On-line degassing method for aluminium melt

A technology for aluminum melt and melt, which is applied in the field of on-line degassing of metal melt, can solve the problems of uneven distribution of purified gas, intensified hydrogen absorption in the melt, and intensified fluctuation of the liquid level of aluminum melt, and achieves improved gas utilization. rate, shorten the diffusion path, and strengthen the effect of gas-liquid contact

Inactive Publication Date: 2011-03-09

SHANGHAI DIANJI UNIV

View PDF3 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The distribution of purified gas in the degassing box is uneven. The gas content in the aluminum melt in the central body area of the degassing box around the rotor is relatively high, while the purified gas content in the melt in the corner area far away from the rotor is very small, which cannot guarantee The entire melt is fully in contact with a sufficient number of air bubbles

In order to improve the gas distribution in the corner area, the rotor speed needs to be increased, which in turn will lead to aggravated fluctuations in the liquid level of the aluminum melt and aggravated hydrogen absorption by the melt, which is not conducive to the purification of the aluminum melt

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0026] Its implementation results are as follows: the aluminum melt flow rate is 10T / h, the hydrogen content of the aluminum melt at the melt inlet is 0.34ml / 100g aluminum liquid, and the hydrogen content of the aluminum melt at the outlet is 0.08ml / 100g aluminum liquid, The hydrogen removal efficiency reached 76%.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

