Sine wave power source satisfying inductive load frequent connection and disconnection and application of sine wave power source

An inductive load, sine wave technology, applied in the direction of electrical components, climate sustainability, high-efficiency power electronic conversion, etc., can solve problems such as not being able to meet the needs of use, and achieve good output dynamic response, wide operating temperature, and obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

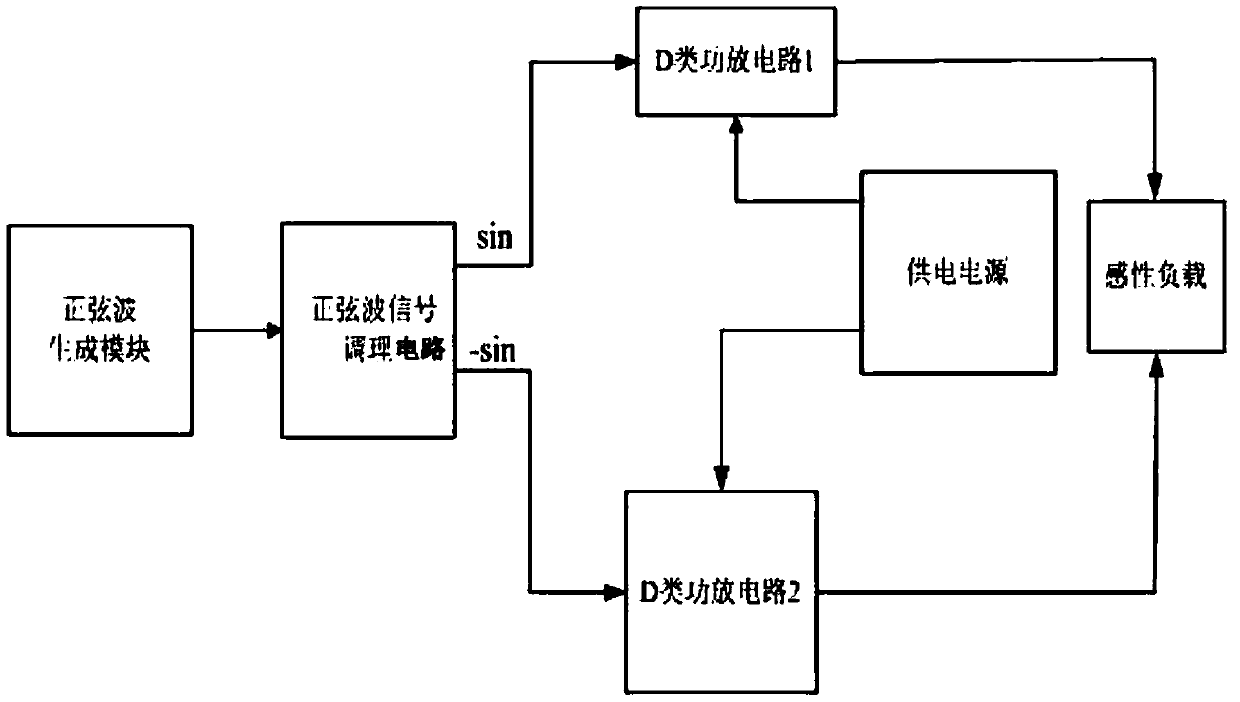

[0030] Such as Figure 1-5 As shown, the present invention includes a sine wave power supply that satisfies the frequent switching of inductive loads, including

[0031] Sine wave generation module: DDS digital frequency synthesis technology is used to generate a sine wave signal of the required frequency and sent to the sine wave signal conditioning circuit; the generated sine wave has low frequency fluctuation rate, and the output frequency and amplitude are not affected by temperature. At the same time, the output frequency can be The advantage of easy adjustment.

