Rod-shaped material with surface having multiple properties and manufacturing method and application of Pickering emulsion thereof

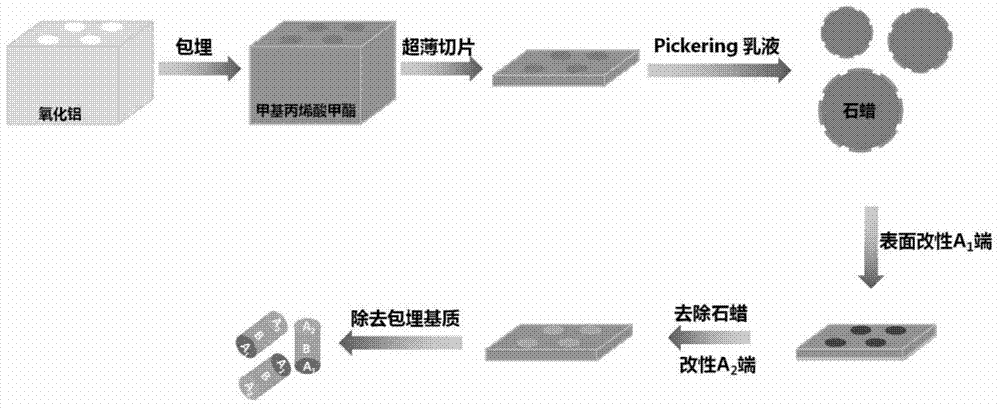

A technology of rod-shaped and metal materials, applied in the direction of nanotechnology for materials and surface science, nanostructure manufacturing, manipulation of single atoms, etc., can solve the problems that cannot meet actual needs, are difficult to meet actual needs, and have low efficiency and output. , to achieve the effect of smooth end surface, uniform scale, simple and feasible steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0076] According to the preparation method of nanorod array slice b, only the electrolyte solution was replaced with 40.0 mL of deionized water, 4.0 g of ferrous sulfate heptahydrate, 0.6 g of ammonium sulfate, 1.2 g of magnesium sulfate, 0.04 g of antacid An electrolyte composed of 80 uL of triol and dilute sulfuric acid with a concentration of 1M, and the pH value of the electrolyte is adjusted to 3 with 1M dilute sulfuric acid;

