Preparation method of zinc oxide lightning arrester valve plate

A zinc oxide, arrester technology, applied in resistors, resistance manufacturing, electrical components and other directions, can solve the problem of low energy consumption, and achieve the effect of low energy consumption, high efficiency and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

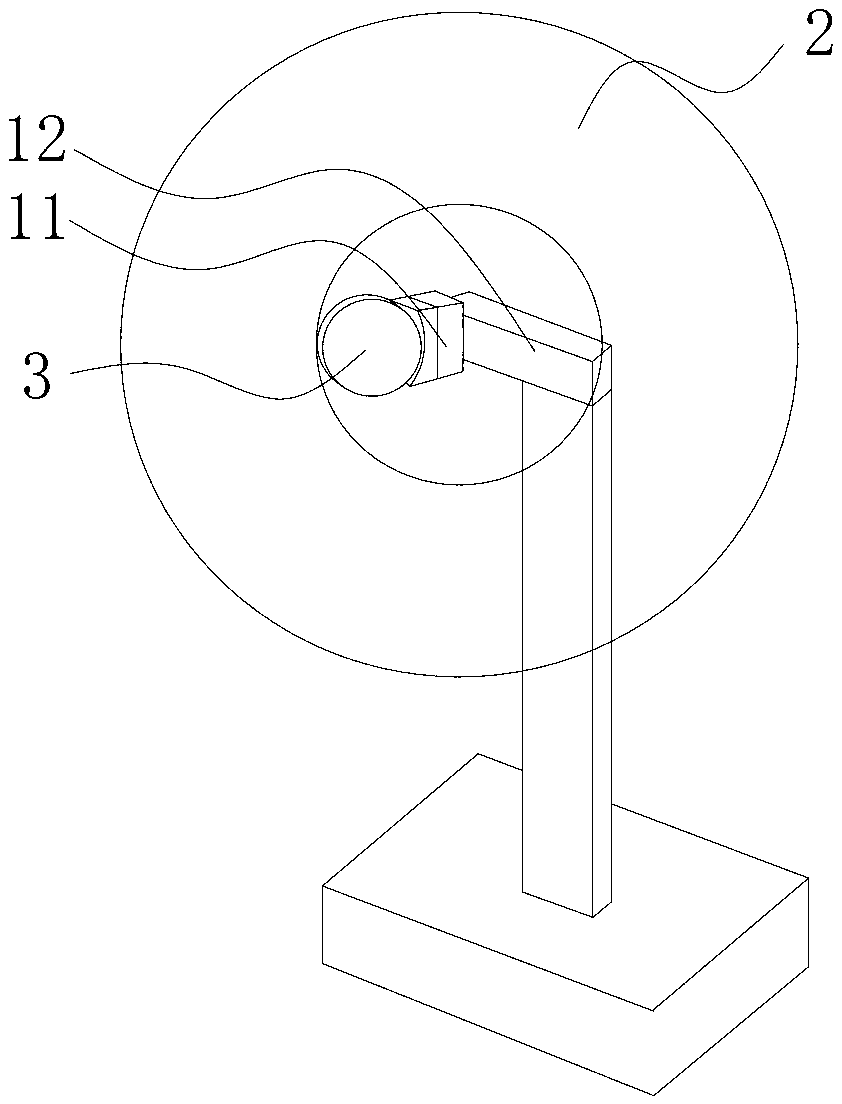

[0027] This embodiment provides a method for preparing a zinc oxide surge arrester valve plate. After the raw material of zinc oxide is ground, granulated, formed, glue removed, high-resistance layer applied, sintered, and glazed, a zinc oxide magnet is formed, and then the cutting step is adopted. Correct the flat shape and shape of the end face of the zinc oxide magnet, spray aluminum on the end face of the zinc oxide magnet after cutting, and make the valve plate of the zinc oxide arrester.

[0028] In this embodiment, the cutting step includes:

[0029] Using a fixture to install and fasten the zinc oxide magnet on the cutting machine table;

[0030] Adjust the tension of the cutter blade, set the cutting depth, align the blade on the radial angle of the end face of the zinc oxide magnet, start cutting, and add circulating coolant at the same time; use the cut end face as the reference plane, stop and set Cutting width and cutting times, continuous automatic cutting after...