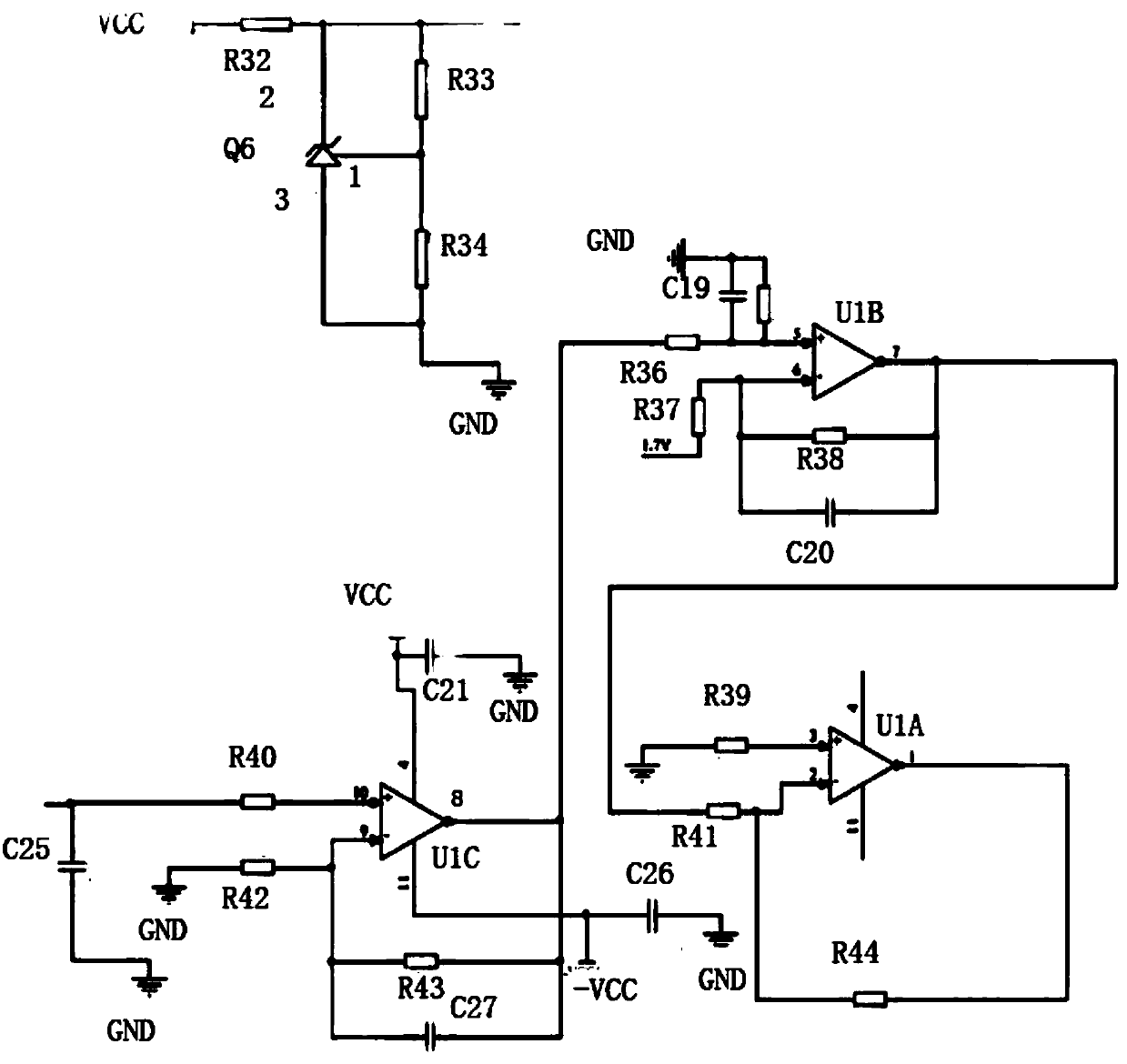

[0032] Sine wave signal conditioning circuit: remove the DC component in the sine wave signal generated by the sine wave generation module, amplify the amplitude of the sine wave signal, and change to obtain two sets of sine wave signals with the same amplitude and a phase difference of 180°, and then Sequentially passed to the back class D power amplifier circuit 1 and class D power amplifier circuit 2 for pro...

