Power driving circuit

A power drive circuit and loop technology, applied in the field of aviation electrical, can solve the problems of complex related circuits, grid voltage fluctuations, power waveform distortion, etc., and achieve the effects of no waveform distortion, small electromagnetic interference, and simple and reliable trigger circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

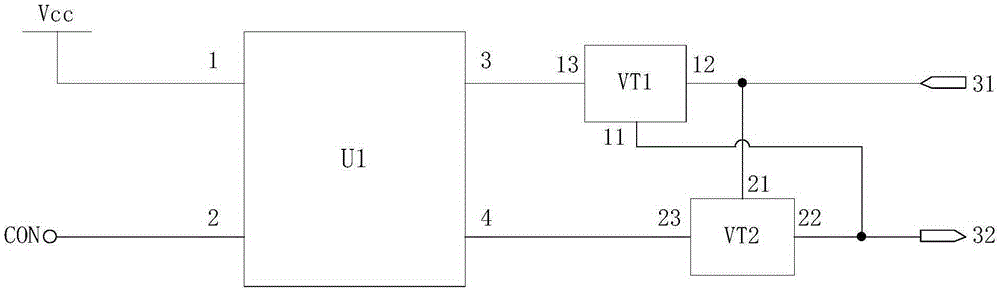

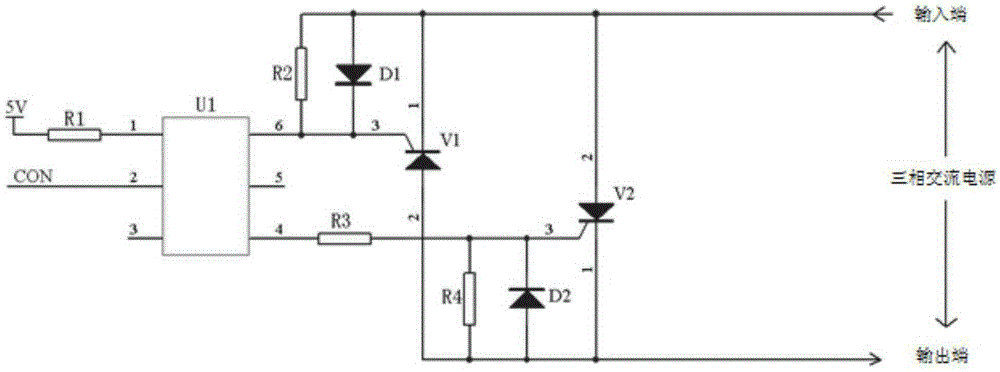

[0031] figure 1 It is a schematic structural diagram of a power drive circuit provided by Embodiment 1 of the present invention. This embodiment is applicable to a power drive circuit of a propeller sequential heating controller. The power drive circuit includes:

[0032] Photocoupler U1, the first thyristor loop VT1 and the second thyristor loop VT2; where

[0033] The first input pin 1 of the photocoupler U1 is connected to the constant voltage power supply Vcc, and the second input pin 2 of the photocoupler U1 is connected to the control signal for generating two driving signals according to the control signal CON. The first output pin 3 and the second output pin 4 output;

[0034] The first output pin 3 of the photocoupler U1 is connected to the gate 13 of the first thyristor circuit VT1, and the second output pin 4 of the photocoupler U1 is connected to the gate 23 of the second thyristor circuit VT2;

[0035] The anode 12 of the first thyristor circuit VT1 and the cath...

Embodiment 2

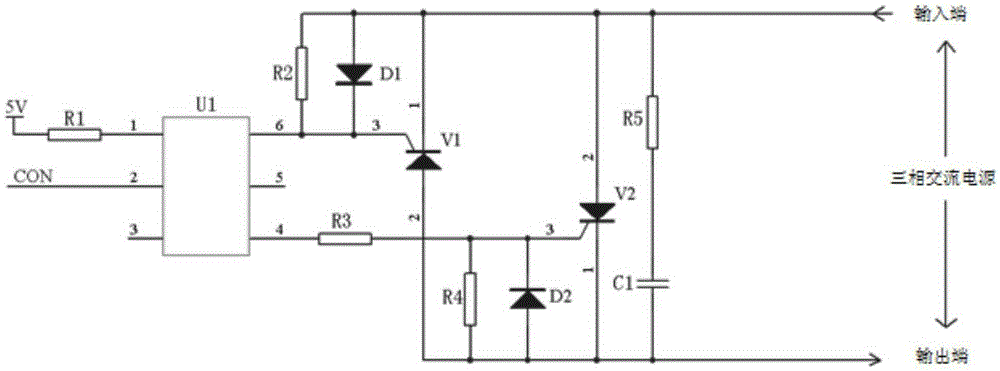

[0042] image 3 A circuit diagram of a power drive circuit provided by Embodiment 2 of the present invention. The technical solution provided by this embodiment is based on the above embodiments, and further includes: a series absorbing capacitor and a absorbing resistor, forming a resistance-capacitance absorbing circuit, and connecting in parallel at both ends of the thyristor loop.

[0043] Such as image 3 As shown, the snubber capacitor C1 and the snubber resistor R5 are connected in series and connected in parallel between the anode and cathode of the thyristor V2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com