Patents

Literature

35results about How to "The effect of the method is obvious" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

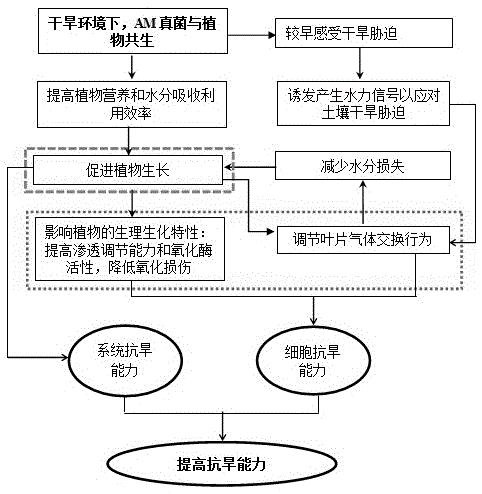

Method for improving growth and drought-resistant ability of wheat by using arbuscular mycorrhizal fungi

ActiveCN103828618AIncrease productionImprove infection symbiosisHorticulture methodsBiotechnologyTriticeae

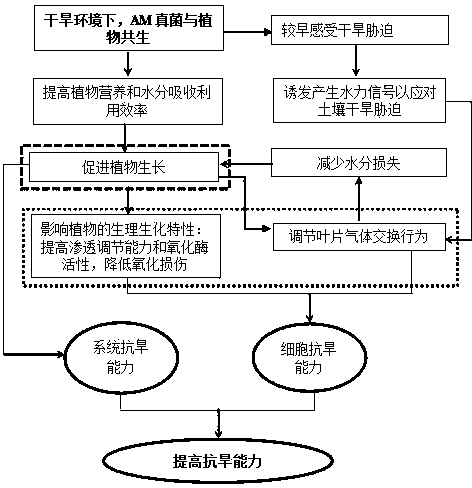

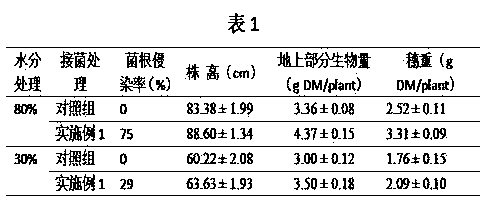

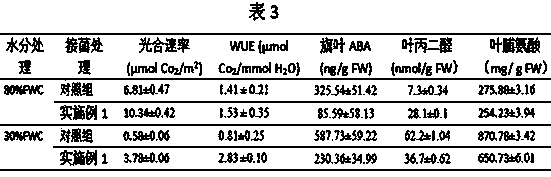

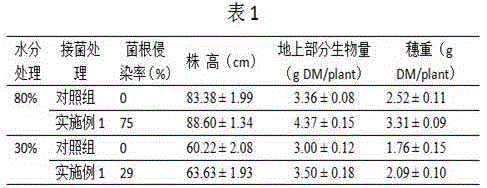

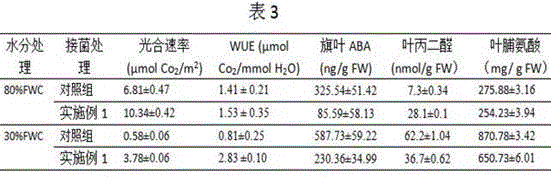

The invention discloses a method for improving growth and drought-resistant ability of wheat by using arbuscular mycorrhizal fungi to bring the reciprocal symbiosis relation between AM fungi and host plants under drought stress into play reasonably and efficiently. According to the method, the AM fungi having a close symbiotic relation with the wheat are selectively used, and the symbiotic relation between the AM fungi and the wheat is built in a condition control mode to promote the wheat growth and improve drought adaptability. The AM fungi comprise one of glomus monosporum and acaulospora laevis, the two kinds of AM fungi are respectively propagated in an expanding mode in an expanding propagation matrix by using red clovers, and then two AM fungi inoculants and the wheat are cultured together in a symbiotic culture medium. The effective path for profitable symbiosis of the AM fungi and the host plants in adversity conditions is provided, the infection and symbiosis relation with the host plants of the AM fungi is improved in a man-made mode, and the yield of dry crops is improved.

Owner:LANZHOU UNIVERSITY

Coal additive and method for raising coke output and performance

InactiveCN101020831AFully carryFast and Efficient CarryCoke ovensSolid fuelsEngineeringProcess engineering

The present invention relates to coal additive and method for raising coke output and performance. The coal additive contains surface activating catalyst, co-solvent, permeation assistant and solvent. When the coal additive is used, the surface activating catalyst is dissolved in the solvent, added into coal through a specific mode, and distributed on the surface of coal and inside coal under the action of the permeation assistant. During producing coke, the coal additive is heated and the volatile component is separated out, to raise the output and performance of the produced coke. The high performance coke may be used in coal burning, dry distilling, gasifying, liquefying and other fields. The present invention can reach the aims of raising the utilization rate of coal, saving coal resource, reducing pollutant, etc.

