Production method of mortised and riveted impeller

A production method and technology of impellers, which are applied to parts of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve the problems of low connection reliability between discs and blades, small fan structure, and production problems. Low efficiency and other problems, to achieve the effect of reducing energy consumption, stable impeller structure, and less production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the production method of tenon riveting impeller, comprises the following steps:

[0027] Step 1, prepare materials:

[0028] Prepare the impeller lower plate, blade, impeller upper plate and shaft sleeve according to the design size requirements,

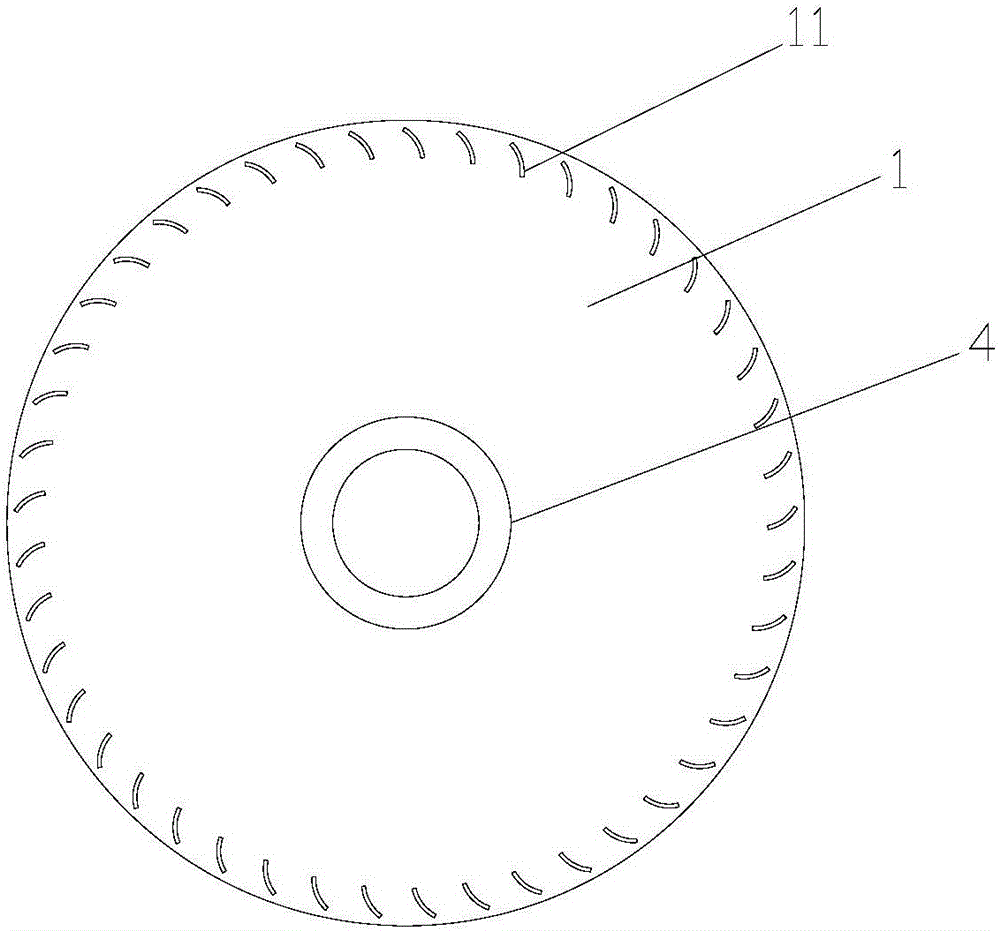

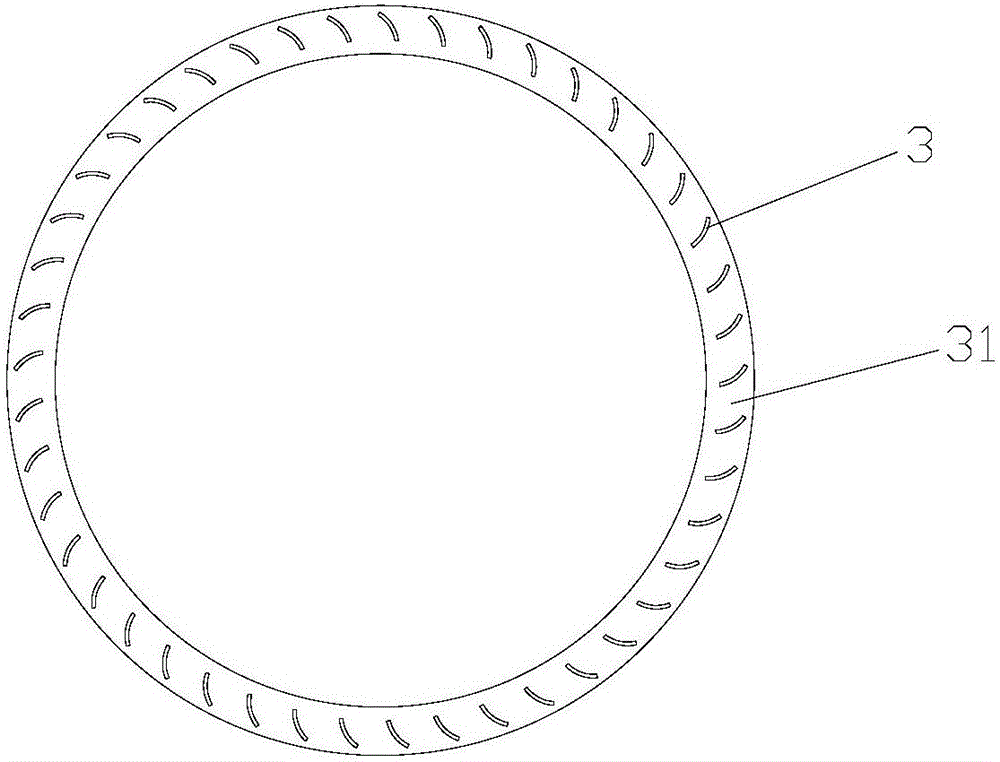

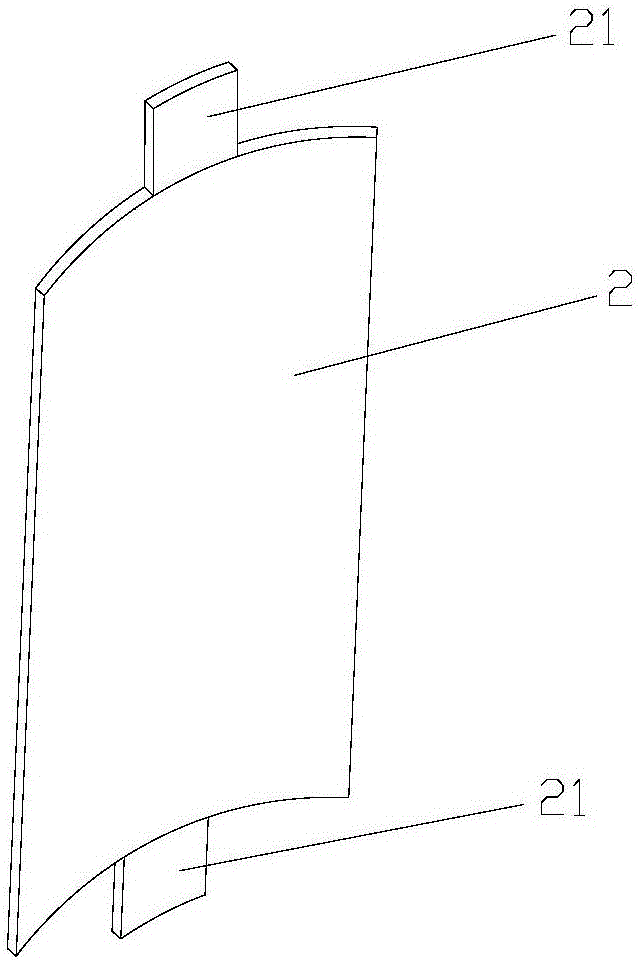

[0029] Among them, the outer surface of the impeller lower disk surface corresponds to the installation of the blades, and the lower disk mortises in a circular distribution are processed by stamping, and the outer surface of the impeller upper disk surface corresponds to the installation of the blades. The aluminum strip is shaped by the impact of the mold, and the two ends of the blade are respectively processed with tenons. The size and structure of the tenons are consistent with the size and structure of the upper plate mortises and the lower plate mortises;

[0030] Step two, assembly:

[0031] a. Assemble the shaft sleeve and the impeller bottom plate, place the impeller bottom plate horizontally on the...

Embodiment 2

[0039] The production method of the tenon riveting impeller comprises the following steps:

[0040] Step 1, prepare materials:

[0041] Prepare the impeller lower plate, blade, impeller upper plate and shaft sleeve according to the design size requirements,

