Polyethyleneglycol dimethyl ether desulfurizing system optimization extracting and concentrating technology

A desulfurization system and process technology, applied in the direction of hydrogen sulfide, chemical instruments and methods, and separation of dispersed particles, can solve the problems of high heat consumption of regeneration tower, air pollution, low desulfurization rate of flash evaporation process, etc., and reduce flash pressure , increase the content of hydrogen sulfide, and effectively use the effect of flash space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

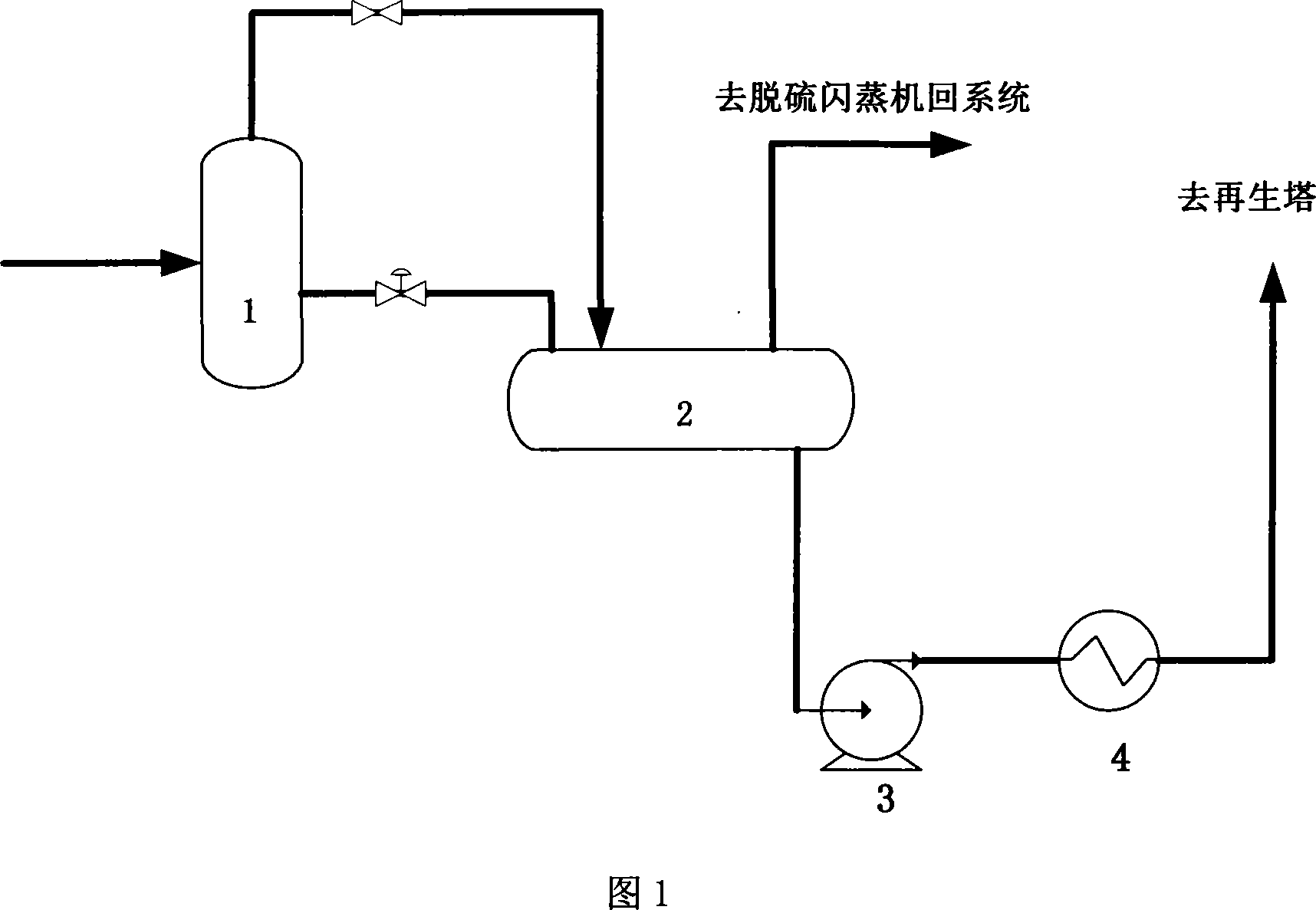

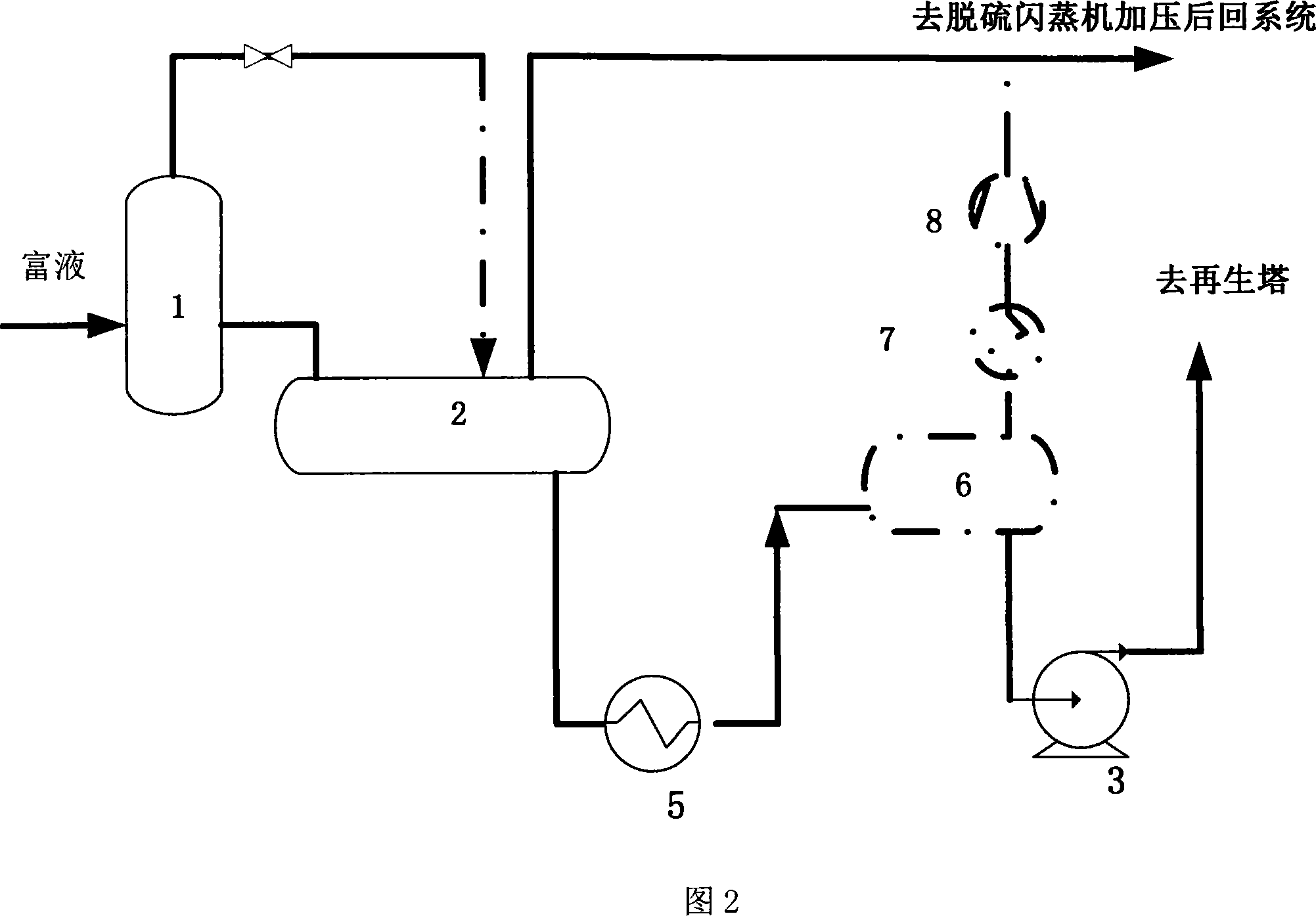

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] Flash evaporation process of the present invention among Fig. 2 is:

[0023] The rich NHD solution that has absorbed hydrogen sulfide is sent to the flash tank I1, and the flash tank I1 is connected to the gas phase inlet flash steam pipeline located on the gas phase outlet side of the flash tank II2. The flash steam pipeline at the gas phase inlet of flash tank II2 is moved to the gas phase outlet side to increase the flash space, enhance the flash evaporation effect and increase the concentration of acid gas.

[0024] The output pipeline of the flash tank II2 is connected with the heat exchanger 5, and the heat exchanger 5 raises the temperature of the rich liquid to 90-130°C (preferably 100-120°C) and sends it to the low-pressure flash tank 6, and the low-pressure flash tank 6 The pressure is less than 30KpA gauge pressure (preferably less th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com