention, the temperature control measurement under different space velocities was carried out, and the temperatures of the upper, middle and lower temperature measurement points of the catalyst bed were recorded in Table 2.

[0059] Table 2 Temperature control measurement data at different space velocities

[0060] Reaction space velocity / h -1

[0061] It can be seen from Table 2 that the temperature difference of the catalyst bed is in the range of 0.3-0.9°C, all of which are less than 1°C.

Embodiment 3

[0063] Taking the LS-300 sulfur recovery catalyst as the investigation object, using the evaluation method of the present invention and the micro-reaction evaluation device, the gas composition at the reactor inlet is H 2 S 2%, SO 2 1%, O 2 2000ppm, H 2 O 30%, the rest is N 2 , the gas volumetric space velocity is 2500h -1 Under the condition of , the Claus activity evaluation at different reaction temperatures was carried out, and the results are shown in Table 3.

[0064] The Claus activity evaluation result under the different reaction temperature of table 3

[0065] Reaction temperature / ℃

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com