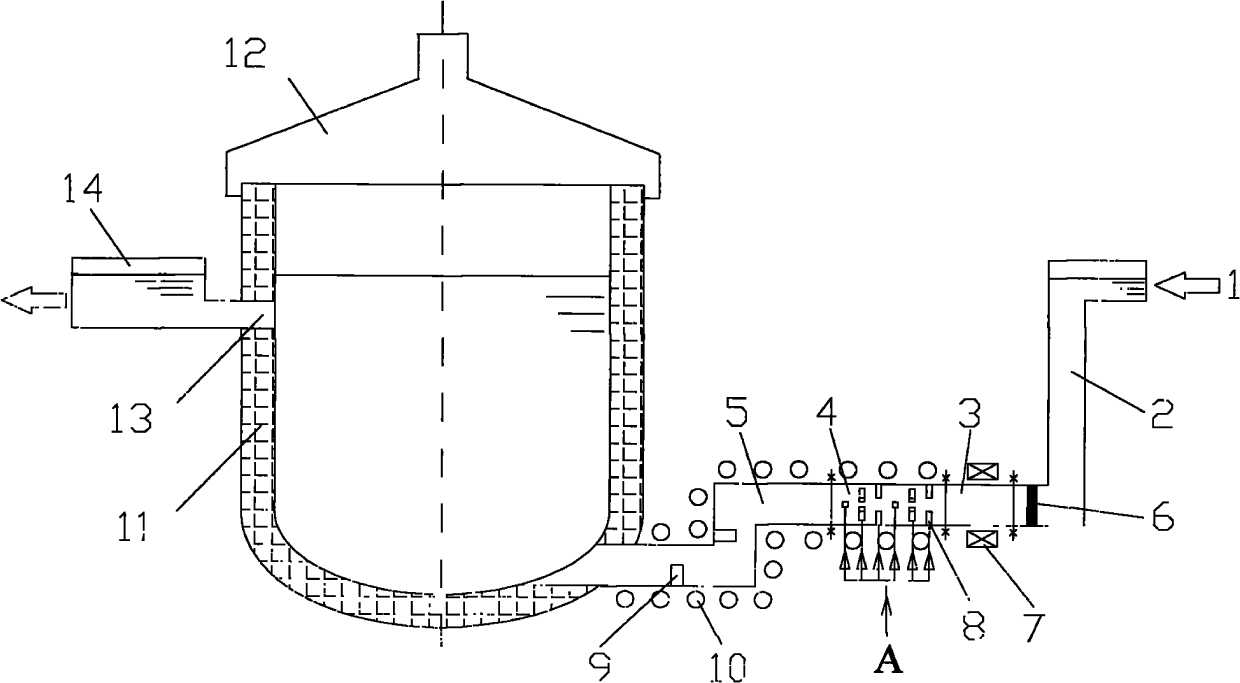

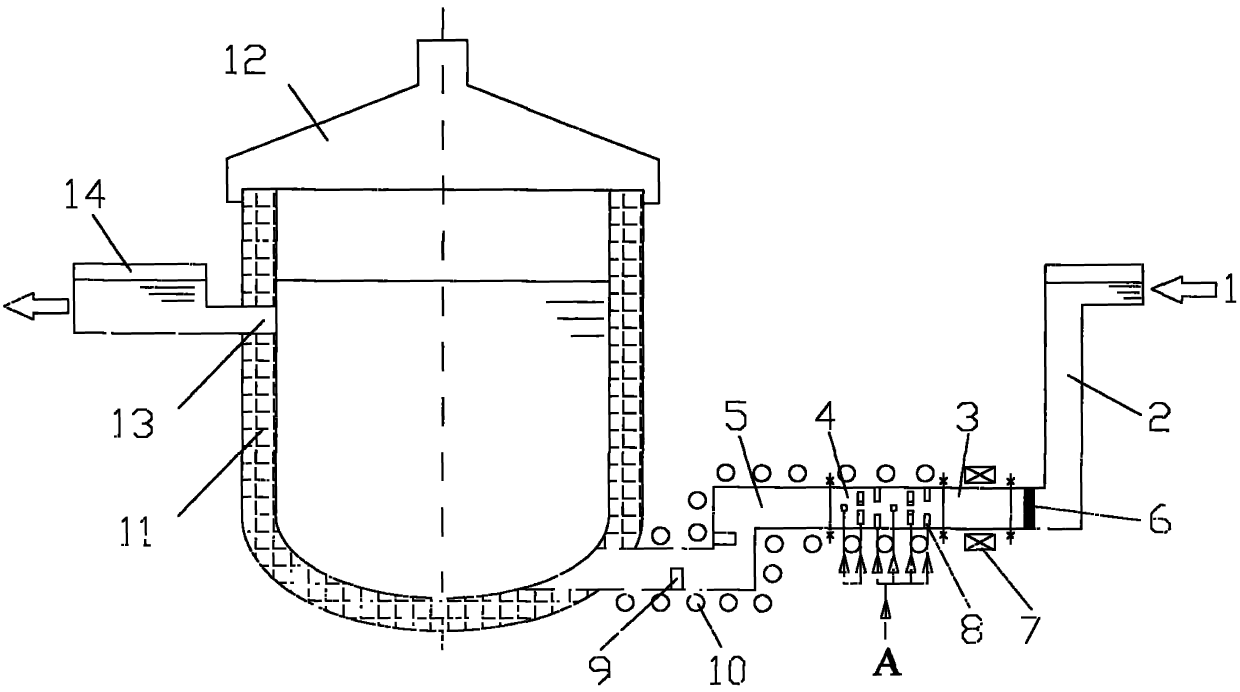

Login to View More Abstract

The invention discloses an on-line degassing method of an aluminium melt, comprising the following steps: 1) leading an aluminium melt to be purified to enter into a runner 2 with a ceramic filter plate 6 via a melt inlet to remove large-sized slag in the molten aluminum; 2) designing a small-diameter channel consisting of an acceleration pipeline 3 and a gas mixed pipe 4 between the melt inlet and a melt outlet; 3) further mixing the aluminium melt with mixed gas evenly via a secondary mixed pipe 5 with a stop dog; 4) discharging the mixture of the molten aluminum and the mixed gas in a standing chamber 11, and forming an argon protective layer above the liquid level of an escaped gas while bubbles disperse and float upwards evenly; and 5) collecting the processed gas via a tail gas collector 12, and discharging the molten aluminum from the melt outlet of the standing chamber. The method in the invention can effectively ensure fully mixed reaction of the molten aluminum with sufficient cleaned gas in a sealed space, shortens the dispersion course of hydrogen in the aluminium melt and achieves the aim of hydrogen removal efficiently.

Description

technical field [0001] The invention relates to an online degassing method for metal melt, in particular to an online purification method for aluminum melt for removing gas in aluminum melt. Background technique [0002] In order to ensure the metallurgical quality of aluminum and its alloys, it is necessary to purify the refined aluminum melt, and reducing the hydrogen content in the aluminum melt is one of the main purposes of aluminum melt purification. At present, the on-line dehydrogenation purification method of aluminum melt is mainly based on the theory of bubble floating, that is, a large number of bubbles are blown into the aluminum melt, and the hydrogen in the aluminum melt is continuously diffused into the bubbles by using the partial pressure difference between the aluminum melt and the bubbles. In, and escape as the bubbles float up to the surface of the melt, so as to achieve the purpose of hydrogen removal. [0003] According to literature search, the curre...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22B21/06C22B9/05C22B9/02

CPCY02P10/20

Inventor 孙会

Owner SHANGHAI DIANJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com