Method for preparing high thermal stability double layer diffusion impervious layer material

A technology with high thermal stability and barrier layer, which is applied in metal material coating process, coating, semiconductor/solid-state device manufacturing, etc., to improve thermal stability, maintain integrity and avoid oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

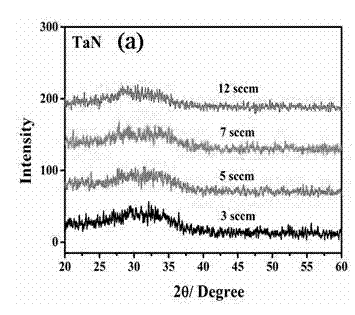

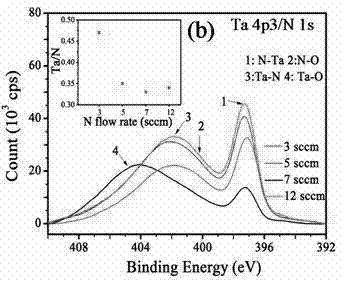

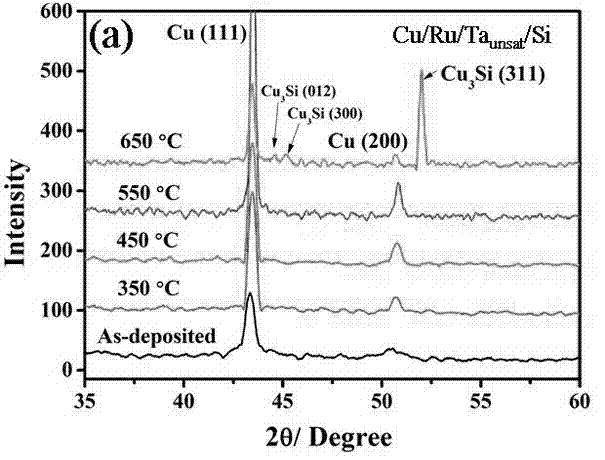

[0028] Ru / TaN films with different N contents were prepared by DC magnetron sputtering. A JGP350 magnetron sputtering apparatus uses an electromagnetic target with a diameter of 60mm and only DC is added, and the maximum sputtering power is 400W. A six-station sample turntable with revolution function, the sample can be heated or water-cooled, the maximum temperature can reach 550°C, the heating rate can be adjusted from 10°C / min to 40°C / min, suitable for the preparation of various materials film. The vacuum system is mainly equipped with a 2XZ-8 mechanical pump and FB600 turbomolecular pump, the highest vacuum degree can reach 6.6×10 -5 Pa, the ultra-high vacuum effectively protects the quality of the film.

[0029] Material preparation: the sputtering target is 99.9% Ta, 99.9% Ru, 99.999% Cu with a diameter of 60 mm and a thickness of about 3 mm, and the substrate is single crystal Si (111). In order to improve the adhesion between the TaN film and the substrate, before th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com