Thermoplastic polyurethane elastomer production device and method

A thermoplastic polyurethane and production device technology, which is applied in the field of thermoplastic polyurethane elastomer production devices, can solve the problems of inaccurate manual proportioning and measurement of raw materials, long processing and preparation process, and uncontrollable reaction temperature, so as to reduce energy consumption and improve the overall Utilization rate, effect of reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

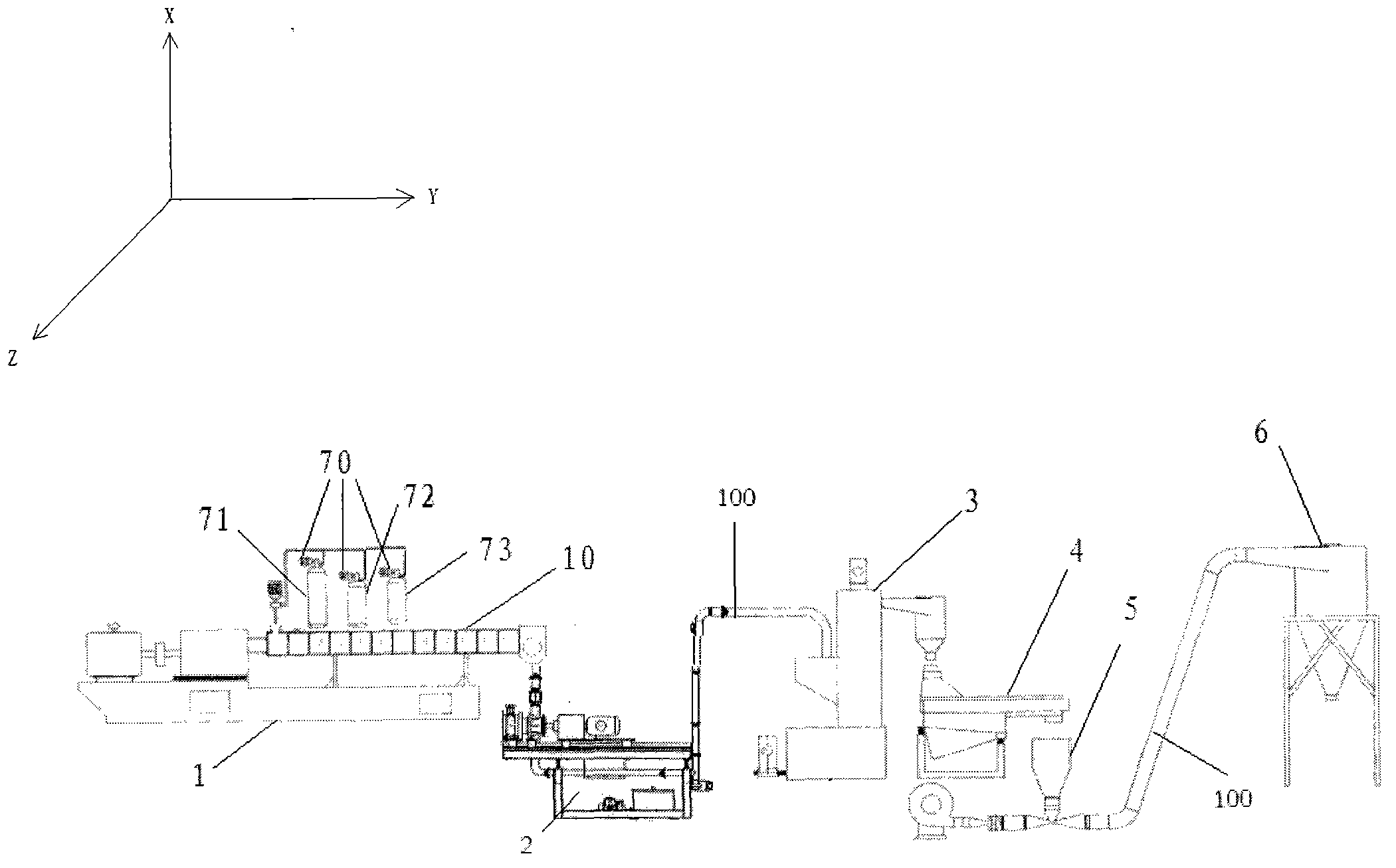

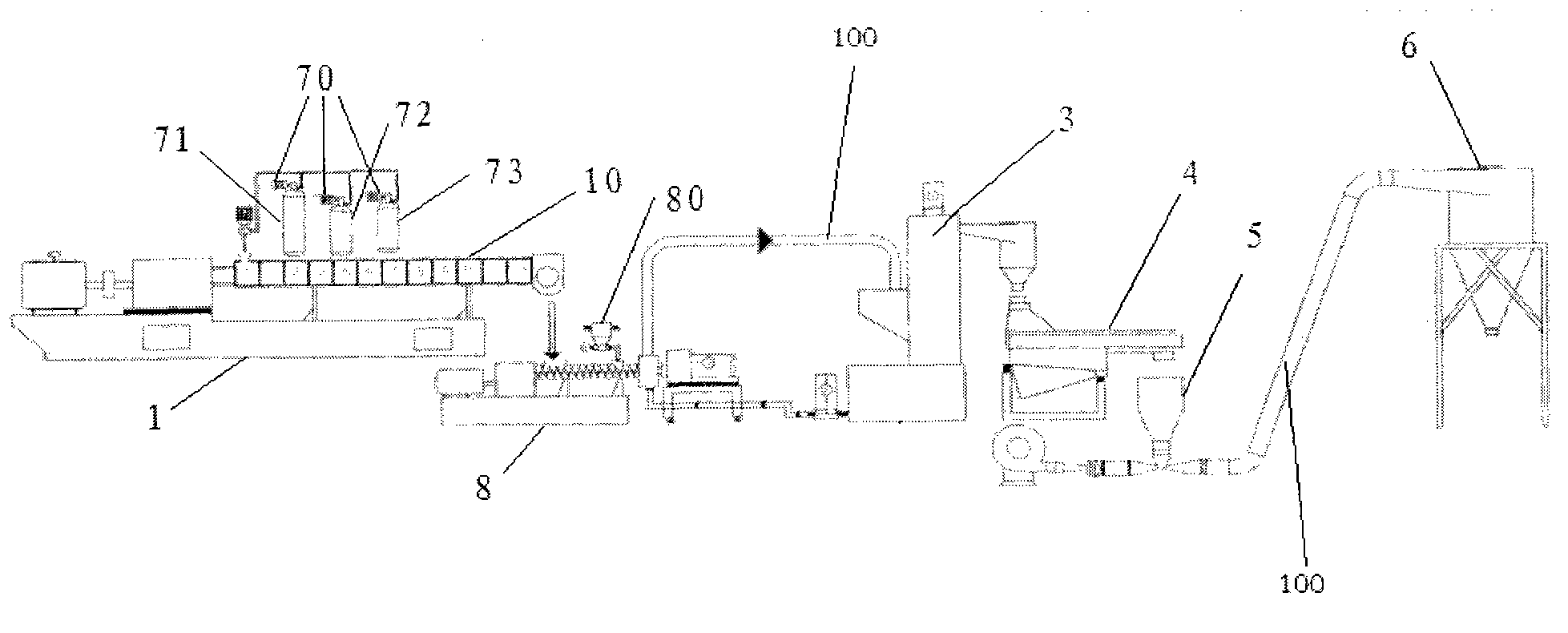

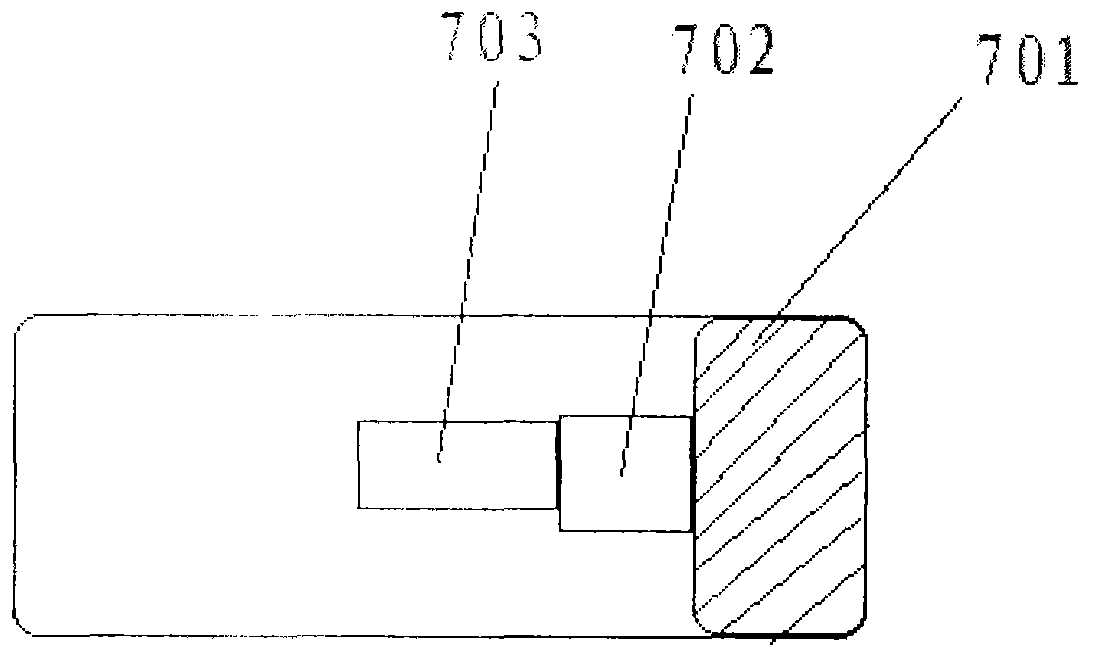

[0030] The thermoplastic polyurethane elastomer production device comprises: a twin-screw extruder 1, an underwater granulator 2 arranged at the rear end of the twin-screw extruder 1 and connected to the twin-screw extruder 1 through a particle conveying pipeline 100, and The dehydrator 3 connected to the water granulator 2 is connected with the dehydrator 3 through the particle conveying pipeline 100. The lower part is provided with a vibrating screen 4 with a discharge port, and the packaging machine 5 arranged under the vibrating screen 4 passes through the packaging machine 5. The silo 6 connected by the material conveying pipeline 100 is directly connected with three liquid material tanks 71, 72, 73 at the front end of the twin-screw extruder 1, and the upper part of the liquid material tank is provided with a raw material metering component 70 for controlling the reaction amount of the raw material. The front part of the screw extruder 1 is provided with at least twelve c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com