Device and method for performing multistage flash, resolution and separation on synthetic ammonia decarburization absorption tower bottom pregnant solution

An absorption tower and a technology for synthesizing ammonia, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of increasing the circulating volume of lean liquid and semi-lean liquid, increasing the processing capacity and energy consumption of the absorption tower, increasing Problems such as the gas phase temperature at the bottom of the absorption tower can be eliminated to achieve the effects of eliminating the bottleneck of the absorption tower, lowering the temperature, and reducing the cost of expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

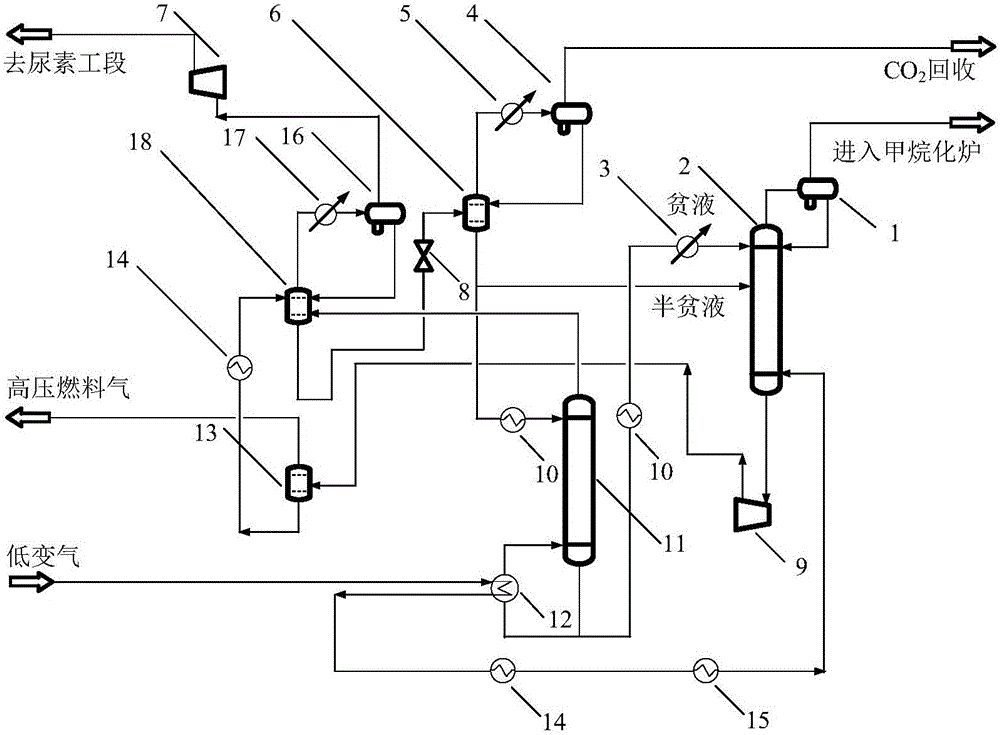

[0030] Such as figure 1 As shown, a multi-stage flash analysis and separation device for decarburization of the rich liquid at the bottom of the absorption tower for synthetic ammonia, including the separation tank 1 at the top of the absorption tower, CO 2 Absorption tower 2, water condenser 3, low-pressure flash tank top separation tank 4, low-pressure flash tank top condenser 5, low-pressure flash tank 6, CO 2 Compressor 7, throttle valve 8, hydraulic turbine 9, lean liquid / semi-lean liquid heat exchanger 10, desorption tower 11, low gas change / desorption tower bottom liquid heat exchanger 12, first-stage high-pressure flash tank 13 , Low gas change / first stage flash tank bottom liquid heat exchanger 14, low gas change / demineralized water heat exchanger 15, secondary high pressure flash tank top separation tank 16, secondary high pressure flash tank top condenser 17. Secondary high-pressure flash tank 18;

[0031] Among them, the rich liquid outlet at the bottom of the ab...

Embodiment 2

[0061] In Example 2, the multi-stage flash separation and analysis method of the present invention is specifically described by taking a 910,000-ton / year synthetic ammonia decarburization absorption tower rich liquid device as an example in a chemical plant.

