Plant-derived PET master batch, preparation method and application thereof

A plant source and masterbatch technology, applied in the field of PET, can solve the problems of not being able to make good use of natural plants, and achieve the effects of improving dyeing performance, reducing carbonization, and improving breaking strength and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

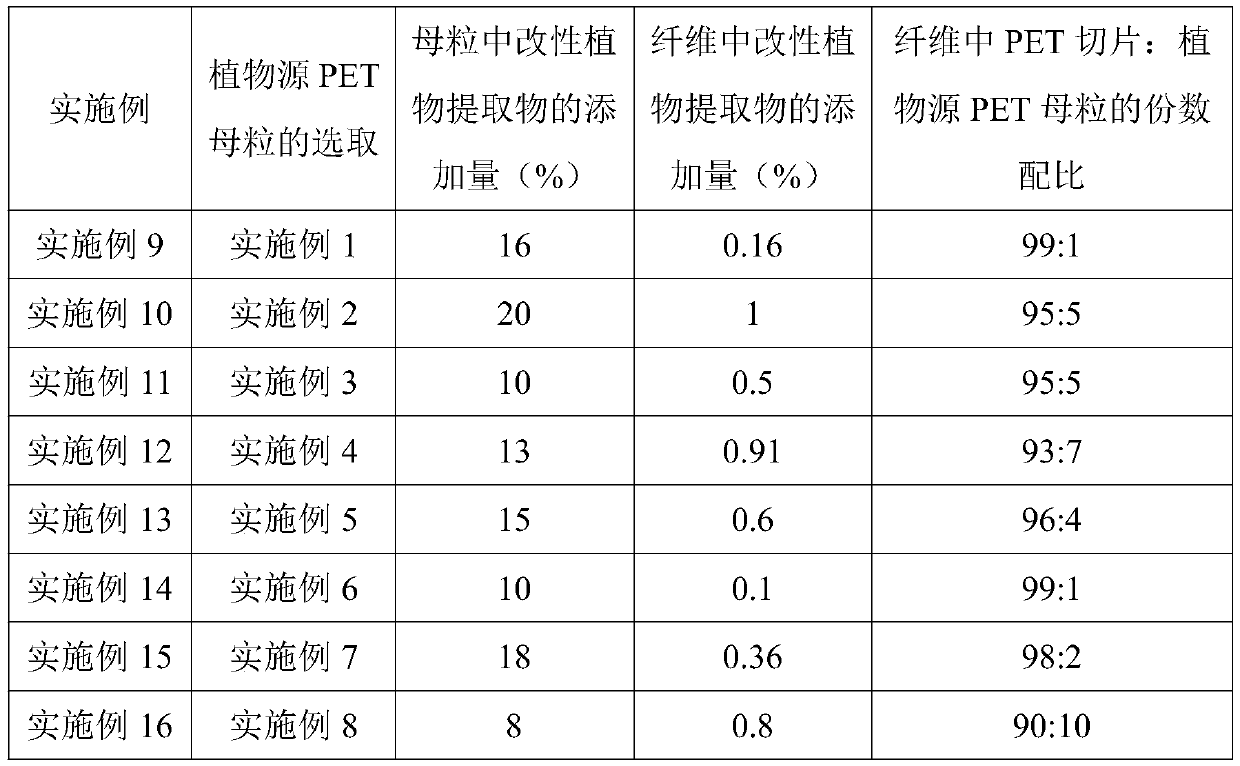

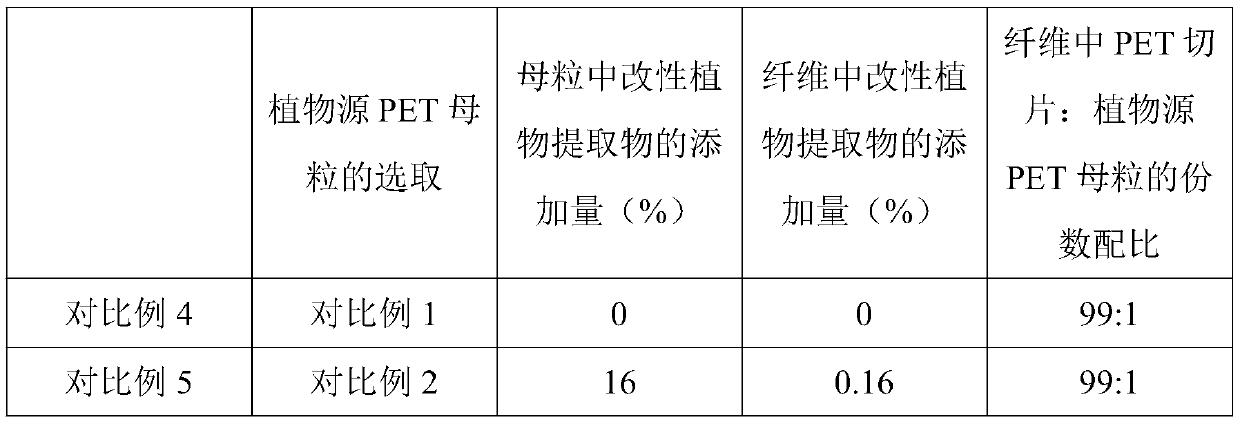

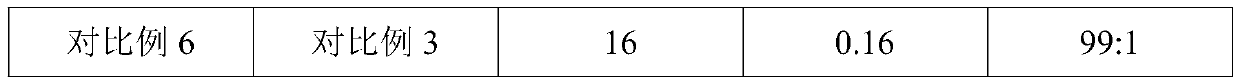

Examples

Embodiment 1-8

[0035] One, the preparation of embodiment 1-8 plant source PET masterbatch

[0036] All plant extract powders are commercially available, and 99.5% of the powder must pass through a 10,000-mesh sieve; the powder is loose in appearance, without agglomeration, and has no visible impurities; the color has the inherent color of the plant, and is uniform; the smell is uniform; Moisture ≤ 5%; total bacterial colony < 1000cfu / g, Salmonella and Escherichia coli cannot be detected.

Embodiment 1

[0037] Embodiment 1 A kind of preparation of lavender PET masterbatch

[0038] Mix 50 parts of lavender extract powder, 15 parts of chitin and 4 parts of starch, add 50 parts of deionized water, adjust the pH to 7 with sodium carbonate, heat to 45-70°C and mix well, shake the resultant and decompress Distill for 0.5-1h, then dissolve in 40 parts of deionized water, filter through a semi-permeable membrane for 0.8h, add 10 parts of acrylic acid to the filtered film, put it into a banbury mixer for 1.1h. The product obtained after banburying is dried and pulverized to obtain modified lavender extract. The prepared modified lavender extract has good compatibility and the mesh number is 10000 mesh.

