Nitrogen rejection and liquifier system for liquified natural gas production

a liquifier and natural gas technology, applied in refrigeration, liquifaction, solidification, etc., can solve the problems of high energy requirements for purifying renewable methane, high capital and operating costs, and high cleanup costs of biogas/landfill gas, etc., to maximize liquefied natural gas production and minimize product flash losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022]Landfill gas is purified and all the water, sulfur compounds, NMOCs and carbon dioxide are removed in a pre-purification process. The purified gas contains methane, nitrogen and oxygen and has the following composition:

TABLE 1NRU Feed Gas CompositionSpeciesMole FractionCarbon Dioxide0.0100Nitrogen0.2160Methane0.7720Oxygen0.0020

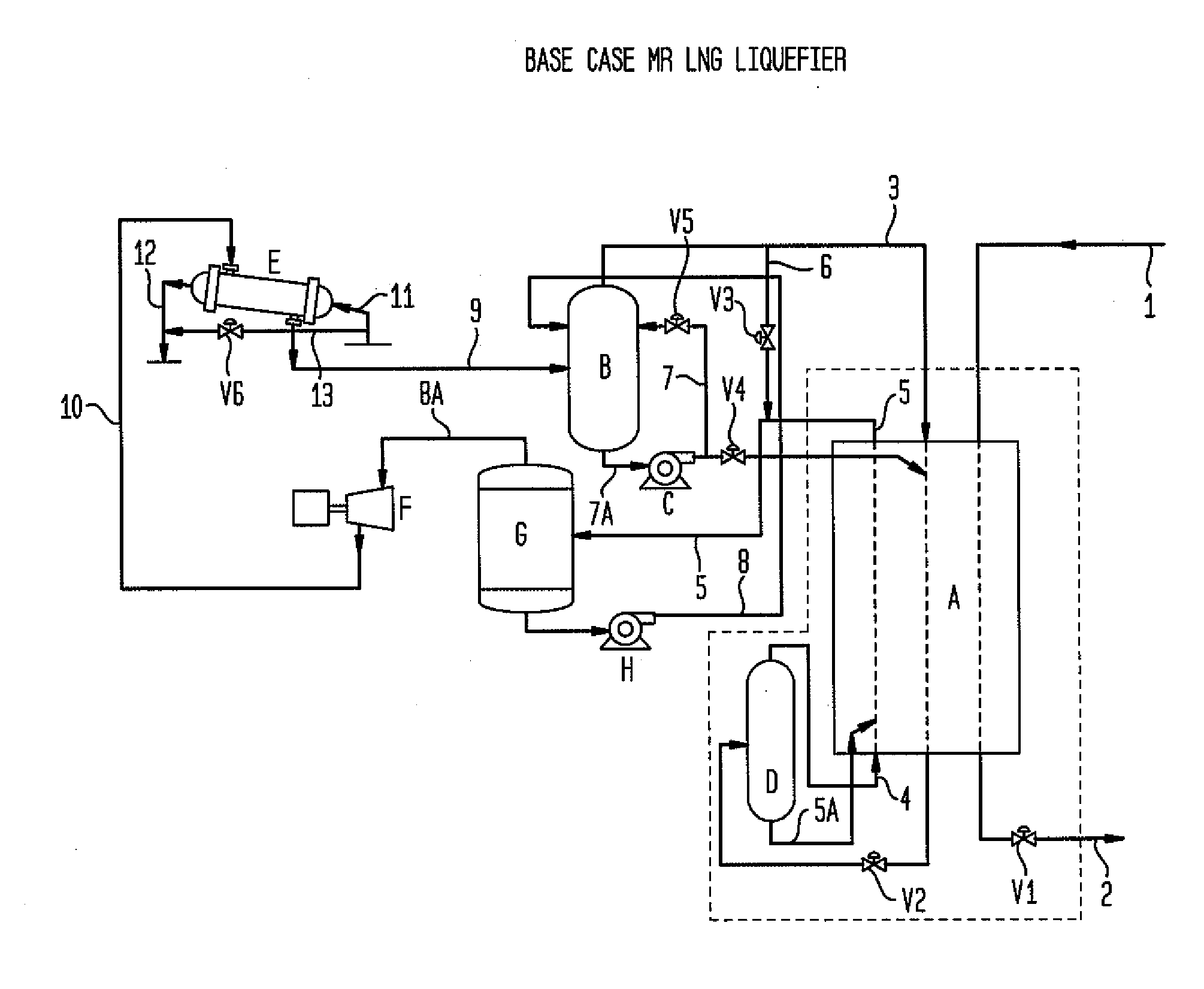

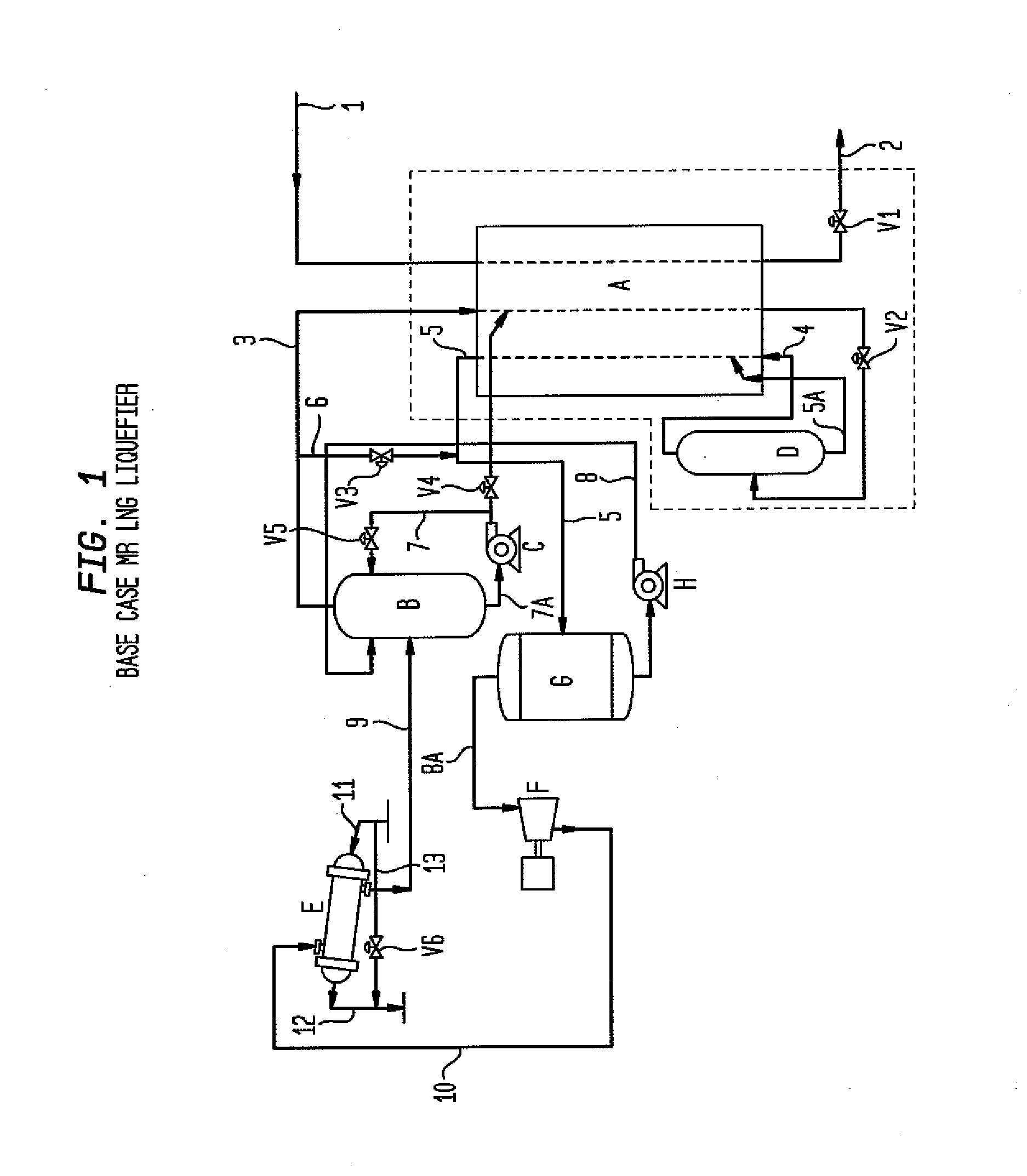

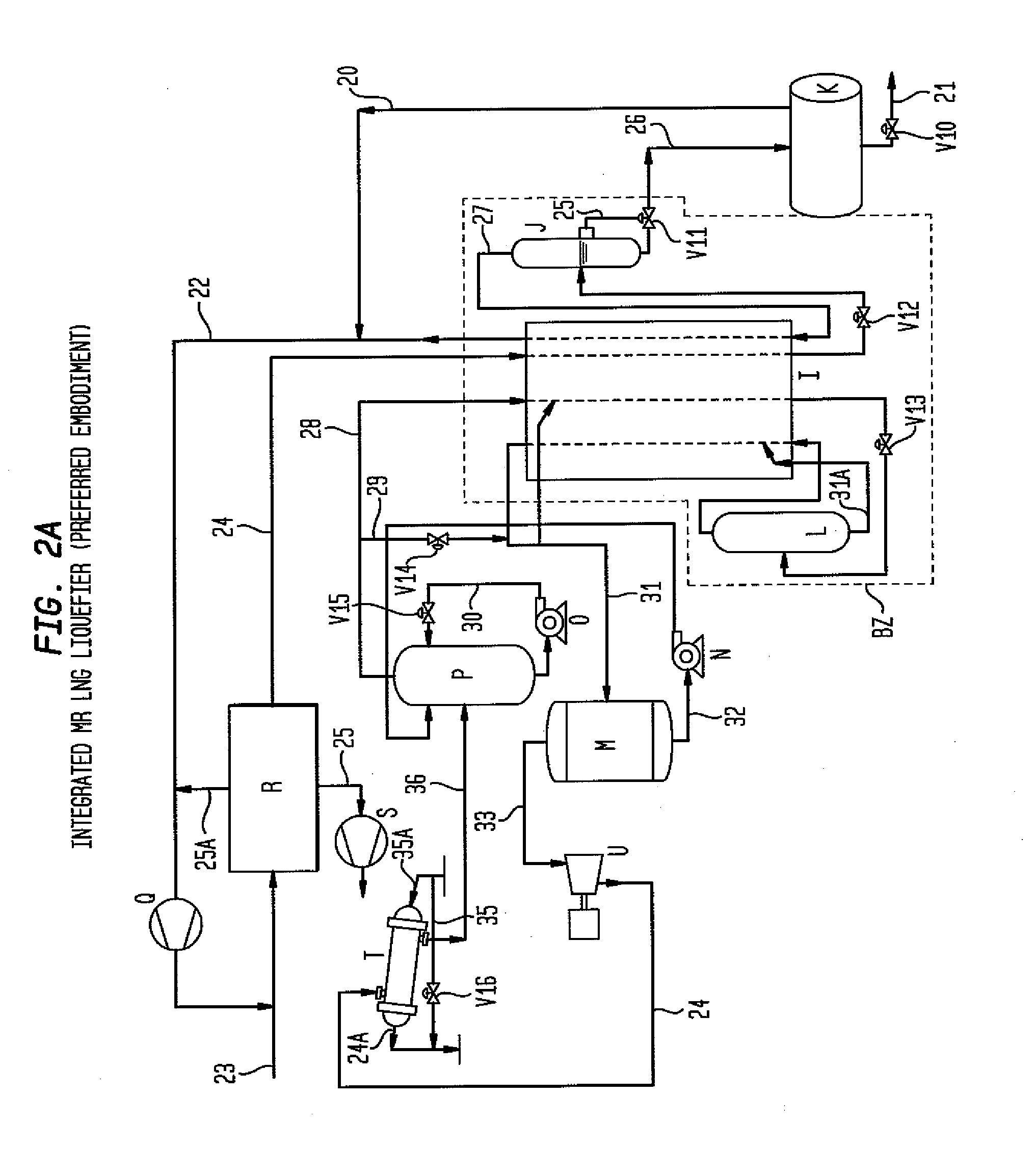

[0023]The gas is further purified in an adsorption system so that the carbon dioxide level is reduced below 50 ppmv and a large portion of the nitrogen is removed. Oxygen usually does not adsorb appreciably and about 50% of the oxygen is removed in each case. FIG. 1 illustrates a typical MR liquefier stream without process integration. In this case both storage tank losses and nitrogen rejection unit waste streams are not recovered.

[0024]Turning to the figures, FIG. 1, represents a base case mixed refrigerant liquefied natural gas liquefier. Purified natural gas is fed through line 1 through main heat exchanger A where it will be warmed and fed through v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com