Multi-channel harmful gas detection device and method based on micro-fluidic chip

A microfluidic chip and harmful gas technology, applied in the direction of measuring devices, material analysis by optical means, and analysis by making materials undergo chemical reactions, can solve problems such as error, difference detection, and inconvenient light absorption detection, etc., to achieve Increased flow rate, simple operation, and increased reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

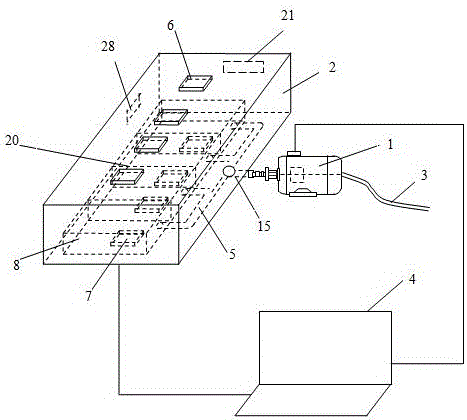

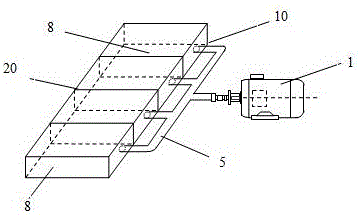

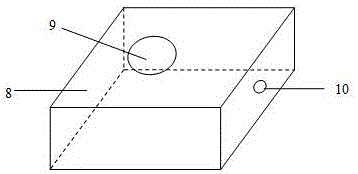

[0033] see figure 1 In the present invention, a multi-channel harmful gas rapid detection device based on a microfluidic chip has a microfluidic chip 20 , a micro pump 1 and a cartridge 2 . The micro air pump 1 is placed in the cavity of the cassette 2, and the micro air pump 1 is arranged outside the cassette 2. One end of the miniature air pump 1 passes through the through hole 15 that is opened on the side wall of the cassette 2 and then connects the collection channel 5 in the cassette 2. A rubber device is installed at the through hole 15 to prevent air leakage. The collection channel 5 is located in the cassette 2. The micro air pump 1 is connected to the microfluidic chip 20 through the collection channel 5 , and pumps gas into the microfluidic chip 20 . There is a flow meter in the micro air pump 1, which is used to measure the volume of gas sucked by the micro air pump 1. The other end of the micro air pump 1 is connected with the waste liquid channel 3 through a ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com