Embodiment 2

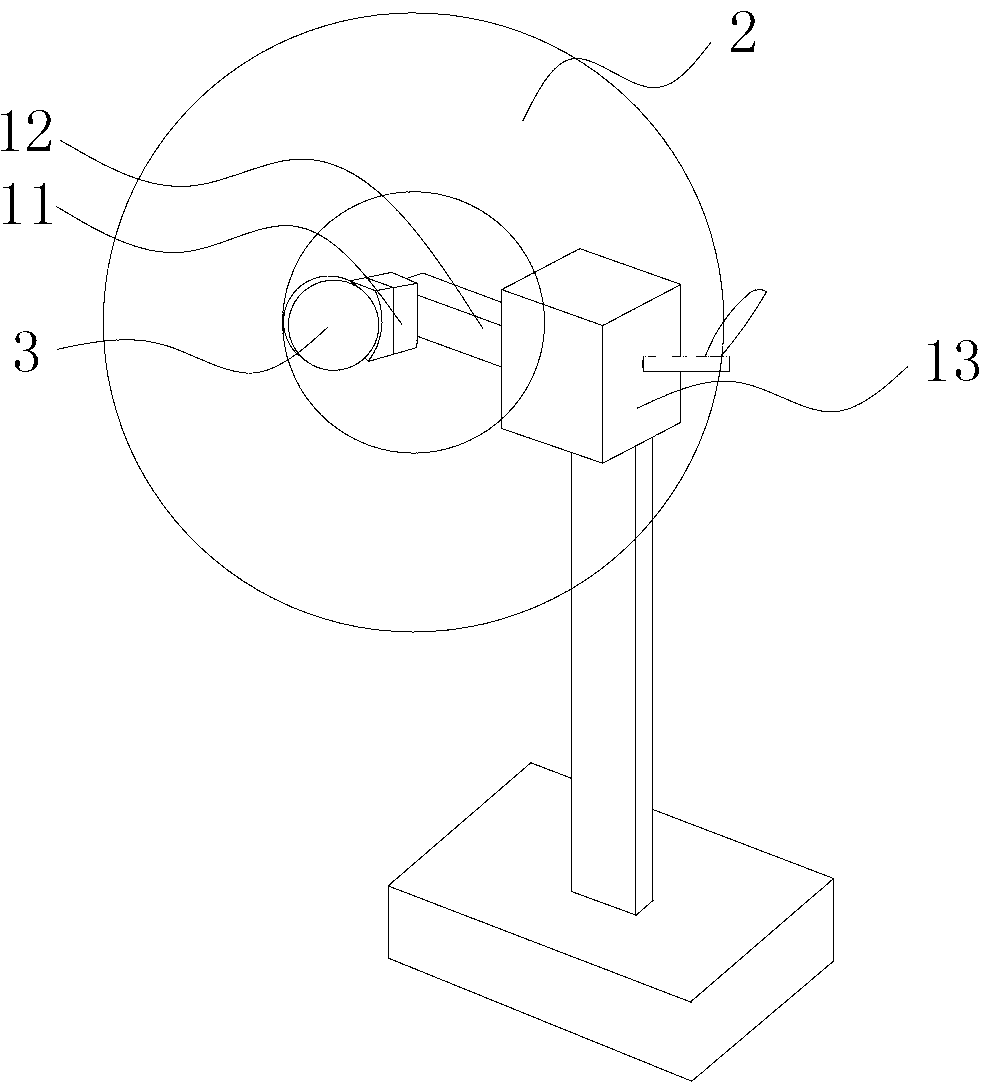

[0042] The only difference between this embodiment and Embodiment 1 is that this embodiment uses a split-type fixture to install and fasten the zinc oxide magnet on the cutting machine table;

[0043] Such as figure 2 As shown, the split-type tooling fixture 1 includes an adhesive material seat 11 and a fixed seat 12. The adhesive material seat 11 and the fixed seat 12 are split structures, and the vertical direction between the adhesive material seat and the fixed seat is adopted. The vertical phase indexing structure 13 is connected, or a horizontal phase indexing structure 14 is used to connect in the horizontal direction between the adhesive material seat and the fixed seat. Using this kind of fixture, during the cutting process, the zinc oxide magnet does not move, that is, the reference remains unchanged, and the vertical phase indexing structure 13 or the horizontal phase indexing mechanism 14 can be adjusted to cut the zinc oxide magnet from the second direction 3. ...

