Process for comprehensively recycling electrolytic manganese residues and manganese tailings

A technology of electrolytic manganese slag and manganese tailings, applied in the direction of improving process efficiency, etc., can solve the problems of high impurity content, no recycling value, occupying land resources, high recycling cost, etc., and achieve low price, low energy consumption, and reduced alkali consumption cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

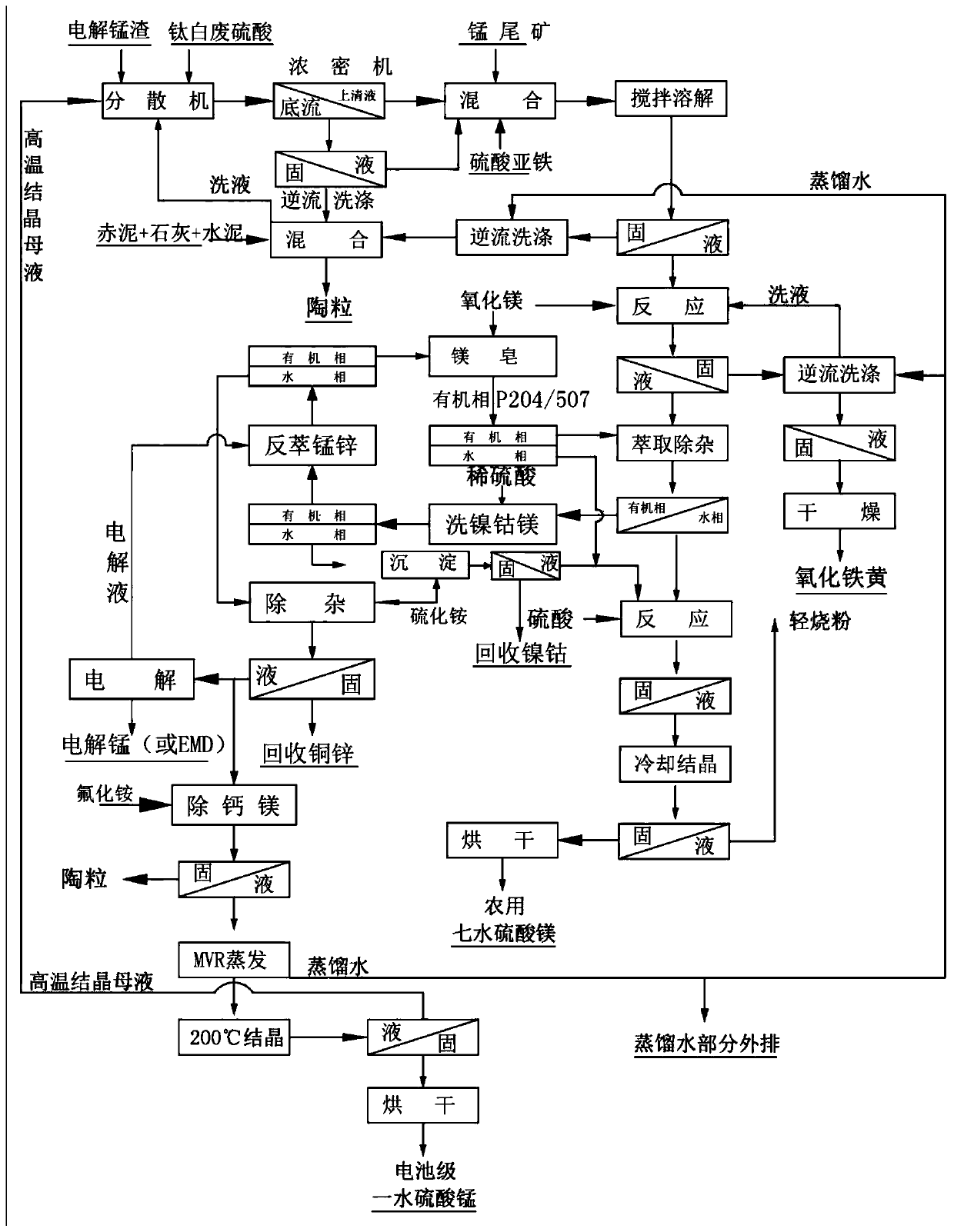

Image

Examples

Embodiment

[0021] A process for comprehensively recycling electrolytic manganese slag and manganese tailings, specifically comprising the following steps:

[0022] 1) Use a disperser to crush the electrolytic manganese slag in liquid phase, mix and react the liquid phase crushed electrolytic manganese slag and waste titanium white sulfuric acid, and use the residual acid and ferrous ions in the waste titanium white sulfuric acid to completely leach the electrolytic manganese slag The manganese ions in various valence states are then separated and concentrated by a thickener to obtain leaching residue and leaching solution;

[0023] 2) After the leaching slag is neutralized and colloidized with alkaline substances, cement lime is added to form and solidify to produce building environmental protection bricks and ceramsite;

[0024] 3) adding manganese tailings to step 1) obtained leaching solution, obtaining the leaching solution whose ferrous ion and sulfuric acid content all meet technol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com