AlN single crystal substrate production apparatus and application method thereof

A technology for producing equipment and substrates, which is applied in the directions of single crystal growth, single crystal growth, crystal growth, etc., can solve problems such as failure to grow, poor equipment stability, and restriction of AlN crystal growth, so as to ensure stability, ensure stability and The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

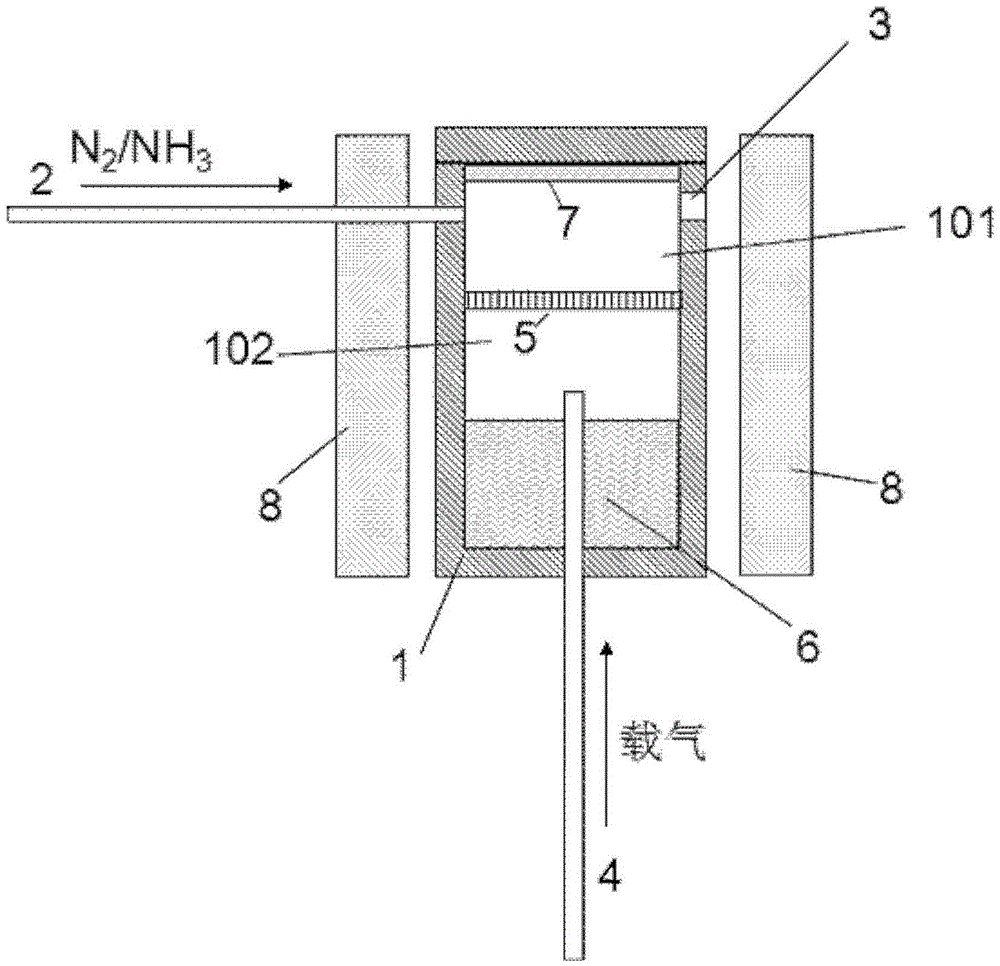

[0037] figure 1 It is a schematic diagram of the first embodiment. In this embodiment, the material of the crucible 1 is pyrolytic boron nitride, and the crucible is heated by the surrounding graphite ring heater 8, and the heating method is high-frequency induction heating. Inside the chamber of the crucible 1 , there is a boron nitride baffle 5 with a hole, which divides the inside of the crucible into a growth chamber 101 and a raw material chamber 102 . One side of the growth chamber 101 is connected with a N 2 / NH 3Gas pipe 2, the material used for gas pipe 2 is metal tungsten or metal molybdenum; a round hole 3 is opened on the other side of the growth chamber 101 as the gas outlet of the reaction chamber; a sapphire substrate 7 is fixed on the top of the growth chamber. The metal Al raw material 6 is placed at the bottom of the raw material chamber 102, and its height is lower than that of the end of the carrier gas tube 4; the carrier gas tube 4 is made of metal tun...

