Insulation method for preventing metal screw or bolt from generating magnetic flux leakage linkage circulation

A screw and bolt technology, which is applied in the field of insulation of metal connectors, can solve the problems of large circulating current, safe and reliable operation of power transmission and transformation circuits, and abnormal operation of oil chromatography.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

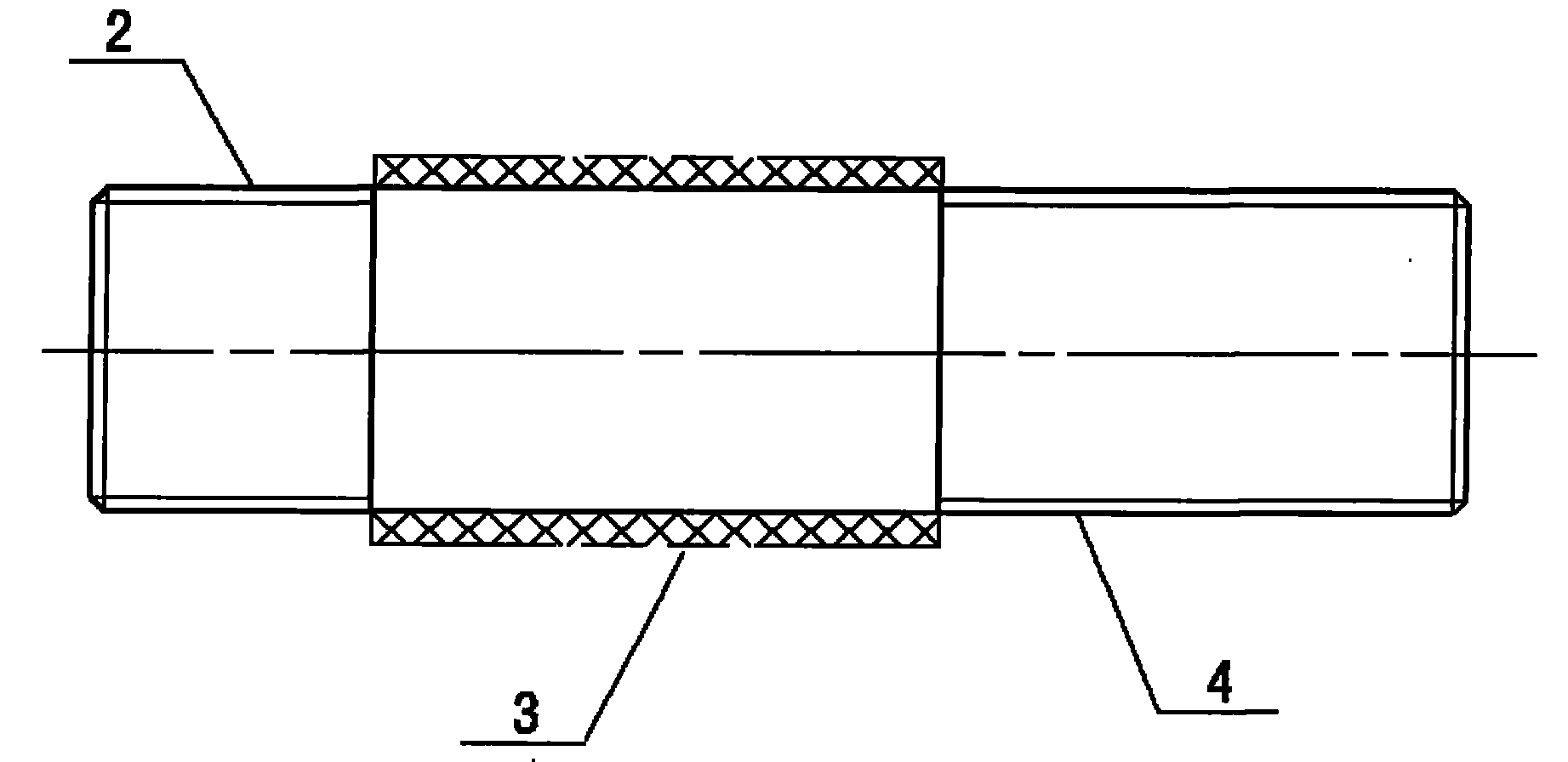

[0018] like figure 1 , figure 2 As shown in the figure, wrap non-woven glass filaments in the middle of the metal screw with a thickness of about 1 to 4 mm, and then infiltrate with thermosetting insulating resin (such as epoxy resin) to form an insulating layer 3. The specific thickness should be the same as the size of the flange hole of the metal structure II To cooperate, it is necessary to ensure that the insulating part of the screw can extend into the flange hole, and at the same time leave a certain gap, so the outer diameter of the screw after insulation must be strictly controlled. The specified thickness makes its surface smooth. The end part 2 is screwed into the blind hole of the flange of the structural part I, and the insulating layer 3 is extended into the flange hole of the structural part II to isolate the structural part I, the structural part II from the middle section of the screw; the end part 4 passes through the gasket and the insulating layer. The w...

