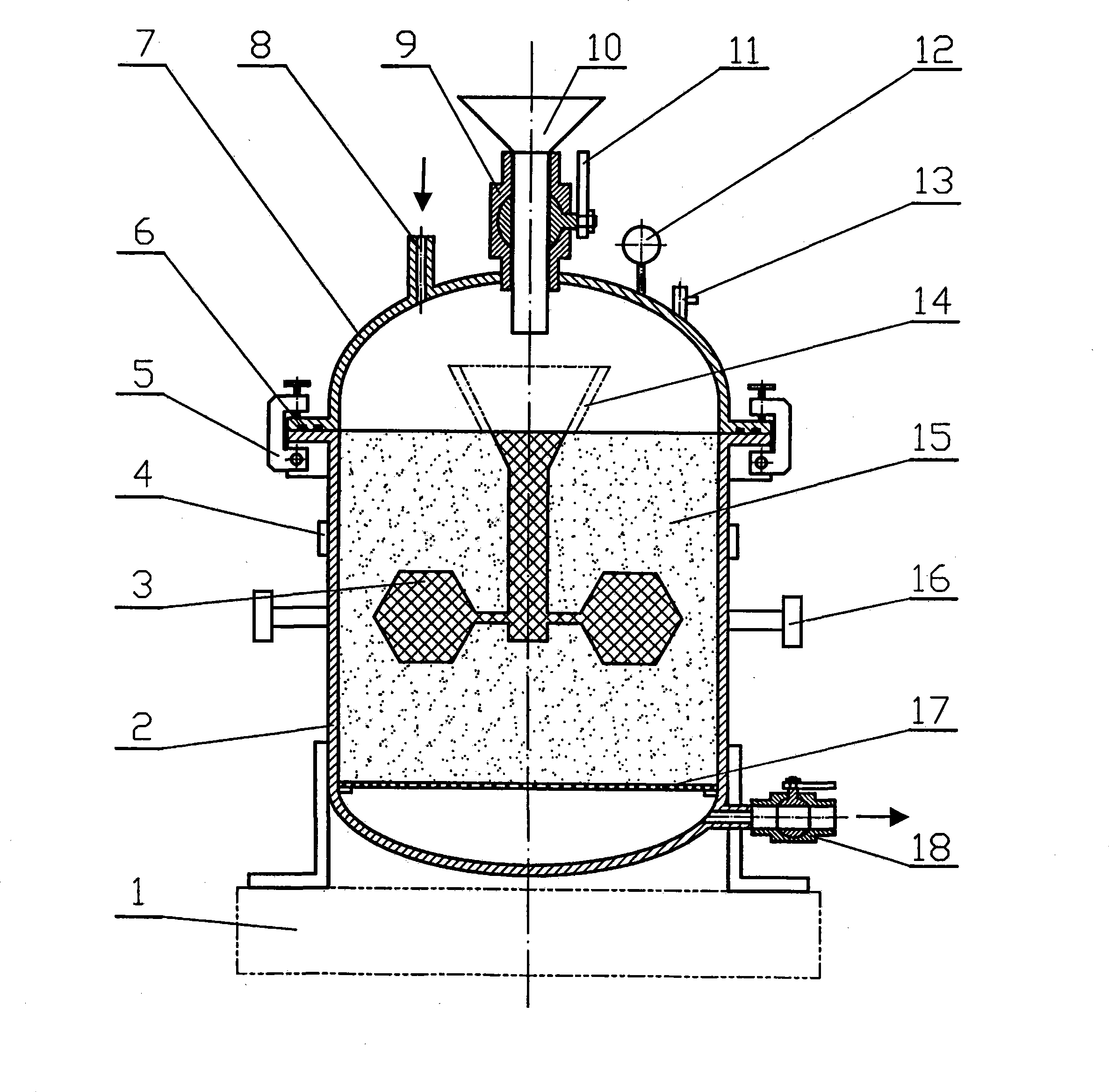

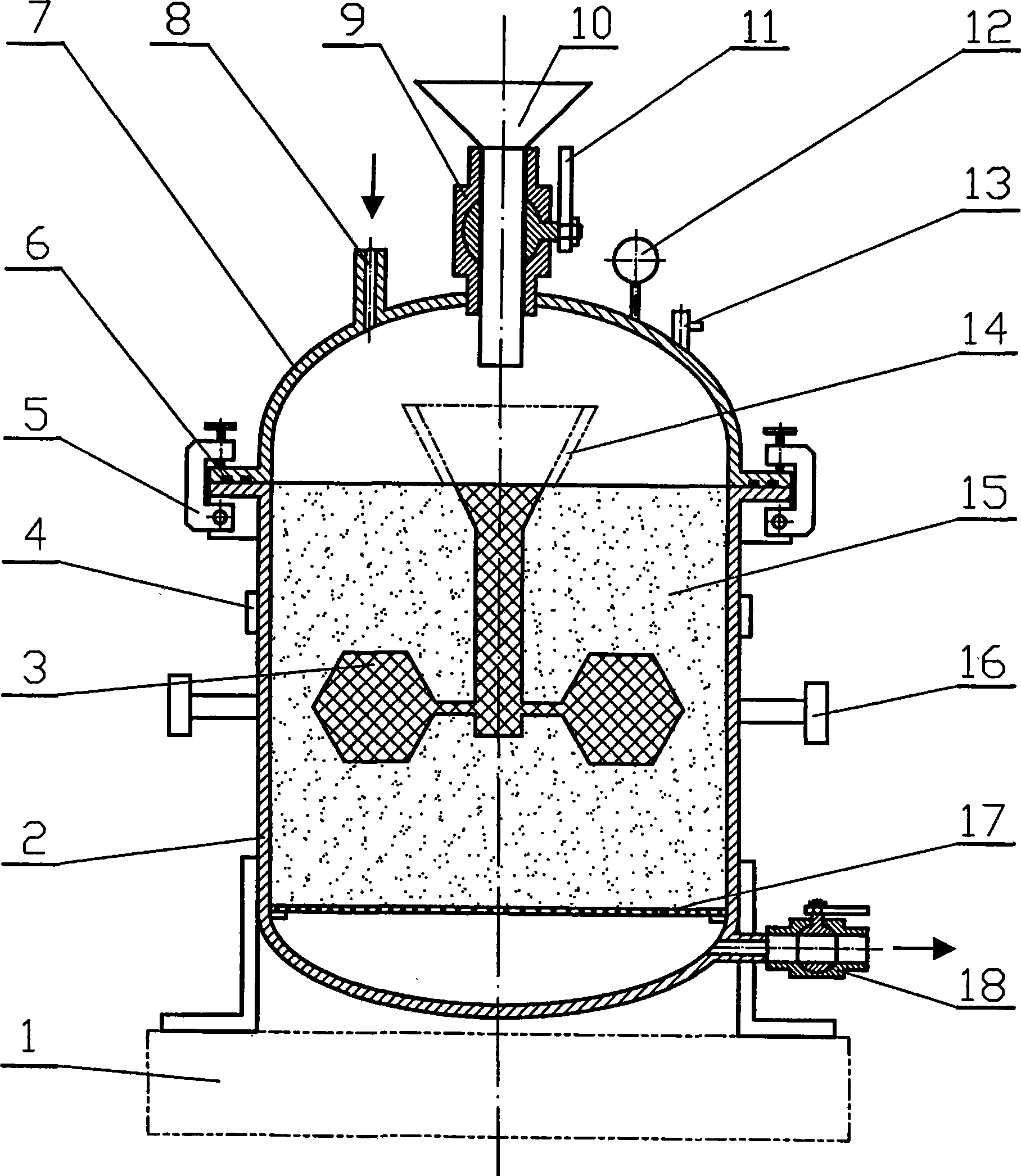

Aluminium alloy or magnesium alloy evaporative-pattern casting compression solidification device

A technology of lost foam casting and magnesium alloy, which is applied in casting molding equipment, metal processing equipment, casting molds, etc. It can solve the problems of low pressurization rate, long pressurization time, and high investment cost, and achieves increased density, full charge, etc. The effect of high pressure rate and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: aluminum alloy casting

[0039]Put the foam pattern (3) of the lost foam part into the pressure-resistant sand box (2), add 20-50 mesh quartz loose sand (15), and vibrate and compact it by the vibration compacting table (1) at the same time; put the sprue cup (14); on the above-mentioned pressure-resistant sand box (2), add a cover pressure-resistant sand box cover (7), tighten the clamping mechanism (5); then ZL101 aluminum alloy is melted, after refining, metamorphism, when aluminum When the alloy temperature is 740°C, pour the molten metal into the sand box from the metal liquid introduction cup (10) preheated at 200°C on the switch valve (9); after pouring a certain amount, quickly take out the metal liquid introduction cup (10) , close the on-off valve (9) and the exhaust valve (18); the compressed air with a pressure of 1.2MPa is introduced from the intake pipe (8), the charging rate is 0.05MPa / s, the pressure is maintained for 0.3min, and then the i...

Embodiment 2

[0040] Embodiment 2: magnesium alloy casting

