Flange forging technology

A flange and process technology, applied in the field of flange production, can solve problems such as time-consuming, save time, provide efficiency, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

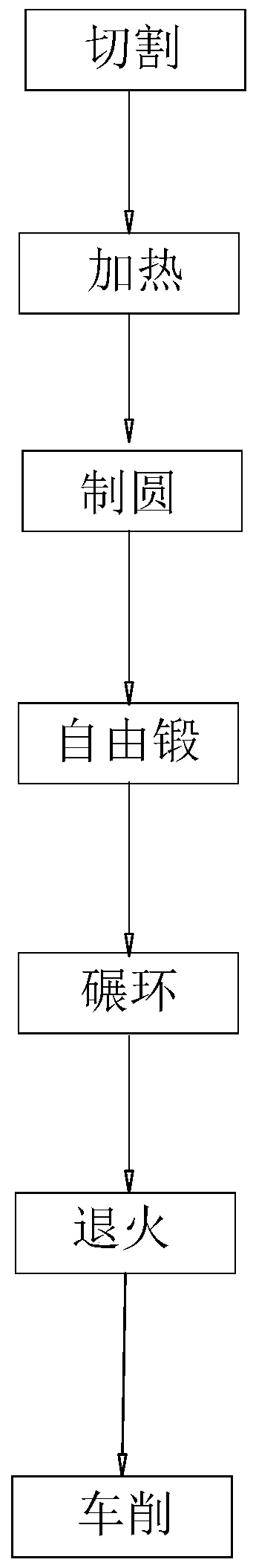

[0035] Example: such as figure 1 As shown, it is a flange forging process disclosed in the present invention, step S1: cutting, using a band saw to cut a long blank with a square cross section, and cut it into multiple billets. The weight of each billet is 1.05 to 1.10 times the weight of the qualified flange. The required weight can be converted into the volume of the required billet through the relational formula of density, mass and volume, and then the length of the required billet can be calculated through the cross-sectional area of the billet, and the required length can be calculated by cutting according to the length. Quality billets.

[0036] Step S2: Heating, placing the billet in a natural gas furnace for heating, the temperature of the natural gas heating furnace is 1180°C~1220°C, so that the temperature of the billet is higher than the recrystallization temperature and lower than the solidus temperature.

[0037] Step S3: making a circle, the billet is placed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com