Doped basic cobalt carbonate/cobalt carbonate composite precursor and preparation method and application thereof

A cobalt carbonate, doped technology, used in cobalt carbonate, cobalt compounds, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

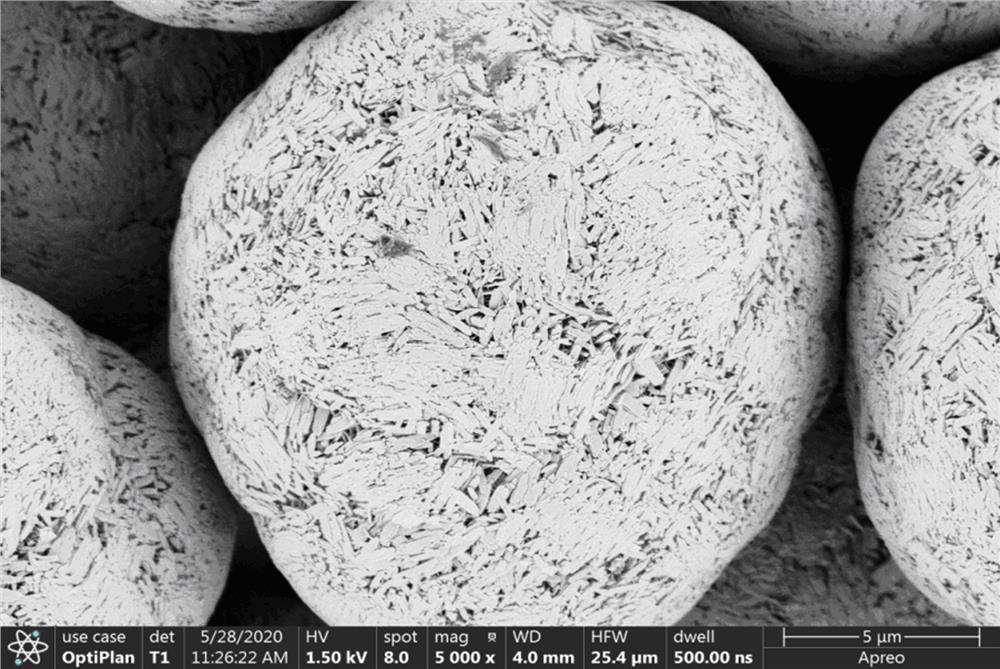

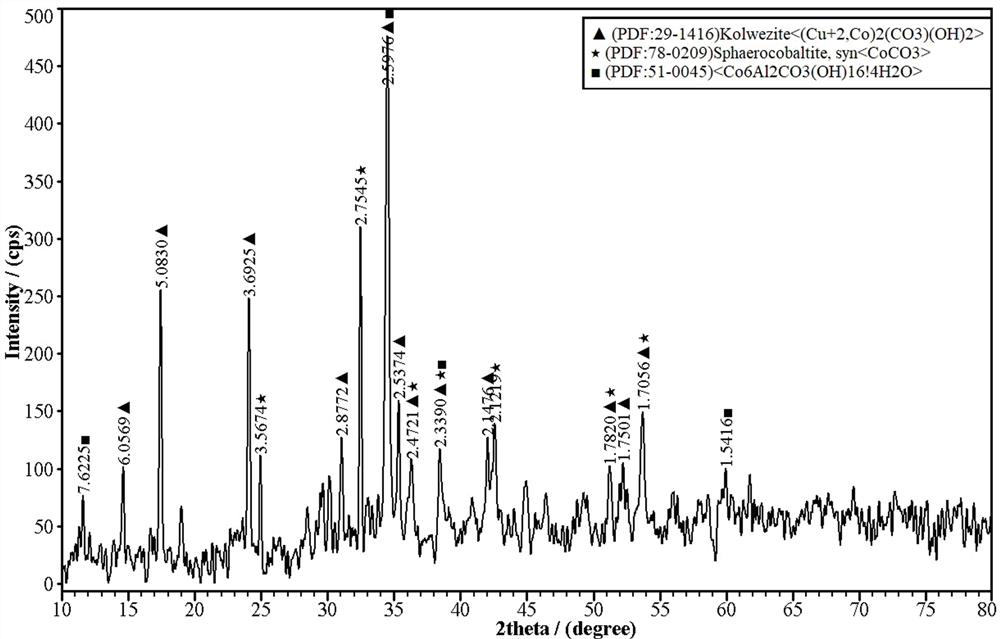

Image

Examples

Embodiment 1

[0031] This embodiment includes the following steps:

[0032] Step S1, using cobalt sulfate as the cobalt source and aluminum sulfate as the aluminum source, prepare a cobalt-aluminum mixed salt solution, wherein the cobalt metal concentration is 1.5mol / L, and the aluminum metal concentration is 0.03mol / L; prepare 2mol / L bicarbonate ammonium solution;

[0033] Step S2, in the 50L reactor, add a certain amount of 1.5mol / L ammonium bicarbonate solution as the base liquid, make the liquid level just below the bottom of the stirring paddle, start stirring, and the stirring line speed is 3 m / s, The reaction temperature of the control system was 45°C. Add the mixed salt solution and ammonium bicarbonate solution prepared in step S1 into the system in parallel, wherein the feed rate of the mixed salt solution is 2.5 L / h, and the ammonium bicarbonate solution feeding control system reaction pH is 7.40~7.50. When the particle size D50 is 10um, the line speed decreases by 0.2 m / s ever...

Embodiment 2

[0036] This embodiment includes the following steps:

[0037] Step S1, using cobalt sulfate as the cobalt source and aluminum sulfate as the aluminum source, prepare a cobalt-aluminum mixed salt solution, wherein the cobalt metal concentration is 1.8mol / L, and the aluminum metal concentration is 0.04mol / L; prepare 3mol / L ammonium bicarbonate solution;

[0038] Step S2, in the 50L reaction kettle, add a certain amount of 1.5mol / L ammonium bicarbonate solution as the base liquid, make the liquid level just below the bottom of the stirring paddle, start stirring, and the stirring line speed is 3.5 m / s, control The reaction temperature of the system is 50°C. Add the mixed salt solution and ammonium bicarbonate solution prepared in step S1 into the system in parallel, wherein the feed rate of the mixed salt solution is 3 L / h, and the ammonium bicarbonate solution feeding control system reaction pH value is 7.30~7.40. When the particle size D50 is 10um, the line speed decreases by...

Embodiment 3

[0041] This embodiment includes the following steps:

[0042] Step S1, using cobalt chloride as the cobalt source and aluminum chloride as the aluminum source, prepare a cobalt-aluminum mixed salt solution, wherein the cobalt metal concentration is 1.8mol / L, and the aluminum metal concentration is 0.05mol / L; prepare 2.5mol / L ammonium bicarbonate solution;

[0043] Step S2, in the 50L reaction kettle, add a certain amount of 1.0mol / L ammonium bicarbonate solution as the primer solution, make the liquid level just below the bottom of the stirring paddle, start stirring, and the stirring line speed is 3.5m / s, The reaction temperature of the control system was 55°C. Add the mixed salt solution and ammonium bicarbonate solution prepared in step S1 into the system in parallel, wherein the feed rate of the mixed salt solution is 3.5 L / h, and the ammonium bicarbonate solution feeding control system reaction pH value is 7.20~7.30. When the particle size D50 is 10um, the line speed de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com