Owner:北京金源化学集团有限公司

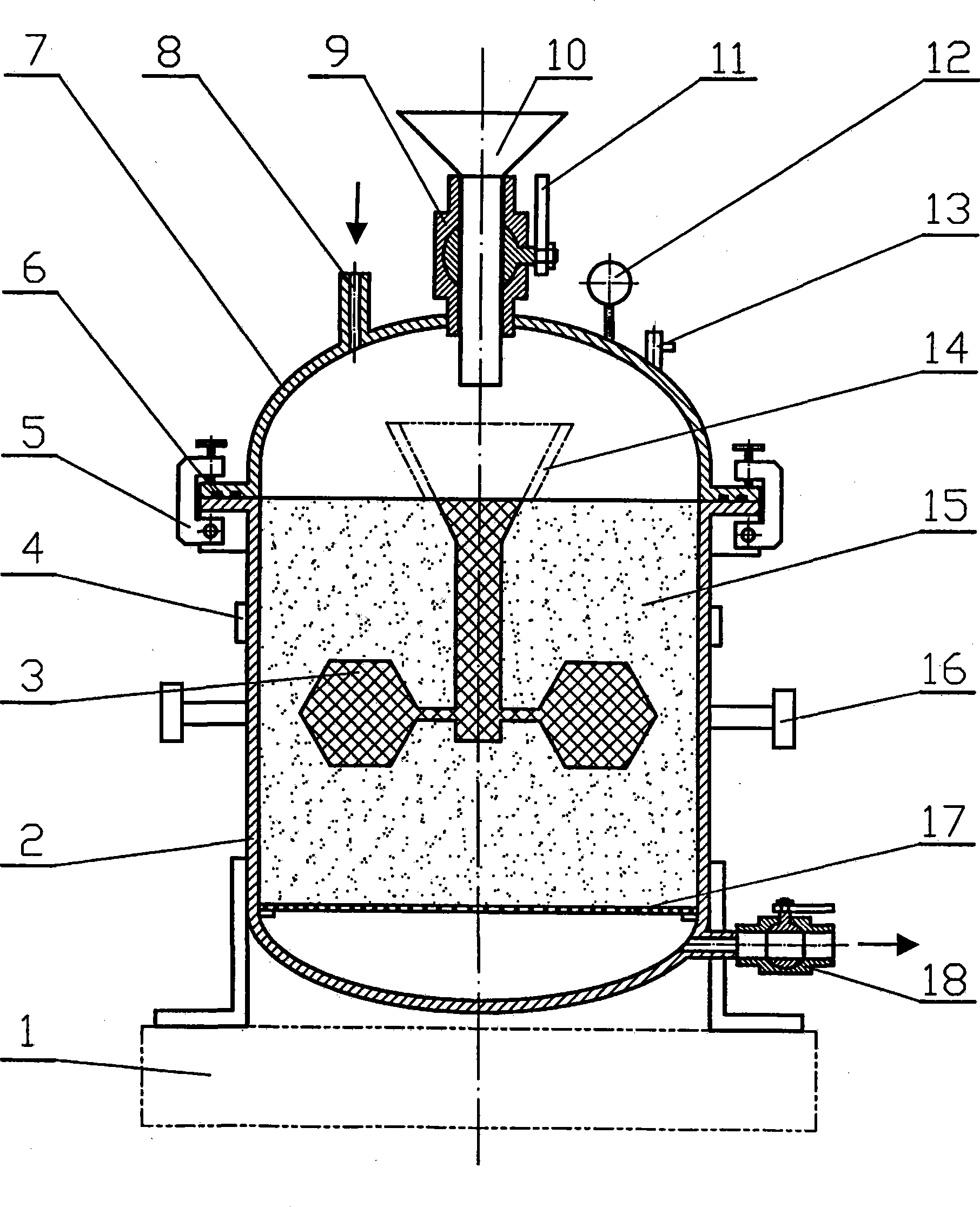

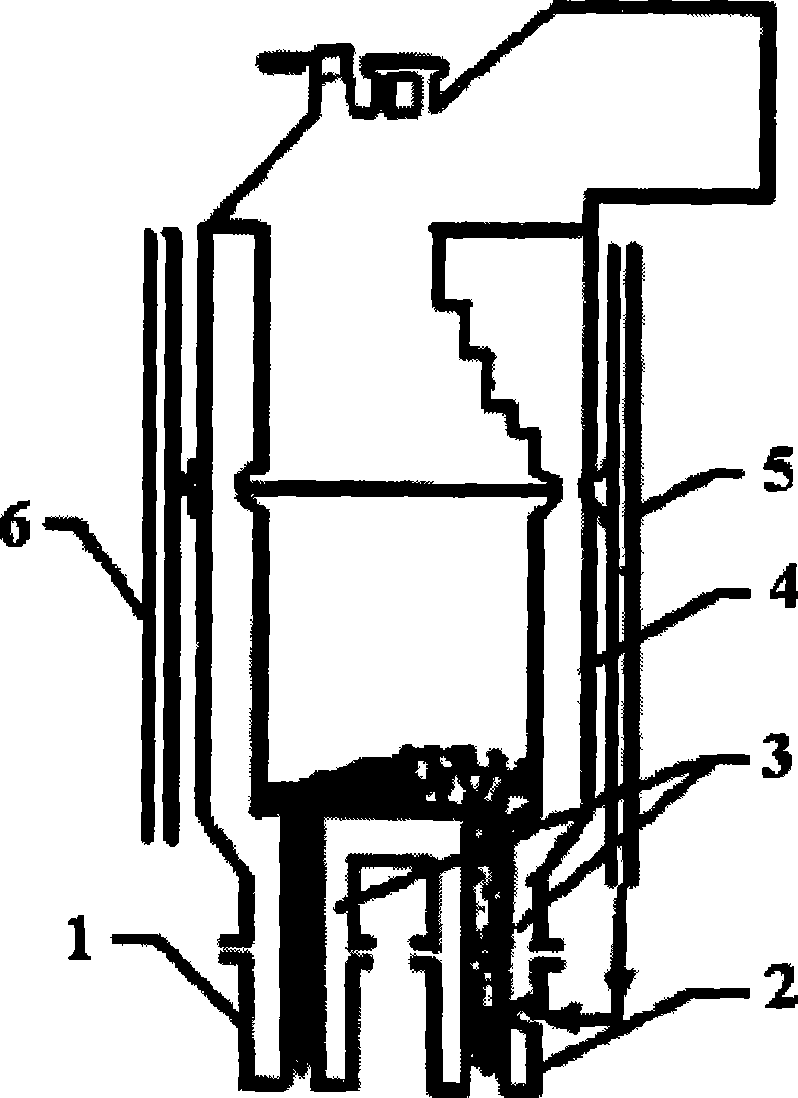

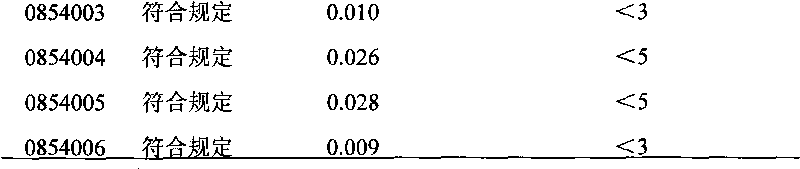

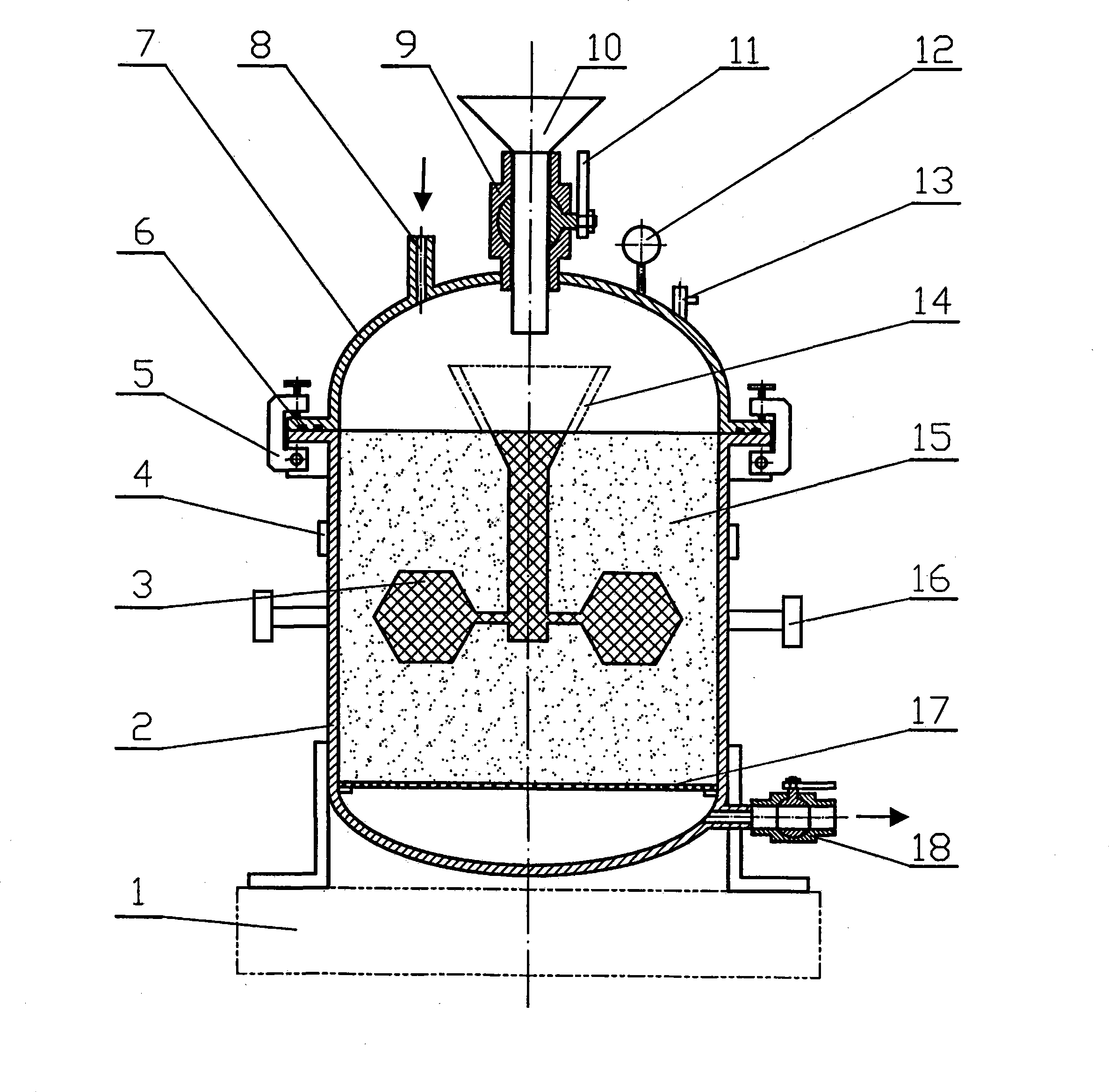

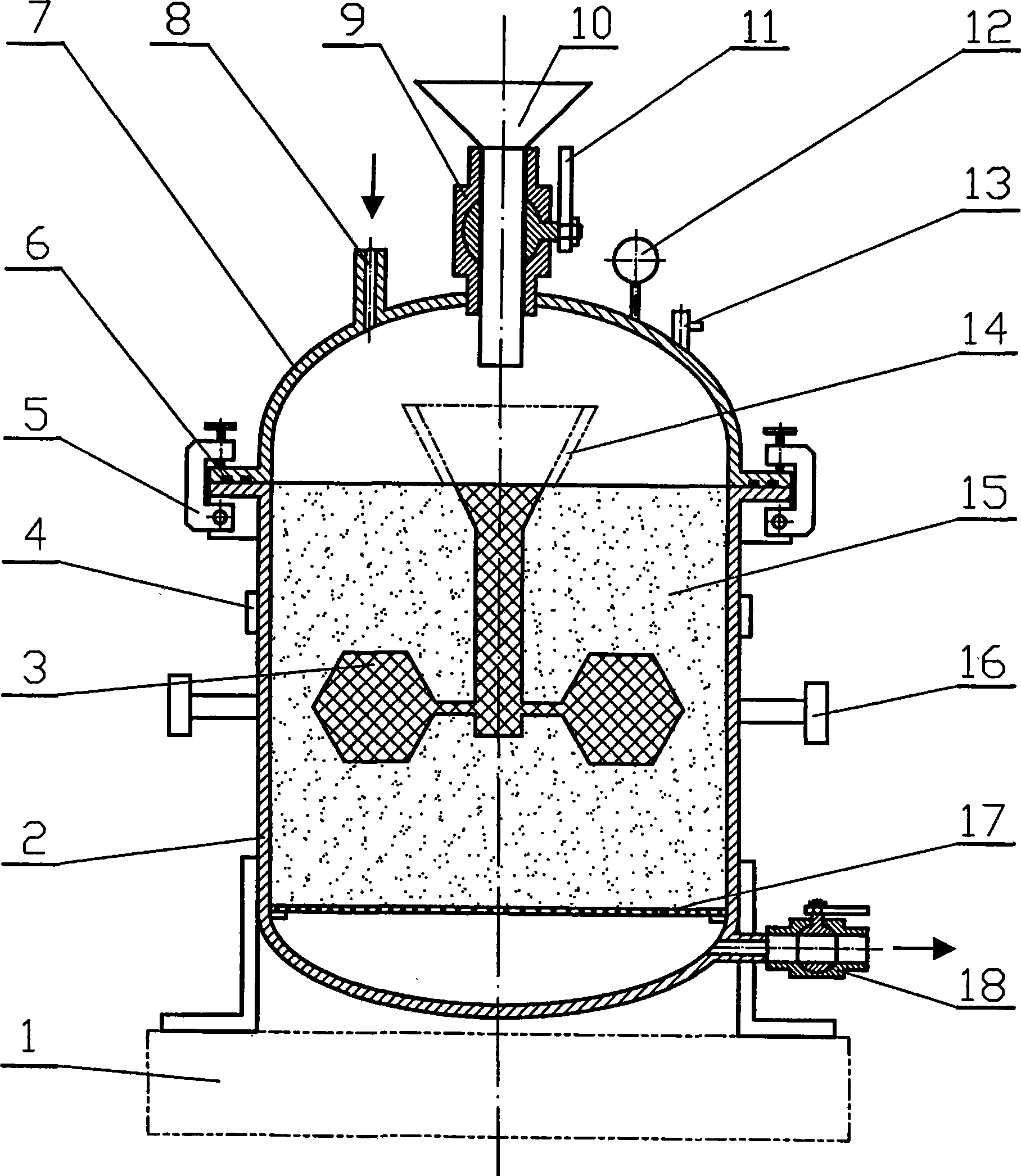

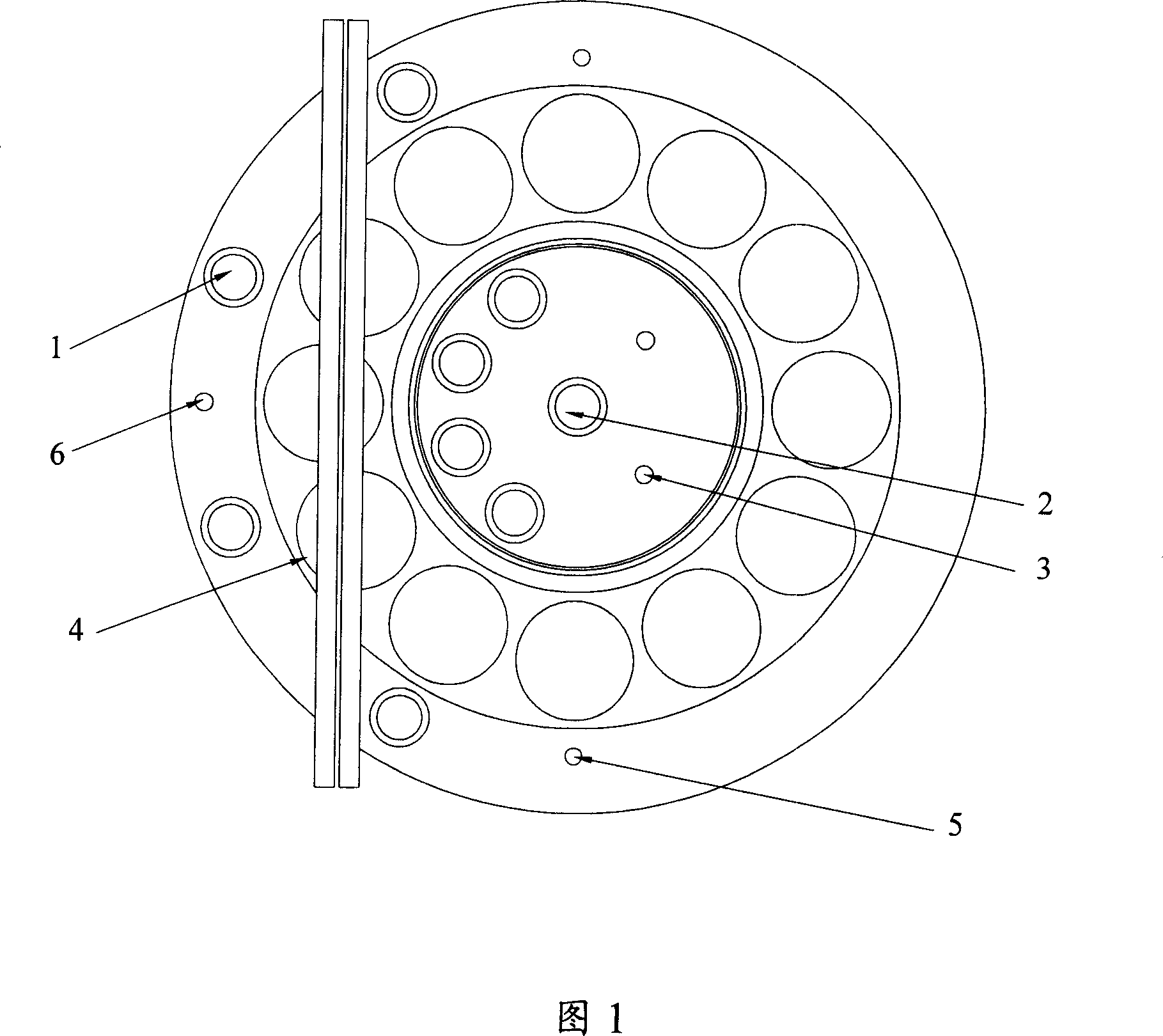

Aluminium alloy or magnesium alloy evaporative-pattern casting compression solidification method and device thereof

InactiveCN101391298AHigh densityGrain refinementFoundry mouldsFoundry coresExhaust valve5005 aluminium alloy

The invention relates to an aluminium alloy or magnesium alloy lost mould casting pressuring solidification method and a device thereof, and the invention belongs to the field of special precision casting. The aluminium alloy or magnesium alloy lost mould casting pressuring solidification method comprises compacting, vacuuming, pouring, pressuring and depressurizing. A pressure resistant sand box of the device is a cylinder-shaped container, the bottom is provided with an exhaust valve, and the inner lower part or the side wall is provided with a ventilation interlayer; the upper surface of a cover of the pressure resistant sand box is respectively provided with a switch valve, a safety valve and a pressure gauge; and the side surface of the pressure resistant sand box or the cover of the pressure resistant sand box is provided with an intake pipe. The aluminium alloy or magnesium alloy lost mould casting pressuring solidification method can obviously reduce casting defects of shrinkage cavity, shrinkage porosity, and the like in aluminium alloy lost mould casting, can effectively reduce pinhole in the aluminium alloy, enhances density of the casting, thins alloy crystal grains, and improves the surface quality and mechanical property of the aluminium alloy or magnesium alloy lost mould casting. The device simplifies lost mould casting pressuring solidification technique, and low production cost, convenient operation, good sealing effect, short sealing time of the sand box and fast pressuring speed.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for improving RH vacuum furnace bottom groove life

The invention provides a method for prolonging the service life of a bottom tank of an RH vacuum furnace. The method is characterized in that: the opposite side of an argon blowing system of a vacuum chamber is added with an argon blowing system, the position of a riser and the position of a downcomer are exchanged when a new varnished tube is mounted, and an argon tube of the riser is connected to the newly added argon blowing system. The method helps realize the alternate use of a circulation tube at the ascending side and a circulation tube at the descending side of the bottom tank by exchanging the position of the riser and the position of the downcomer, thus avoiding that the circulation tube at one side always bears the intense scouring of the raising steel flow, effectively prolonging the service life of the circulation tubes, and further prolonging the service life of the bottom tank. The method has obvious effect and can help improve the average service life of the bottom tank by more than one fold.

Owner:ANGANG STEEL CO LTD

Method for effectively preventing iron deficiency yellowtop of fruit trees

ActiveCN105359693AReduce incidenceThe effect of the method is obviousFertilising methodsOrganic fertilisersFruit treeLeaf blade

The invention provides a method for effectively preventing fruit trees iron deficiency yellowtop, which comprises steps: high concentration leaf fertilizers are sprayed in a spring sleep late, and the high concentration leaf fertilizers are sprayed in a mature period of blades for the first time. The method for effectively preventing the fruit trees iron deficiency yellowtop prevents fruit tree yellowtop from happening by spraying different formulas of high concentration leaf fertilizers according to different radios of required iron elements of fruit trees in development stages of the fruit trees from a spring dormant period of the fruit trees, a blade mature period to a senescence phase. The method for effectively preventing the fruit trees iron deficiency yellowtop is obvious in effects, obviously reduces occurrence rate of fruit trees yellowtop, enables the fruit trees in a 0-level etiolation degree to achieve 96-97% total amount of the fruit trees, and is obvious in the prevention effect of the fruit trees yellowtop in saline areas.

Owner:SHANDONG WEIFANG ACADEMY OF AGRICULTURAL SCIENCES

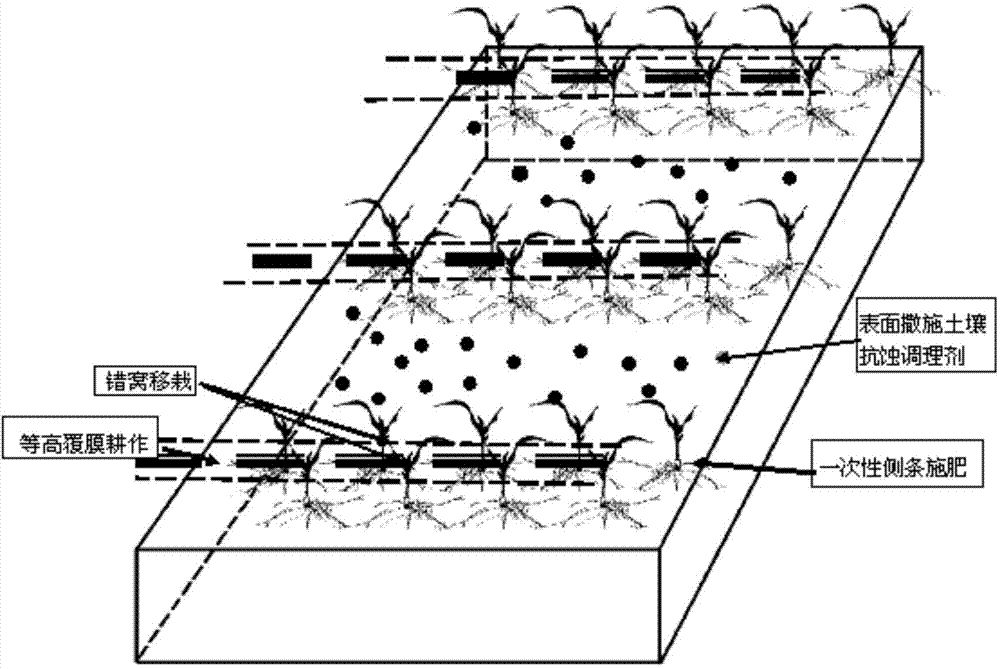

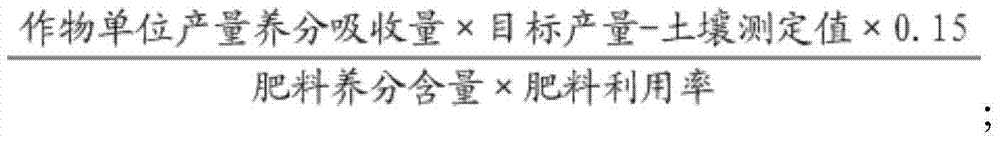

Corrosion-resistant and beneficiating non-point source pollution control method for spring corn slope cropland

ActiveCN103688620AIncrease profitReduce churnAgriculture gas emission reductionHorticultureSheet mulchingPlastic mulch

The invention relates to a corrosion-resistant and beneficiating non-point source pollution control method for a spring corn slope cropland. The method comprises the following steps of isometry mulch laminating and transplanting of narrow rows, soil anti-corrosion conditioner applying of wide rows and one-time reasonable fertilization. Advantages of single technologies such as isometry mulch laminating of a slope, applying of a soil anti-corrosion conditioner and slow release fertilizer applying are integrated to overcome disadvantages, so loss of water, soil and nutrient is reduced and soil quality is improved. Isometry mulch laminating of a cross slope is combined with a high molecular chemical-physical conditioner and the synergism slow release fertilizer, and labor and capital investments are reduced. Compared with the traditional method in which only pure ridge culture of cross slopes, straw mulching and excessive fertilizer applying are adopted, the corrosion-resistant and beneficiating non-point source pollution control method for the spring corn slope cropland has the advantages of improving the water content by 5-9%, reducing soil bulk weight by 0.05-0.1g / cm<3> and reducing surface runoff by about 15%.

