Method for converting nano graphite into one-dimensional carbon nano fiber by laser irradiation

A carbon nanofiber and nanographite technology, applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of polluted environment, long manufacturing cycle, small output and difficult continuous growth, etc., to avoid environmental pollution and save manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

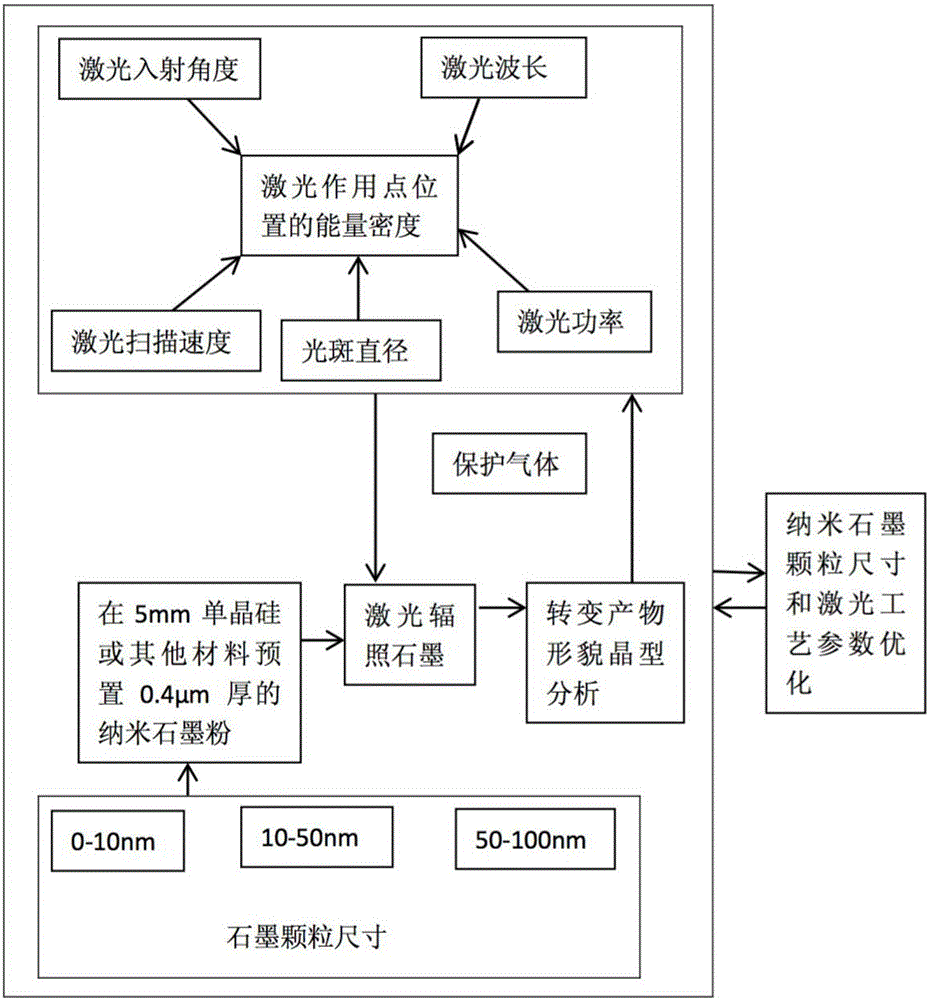

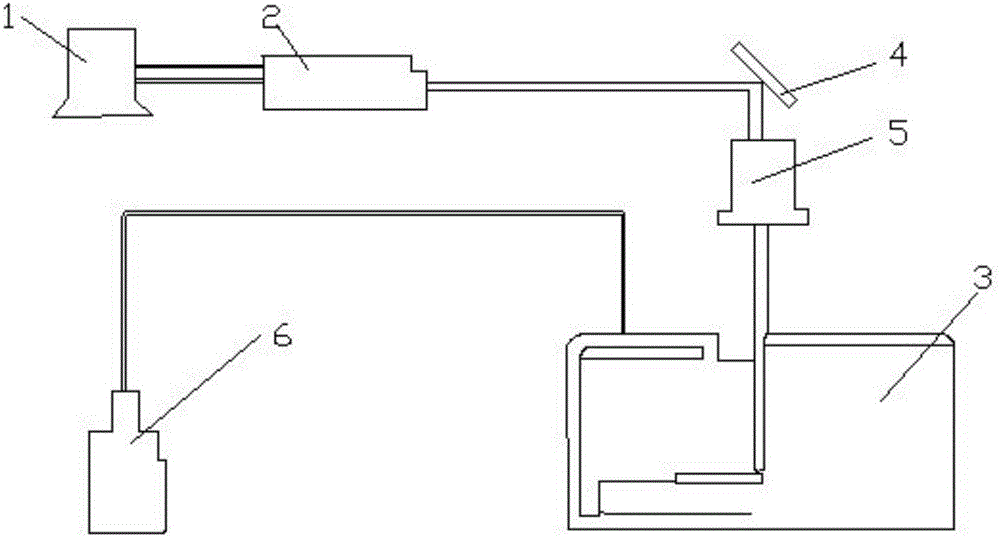

[0042] Such as figure 1 As shown, a method for converting one-dimensional carbon nanofibers into one-dimensional carbon nanofibers by laser irradiation of nano-graphite in this embodiment comprises the following steps: figure 2 as shown, figure 2 It is a schematic diagram of an experimental device for transforming one-dimensional carbon nanofibers into one-dimensional carbon nanofibers by laser irradiation of the present invention; it mainly includes a computer 1, the computer 1 is connected to the laser 2, and the laser 2 and the airtight container 3 are scanned The vibrating mirror 4 provides an angle of vertical incidence; the airtight container 3 is also installed with a protective atmosphere device 5;

[0043]1) According to the melting point of graphite, material properties, phase transition temperature, graphite size, (the physical parameters of nano-graphite are shown in Table 1, and Table 1 is the physical parameter table of nano-graphite of the present embodiment)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com