Reaction kettle for chemical production

A technology of chemical production and reactor, applied in chemical/physical/physicochemical stationary reactors, cleaning methods and utensils, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

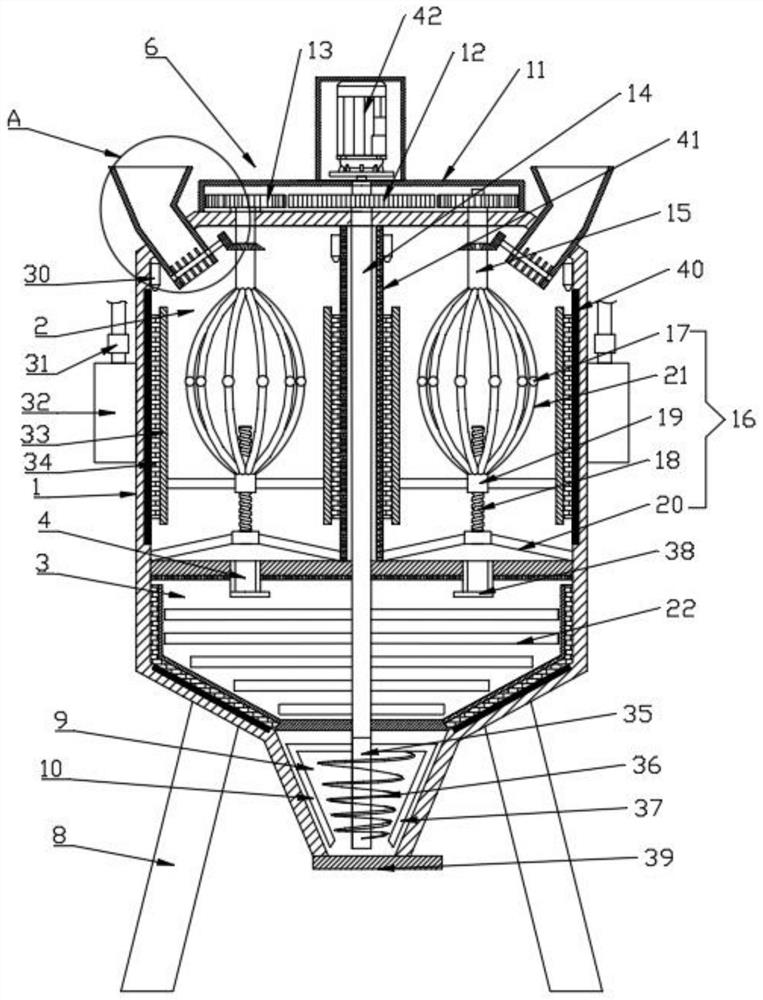

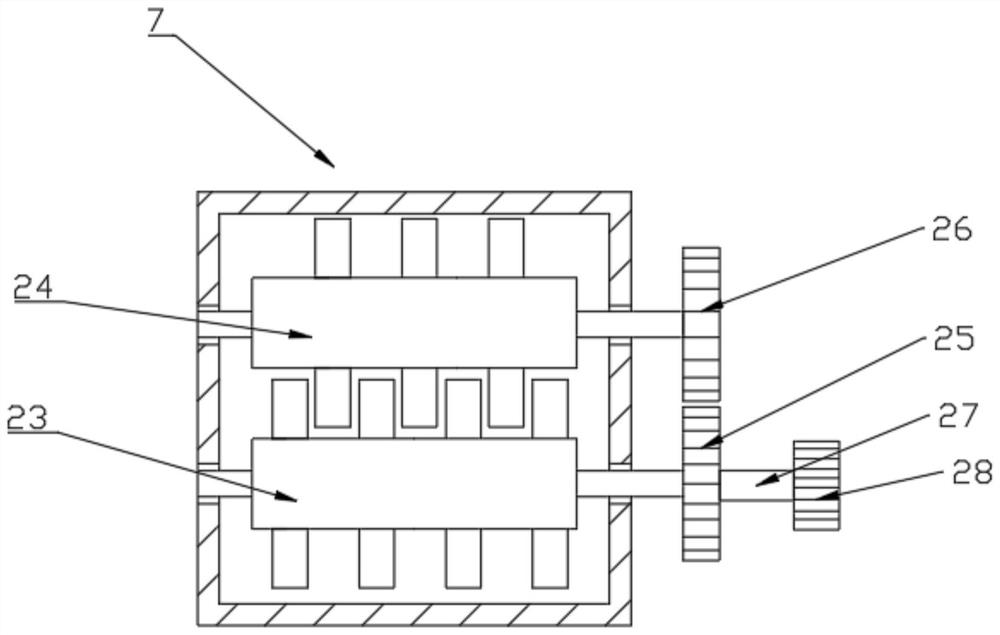

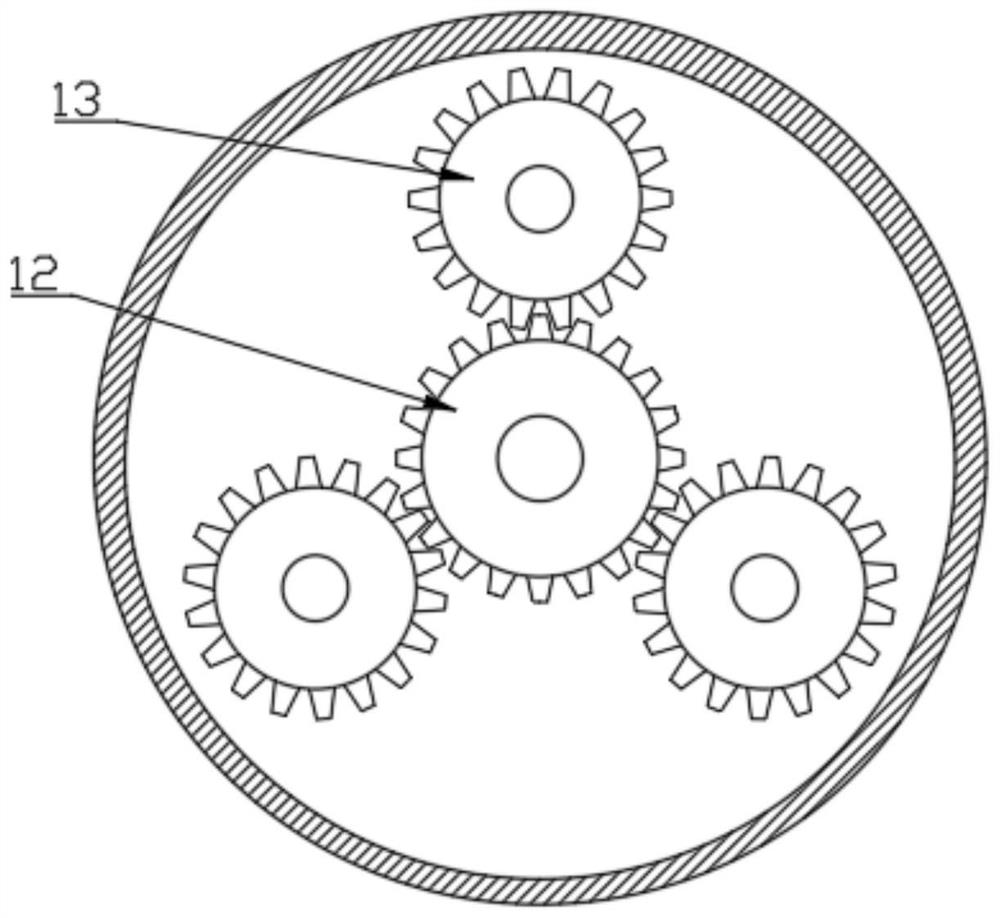

[0025] see Figure 1-5 , a reaction kettle for chemical production, comprising a main kettle body 1, a secondary kettle body 2 and a mixing kettle body 3, the said secondary kettle body 2 is provided with a plurality of said secondary kettle bodies 2 and the mixing kettle body 3 It is located in the main kettle body 1, and a plurality of secondary kettle bodies 2 are connected with the mixing kettle body 3 through the feeding pipe 4. The first valve 38 is arranged on the feeding pipe 4, and the top of the main kettle body 1 A plurality of feeding passages 5 are arranged at the position of the secondary kettle body 2, and a drive mechanism 6 is provided on the top of the main kettle body 1, a pulverizing device 7 is arranged in the feeding passage 5, and a bottom of the discharge passage 9 is provided with There is a second valve 39, the bottom of the main kettle body 1 is provided with a support foot 8, and the center of the bottom of the main kettle body 1 is provided with a ...

Embodiment 2

[0030] This embodiment has been improved on the basis of Embodiment 1, specifically:

[0031] The top of the inner wall of the secondary kettle body 2 and the mixing kettle body 3 is provided with a high-pressure nozzle 30, and the high-pressure nozzle 30 is connected with the water tank 32 provided on the side of the main kettle body 1 through a water pipe and a water pump 31. The threaded sleeve The side wall of the cylinder 19 and the first rotating shaft 14 are located on the side wall of the rod body of the mixing kettle body 3 and are provided with a cleaning plate 33. There is a brush 34, and by setting a high-pressure nozzle 30 and a cleaning plate 33, it can not only scrape off the materials stuck to the side wall of the kettle body, but also facilitate the cleaning of the inner wall of the kettle body, thereby reducing the impact on subsequent products.

[0032] The working principle of the present invention is: different reaction raw materials are respectively enter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com