[0042] Among them, the outer surface of the impeller lower disk surface corresponds to the installation of the blades, and the lower disk mortises in a circular distribution are processed by stamping, and the outer surface of the impeller upper disk surface corresponds to the installation of the blades. The aluminum strip is shaped by the impact of the mold, and the two ends of the blade are respectively processed with tenons. The size and structure of the tenons are consistent with the size and structure of the upper plate mortises and the lower plate mortises;

[0043] Step 2, assembling the impeller upper plate, blades and impeller lower plate;

[0044] a. Place the lower plate of the impeller horizontally on the ins...

Embodiment 3

[0052] The production method of the tenon riveting impeller comprises the following steps:

[0053] Step 1, prepare materials:

[0054] Prepare the impeller lower plate, blade, impeller upper plate and shaft sleeve according to the design size requirements,

[0055] Among them, the outer surface of the impeller lower disk surface corresponds to the installation of the blades, and the lower disk mortises in a circular distribution are processed by stamping, and the outer surface of the impeller upper disk surface corresponds to the installation of the blades. The aluminum strip is shaped by the impact of the mold, and the two ends of the blade are respectively processed with tenons. The size and structure of the tenons are consistent with the size and structure of the upper plate mortises and the lower plate mortises;

[0056] Step two, assembly:

[0057] a. Assemble the shaft sleeve and the impeller bottom plate, place the impeller bottom plate horizontally on the pre-instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com