LED lamp reuse process

A technology of LED lamps and processes, applied in the direction of solid waste removal, etc., can solve the problems of reducing the quality of recycled products and increasing the difficulty of separating phosphors, and achieve the effect of good separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

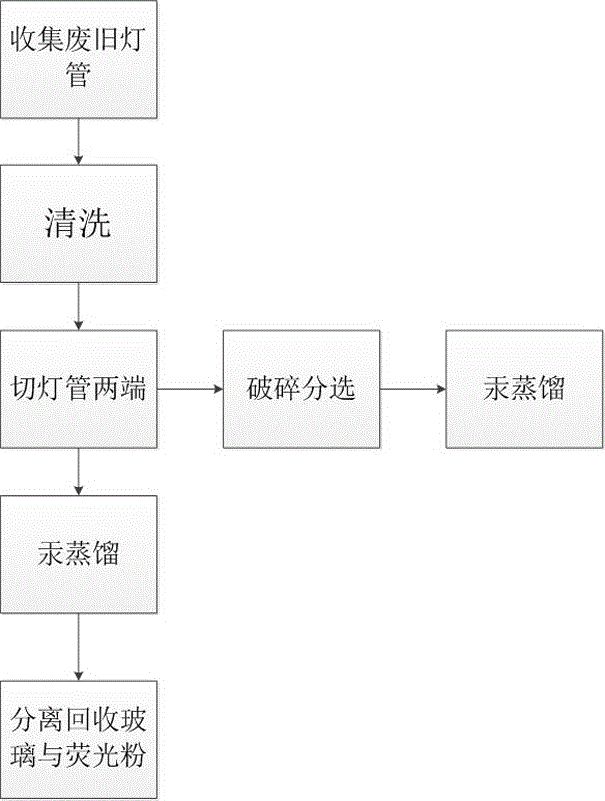

[0023] Such as figure 1 As shown, the LED lamp recycling process includes the following steps:

[0024] (A) Use waste fluorescent lamp recycling boxes in residential areas to recycle waste fluorescent lamps, and transfer them to the cleaning machine installed in the recycling workshop, and use the cleaning machine to clean the outside of the lamp tube;

[0025] (B) Use a cutting machine to cut both ends of the fluorescent lamp in a confined space, separate the lamp tube and the two lamp caps, remove the electronic components in the lamp tube, and then transfer the electronic components and lamp caps to the crusher for crushing, and the broken The final metal fragments and plastic fragments are separated, and the metal fragments and plastic fragments are sent to the metal recycler and the plastic recycler respectively, and the metal recycler and the plastic recycler are heated to distill off the mercury adsorbed on the metal fragments and plastic fragments;

[0026] (C) Heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com