Fast copper bar cut-off machine

A cutting machine and bar cutting machine technology, which is applied to metal sawing equipment, sawing machine devices, metal processing equipment, etc., can solve the problems of material waste and uneven cutting surface of metal bars, save raw materials, improve efficiency, and improve utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

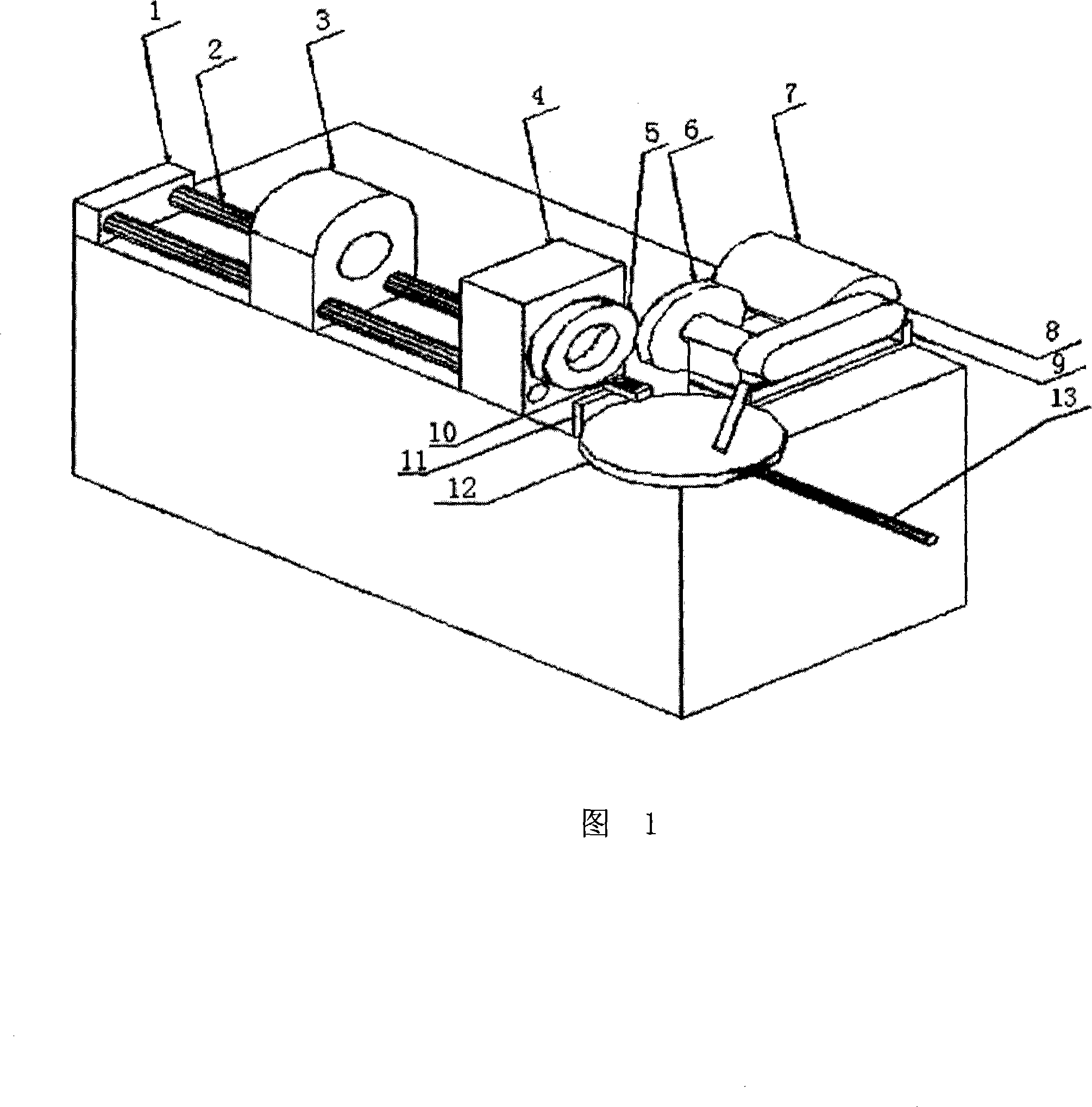

[0017] Embodiment: Referring to FIG. 1 , a fast copper rod cutting machine provided by the present invention includes a base on which a chuck 5 fixing seat, that is, a spindle box 4 and a sawing motor 7 are provided. A rotating motor and a driving gear set are arranged in the base. The outside of the main shaft box 4 is provided with a collet 5, which is fixedly connected with the rotating shaft in the main shaft case 4, and the belt pulley of the rotating shaft is connected with the drive gear group through a belt; Two parallel guide posts 2 are arranged on the top, and the spindle box 4 is arranged at one end of the guide posts 2 . A pipe slider 3 is arranged on the guide post 2 . A pipe hole is provided on the pipe slider 3, and the central axis of the pipe hole overlaps with the axis of the rotating shaft. Pipe slider 3 is used to support the other end of the metal rod. While spinning, the other end of the metal rod rests in the tube hole.

[0018] A saw motor slide bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com