Embodiment 2

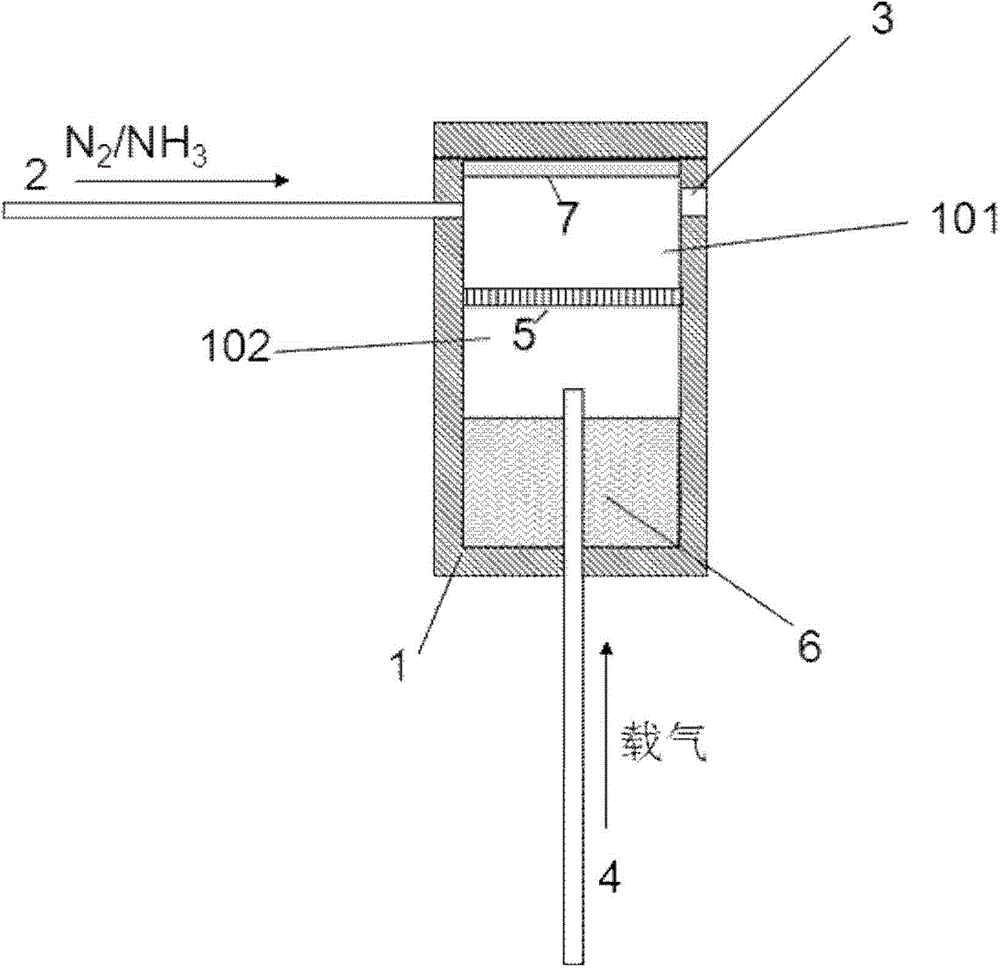

[0039] figure 2 It is a schematic diagram of the second embodiment. control figure 1 , figure 2 The difference is that there is no heater 8 independent of the crucible 1, but the crucible 1 itself is used as the heater. In this embodiment, the material of the crucible 1 is a material with high electrical conductivity, including metal tungsten, metal molybdenum, graphite, metal titanium, metal iridium and other materials, and the heating method is high-frequency induction heating. The advantage of this embodiment is that the heater 8 around the crucible 1 is omitted, and the structure is simpler; and the heating speed is faster by directly heating the crucible 1 .

