Open-close type current transformer

A current transformer, open-close technology, applied in the direction of inductors, voltage/current isolation, circuits, etc., can solve the problems of insufficient flatness of the end face of the lamination, low lamination coefficient, increase of copper, etc., to reduce the cross-sectional area of the iron core, The end face is tightly combined to reduce the effect of magnetic leakage air gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

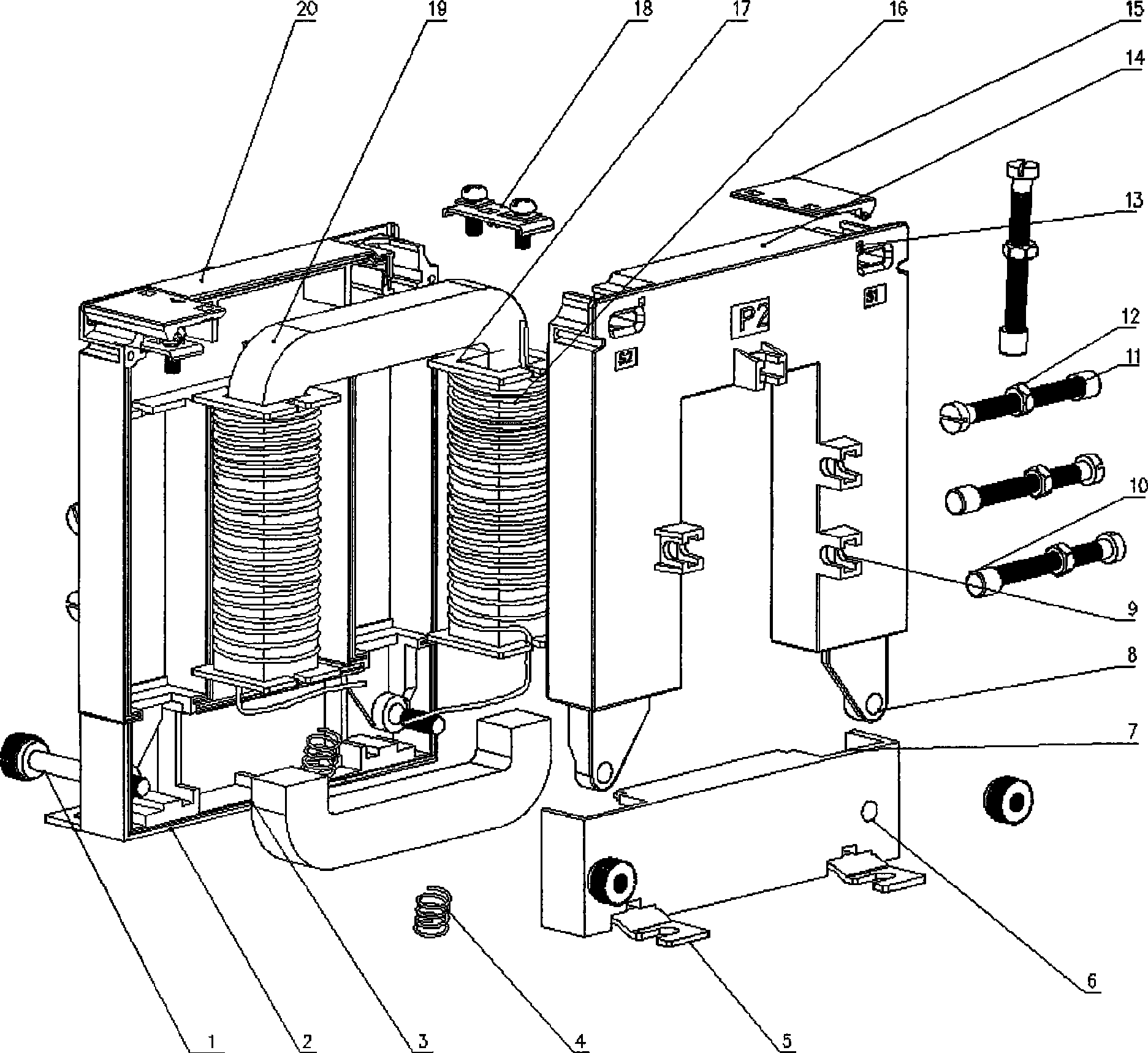

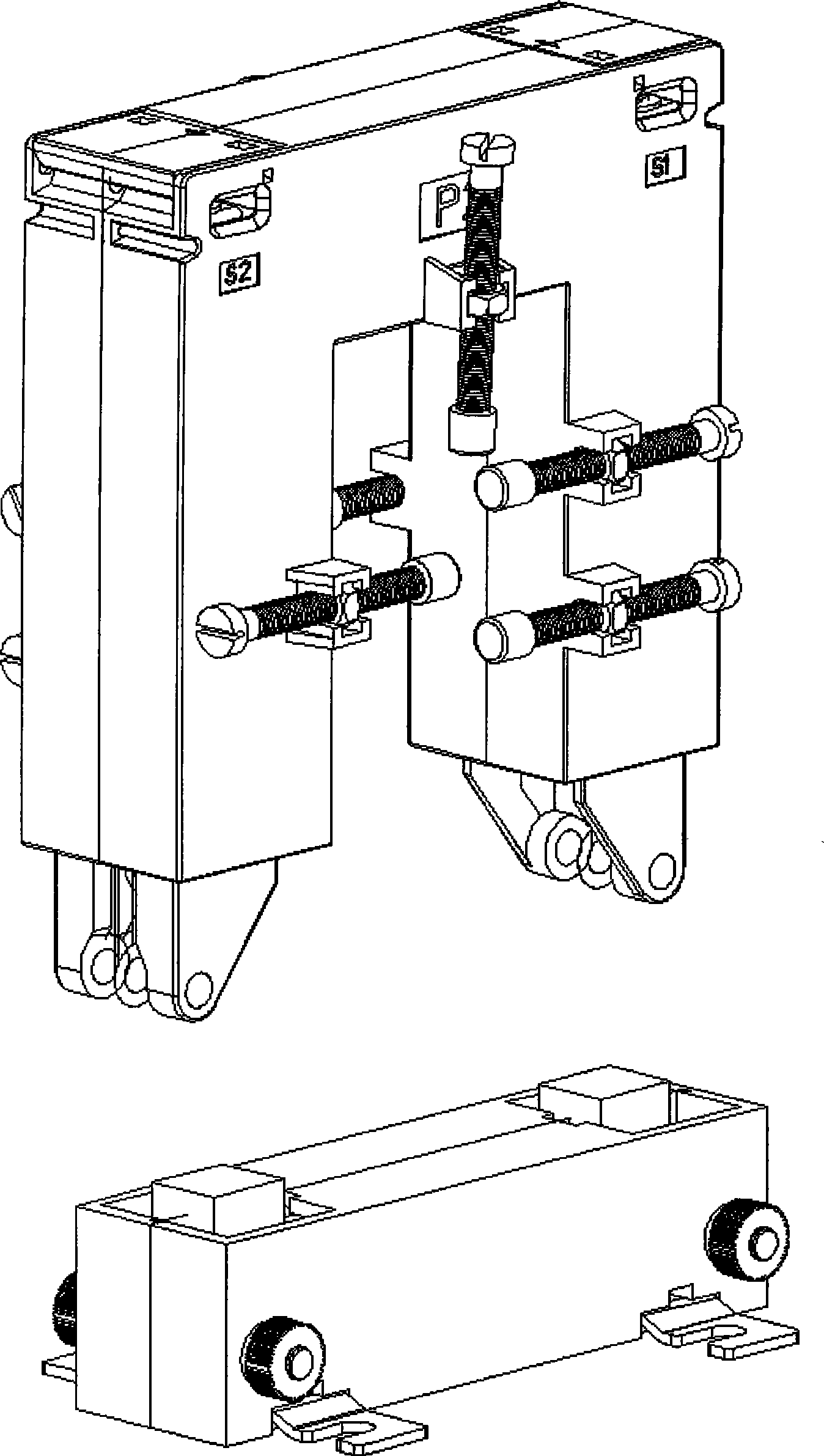

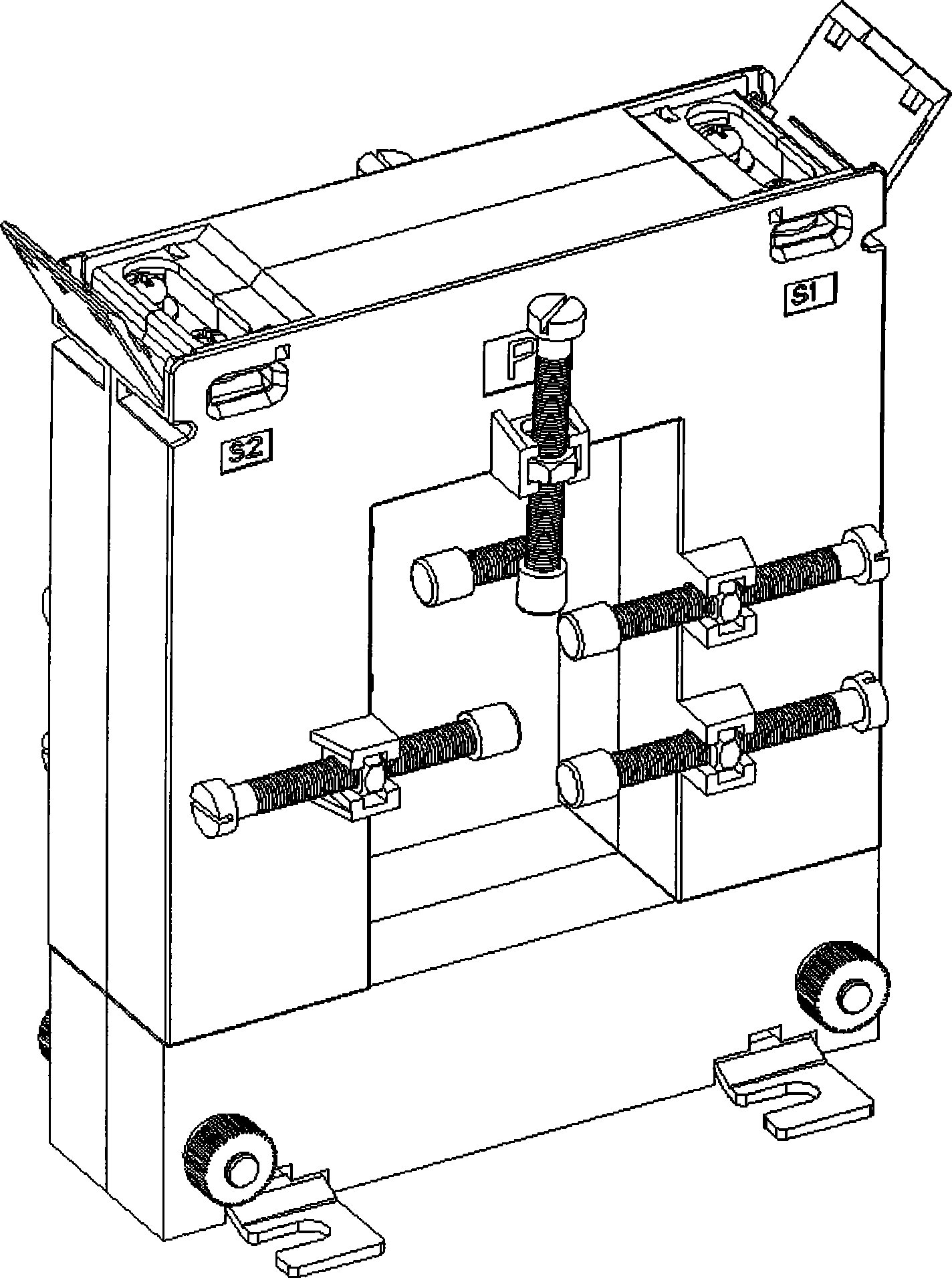

[0020] Such as figure 1 As shown, a split-type current transformer includes a housing, an iron core, a coil, and terminals. The iron core is composed of two iron cores that can be spliced into a square ring, and the upper one is a large iron core 19 The following is the small iron core 3, and the coil 16 is wound on the large iron core 19; the housing is a hollow square housing, which consists of an upper housing in the shape of an inverted "concave" at the front and back and a rectangular parallelepiped lower housing. The shell structure; the upper shell is composed of the front shell 14 and the rear shell 20 fixed together, the inside of the upper shell is packaged with a large iron core 19, there are connecting claws on both sides of the lower end of the upper shell, and there are screw holes 8 on the connecting claws , two corners of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com