Owner:INST OF ENVIRONMENT & SUSTAINABLE DEV IN AGRI CHINESE ACADEMY OF AGRI SCI

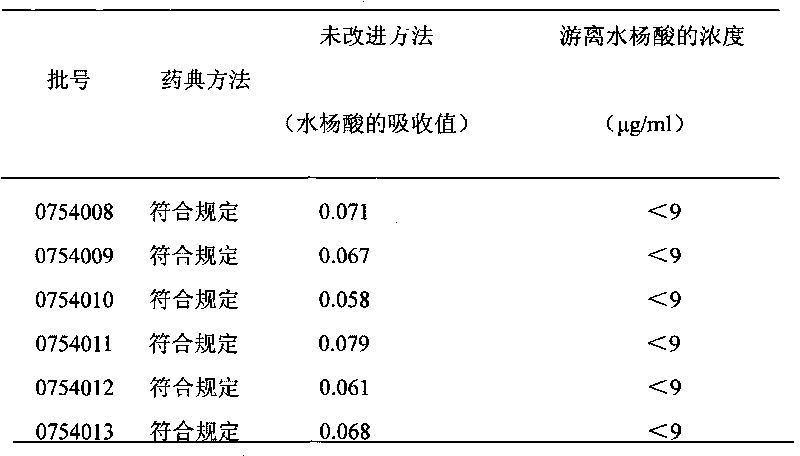

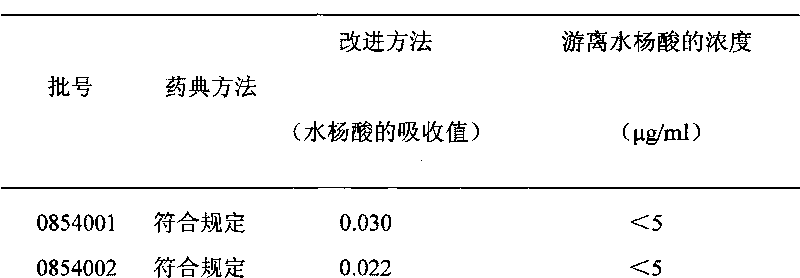

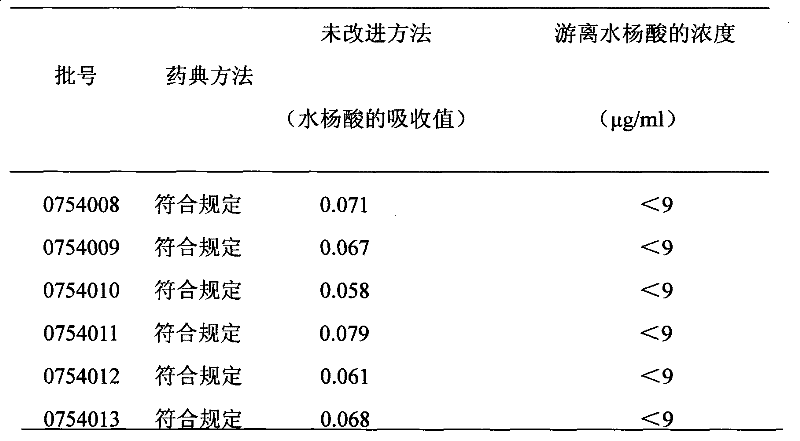

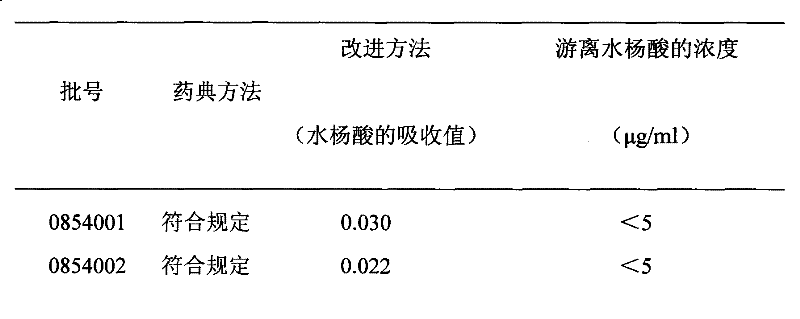

Aspirin enteric coated tablet with low content of free salicylic acid and preparation process thereof

ActiveCN101732279AReduce contentThe effect of the method is obviousOrganic active ingredientsAntipyreticSalicylic acidNuclear chemistry

The invention provides an aspirin enteric coated tablet with low content of free salicylic acid. A given amount of tartaric acid is added in the recipe of a tablet core, and the content of the free salicylic acid is effectively lowered. The invention provides an improved process. The invention has simple, convenient and easy method and is suitable for industrialized production.

Owner:SHANGHAI SINE PROMOD PHARMA

Method for collecting sacalia bealei eggs

The invention discloses a method for collecting sacalia bealei eggs. The method for collecting sacalia bealei eggs is based on culture experimental research conducted for multiple years. Compared with the prior art, the method sufficiently considers ecological and biological characteristics of sacalia bealei such as the egg-laying period, egg-laying behavior and the environmental requirement for egg-laying; by the adoption of the method, the tortoise egg collection problem in the artificial sacalia bealei culture process can be effectively solved, under the condition that interference with female tortoises is fully reduced, tortoise egg collection efficiency is remarkably improved, it is guaranteed that 80% or above of tortoise eggs can be collected safely, tortoise egg losses are remarkably reduced, and breeding efficiency is improved; the method is obvious in effect and easy to operate, space resources are saved, labor cost is saved, and the method is beneficial to application and popularization.