Embodiment 2

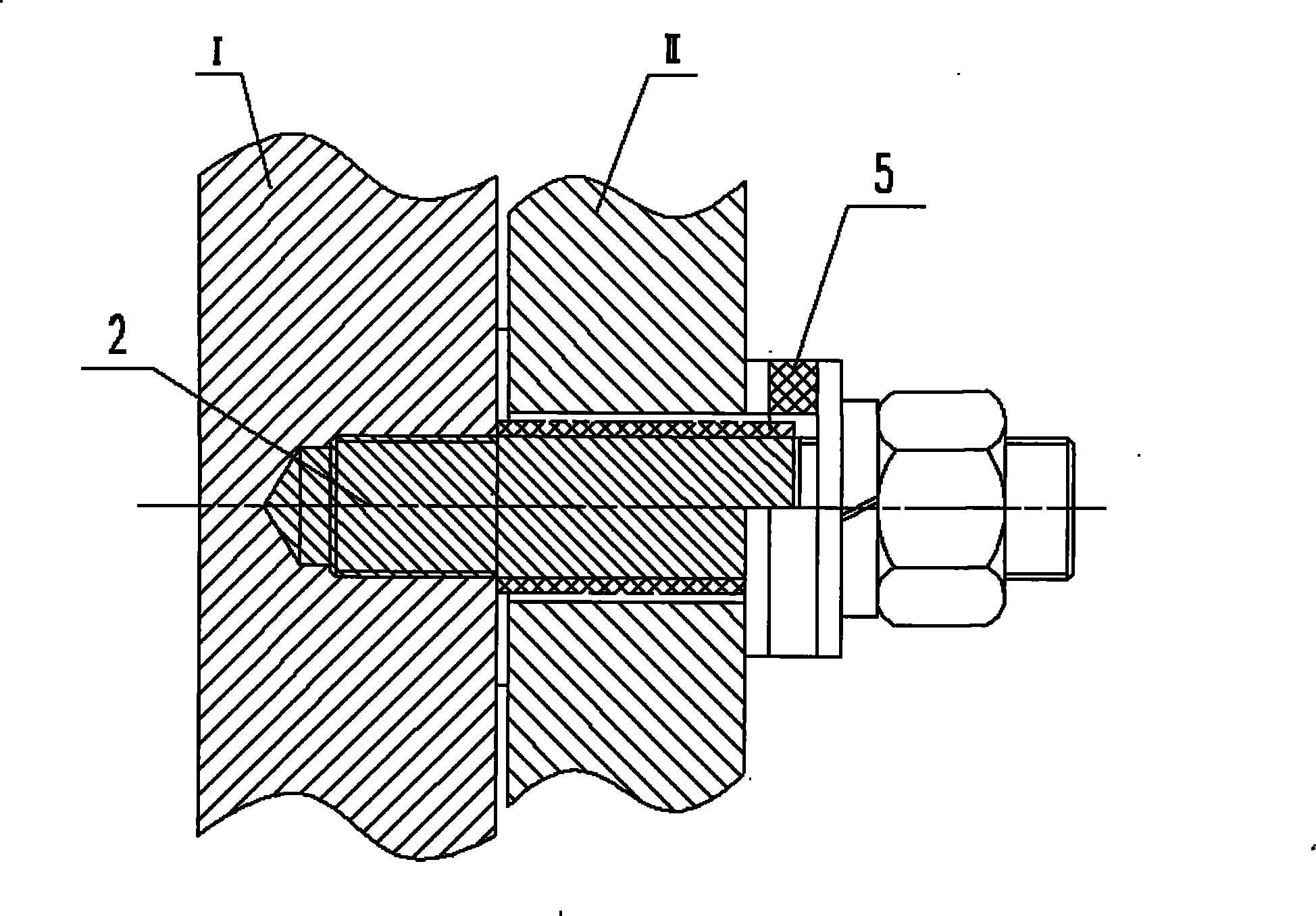

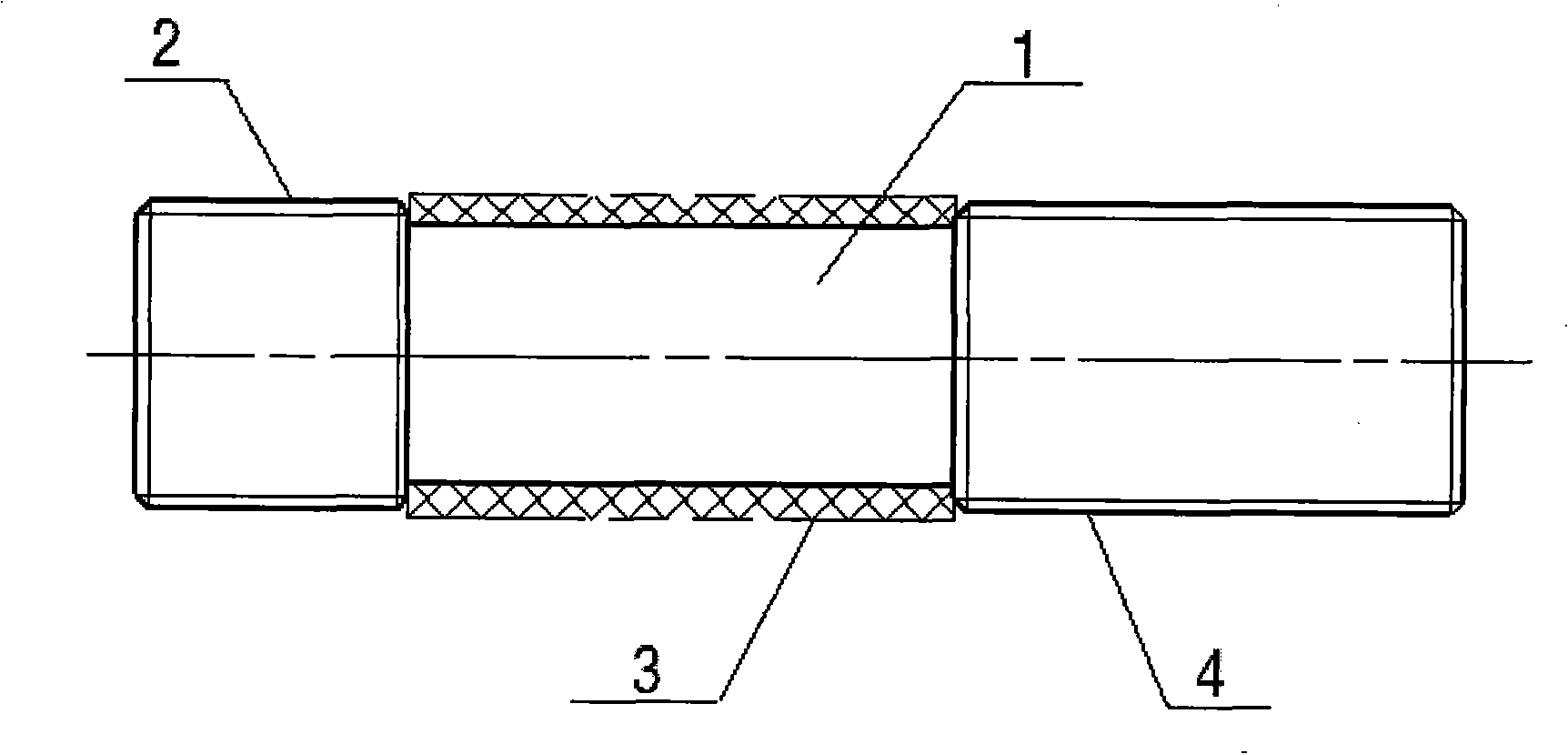

[0020] like image 3 , Figure 4 As shown, the middle of the metal screw can also be processed into a thin waist in advance. 1. Wrap non-weft glass filaments in the middle of the screw, with a thickness of about 1-4 mm. The specific method and requirements for insulating are the same as in Example 1. The end 2 is screwed into the structural member In the flange blind hole of I, the insulating layer 3 extends into the flange hole of the structural part II, and isolates the structural part I, the structural part II from the thin waist part 1 in the middle of the screw; the end part 4 passes through the gasket and the insulating washer 5, the spring The washer is connected to the nut; the insulating layer 3 of the screw must extend into the insulating washer 5.

Embodiment 3

[0022] When metal bolts are used for connection, the middle of the bolt has a thin waist or no thin waist, such as Figure 5 , Figure 6 As shown, there is no thin waist in the middle of the bolt, and there is no weft glass filament winding in the middle, with a thickness of about 1-4 mm. The specific method and requirements of the insulation are the same as in Example 1. Pass the insulating layer 3 through the flange holes of the structural parts II and I, and the end 2 connects the nuts through the washers and spring washers; the insulating layer 3 extending into the flange holes of the structural parts I and II connects the structural parts I, II and The insulating layer 3 in the middle of the bolt is isolated for one section; the bolt is fastened after the end part 4 is combined with the washer and the insulating washer; the insulating layer 3 of the bolt must extend into the insulating washer 5 .

[0023] The metal screw or bolt insulation method of the present invention...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com