Supercritical hydrothermal combustion type downhole steam generator for heavy oil thermal recovery

A technology of steam generator and supercritical water, which is applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc. It can solve the problems of high energy consumption and large pollution, and achieve the protection of reactors, overcoming safety problems, and thermal efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

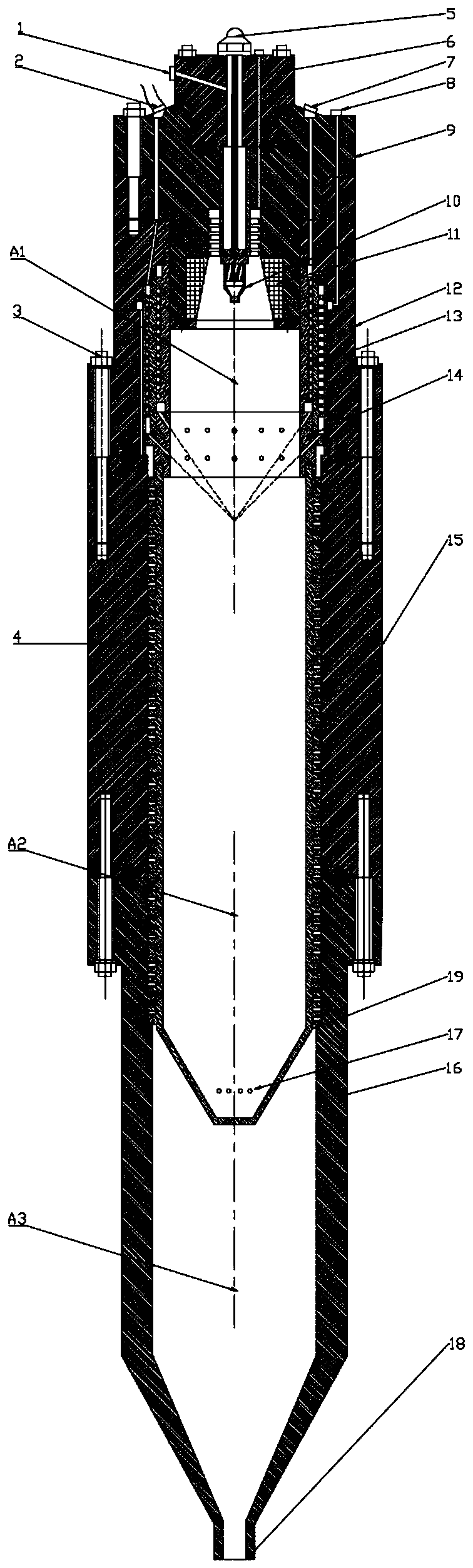

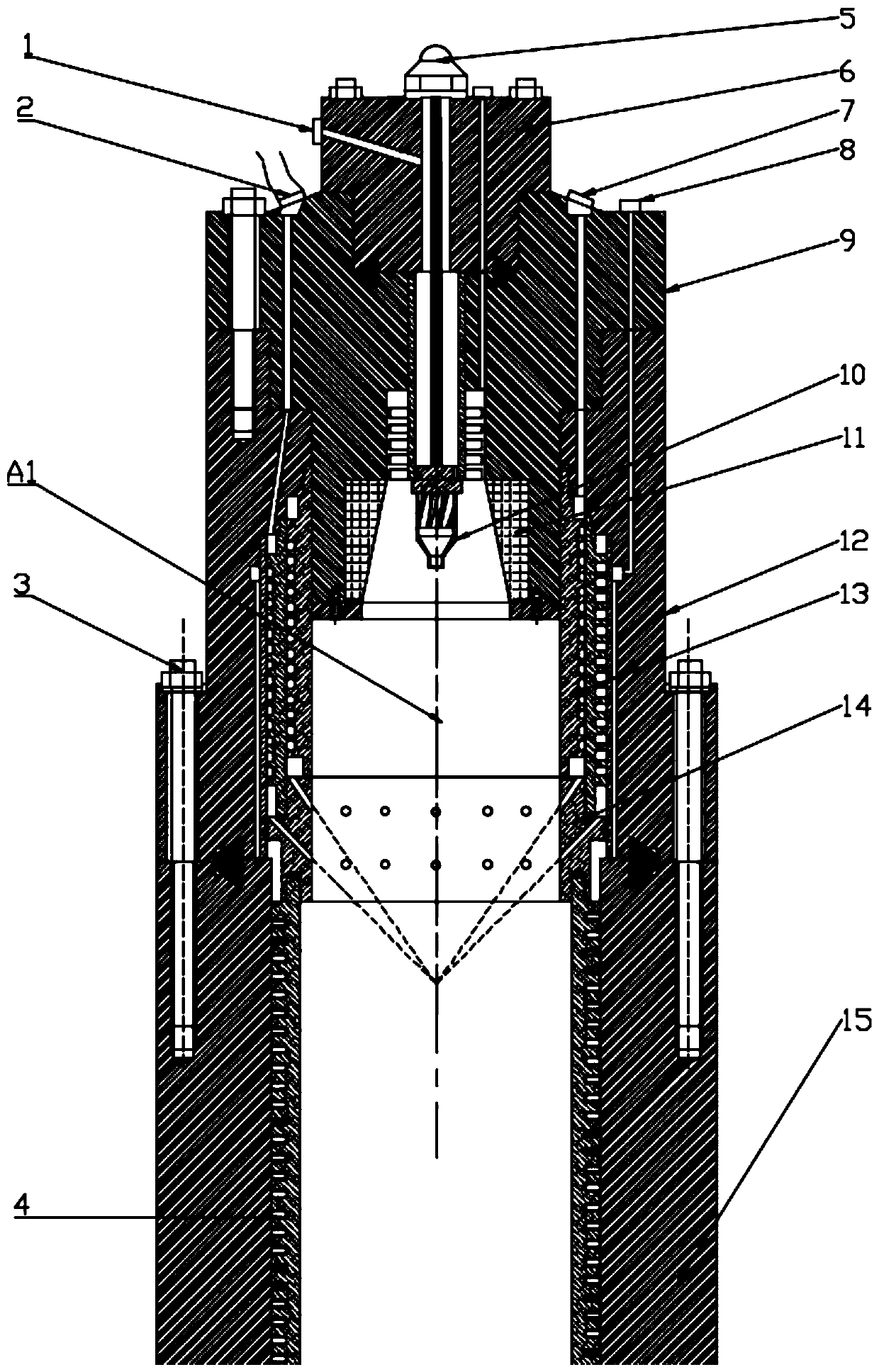

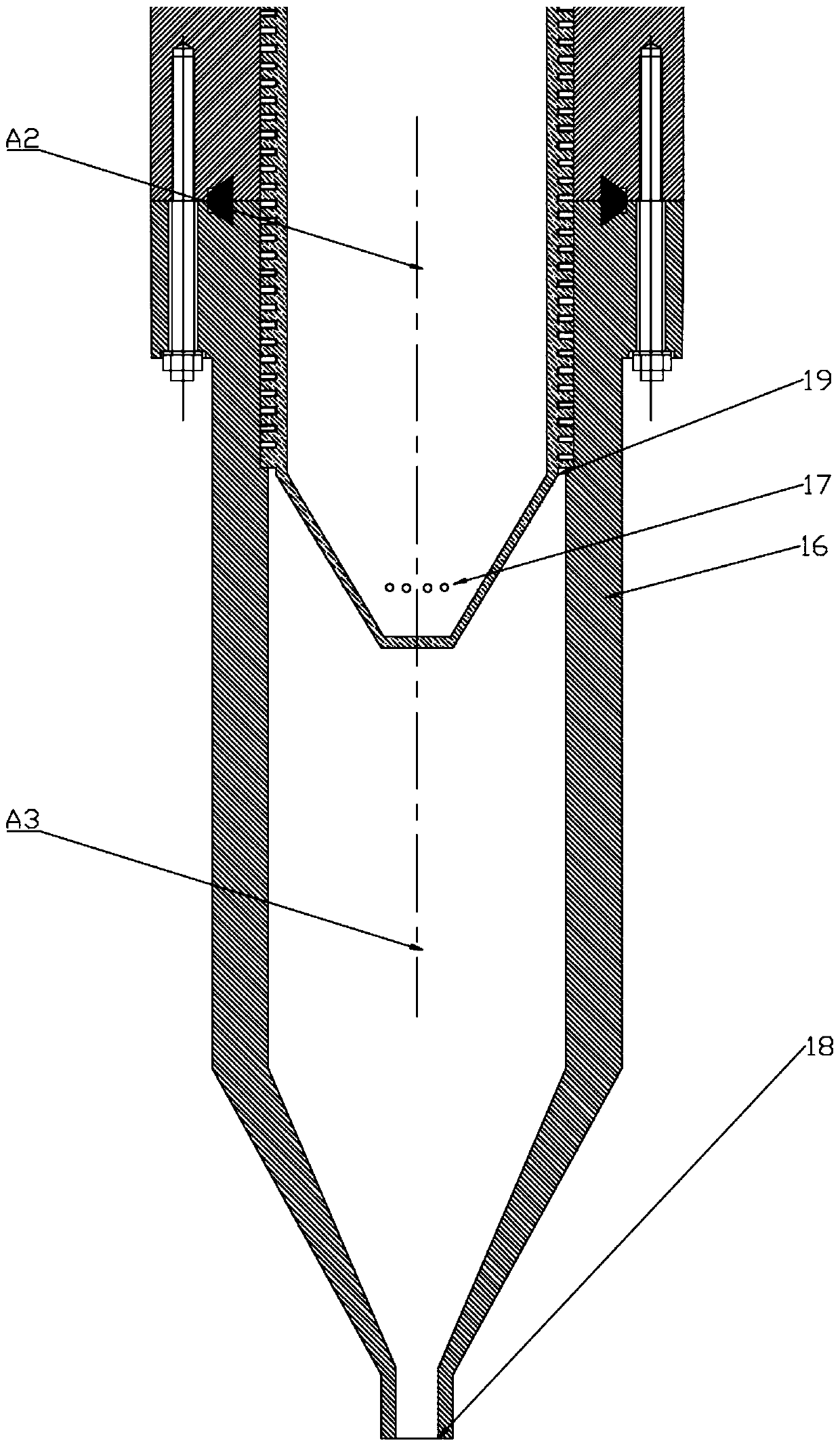

[0022] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0023] like figure 1 , figure 2 and image 3 As shown, a supercritical hydrothermal combustion type downhole steam generator for heavy oil thermal recovery of the present invention mainly consists of a top end cover 6, a middle end cover 9, a backflow stable combustion zone shell 12, a main reaction zone shell 15 and The shell 16 of the blending zone is connected and assembled by fixing bolts 3 in sequence.

[0024] Among them, the top end cover 6 is provided with a swirler fuel inlet 1 and an axial heating rod 5, and the insertion hole of the heating rod 5 runs through the center of the middle end cover 9, and the middle end cover 9 is provided with a main combustion hole jet fuel inlet 2, The jet oxidant inlet 7 of the main combustion hole, the cooling water inlet 8 and the swirl nozzle 10, the swirl nozzle 10 communicates with the fuel in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com