Owner:广东象头山国家级自然保护区管理局 +1

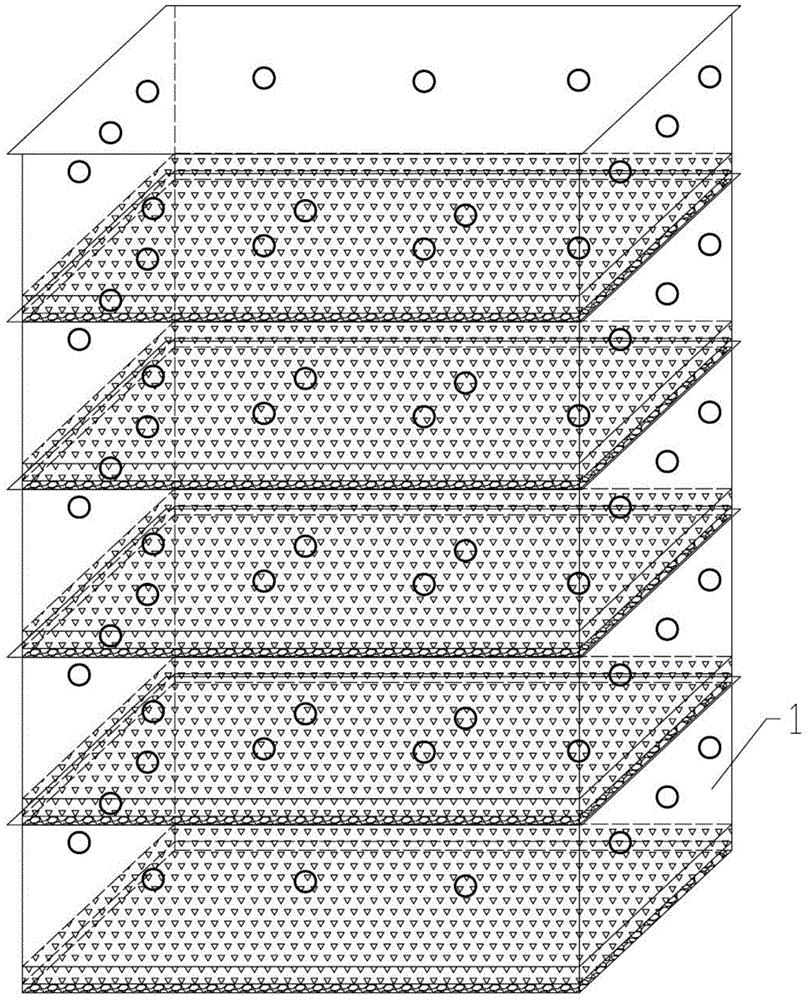

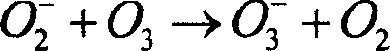

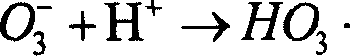

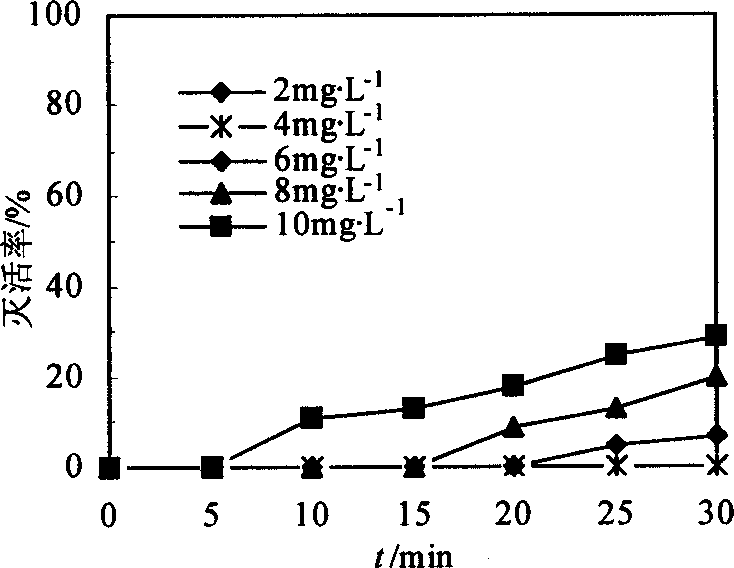

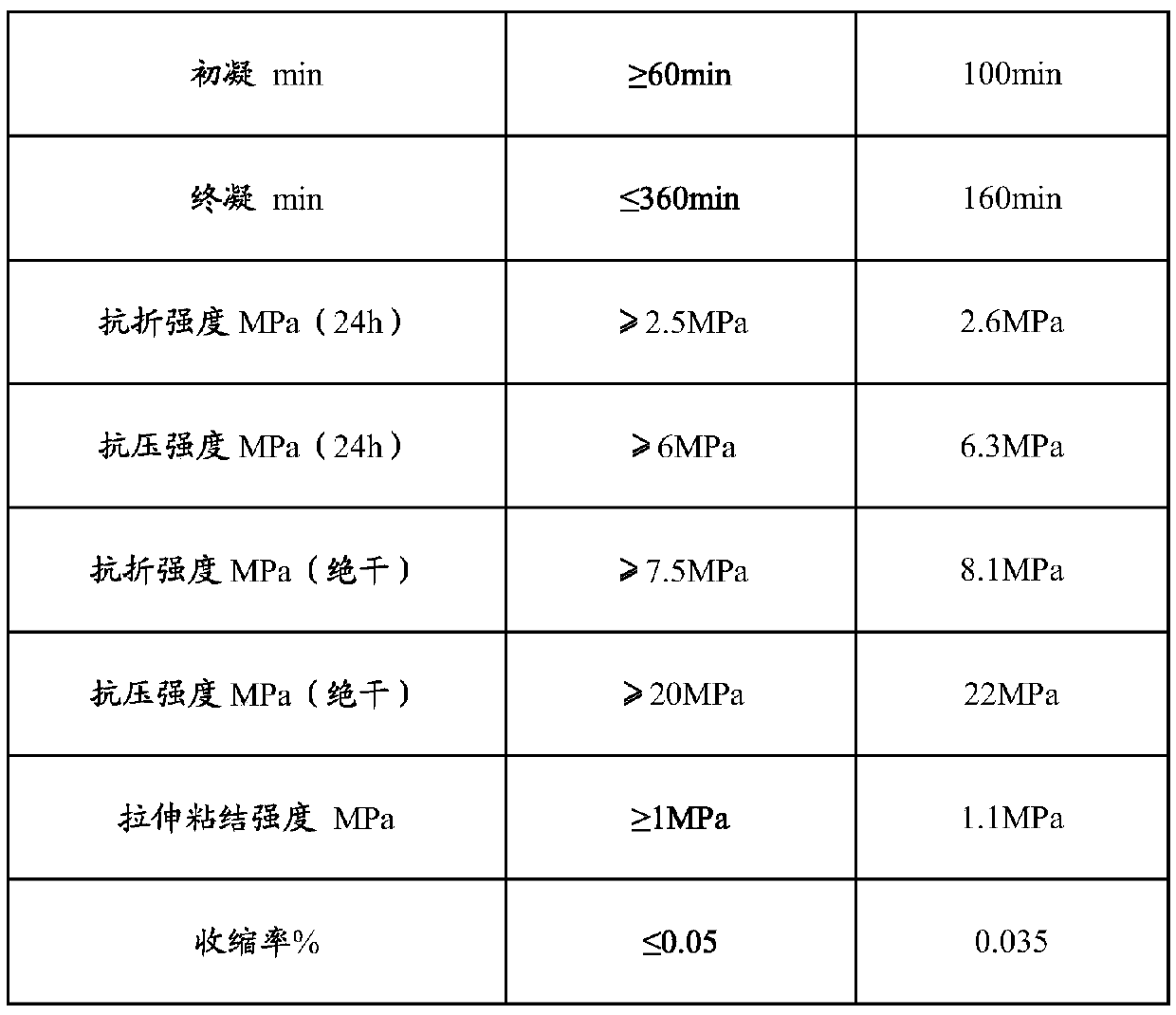

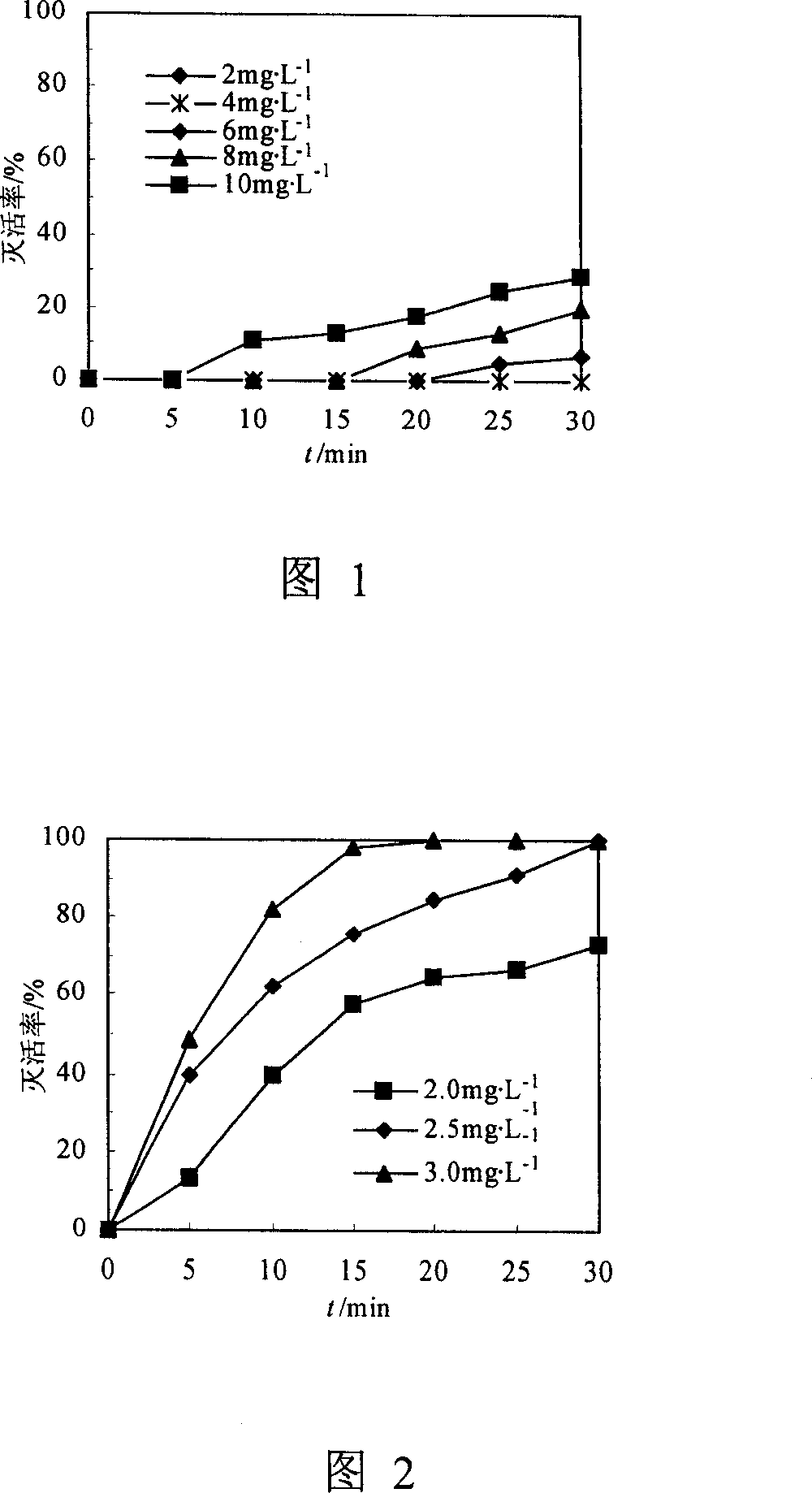

Water treatment for killing living animals such as fleas by O3/H2O2

InactiveCN1583596AImprove Quality MigrationSave volumeWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by oxidationZooplanktonFlea

A water treating method for killing the flea kind of zooplanktons by use of O3 / H2O2 features that before the water is conventionally treated, the O3 and H2O2 are proportionally added to it and then stayed in water for 20-30 min.