[0041] Put the foam pattern of the lost foam part into the pressure-resistant sand box (2), add 20-50 mesh pearl loose sand, and vibrate and compact it by the vibration compacting table (1) at the same time; cover the surface of the loose sand (15) with a plastic film, Vacuum the vacuum to -0.05MPa, then put the sprue cup (14); on the above-mentioned pressure-resistant sand box (2), cover the pressure-resistant sand box cover (7), and tighten the clamping mechanism (5) ; for AZ91D magnesium alloy, in SF 6 plus CO 2 Melting, refining and metamorphism under mixed protective gas. When the magnesium alloy temperature is 730°C, the molten metal preheated at 200°C from the on-off valve (9) is introduced into the cup (10) and poured into the pressure-resistant sandbox; Finally, sprinkle some dry sand with sulfur (anti-magnesium alloy combustion), quickly take out the molten metal into the cup (10), close the switch valve (9) and exhaus...

Embodiment 3

[0042] Example 3: Vibration of aluminum alloy and solidification under variable pressure

[0043] Put the foam pattern of the lost foam part into the pressure-resistant sandbox (2), add 20-50 mesh quartz loose sand, and vibrate and compact it by the vibration compacting table (1) at the same time; cover the surface of the loose sand (15) with a plastic film, Vacuum the vacuum to -0.01MPa, then put the sprue cup (14); on the above-mentioned pressure-resistant sand box (2), cover the pressure-resistant sand box cover (7), and tighten the clamping mechanism (5) ; A356 aluminum alloy is melted, refined and deteriorated. Open the vibrating table (1) before pouring, and carry out 50Hz micro-vibration to the sand box. The molten metal is poured into the pressure-resistant sand box in the introduction cup (10); after pouring a certain amount, quickly take out the molten metal introduction cup (10), close the on-off valve (9) and the exhaust valve (18); stop the vibration, The gas pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com