Preparation method of layered functional material calcium sulphoaluminate

A technology of calcium sulfoaluminate and functional materials, applied in chemical instruments and methods, aluminum compounds, aluminum sulfur compounds, etc., can solve problems such as long reaction time and troublesome operation, and achieve good batch stability, convenient operation, and distribution narrow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

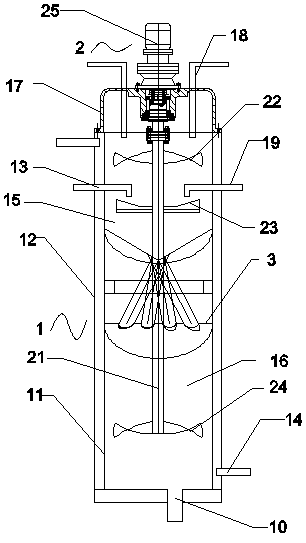

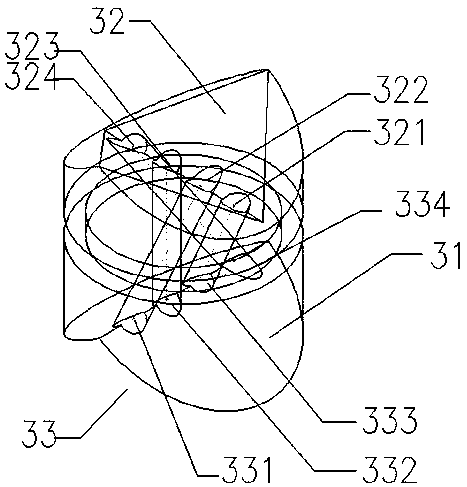

[0021] The preparation method of the layered functional material calcium sulfoaluminate in this example, the fully back-mixed explosive nucleation reactor used in the preparation method includes a reaction cylinder 1, a stirrer 2 and a mixer 3; a stirrer 2 and a mixer 3 are all arranged in the reaction cylinder 1, and the stirrer 2 is driven by a stirring motor.

[0022] The reaction cylinder 1 includes an inner cylinder 11 and an outer cylinder 12; a heat exchange cavity is formed between the inner cylinder 11 and the outer cylinder 12, and an outlet of the heat exchange cavity is provided on the upper side of the outer cylinder 12 13. A heat exchange cavity inlet 14 is provided on the lower side of the outer cylinder 12; the reaction cylinder 1 is divided into an upper reaction cylinder 15 and a lower reaction cylinder 16 by a mixer 3 in the reaction cylinder 1; The reaction cylinder 1 is provided with a cylinder cover 17 and the cylinder cover 17 is provided with a first fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com