Owner:HARBIN INST OF TECH +1

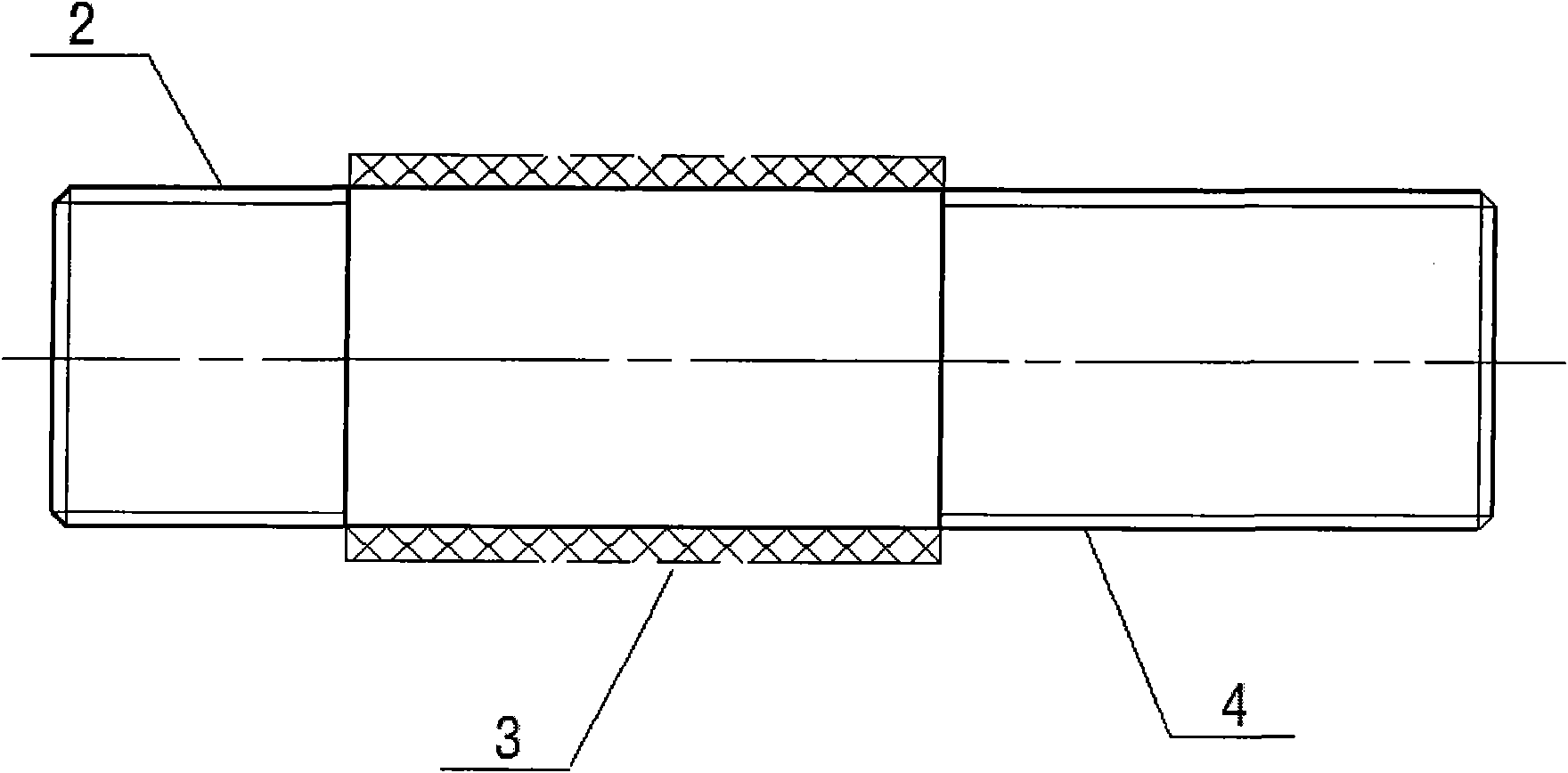

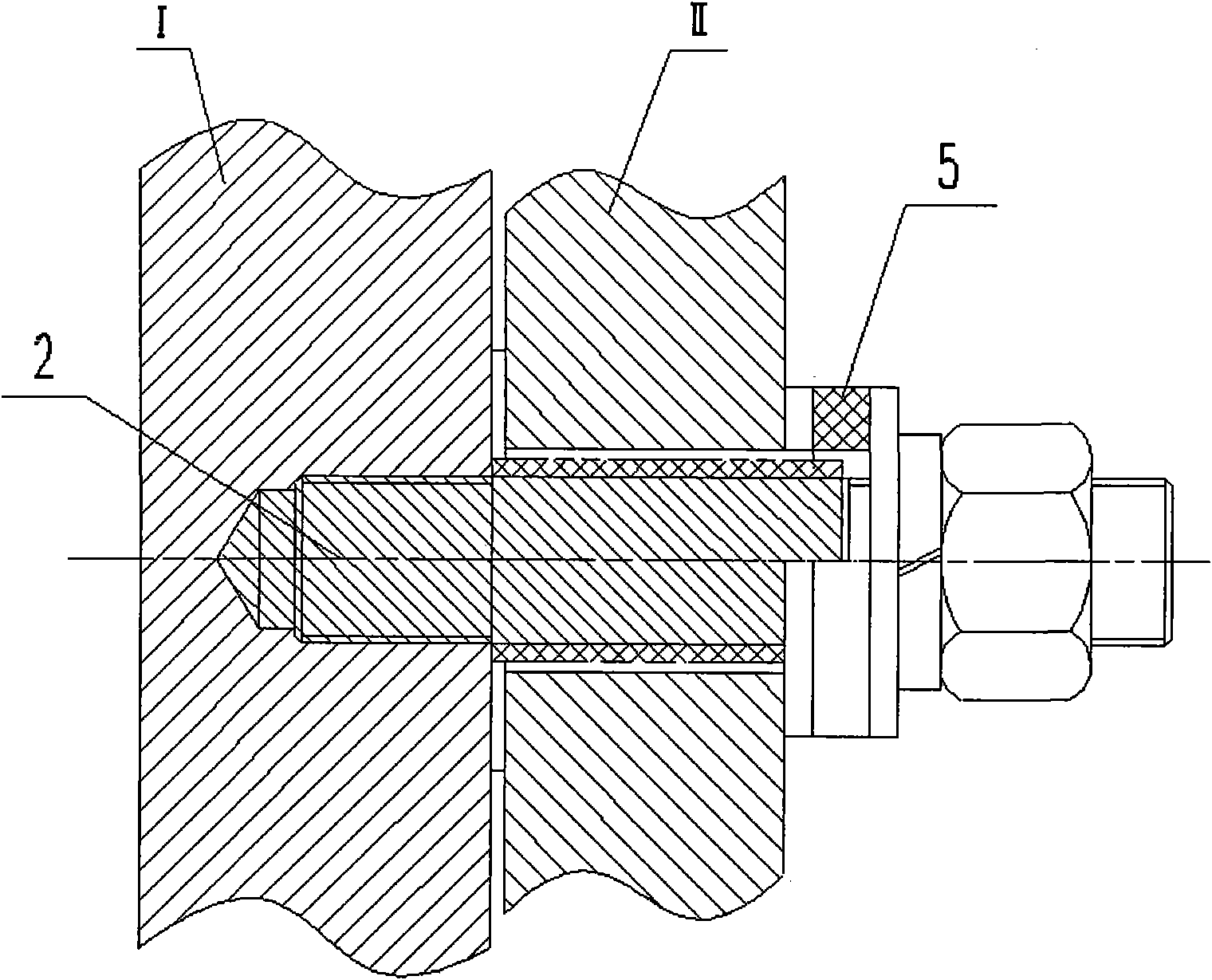

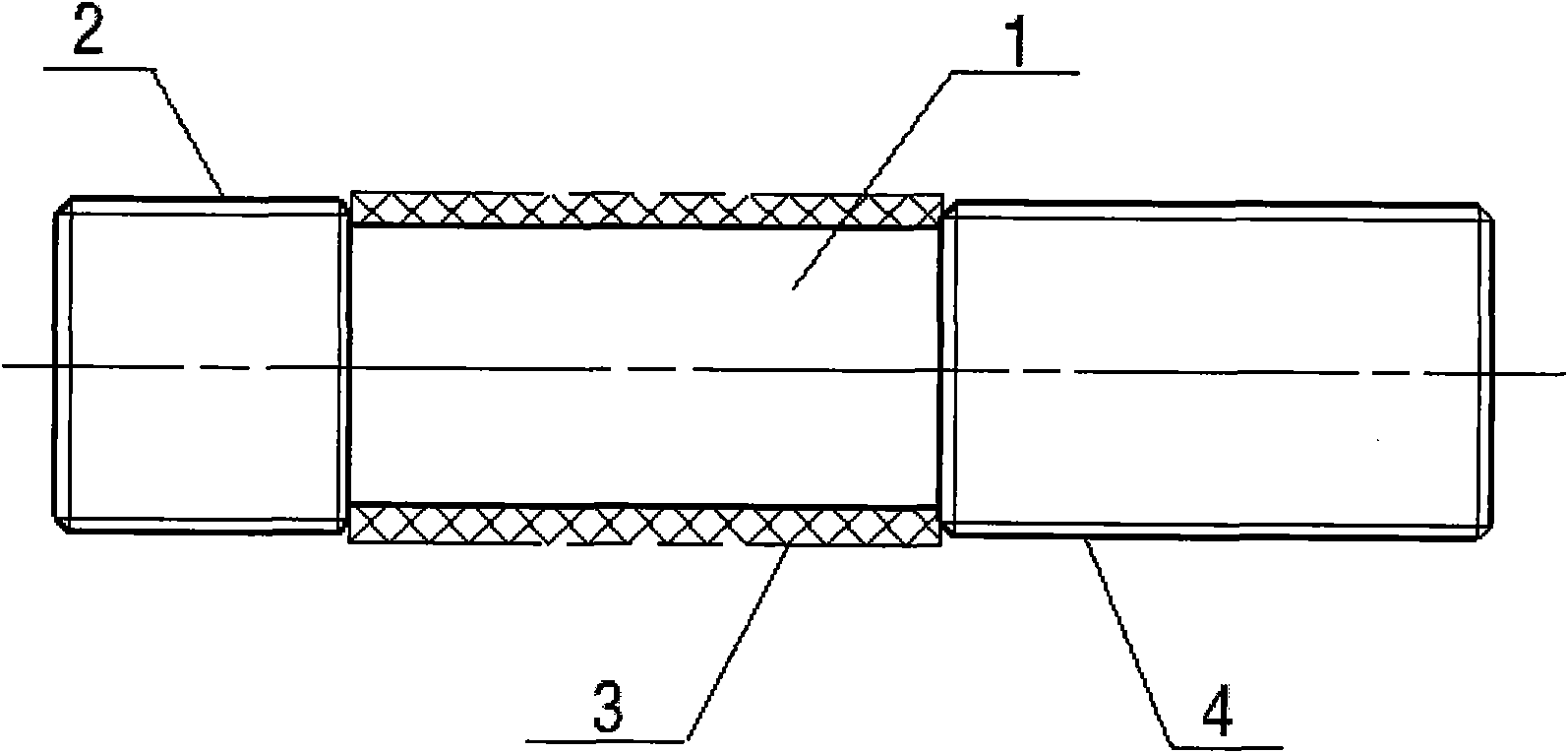

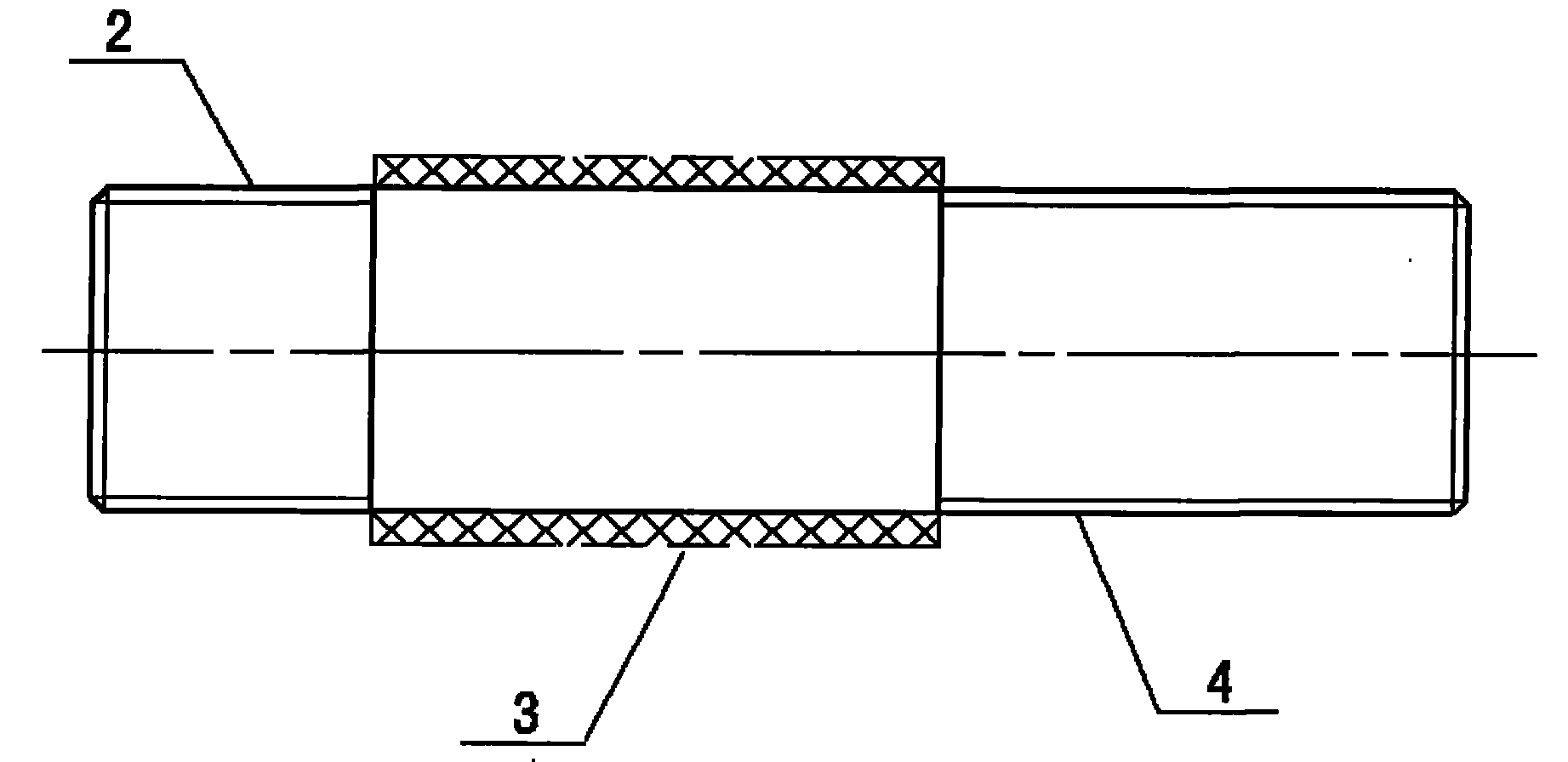

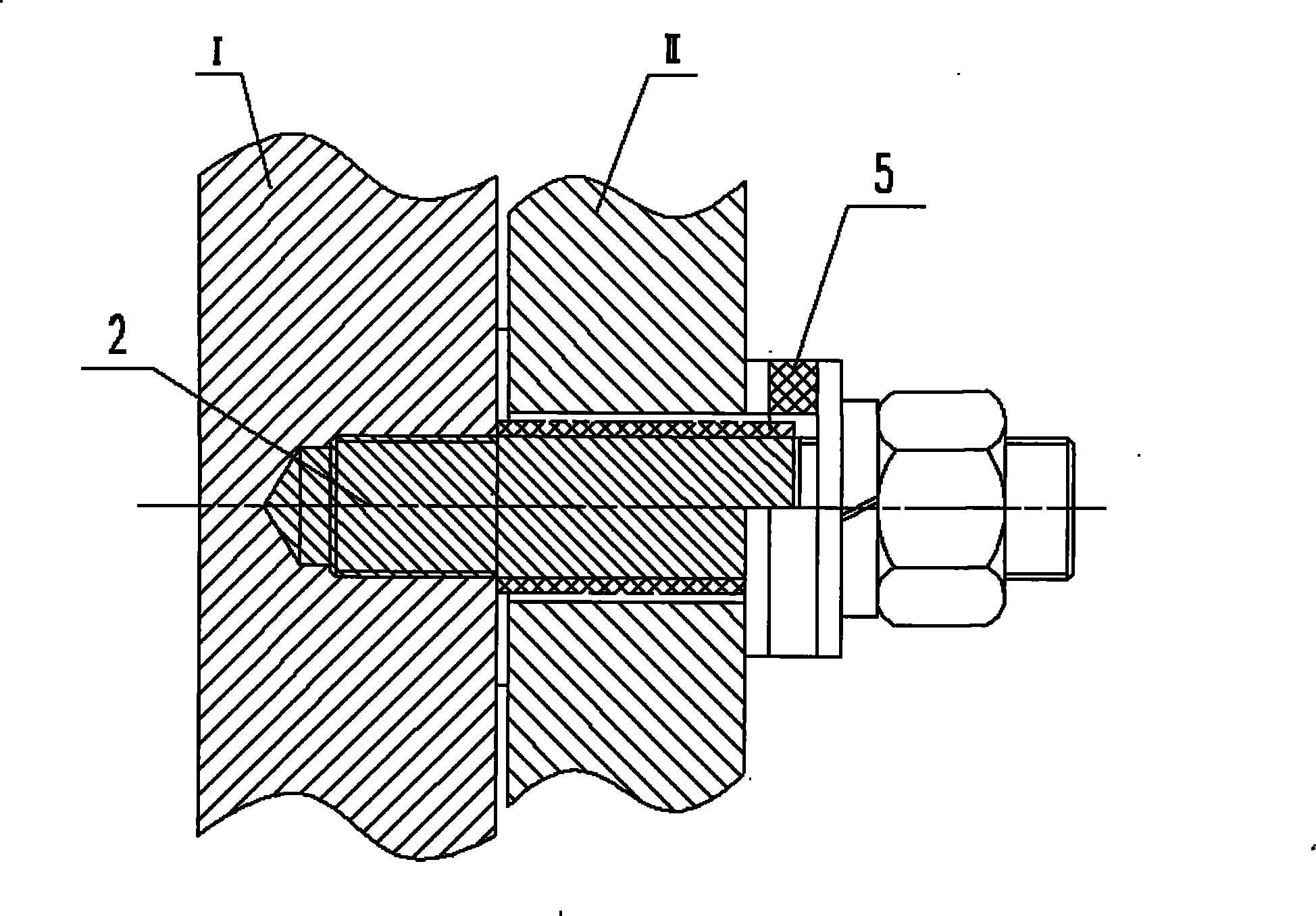

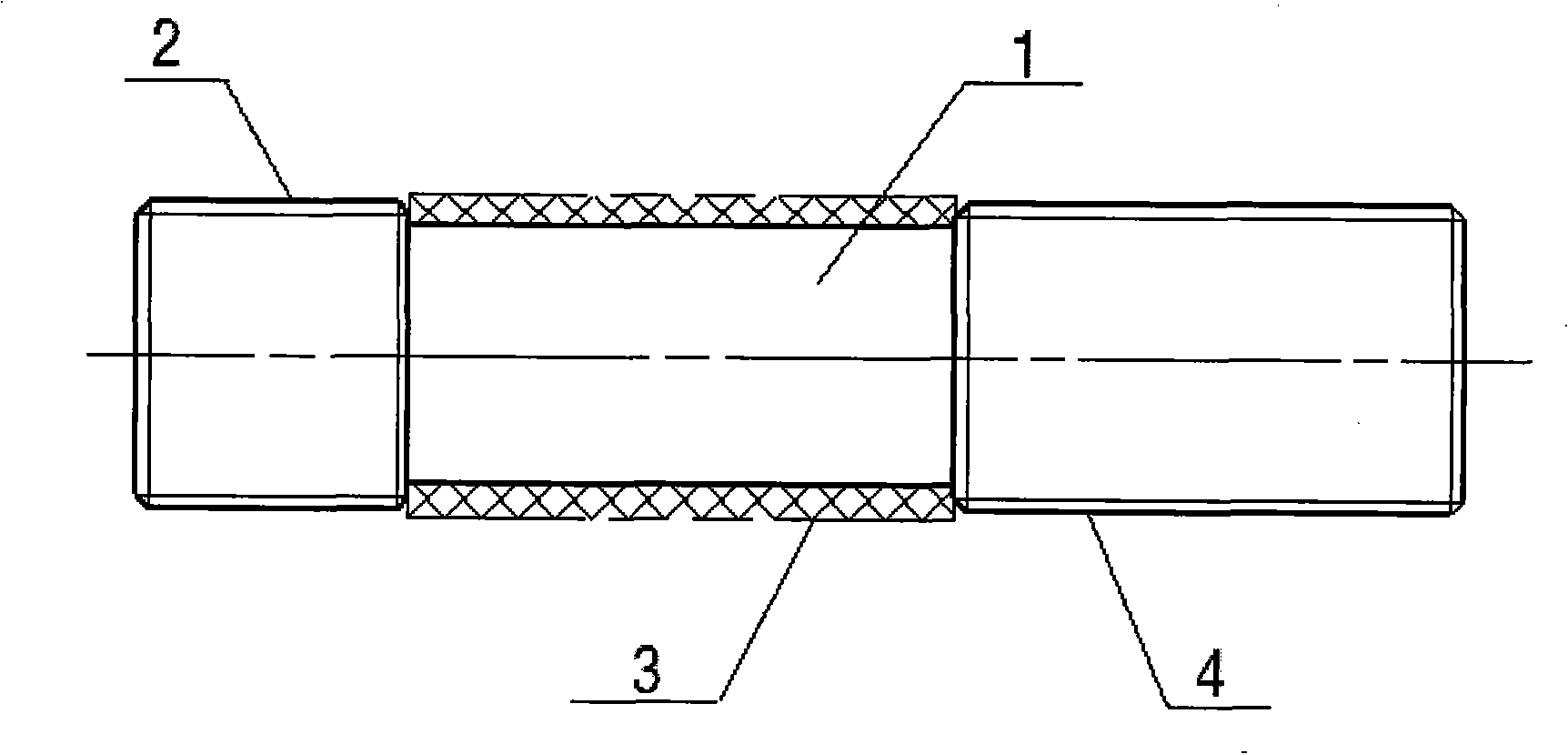

Insulation method for preventing metal screw or bolt from generating magnetic flux leakage linkage circulation

ActiveCN101552109AThe effect of the method is obviousGood effectTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureInsulation layerEngineering

The invention discloses an insulation method for preventing a metal screw or a bolt from generating magnetic flux leakage linkage circulation; the insulation method is characterized by comprising the following steps of wrapping the middle of the screw or the bolt by weft-free glass filaments with thickness of 1-4mm, using thermosetting insulation resin for infiltrating the glass filaments to form an insulation layer, and processing the surface after the insulation layer is solidified so as to lead the surface to be smooth and lead the outer diameter size of the screw or the bolt insulated by wrapping to be capable of extending into the hole of a structure part flange; and the insulation layer separates the structure part from one section of the middle part of the screw.

Owner:CHINA XD ELECTRIC CO LTD

A method of using arbuscular mycorrhizal fungi to improve wheat growth and drought resistance

The invention discloses a method for improving growth and drought-resistant ability of wheat by using arbuscular mycorrhizal fungi to bring the reciprocal symbiosis relation between AM fungi and host plants under drought stress into play reasonably and efficiently. According to the method, the AM fungi having a close symbiotic relation with the wheat are selectively used, and the symbiotic relation between the AM fungi and the wheat is built in a condition control mode to promote the wheat growth and improve drought adaptability. The AM fungi comprise one of glomus monosporum and acaulospora laevis, the two kinds of AM fungi are respectively propagated in an expanding mode in an expanding propagation matrix by using red clovers, and then two AM fungi inoculants and the wheat are cultured together in a symbiotic culture medium. The effective path for profitable symbiosis of the AM fungi and the host plants in adversity conditions is provided, the infection and symbiosis relation with the host plants of the AM fungi is improved in a man-made mode, and the yield of dry crops is improved.

Owner:LANZHOU UNIVERSITY

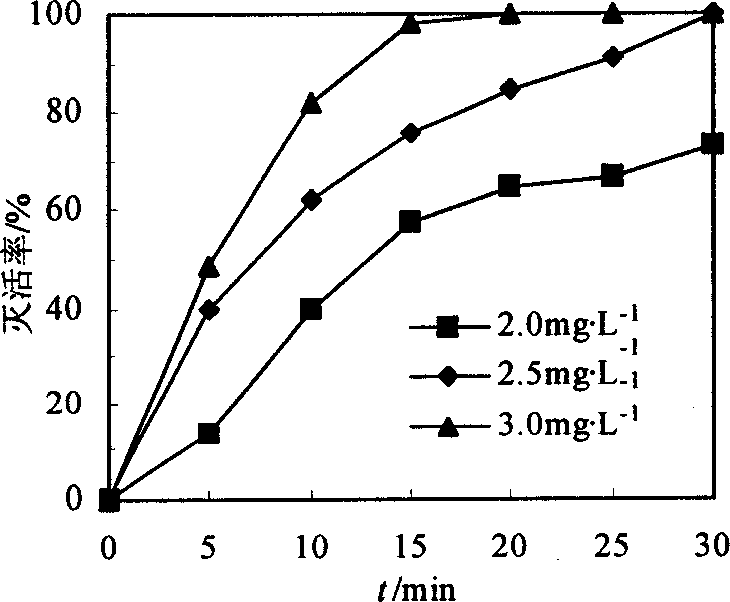

Water treatment method capable of killing midge larva by ozone

InactiveCN1730408AReduce mutagenicityStrong oxidation disinfection effectBiocideAnimal repellantsLitterMidge

Disclosed is a water processing method for complete eradication of chironomus larvas through ozone, the method comprises pre-letting ozone into primary water before conventional processing, the ozone charge amount in each litter of water is 2.5-3.0mg, the time of contact is 20-30 mins.

