Method for recovering tank car unloading gas and storage tank flash stream of LNG (liquefied natural gas) automobile gas station

A technology of unloading gas and flash gas, which is applied in the container discharge method, container filling method, fixed-capacity gas storage tank, etc., can solve the problems of waste safety, hidden dangers, etc., and achieve the goal of improving safety, reliability and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

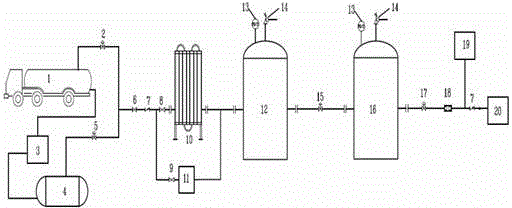

[0024] As attached figure 1 As shown, the specific operation steps of the present invention are as follows:

[0025] (2) When the unloading process starts, close the shutoff valve of the main pipe to connect the liquid phase and gas phase of the LNG tanker and the LNG storage tank for unloading. After the LNG unloading process is completed, when the gas phase pressure of the LNG tanker is 0.6-0.8MPa When, open the stop valve on the main pipe and the pressure regulating valve of the unloading gas pipeline, and close the pressure regulating valve of the flash steam pipeline;

[0026] (3) The unloading gas uses its own pressure to pass through the stop valve and the one-way check valve along the pipeline, enters the air-heated heater or the water bath electric heater, and enters the buffer tank after being heated by the heater. After the unloading gas comes out of the buffer tank After going through the pipeline through the primary pressure reducing valve for pressure reduction, it e...

Embodiment 2

[0038] When it is cold in winter when the temperature is less than 10℃, close the shut-off valve 8 in front of the air temperature heater 10, open the shut-off valve 9 in front of the water bath electric heater 11, and let the unloading gas enter the buffer after being heated by the water bath electric heater 11 Tank 12 avoids frosting of pipes due to low temperature in winter in the north. The rest is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com