[0039] Add 4 parts of reaction aids in 160 parts of modified lavender extracts, stir with the speed of 1800rad / min. 840 parts of PET slices were melted and stirred, then added modified lavender extract containing reaction aids, 0.16 parts of EBS P-200, 0.164 parts of tourmaline powd...

Embodiment 2

[0040] Embodiment 2 A kind of preparation of Peppermint PET masterbatch

[0041] Mix 65 parts of mint extract powder, 25 parts of chitin and 7 parts of starch, add 80 parts of deionized water, adjust the pH to 7 with sodium carbonate, heat to 45-70°C and mix well, shake the resultant and decompress Distilled for 1 hour, then dissolved in 50 parts of deionized water, filtered through a semi-permeable membrane for 1.5 hours, added 16 parts of acrylic acid to the filtered film, and put it into a banbury mixer for 2 hours. The product obtained after banburying is dried and pulverized to obtain a modified peppermint extract, which has good compatibility and has a mesh size of 10,000 mesh.

[0042] Add 0.6 parts of reaction auxiliary agent to 20 parts of modified peppermint extract, and stir at a speed of 1500-2000rad / min. Melt 80 parts of PET slices at 200-260 °C, after stirring, add modified peppermint extract containing reaction aids, 0.4 parts of EBS P-200, 0.031 parts of tourm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com