Plastic composite tubular product sample cutting machine for steel wire gauze framework

A technology of composite pipes and wire mesh, which is applied in the direction of metal sawing equipment, sawing machine devices, and knives of sawing machine devices. Simple, low-cost-to-manufacture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

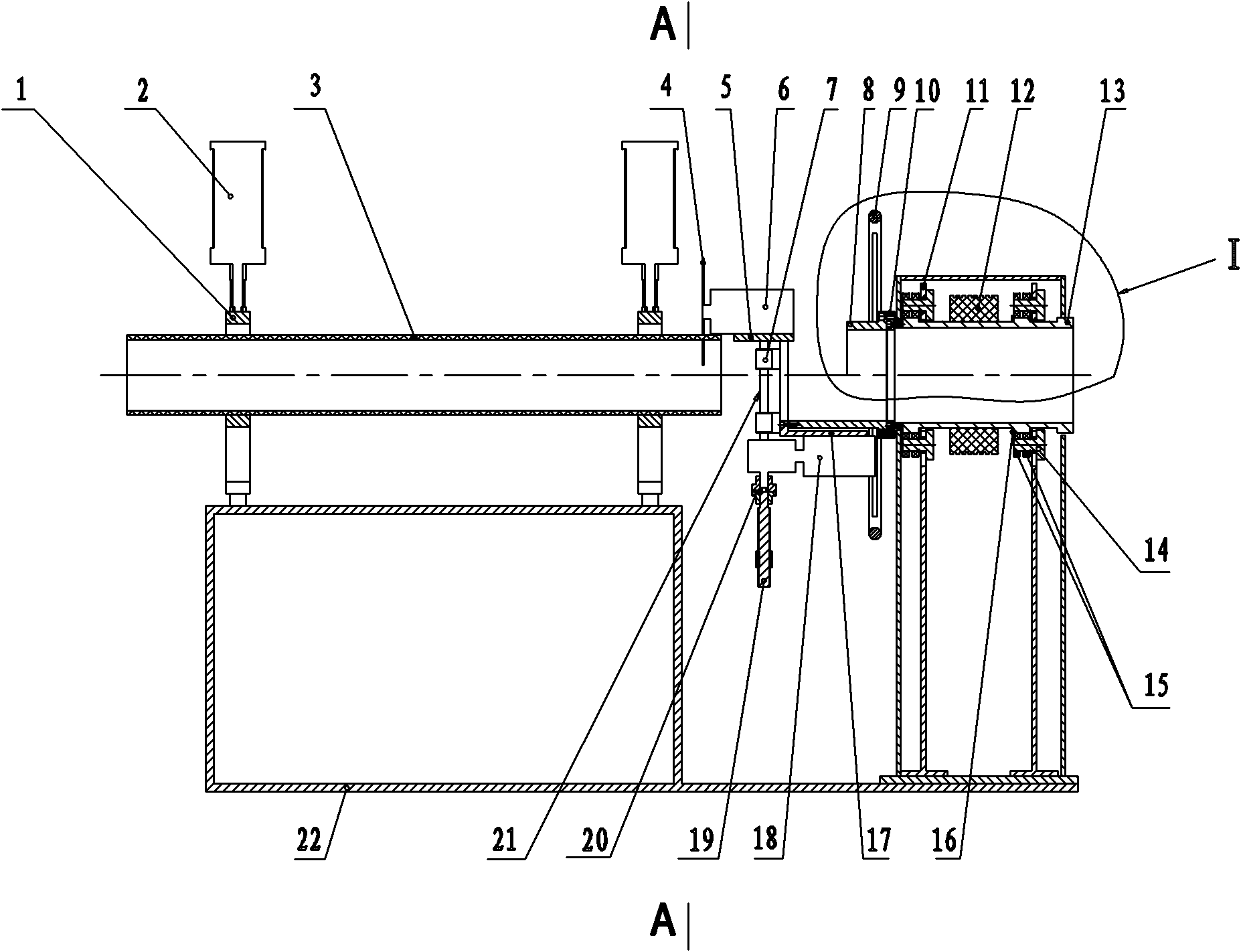

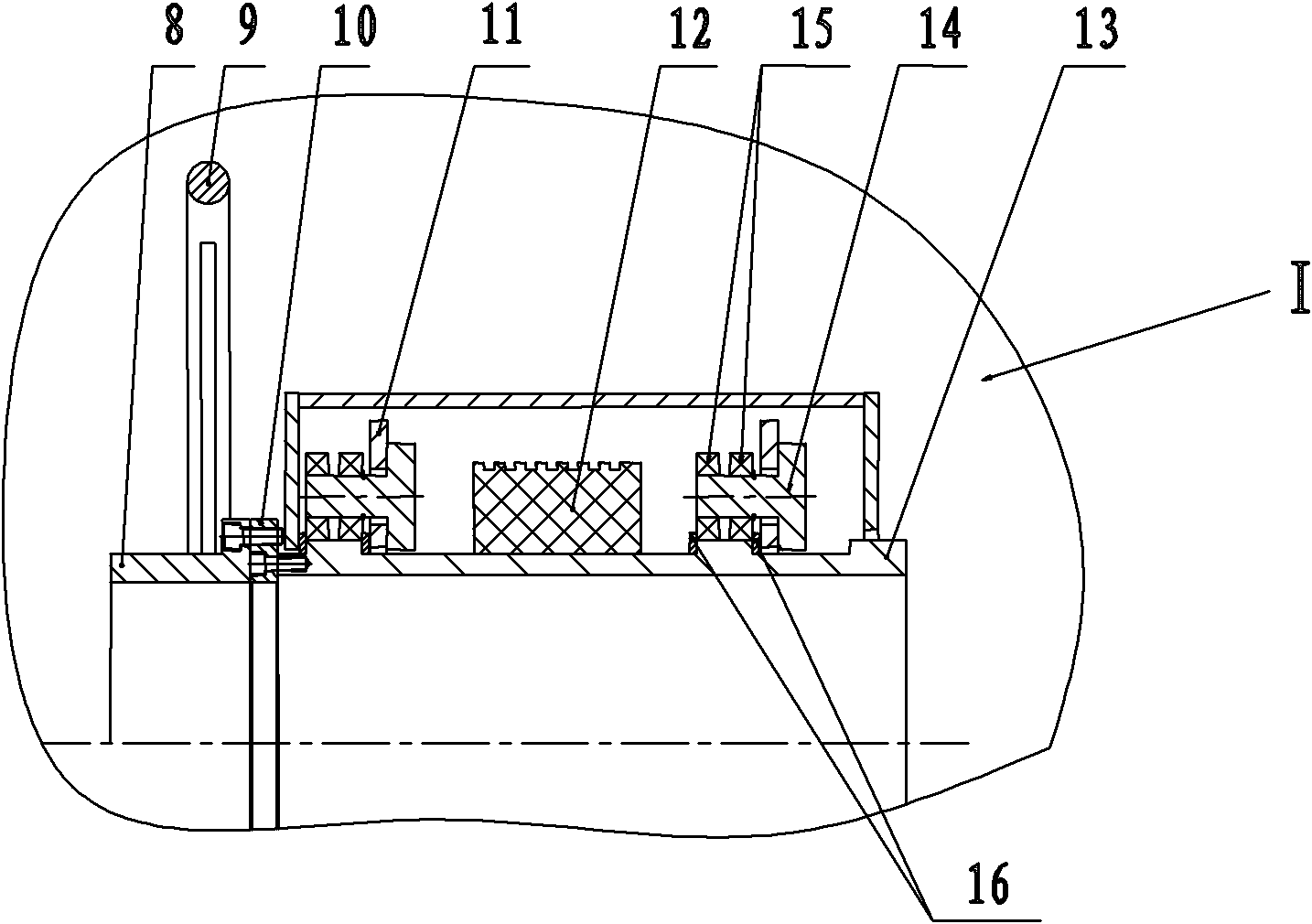

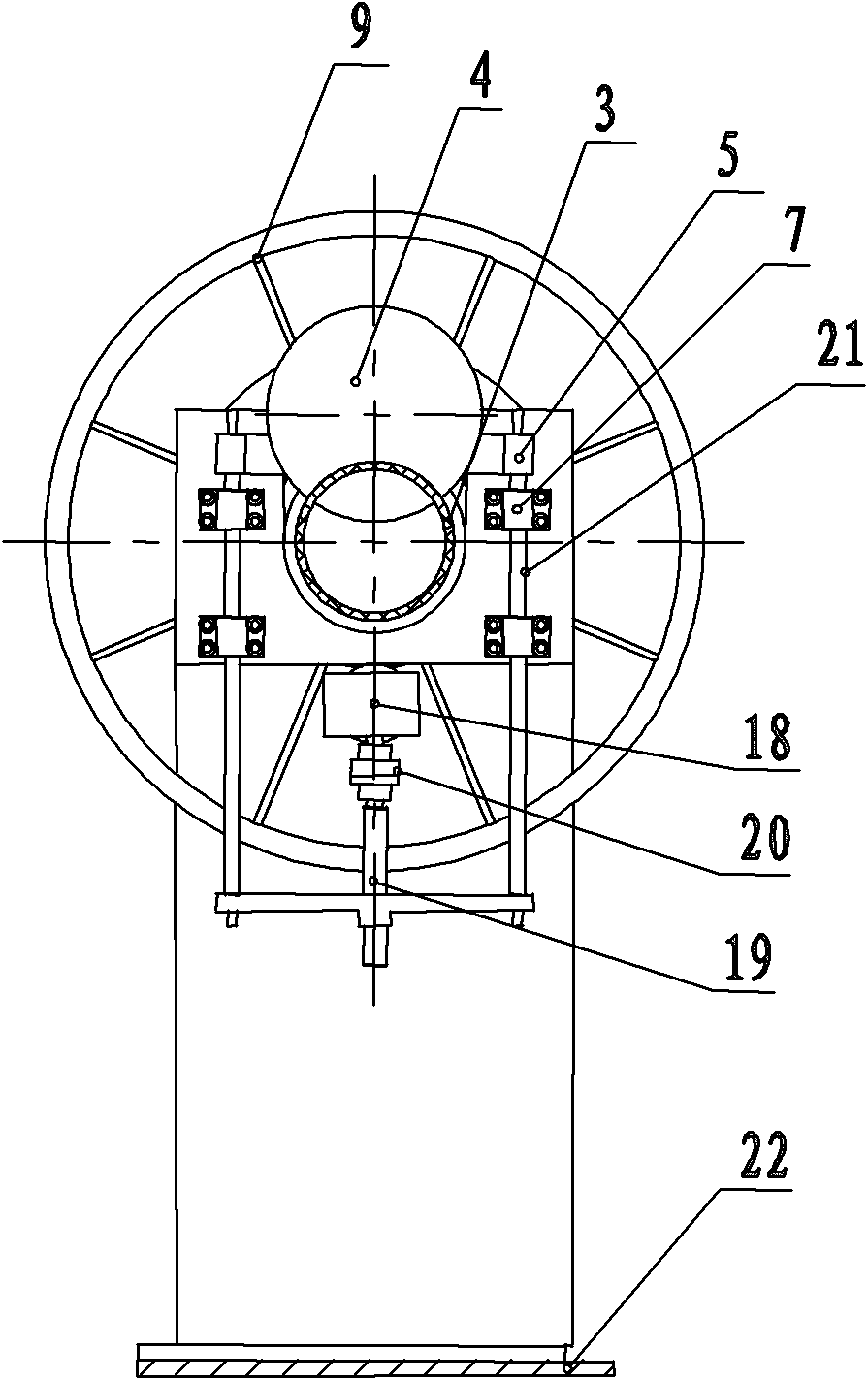

[0031] Such as Figure 1-3 As shown, a steel mesh skeleton plastic composite pipe sample cutting machine includes a high-speed resin saw blade 4, a cutting motor 6, a cutting motor fixing plate 5, a connecting part 8, a hand wheel 9, a connecting flange 10, a large wheel bracket 11, Collector ring 12, bull wheel 13, positioning shaft 14, bearing 15, bearing limit block 16, deceleration motor 18, deceleration motor fixing plate 17, coupling 20, screw rod 19, guide post 21, guide post limit block 7. Cylinder 2, frame 22 and Huff clamp block 1. The half jacket 1 is fixed on the frame 22, the half jacket 1 is connected with the cylinder 2, and the steel mesh skeleton plastic composite pipe 3 is sandwiched