Owner:HARBIN INST OF TECH

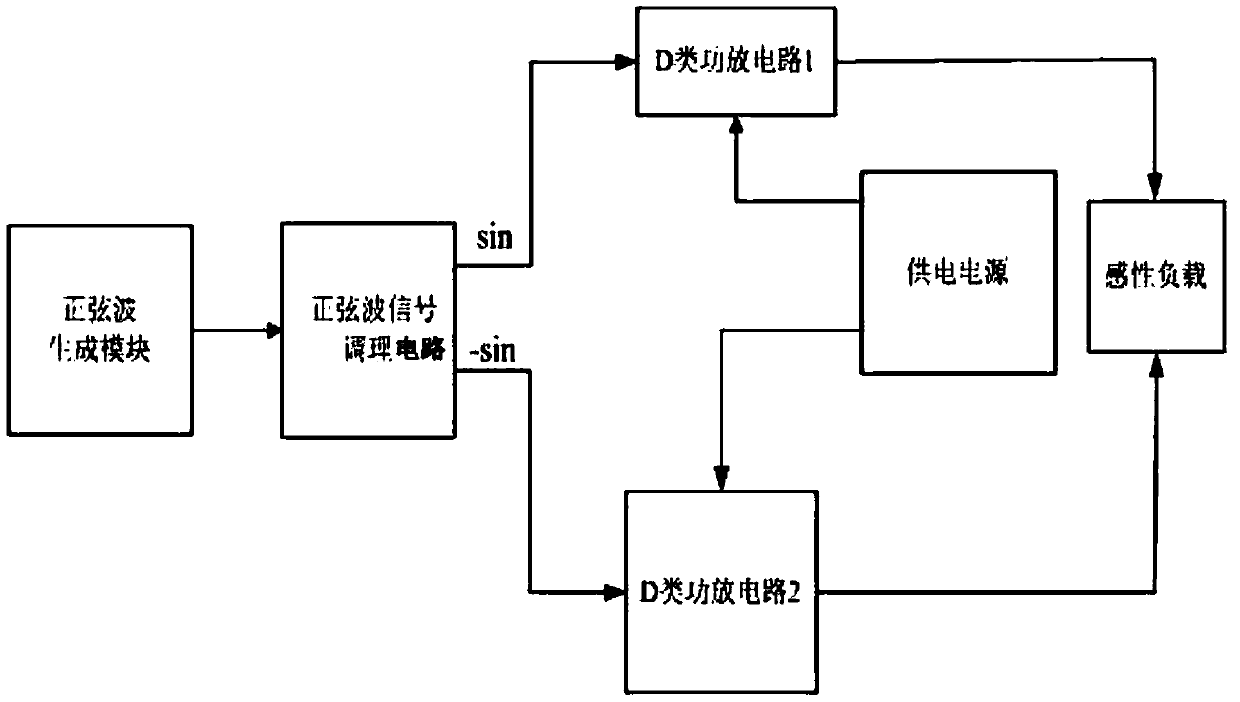

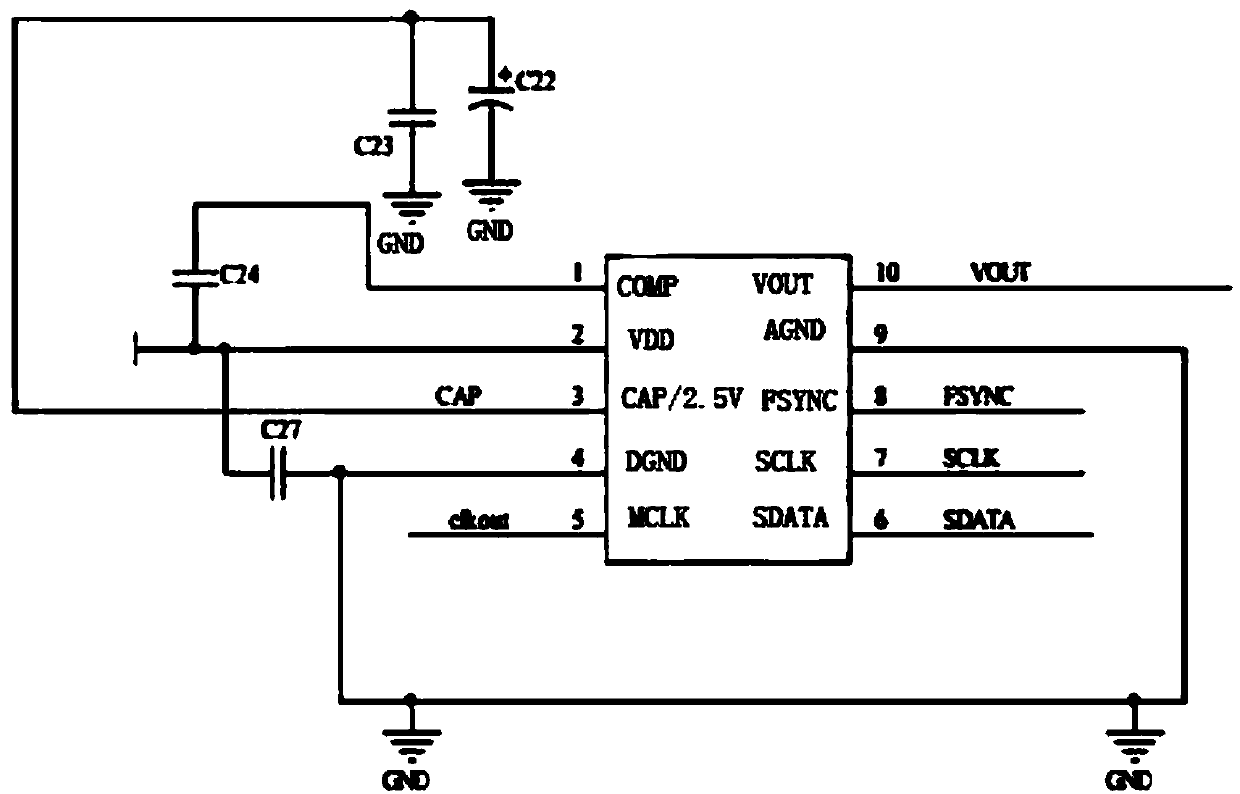

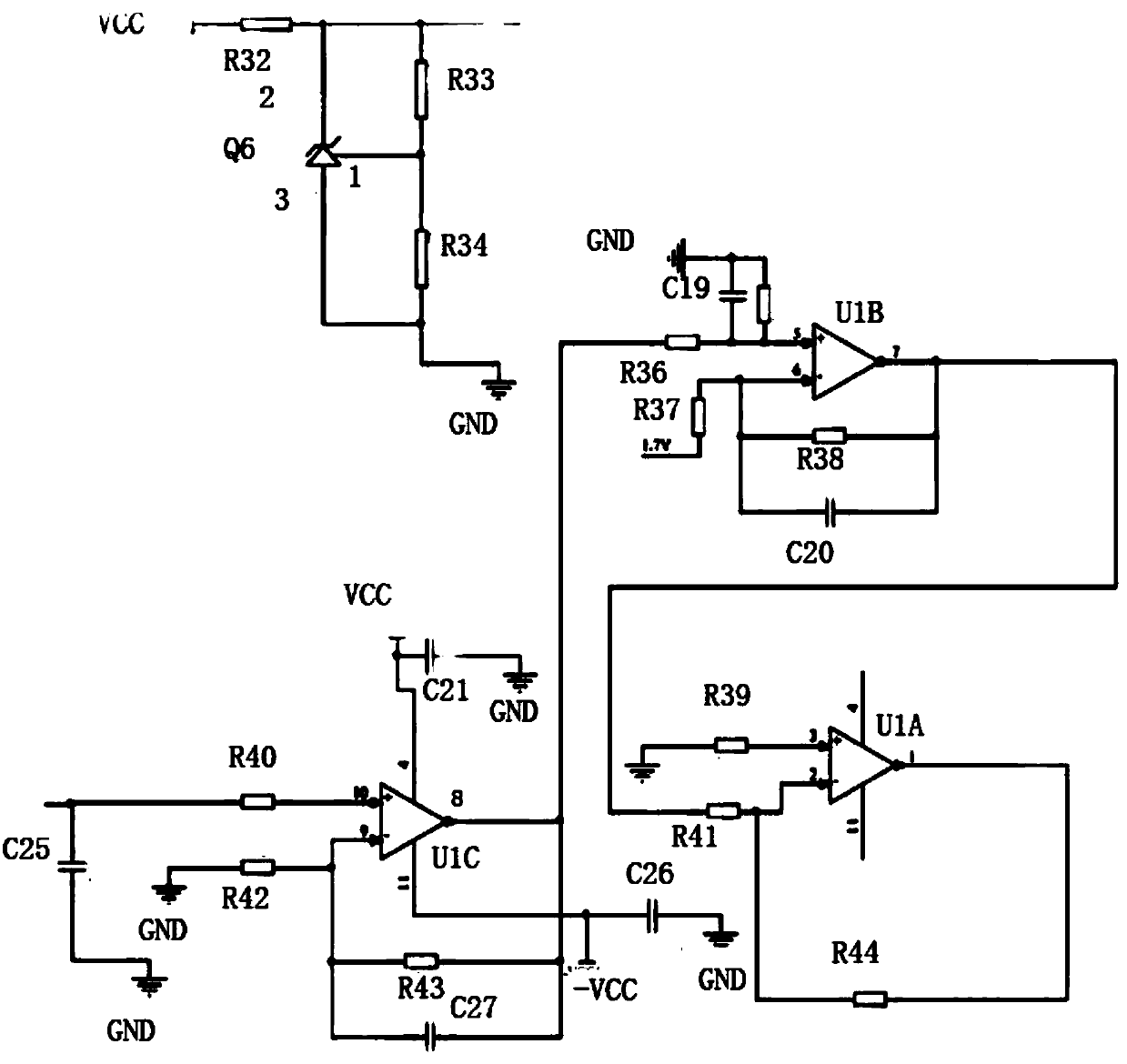

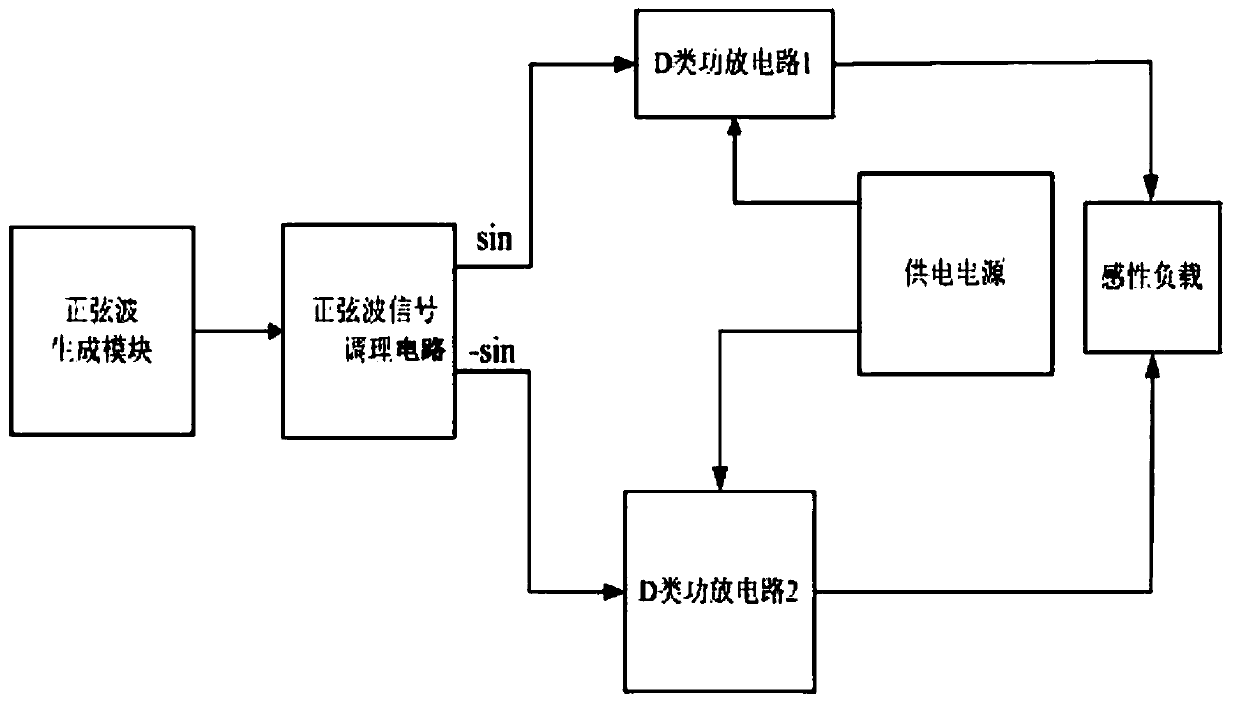

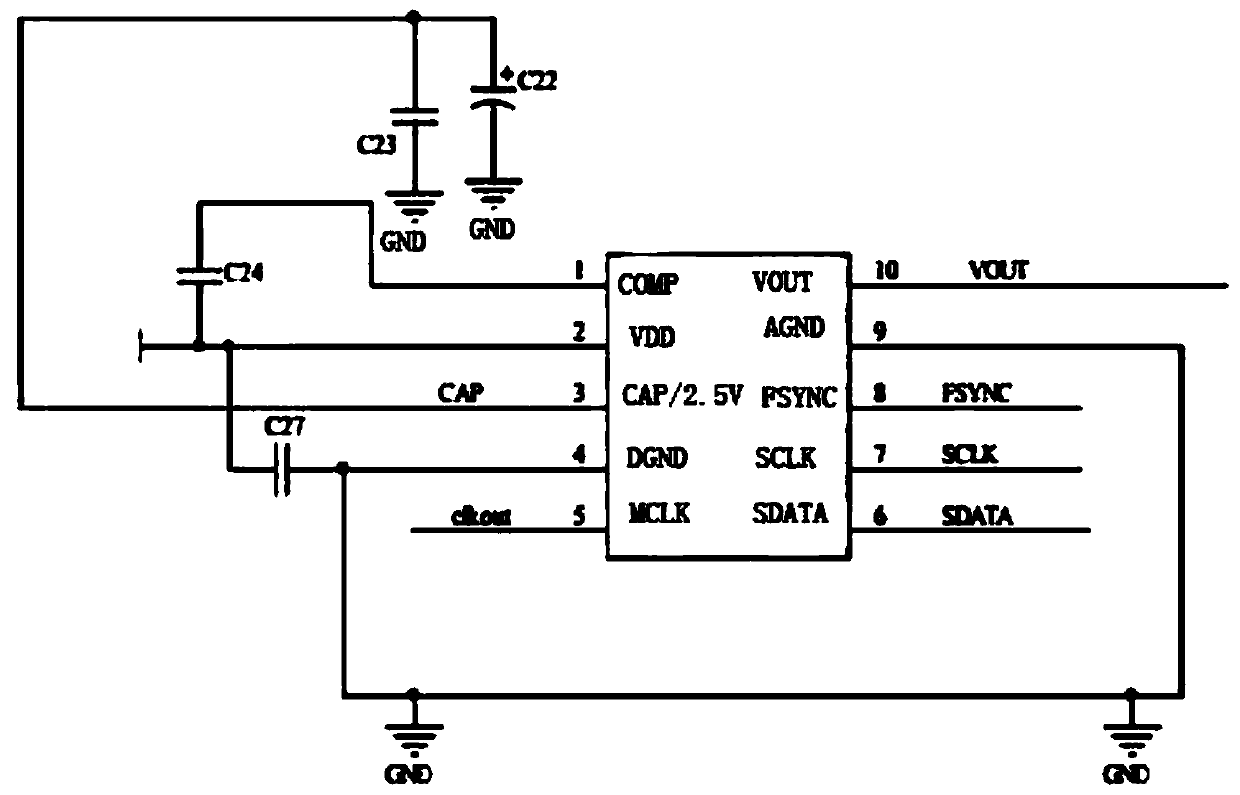

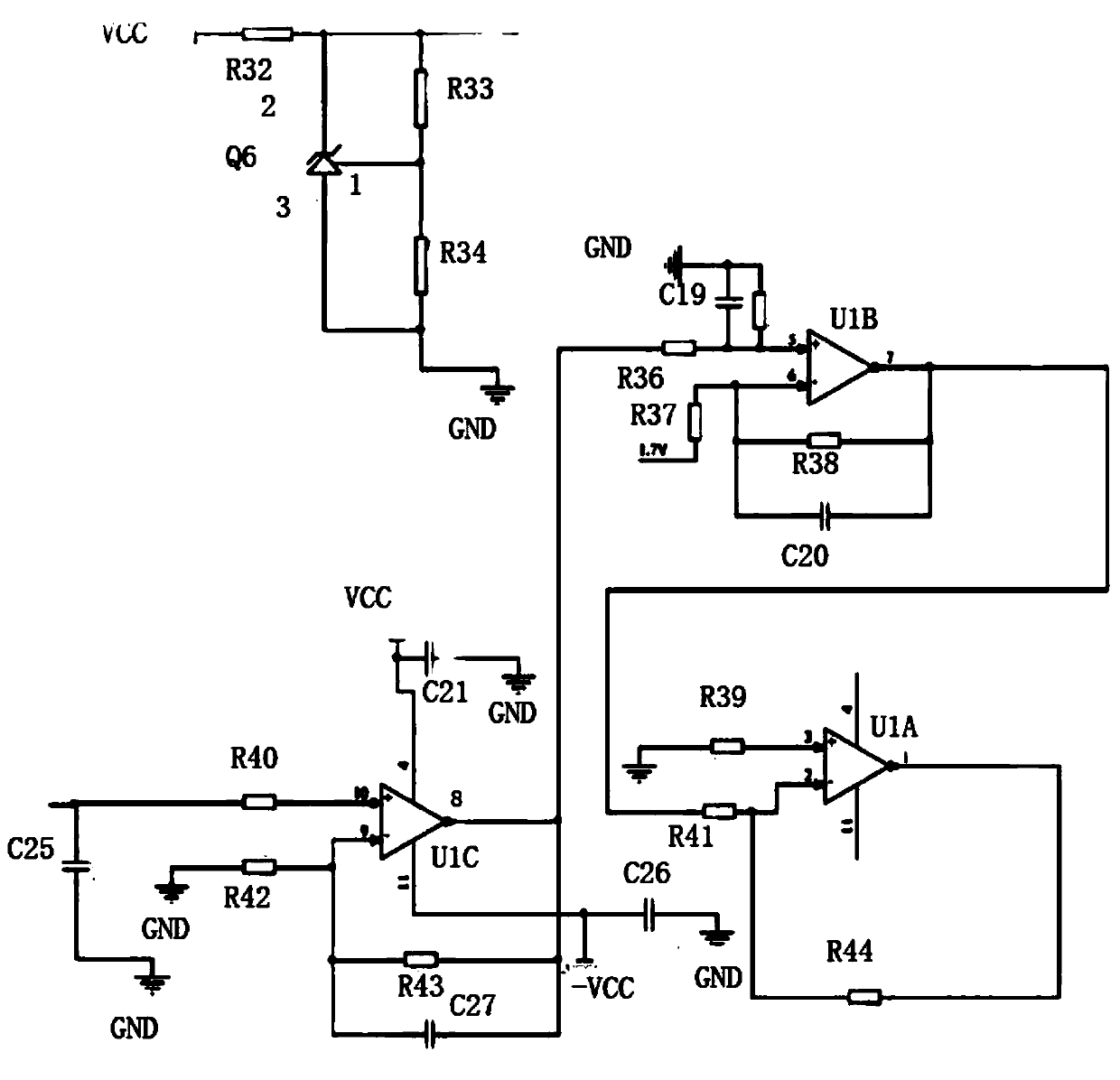

Sine wave power source satisfying inductive load frequent connection and disconnection and application of sine wave power source

ActiveCN107742988ANo waveform distortionWide operating temperatureEfficient power electronics conversionDc-ac conversion without reversalSignal conditioning circuitsPhase difference

The invention discloses a sine wave power source satisfying inductive load frequent connection and disconnection. The sine wave power source comprises a sine wave generating module, the sine wave signal conditioning circuit and a D type power amplifier circuit, a DDS numerical frequency compounding technology is adopted to generate a sine wave signal with a needed frequency, and the sine wave signal is sent to a sine wave signal conditioning circuit; the sine wave signal conditioning circuit removes a direct current component in the sine wave signal generated by the sine wave generating module, amplifies the amplitude value of the sine wave signal and conducts change to obtain two sets of sine wave signals of which the amplitude value is the same and the phase difference is 180 degrees, then two sets of sine wave signals are transferred to a subsequent first D type power amplifier circuit and second D type power amplifier circuit in sequence to be processed; the D type amplifier circuit is used for amplifying power, processing a signal of each of the two sets of sine wave signals of which the amplitude value is the same and the phase difference is 180 degrees and then transferringthe processed signal to a power source and an inductive load. Through the principle, the sine wave power source can be utilized in the environment in which it is required that the output load of the inductive load is large, and a sine wave power source is continuously connected and disconnected.

Owner:MIANYANG WEIBO ELECTRONICS

Method for improving condition of Sophora buds from golden Sophora japonica

ActiveCN107714762AThe configuration and completion process is simpleEasy to operatePlant ingredientsBudCell budding

The invention discloses a method for improving condition of Sophora buds from golden Sophora japonica. The method comprises the following steps: (1) water is added into an enzyme deactivating apparatus, alkali lye is added, and heating is carried out; (2) water and alkali lye are added into the enzyme deactivating apparatus every two hours in the heating process of the step (1), in order to guarantee alkali lye in a pot is kept at a certain concentration, heating is carried out till water is boiled, Sophora buds are added into the enzyme deactivating apparatus for carrying out enzyme deactivation, boiling state is kept and enzyme deactivation is carried out for 12-15 minutes, and the product is obtained. The method has obvious effects, processed Sophora buds from golden Sophora japonica have golden yellow color, good condition, and high price.

Owner:GUANGXI INST OF BOTANY THE CHINESE ACAD OF SCI

Coking additive for improving coke performance and coking method

The invention discloses a coking additive for improving coke performance. The coking additive consists of surface activation catalysts, dissolution aids, penetrating aids and oily solvents, wherein the surface activation catalysts refer to SiC powder and sodium naphthenate; the dissolution aids refer to alpha-hydroxyl propanamide, acetylthiophene and p-toluene sulfonic acid; the penetrating aids refer to polyoxyethylene polyoxypropylene monobutyl ether, polyoxyethylene sorbitan tristearate, chlorophenyl silicone oil and molybdenum triethanolamine; and the oily solvents refer to coal tar, asphalt and residual oil. The coking method comprises the step of adding the coking additive into coal, wherein the addition amount of the additives in the coal is 0.5-3wt%.

Owner:马新攀

Aluminium alloy or magnesium alloy evaporative-pattern casting compression solidification device

InactiveCN101391298BHigh densityGrain refinementFoundry mouldsFoundry coresExhaust valve5005 aluminium alloy