Embodiment 2

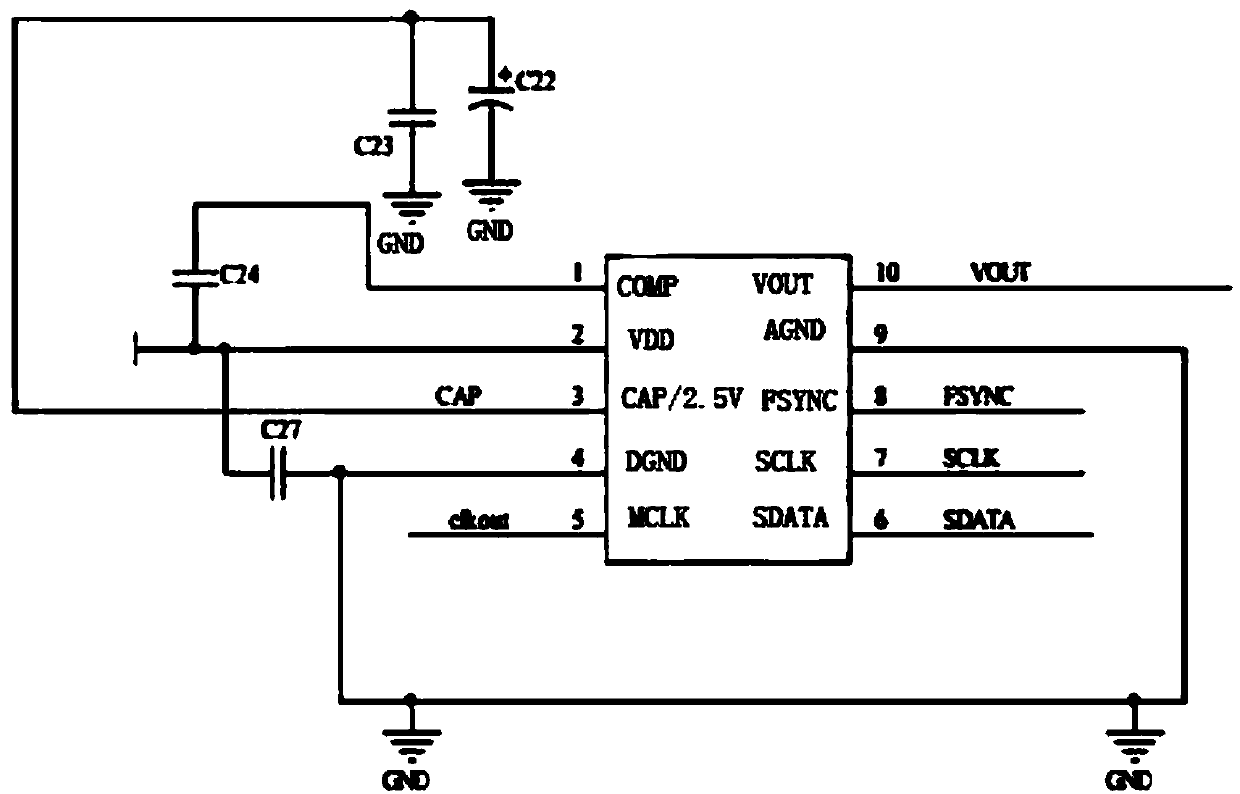

[0039] The present embodiment is preferably as follows on the basis of Embodiment 1: the sine wave generating module includes an AD9833EP chip, a capacitor C22 of 10UF / 50V, a capacitor C24 of 0.1u and a capacitor C27 of 0.1u, between the port COMP and the port VDD of the AD9833EP chip Connect the capacitor C24 between them, connect the capacitor C27 between the port VDD and the port DGND of the AD9833EP chip, connect the pull-down capacitor C23 and C22 to the port CAP / 2.5V, connect the port VDD to the power supply VCC, connect the port DGND and the port AGND to ground, and connect the port VOUT Connect the signal output terminal VOUT. Among them, AD9833EP is a chip that generates sine wave signals. It can generate sine wave signals with required frequency through software control. The sine wave signal generated by this chip: 0.306 (sin2*π*400*t)+0.344; where t is a time variable, The unit is s, and the output sine wave is a sine wave with DC bias. This signal needs to be modu...

Embodiment 3

[0057]An application of a sine wave power supply that satisfies the frequent on-off of inductive loads. It is used in an application environment that requires a large inductive load or resistive load as the output load, and requires continuous connection and disconnection of the sine wave power supply.

[0058] The sine wave power supply of the present invention can be used in the application environment where the inductive load that requires a large output load and requires continuous connection and disconnection of the sine wave power supply. The sine wave inverter on the market is frequently connected and disconnected When the load is off, there is a risk of damage to the conventional sine wave inverter due to the back electromotive force when the inductive load is disconnected. And our sine wave inverter has the following advantages: (1) The frequency of load on and off is 0-100Hz; (2) The output frequency fluctuation rate of the sine wave power supply is less than 0.25%; (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com