On-line degassing device for aluminium melt

A gas device and aluminum melt technology, applied in the field of aluminum melt on-line purification device, can solve problems such as unfavorable aluminum melt purification, gas suction phenomenon, melt tumbling, etc., to reduce technical production costs, improve gas utilization rate, Avoid the effect of entrainment and hydrogen absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

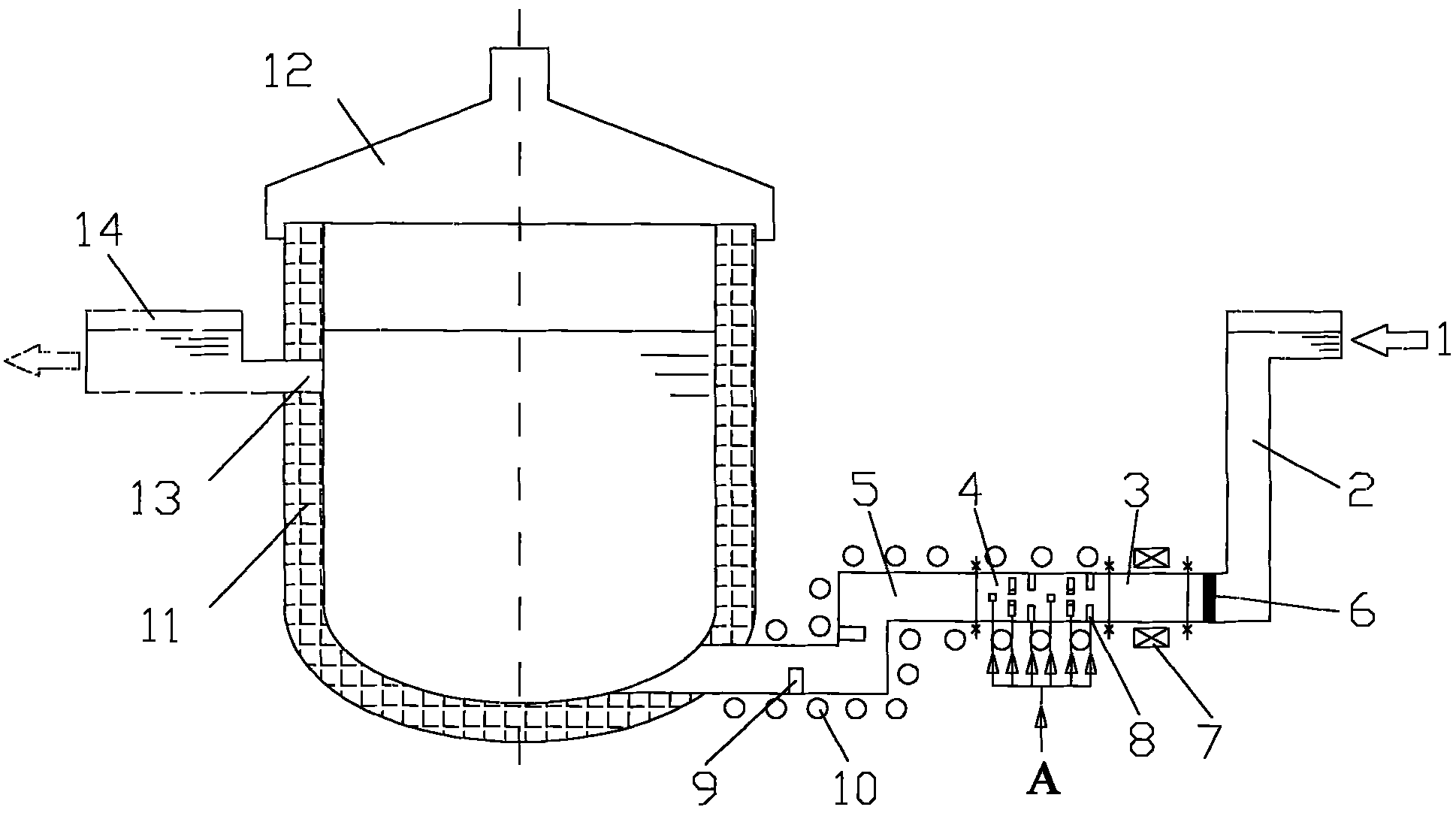

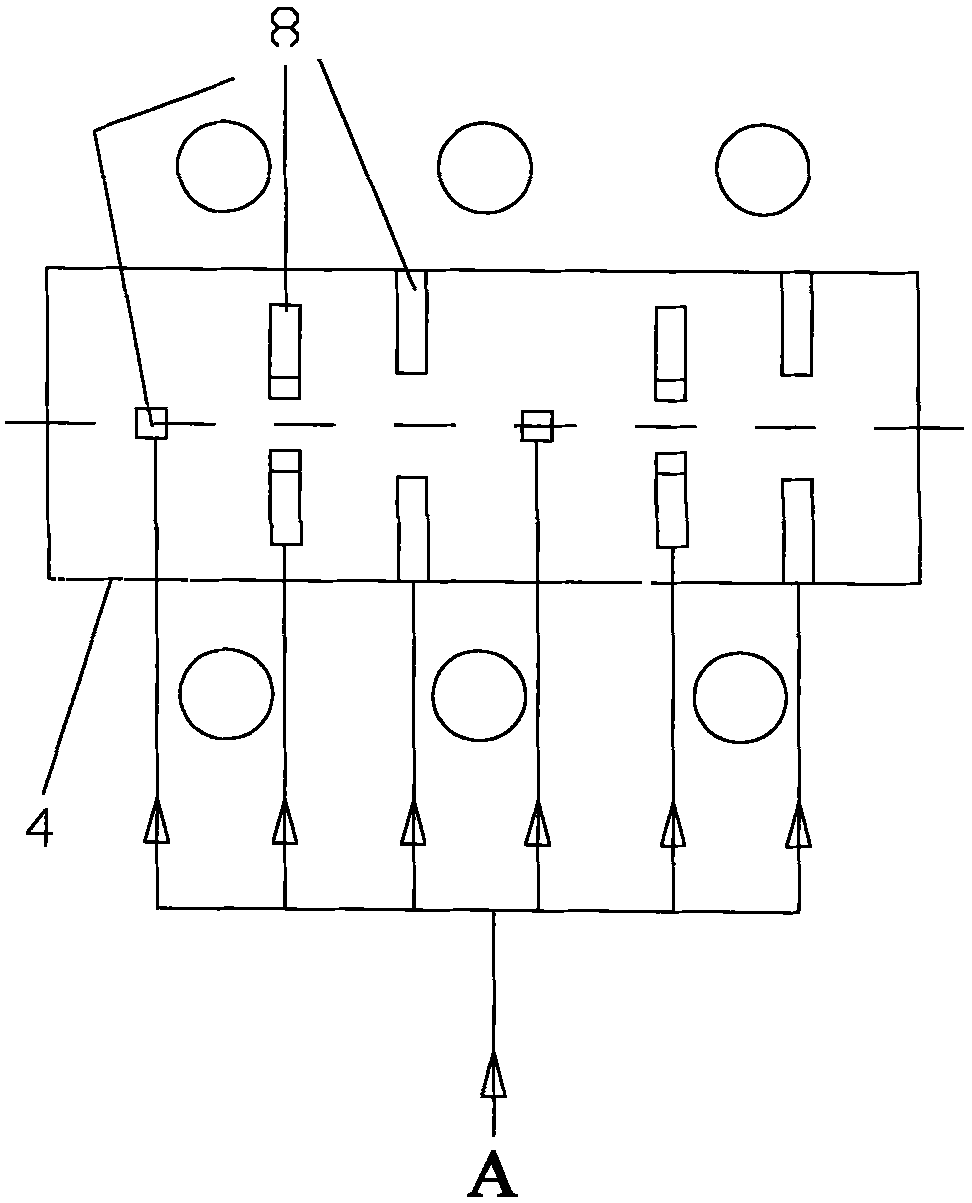

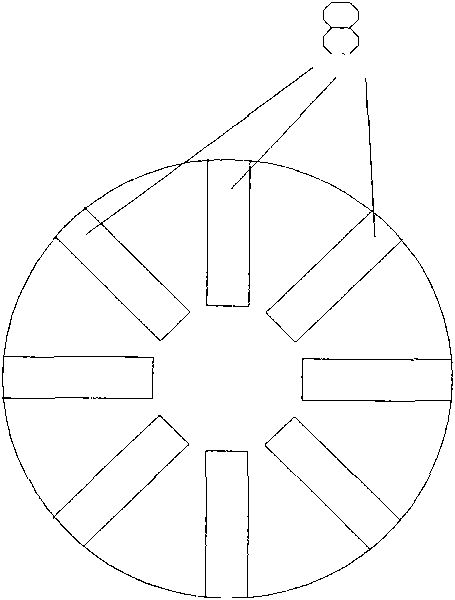

[0025] Such as figure 1 As shown, it is a preferred embodiment of the present invention, which mainly consists of an aluminum melt inlet 1, a flow channel 2, an acceleration pipeline 3, a gas mixing tube 4, a secondary mixing tube 5, a ceramic filter plate 6, and an electromagnetic pump 7. Composed of jet pipe 8, block 9, heat preservation and heating device 10, static chamber 11, tail gas collection device 12, melt outlet 13, etc. The flow channel 2, acceleration pipeline 3, gas mixing tube 4, and secondary mixing tube 5 are all made of ceramic tubes, which are sequentially connected by flanges, and heat preservation and heating devices 10 are provided around the gas mixing tube 4 and secondary mixing tube 5 . The front end of the runner 2 is a melt inlet 1, and the end is provided with a ceramic filter plate 6 of 10-50 mesh. An electromagnetic pump 7 is arranged outside the acceleration pipeline 3 . The gas mixing tube 4 is provided with a plurality of axially distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com