Totally-closed multi-direction horizontal type die forging technology special for oil drill rod joint

A fully enclosed technology for oil drill pipe joints, which is applied in the field of fully enclosed multi-directional horizontal die forging technology for oil drill pipe joints. It can solve the problems of affecting the mechanical properties of products, unbalanced internal quality of joint products, and easy deviation caused by inner holes. problems, to achieve the effect of improving the comprehensive mechanical properties of the product, improving the efficiency of machining, and meeting the requirements of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

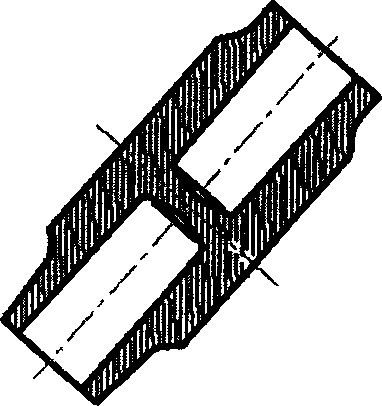

[0029] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0030] The technical scheme of concrete implementation of the present invention is:

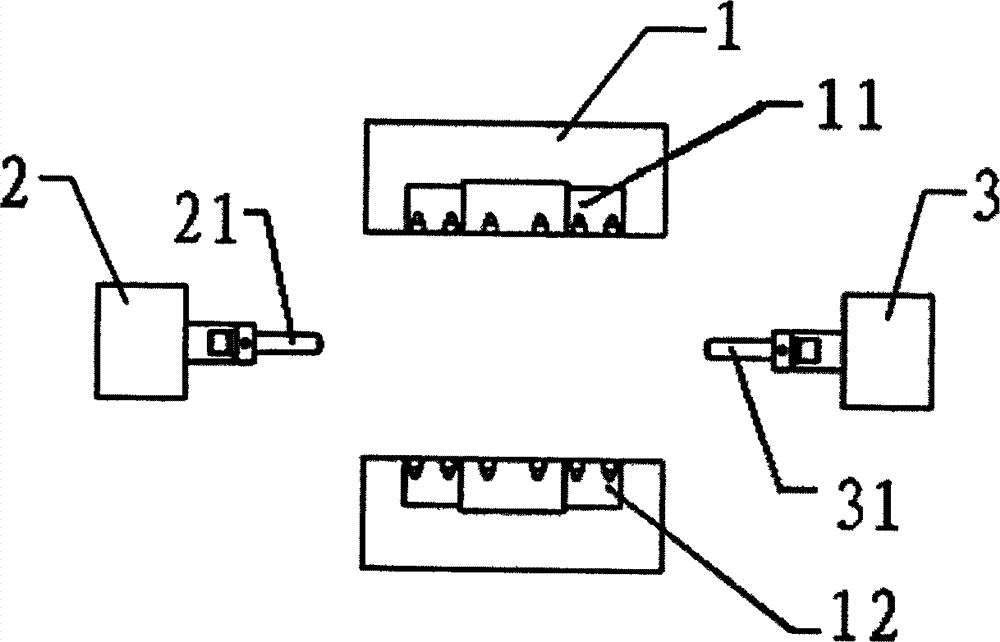

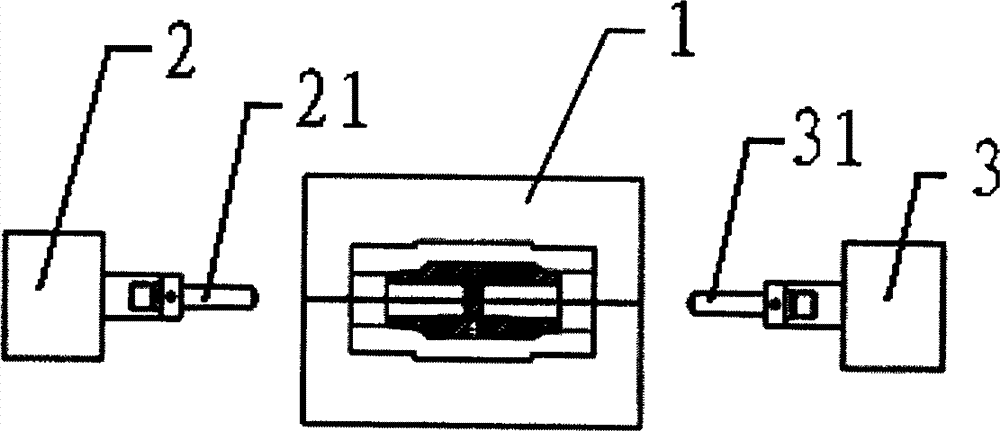

[0031] Such as figure 1 , figure 1 As shown, a special fully enclosed multi-directional horizontal die forging process for oil drill pipe joints includes the following steps in turn:

[0032] (1) Put the billet after heating, descaling and billet making into the lower die cavity of the multi-directional integral die forging hydraulic press;

[0033] (2) The main position press 1 of the multi-directional integral die forging hydraulic press closes the mold, reaches the predetermined pressure and is in the pressure maintaining state;

[0034] (3) The left side press 2 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com