Shell ice cutting device

A cutting device and tube ice technology, which is applied in ice manufacturing, ice storage/distribution, lighting and heating equipment, etc., can solve the problems of tube ice finished products of different sizes, uneven end faces, jagged, etc., to achieve consistent length, The end surface is smooth and beautiful, and the effect of use is beautiful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

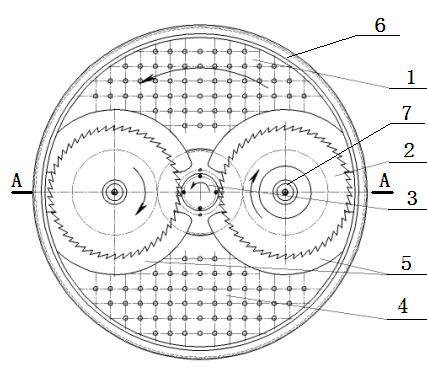

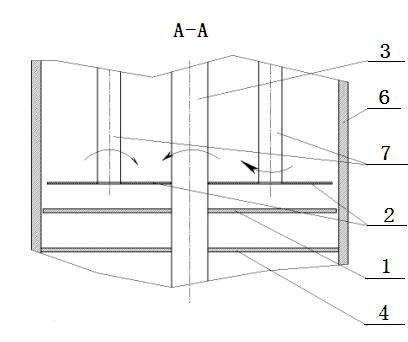

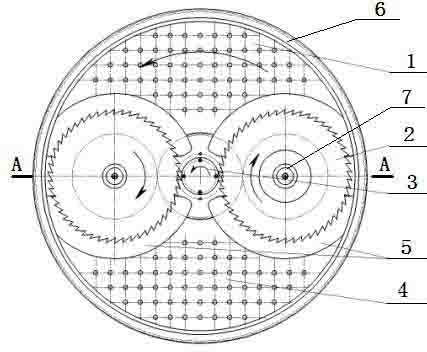

[0011] Such as figure 1 Shown is the schematic diagram of the present invention, figure 2 shown as figure 1 The A-A sectional view of the present invention includes the ice cutting carousel (1), the ice deflector (4), the ice outlet (5) and the outer tub of the tube ice machine (6), which is characterized in that: above the ice cutting carousel (1) , the rotating shaft (3) is connected to the circular saw blade (2) through the saw blade rotating shaft (7), and the rotating direction of the circular saw blade (2) is opposite to that of the ice cutting turntable (1).

[0012] When the present invention works, driven by the rotating shaft 3, the circular saw blade (2) is driven to rotate at a high speed through the saw blade rotating shaft (7), and the tubular long ice falling on the ice cutting turntable (1) is cut according to the required This method can ensure that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com