between the two half jackets 1; the two half clamp blocks 1 are pushed by the two cylinders 2 Next, clamp the plastic composite pipe 3 with steel mesh skeleton; the large wheel 13 is hollow cylindrical, which reduces weight and cost on the one hand; On the frame 22, it is locat...

Embodiment 2

[0037] Such as Figure 4-6 As shown, a steel mesh skeleton plastic composite pipe sample cutting machine includes a high-speed resin saw blade 4, a cutting motor 6, a cutting motor fixing plate 5, a connecting part 8, a connecting flange 10, a large wheel bracket 11, and a collector ring 12 , large wheel 13, positioning shaft 14, bearing 15, bearing limit block 16, gear motor 18, gear motor fixing plate 17, shaft coupling 20, screw mandrel 19, guide post 21, guide post limit block 7, cylinder 2 , Bullet drive motor 25, belt 24, belt pulley 23, frame 22 and Hough clip block 1. Compared with Example 1, the steel mesh skeleton plastic composite pipe sample cutting machine has removed the hand wheel 9, and increased the large wheel drive motor 25, the belt 24 and the pulley 23; the large wheel drive motor 25 is installed on the frame 22, and the pulley 23 Be fixed on bull wheel 13, belt 24 connects belt pulley 23 and the output shaft of bull wheel drive motor 25. Other parts and...

Embodiment 3

[0039] The difference between the wire mesh skeleton plastic composite pipe sample cutting machine and the embodiment 2 is that the hand wheel 9 in the embodiment 1 is fixed on the big wheel 13 . This embodiment can conveniently realize the conversion between full-automatic and semi-automatic operation modes.

[0040] In the present invention, since the high-speed resin saw blade 4 is a toothless saw blade, during the feeding process, the high-speed resin saw blade 4 and the plastic part and steel wire part of the composite pipe are completely cut by friction, regardless of the thickness and density of the steel wire , the steel wires are all broken by the friction of the knife-edge surface of the high-speed resin saw blade 4, thus avoiding the phenomenon that the toothed saw blades hook the steel wires and cause the steel wires to be broken due to the sawtooth width being greater than the diameter of the steel wires, thus avoiding The problem of steel wire displacement on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com