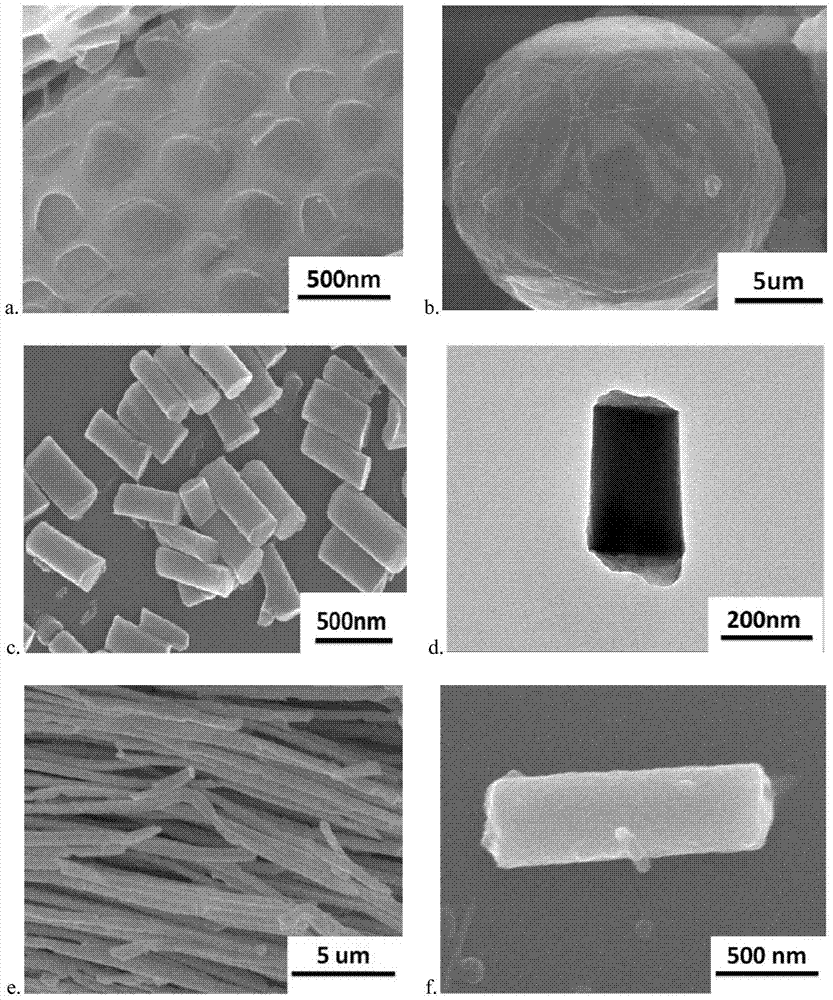

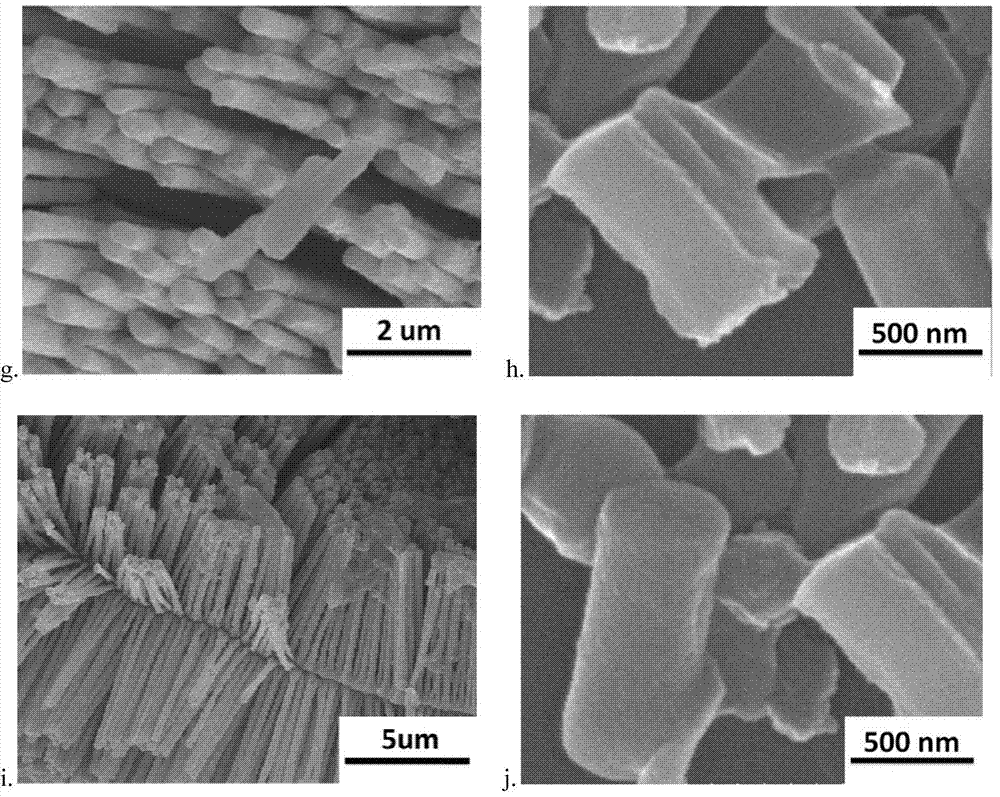

[0077] And the potential E is replaced by 2.5V, and the Fe nanowires with a length of 10um dispersed in the alumina template are obtained. The electron micrograph is as follows figure 2 g shown.

[0078] The nanorod array slice d used in the following embodiment 4 is prepared according to the following method:

[0079] According to the preparation method of the nanorod array slice b, only the electrolyte solution was replaced with an electrolyte solution consisting of 25.0ml of deionized water, 5.26g of nickel sulfate hexahydrate, 0.75g of boric ...

Embodiment 1

[0082] 1) Emulsify the nanorod array slice a with Pickering particles:

[0083] The slices were first treated with organic solvents to improve their hydrophilic and lipophilic properties, and then the nanorod array slice a was placed in a Pickering emulsion composed of paraffin and water with a mass ratio of 1:10 for high-speed shear emulsification. High-speed shear emulsification in the system, using the Pickering effect of slices to form a stable emulsion. The obtained Pickering emulsion system is cooled and washed to obtain a paraffin ball wrapped in nanorod array section a, which is the ball material provided by the invention, and its electron micrograph is as follows figure 2 b;

[0084] The ball material is composed of silica nanorod array slices and paraffin solid spheres; wherein, the silica nanorod array slices wrap the paraffin solid spheres; the silica nanorod array slices are composed of silica nanorods and a matrix; The silicon nanorods have a length of 400nm a...

Embodiment 2

[0093] 1) step 1) is the same as step 1) of embodiment 1);

[0094] Only replace the nanorod array slice a used in step 1) with the nanorod array slice b;

[0095] The ball material is composed of gold nanorod array slices and paraffin solid balls; wherein, the gold nanorod array slices wrap the paraffin solid balls; the gold nanorod array slices are composed of gold nanorods and matrix; Uniformly dispersed in the matrix PMMA.

[0096] 2) Put the paraffin sphere wrapped in the nanorod array slice b obtained in step 1) in deionized water and SH-PEG (the concentration of SH-PEG in the reaction system is 5mM) on a shaker at room temperature for complexation Coordination reaction for 6 hours, to obtain rod A 1 Type B material ball;

[0097] 3) The stick A obtained in step 2) 1 B-type material balls were dissolved in tetrahydrofuran to remove paraffin, placed in deionized water and SH-PS (the concentration of SH-PS in the reaction system was 5mM) on a shaker at room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com