Embodiment 3

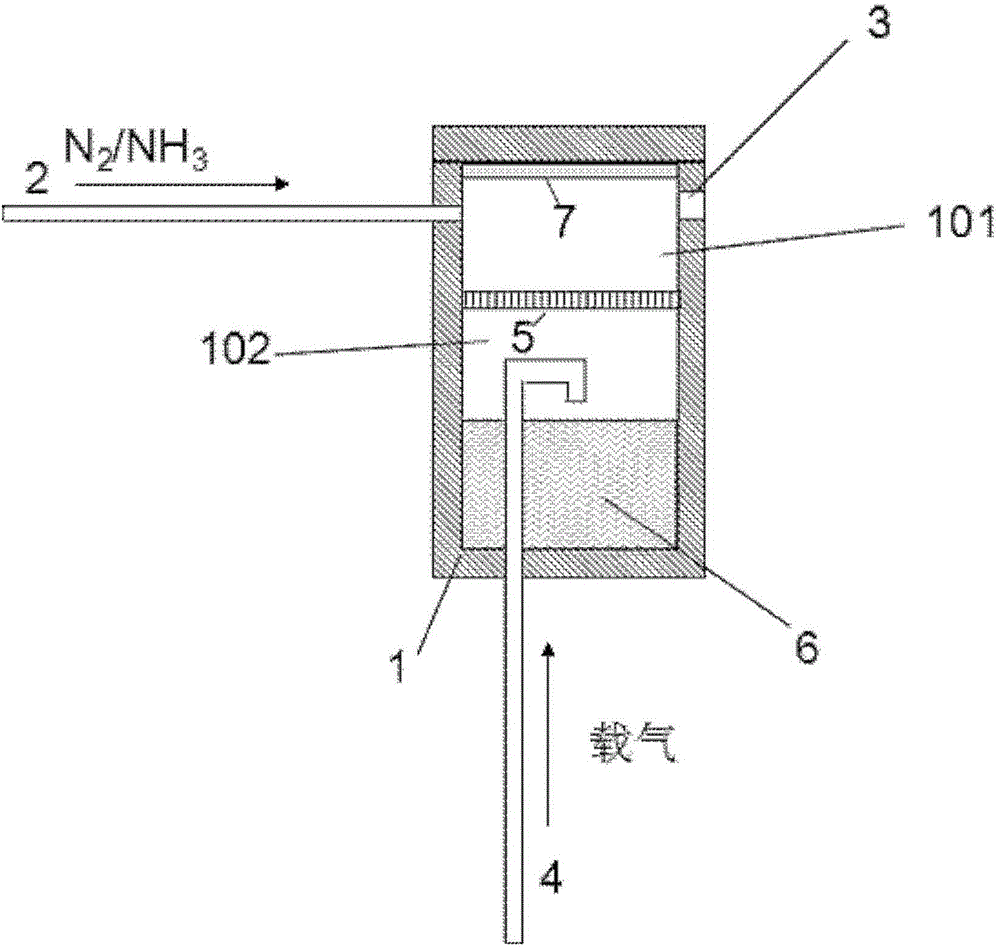

[0041] image 3 It is a schematic diagram of the third embodiment. control figure 2 , image 3 The difference is that the shape of the end of the carrier gas tube 4 is different. In this embodiment, the carrier gas pipe 4 is divided into an elbow inside the crucible 1, and its opening is placed downward. The elbow can be a right-angle elbow or an arc elbow, as long as the direction of the gas outlet is downward. The advantage of this embodiment is that the carrier gas is blown to the surface of the metal source 6, so that more source vapor can be taken away, and a faster AlN crystal growth rate can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com