Embodiment 3

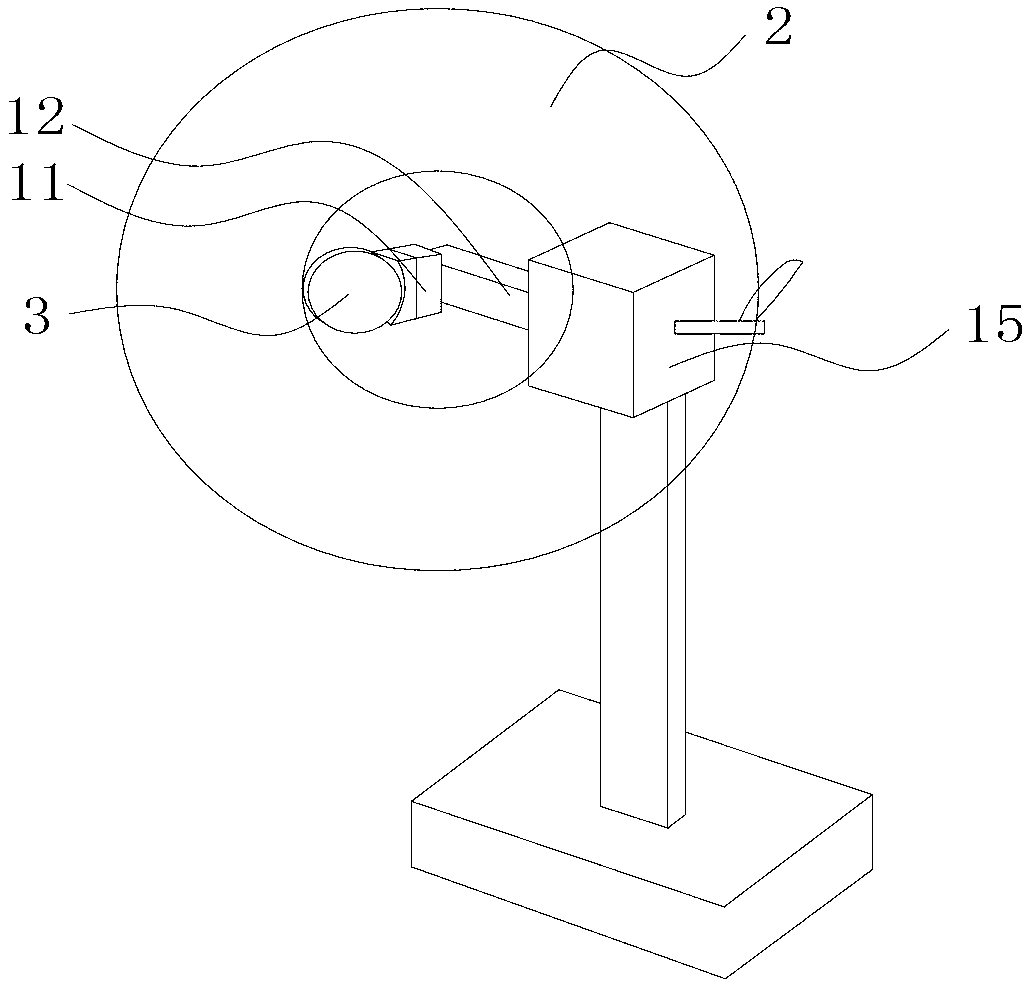

[0045] The difference between this embodiment and Embodiment 2 is that: in this embodiment, in addition to adopting a vertical phase indexing structure 13 to connect the vertical direction between the adhesive material seat 11 and the fixed seat 12, it is also possible to The horizontal direction between the adhesive material seat and the fixed seat is connected by a horizontal phase indexing structure 14, such as image 3 As shown, the vertical phase indexing structure and the horizontal phase indexing structure can be a combined indexing structure 15, so that the zinc oxide magnet can be cut from three-dimensional directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com