The invention relates to an aluminium alloy or magnesium alloy lost mould casting pressuring solidification method and a device thereof, and the invention belongs to the field of special precision casting. The aluminium alloy or magnesium alloy lost mould casting pressuring solidification method comprises compacting, vacuuming, pouring, pressuring and depressurizing. A pressure resistant sand boxof the device is a cylinder-shaped container, the bottom is provided with an exhaust valve, and the inner lower part or the side wall is provided with a ventilation interlayer; the upper surface of acover of the pressure resistant sand box is respectively provided with a switch valve, a safety valve and a pressure gauge; and the side surface of the pressure resistant sand box or the cover of thepressure resistant sand box is provided with an intake pipe. The aluminium alloy or magnesium alloy lost mould casting pressuring solidification method can obviously reduce casting defects of shrinkage cavity, shrinkage porosity, and the like in aluminium alloy lost mould casting, can effectively reduce pinhole in the aluminium alloy, enhances density of the casting, thins alloy crystal grains, and improves the surface quality and mechanical property of the aluminium alloy or magnesium alloy lost mould casting. The device simplifies lost mould casting pressuring solidification technique, and low production cost, convenient operation, good sealing effect, short sealing time of the sand box and fast pressuring speed.

Owner:HUAZHONG UNIV OF SCI & TECH

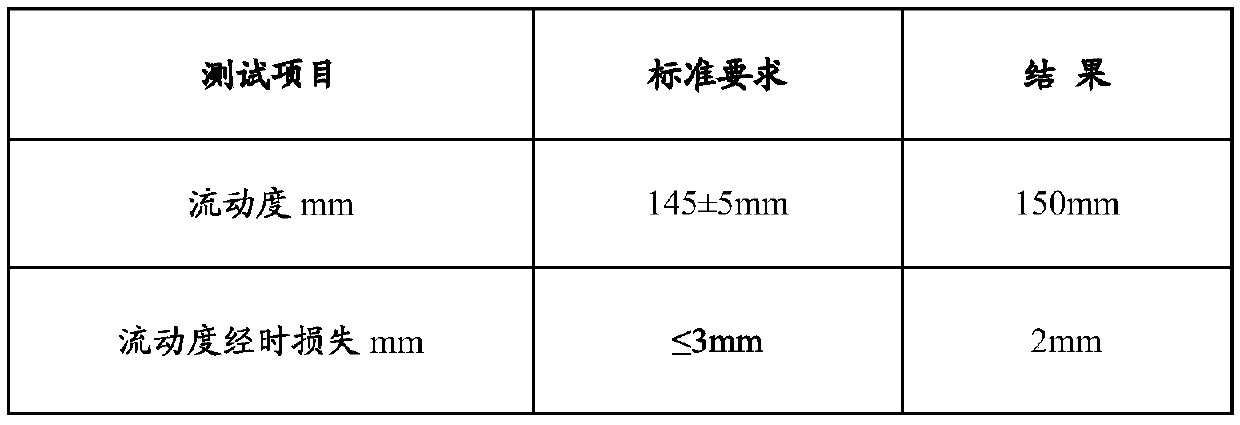

Ardealite pretreatment method and application thereof

InactiveCN111499237ARealize resource utilizationAchieving Scale ProcessingPretreatment methodPhysical chemistry

The invention discloses an ardealite pretreatment method. The ardealite pretreatment method comprises the following steps: sieving large blocks of ardealite; grinding the sieved large ardealite blocks; placing the ground ardealite in a microwave field for irradiation, and raising a temperature; calcining the ardealite having undergone microwave irradiation; aging the calcined ardealite; and testing the pH value of the aged ardealite, and if the pH value is not within the range of 5-7, adjusting the pH value to 5-7. The invention further discloses an ardealite gypsum plaster board and a preparation method thereof. By means of the ardealite pretreatment method, the setting time and strength of ardealite are improved, and ardealite can be successfully added into a gypsum plaster board. The invention further provides ardealite self-leveling mortar and a preparation method thereof. The performance of the ardealite self-leveling mortar meets standard requirements prescribed in JC / T 1023-2007.

Owner:CHINA NAT BUILDING MATERIALS TECHCAL INNOVATION & RES INST LIMITED

Control method of parasitic tea on camellia trees

ActiveCN107593791AReduced incidence of harmThe effect of the method is obviousBiocidePlant growth regulatorsFruit treeClematis

The invention relates to a control method of parasitic tea on camellia trees and belongs to the field of parasitic tea control technology for fruit trees. The control method of parasitic tea on camellia trees comprises the following steps: 1) deeply turning soil 15-25 cm to inhibit germination of parasitic tea seeds; and 2) continuously spraying a special treatment agent for three times every halfa month since spring. The special treatment agent is composed of the following raw materials (by weight): 20-30 parts of a Caulis Clematis armandii extract, 10-15 parts of a Prunella vulgaris extractand 50-60 parts of an auxiliary agent. The special treatment agent is sprayed onto branches and leaves of parasitic tea, and has high control rate for the harm of parasitic tea on camellia trees. Themethod is simple and feasible, is convenient to operate, and is easy for realization.

Owner:台州中知英健机械自动化有限公司

Method for influencing weather artificially on vegetation areas

InactiveCN105613154AThe effect of the method is obviousHigh speedWeather influencing devicesVegetationSuper absorbent

The invention belongs to the field of artificial influenced weather and particularly relates to a method for influencing weather artificially on vegetation areas. The method comprises the following steps: (1), preparation of hail-suppression shells for the vegetation areas: each hail-suppression shell comprises a shell head and filler, the filler comprises substances in parts by weight as follows: 5-10 parts of super absorbent resin and 5-20 parts of fertilizers for vegetation, and the super absorbent resin is starch super absorbent resin or cellulose super absorbent resin; (2), preparation of a catalyst for the vegetation areas: the catalyst comprises substances in parts by weight as follows: 5-20 parts of salt A and 5-8 parts of salt B; (3), subduction of ice nucleuses in cloud layers: the hail-suppression shells are ejected above the cloud layers through anti-aircraft artilleries, and the catalyst is uniformly ejected into the cloud layers by the anti-aircraft artilleries after 10-20 min. According to the method for influencing the weather artificially, the quantity of the catalyst and the hail-suppression shells is small, the effect is good, and no pollution is caused to the environment.

