Automatic quick cable-stripping machine

A wire stripping machine, fast technology, applied in the direction of line/collector parts, electrical components, equipment for dismantling/armored cables, etc. The effect of cutting labor saving and good electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

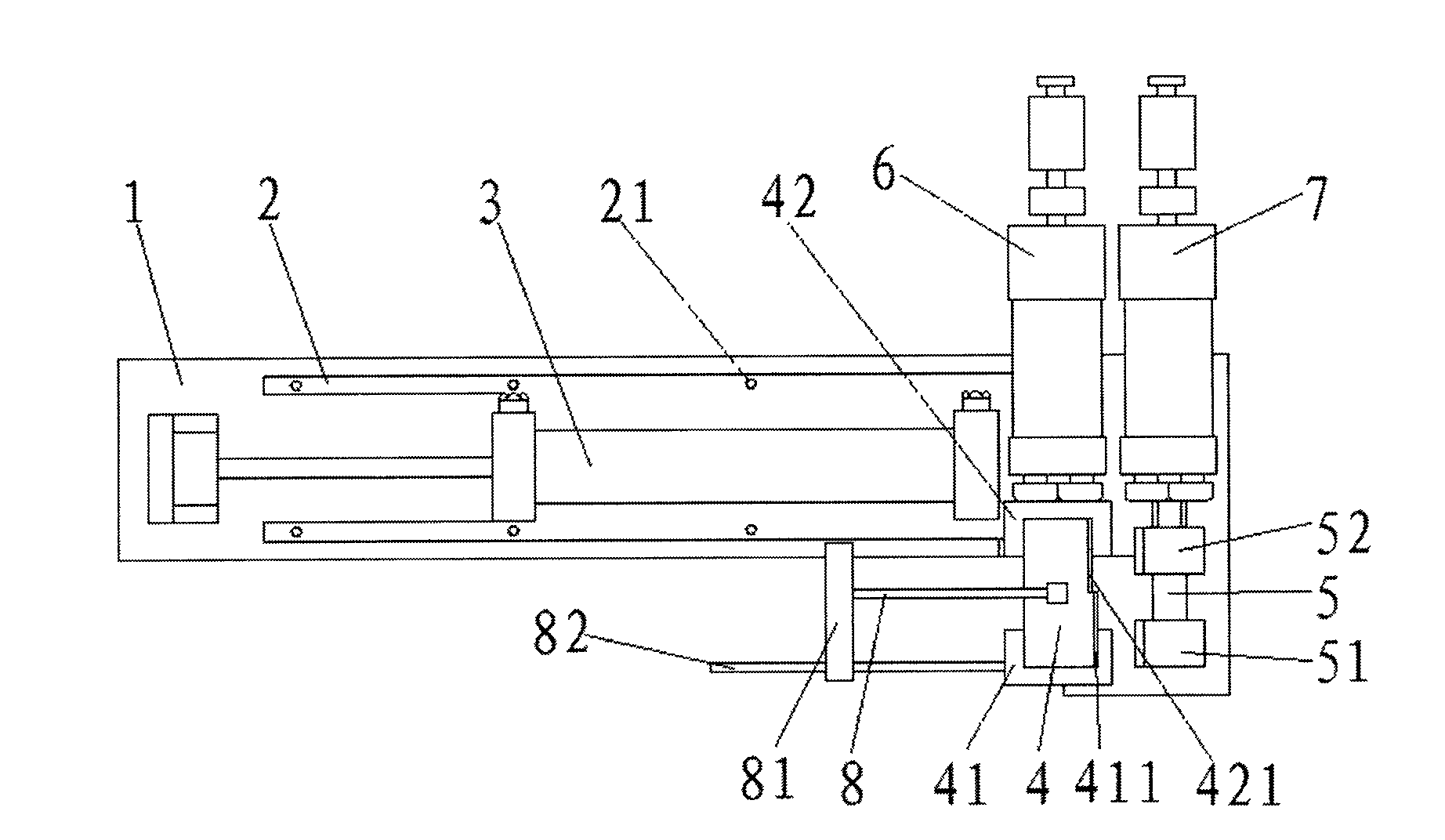

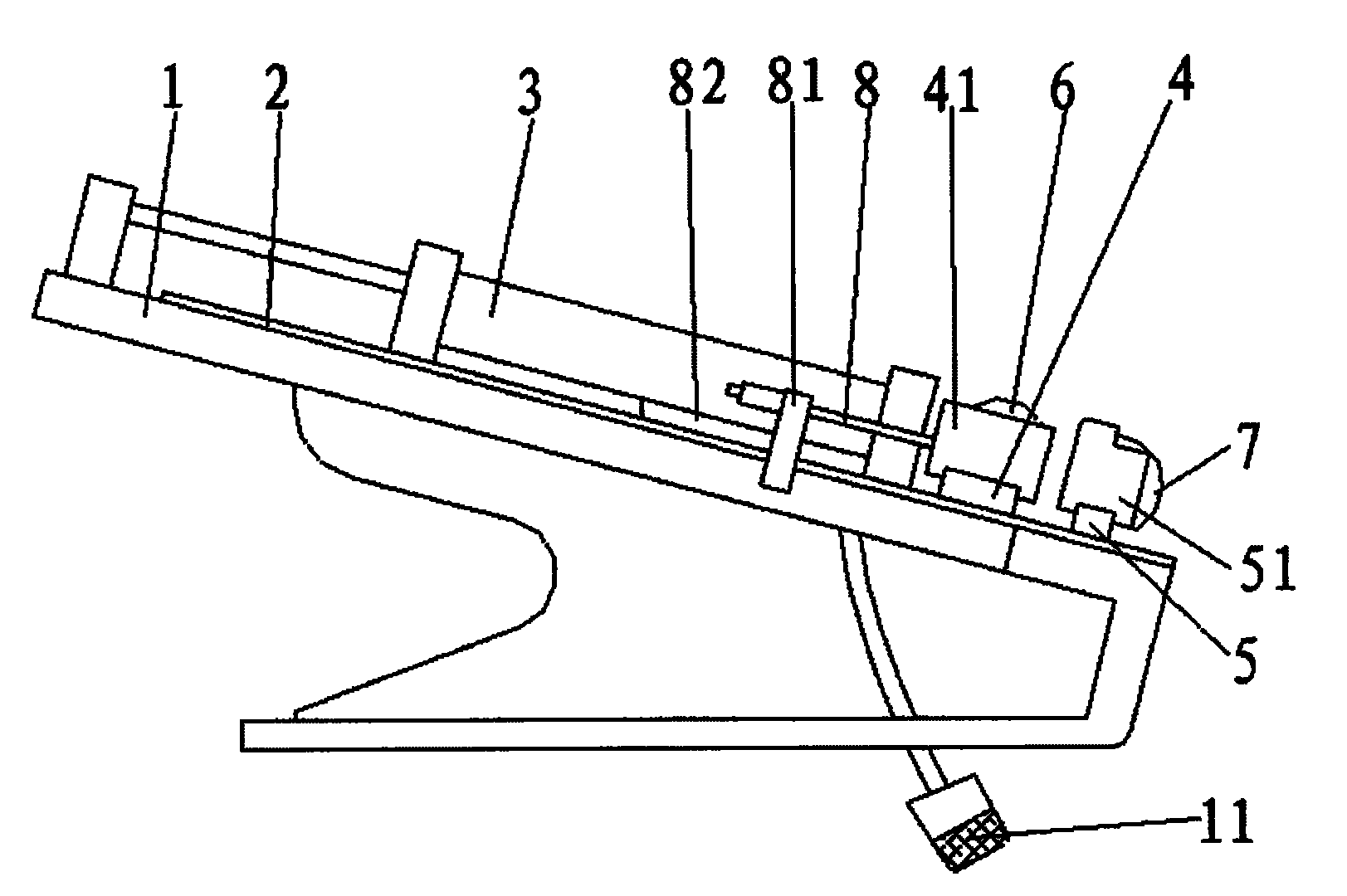

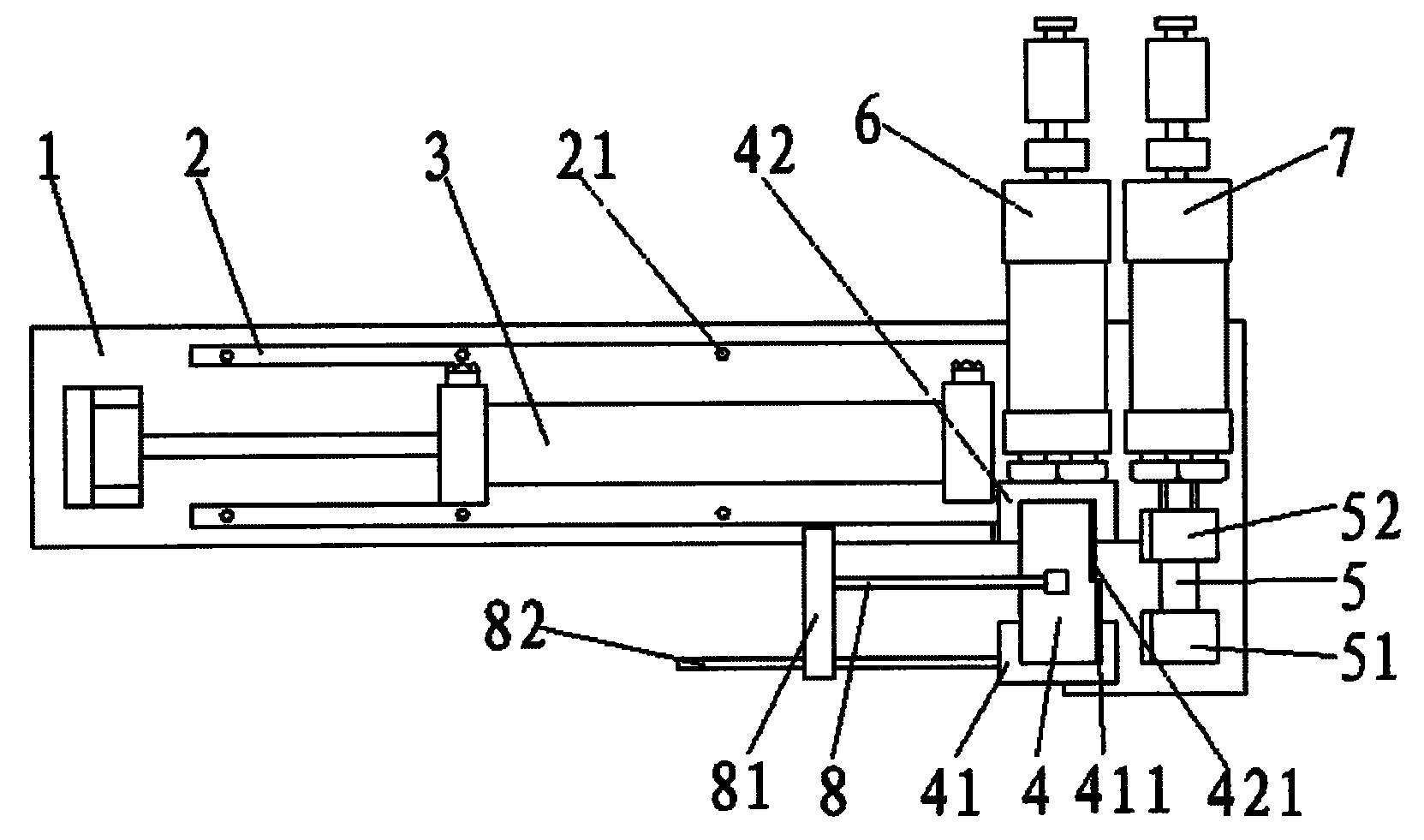

[0014] Such as figure 1 , figure 2 As shown, an automatic fast wire stripping machine includes a base 1, a slide 2 is provided on the base 1, and is fixed by screws 21; a first cylinder 3 is provided on the slide 1, and a foot switch 11 starts, the first cylinder 3 is driven by the air pump to move, the upper guide rail 4 and the lower guide rail 5 are fixed side by side on one end of the base 1 respectively, the upper guide rail 4 is provided with a left slider 41 and a right slider 42, the right The slide block 42 is connected on the second cylinder 6, the left slide block 41 is provided with a left blade 411, the right slide block 42 is provided with a right blade 421, and the lower guide rail 5 is provided with a left clamping block 51 and The right clamping block 52, the right clamping block 52 is connected to the third cylinder 7, the base 1 is provided with a wire retaining rod 8, and is connected to the base 1 through a fixed block 81, and one end of the cable withst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com