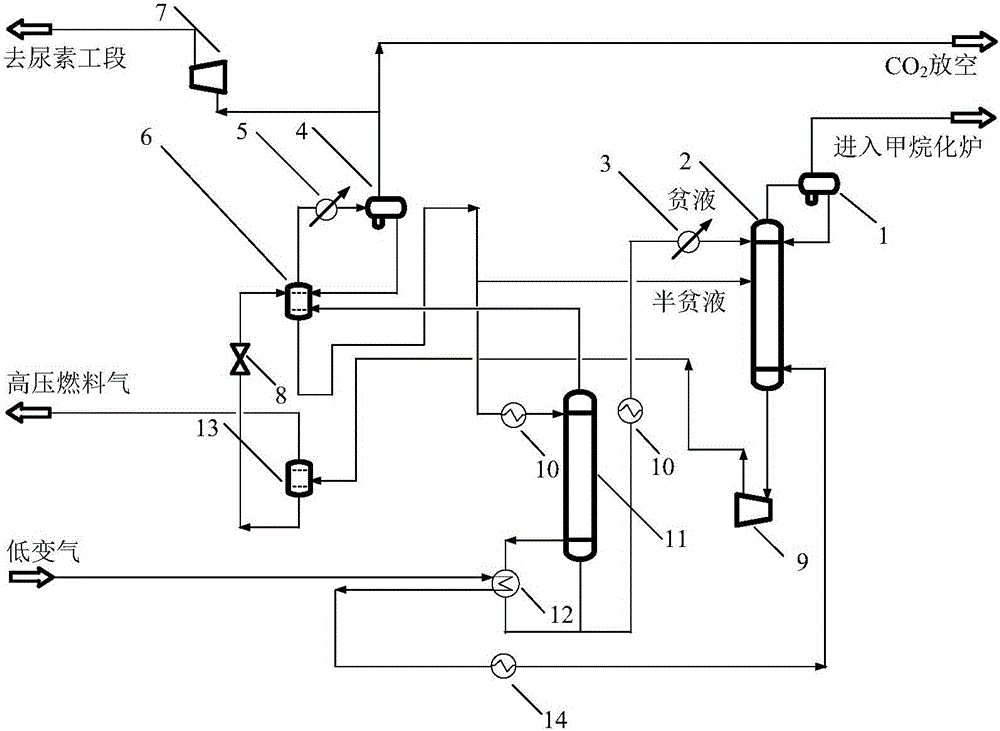

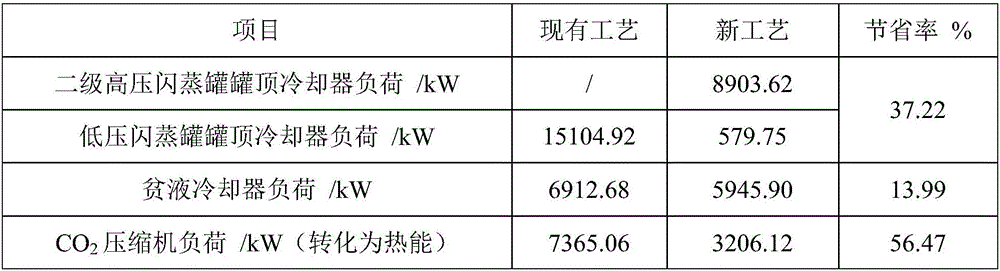

[0062] Table 4 is the 910,000 tons / year synthetic ammonia decarburization absorption tower bottom rich liquid analytical separation comparative example 1 and embodiment 1 device raw materials and composition, the raw materials, composition, product regulations and absorbent (MEA) of the two processes are exactly the same, Among them, the embodiment process is as follows figure 1 As shown, compare for example figure 2 shown. In Example 1, the medium and low-change gas is cooled to 40°C by three heat exchangers and then enters the absorption tower. The liquid phase pressure at the bottom of the first-stage high-pressure flash tank is 1.2MPa, and after heat exchange, the temperature is raised to 90°C and then enters the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com