Owner:WUXI XINMAO TECH

Water treatment method for killing living animals such as fleas by O3/H2O2

InactiveCN1263687CReduce mutagenicityMutagenicity does not increaseWater/sewage treatment using germicide/oligodynamic-processWater/sewage treatment by oxidationZooplanktonFlea

A water treating method for killing the flea kind of zooplanktons by use of O3 / H2O2 features that before the water is conventionally treated, the O3 and H2O2 are proportionally added to it and then stayed in water for 20-30 min.

Owner:HARBIN INST OF TECH +1

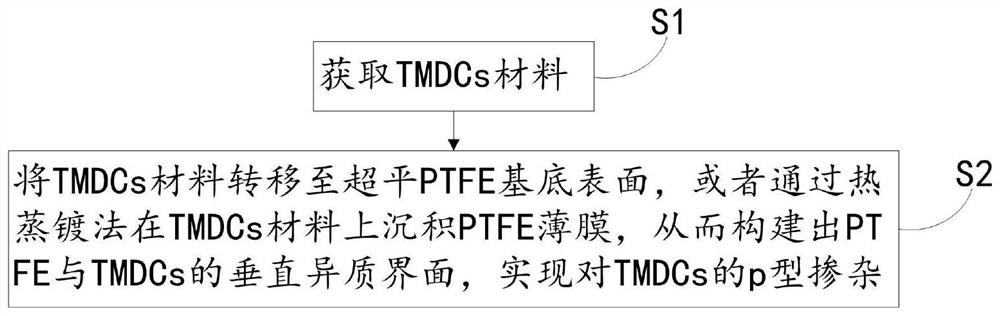

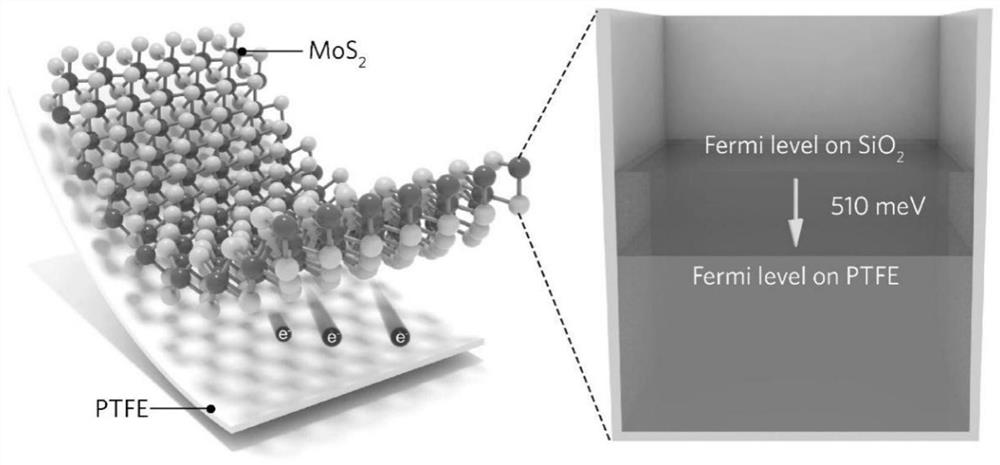

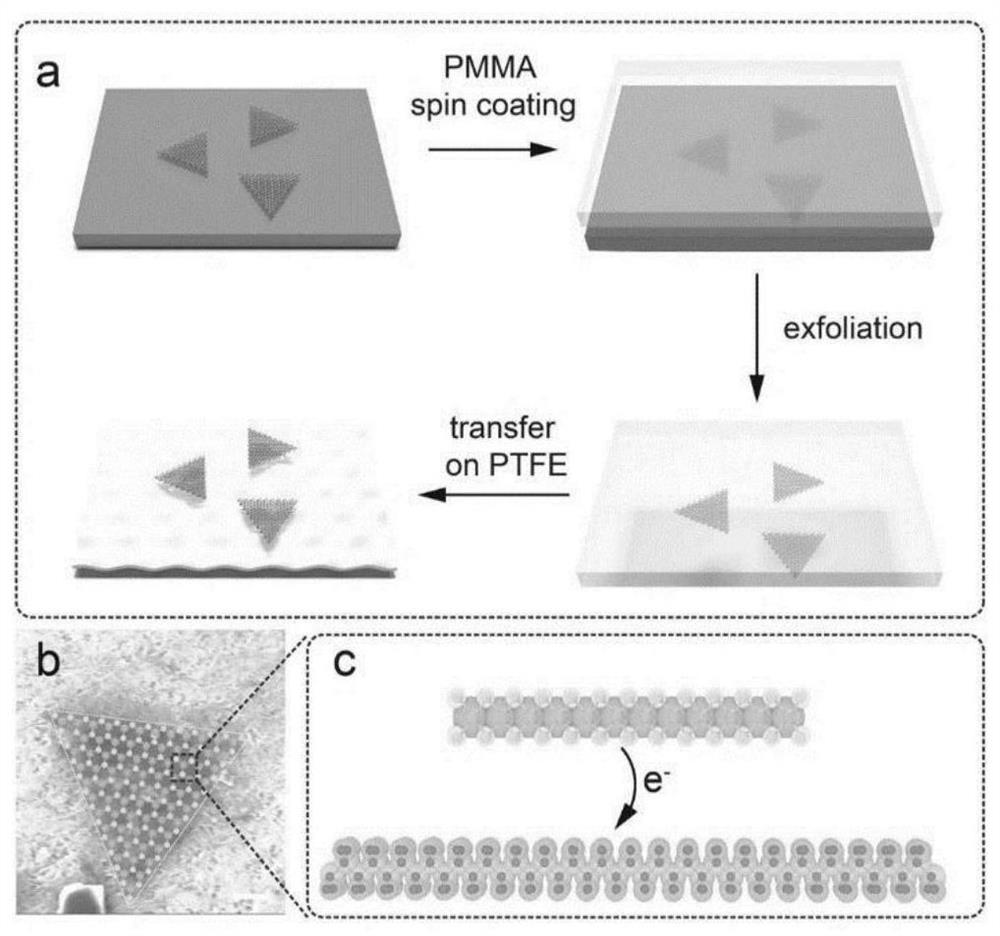

A kind of method and semiconductor that carry out p-type doping to tmdcs based on ptfe

ActiveCN113451139BThe effect of the method is obviousLong-term stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesPhysical chemistryCompounds of fluorine

The invention discloses a method and semiconductor for p-type doping of TMDCs based on PTFE, belonging to the technical field of advanced semiconductor devices. The method is as follows: transferring TMDCs material to a fluorine-containing ultra-flat PTFE substrate, thereby constructing a TMDs And the vertical heterointerface of PTFE, the interface has efficient hole doping regulation for TMDCs, by measuring the spectral structure and fluorescence lifetime of the transferred TMDCs, and characterizing the change of its energy band structure, it can be determined to realize the p-type of TMDCs Doping to obtain p-type doped TMDCs semiconductors, thus expanding the application in optoelectronic or electronic devices. The invention realizes the conversion of two-dimensional TMDCs from n-type to p-type doping at room temperature, and the adjustment effect is long-term, stable and suitable for large-scale production requirements. The method is easy to operate and has single atomic layer controllable doping accuracy. The strong electronegativity effect of fluorine compounds realizes the hole-doping type of 2D TMDCs.

Owner:FUDAN UNIV

Water treatment method capable of killing midge larva by ozone

InactiveCN1318319CReduce mutagenicityStrong oxidation disinfection effectBiocideAnimal repellantsLitterMidge

Disclosed is a water processing method for complete eradication of chironomus larvas through ozone, the method comprises pre-letting ozone into primary water before conventional processing, the ozone charge amount in each litter of water is 2.5-3.0mg, the time of contact is 20-30 mins.

Owner:HARBIN INST OF TECH

Method for Improving Sunlight Fastness of Flame Retardant Knitted Fabric

ActiveCN110306313BImprove light fastnessThe effect of the method is obviousSucessive textile treatmentsTwo or more solvent application treatmentPolymer scienceEngineering

The invention provides a method for improving the light fastness of flame-retardant knitted fabrics, which effectively solves the problems of low light fastness and serious fading of traditional flame-retardant knitted fabrics. It includes the following steps: Step 1, dyeing; dyeing the knitted fabric lightly; Step 2, flame-retardant finishing; performing flame-retardant finishing on the knitted fabric in step 1 according to the normal process, so that the knitted fabric is endowed with fireproof and flame-retardant functions; Step 3, Padding and rolling treatment; the knitted fabric after flame retardant finishing in step 2 is subjected to padding and rolling treatment with live dyes, penetrants and dyeing catalysts; step 4, stacking; step 5, washing; step 4 The flame-retardant knitted fabric that has been piled up for a long time is washed in the overflow dyeing machine to wash away excess dyes and auxiliaries, and the fabric of the flame-retardant knitted fabric is retracted; step 6, setting and drying; step 7, padding again; Use the formaldehyde-free color-fixing agent to pad the flame-retardant knitted fabric after setting and drying in step six; further increase the fastness; step eight, test and compare; the effect of this method is obvious.

Owner:新乡市新星特种织物有限公司

A method for improving the appearance of japonica japonica rice

The invention discloses a method for improving condition of Sophora buds from golden Sophora japonica. The method comprises the following steps: (1) water is added into an enzyme deactivating apparatus, alkali lye is added, and heating is carried out; (2) water and alkali lye are added into the enzyme deactivating apparatus every two hours in the heating process of the step (1), in order to guarantee alkali lye in a pot is kept at a certain concentration, heating is carried out till water is boiled, Sophora buds are added into the enzyme deactivating apparatus for carrying out enzyme deactivation, boiling state is kept and enzyme deactivation is carried out for 12-15 minutes, and the product is obtained. The method has obvious effects, processed Sophora buds from golden Sophora japonica have golden yellow color, good condition, and high price.

Owner:GUANGXI INST OF BOTANY THE CHINESE ACAD OF SCI

Preparation method and equipment of color carbon-base film

InactiveCN1955335AUniform thicknessUniform colorVacuum evaporation coatingSputtering coatingAlkaneSputtering

This invention provides a preparation of composing multicolor thin film of carbon radical, among them use gas low molecular hydrocarbons as main carbon source, sputtering graphite as assistant carbon source, Density of gas hydrocarbon is 5% to 80%. Reaction temperature of coating is controlled at 50deg.C to 300deg.C,reaction time is controlled in 5min to 150min. This invention simultaneously provides a coating equipment of reactive magnetron sputtering that carries out above-mentioned method, gas alkanes is used as main carbon source, sputtering graphite is usedas assistant carbon source.

Owner:BEIJING POWERTECH +1

A Method for Artificial Weather Modification in Vegetated Area

The invention belongs to the field of artificial influenced weather and particularly relates to a method for influencing weather artificially on vegetation areas. The method comprises the following steps: (1), preparation of hail-suppression shells for the vegetation areas: each hail-suppression shell comprises a shell head and filler, the filler comprises substances in parts by weight as follows: 5-10 parts of super absorbent resin and 5-20 parts of fertilizers for vegetation, and the super absorbent resin is starch super absorbent resin or cellulose super absorbent resin; (2), preparation of a catalyst for the vegetation areas: the catalyst comprises substances in parts by weight as follows: 5-20 parts of salt A and 5-8 parts of salt B; (3), subduction of ice nucleuses in cloud layers: the hail-suppression shells are ejected above the cloud layers through anti-aircraft artilleries, and the catalyst is uniformly ejected into the cloud layers by the anti-aircraft artilleries after 10-20 min. According to the method for influencing the weather artificially, the quantity of the catalyst and the hail-suppression shells is small, the effect is good, and no pollution is caused to the environment.

Owner:WUXI XINMAO TECH

Coal additive and method for raising coke output and performance

InactiveCN100412166CGuaranteed long-term use in large areasSafe and convenient transportationCoke ovensSolid fuelsProcess engineeringPermeation

The present invention relates to coal additive and method for raising coke output and performance. The coal additive contains surface activating catalyst, co-solvent, permeation assistant and solvent. When the coal additive is used, the surface activating catalyst is dissolved in the solvent, added into coal through a specific mode, and distributed on the surface of coal and inside coal under the action of the permeation assistant. During producing coke, the coal additive is heated and the volatile component is separated out, to raise the output and performance of the produced coke. The high performance coke may be used in coal burning, dry distilling, gasifying, liquefying and other fields. The present invention can reach the aims of raising the utilization rate of coal, saving coal resource, reducing pollutant, etc.

Owner:北京金源化学集团有限公司

Aspirin enteric coated tablet with low content of free salicylic acid and preparation process thereof

ActiveCN101732279BReduce contentThe effect of the method is obviousOrganic active ingredientsAntipyreticSalicylic acidNuclear chemistry

The invention provides an aspirin enteric coated tablet with low content of free salicylic acid. A given amount of tartaric acid is added in the recipe of a tablet core, and the content of the free salicylic acid is effectively lowered. The invention provides an improved process. The invention has simple, convenient and easy method and is suitable for industrialized production.

Owner:SHANGHAI SINE PROMOD PHARMA

A sine wave power supply and its method for satisfying frequent on-off of inductive loads

ActiveCN107742988BNo waveform distortionWide operating temperatureEfficient power electronics conversionDc-ac conversion without reversalSignal conditioning circuitsHemt circuits

The invention discloses a sine wave power source satisfying inductive load frequent connection and disconnection. The sine wave power source comprises a sine wave generating module, the sine wave signal conditioning circuit and a D type power amplifier circuit, a DDS numerical frequency compounding technology is adopted to generate a sine wave signal with a needed frequency, and the sine wave signal is sent to a sine wave signal conditioning circuit; the sine wave signal conditioning circuit removes a direct current component in the sine wave signal generated by the sine wave generating module, amplifies the amplitude value of the sine wave signal and conducts change to obtain two sets of sine wave signals of which the amplitude value is the same and the phase difference is 180 degrees, then two sets of sine wave signals are transferred to a subsequent first D type power amplifier circuit and second D type power amplifier circuit in sequence to be processed; the D type amplifier circuit is used for amplifying power, processing a signal of each of the two sets of sine wave signals of which the amplitude value is the same and the phase difference is 180 degrees and then transferringthe processed signal to a power source and an inductive load. Through the principle, the sine wave power source can be utilized in the environment in which it is required that the output load of the inductive load is large, and a sine wave power source is continuously connected and disconnected.

Owner:MIANYANG WEIBO ELECTRONICS

Insulation method for preventing metal screw or bolt from generating magnetic flux leakage linkage circulation

ActiveCN101552109BThe effect of the method is obviousGood effectTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureInsulation layerEngineering

Owner:CHINA XD ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com