Production method of silicon dioxide ultrafine powder

A silicon dioxide and production method technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve problems such as environmental pollution, long precipitation time, complex chemical production process, etc., and achieve the effect of no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

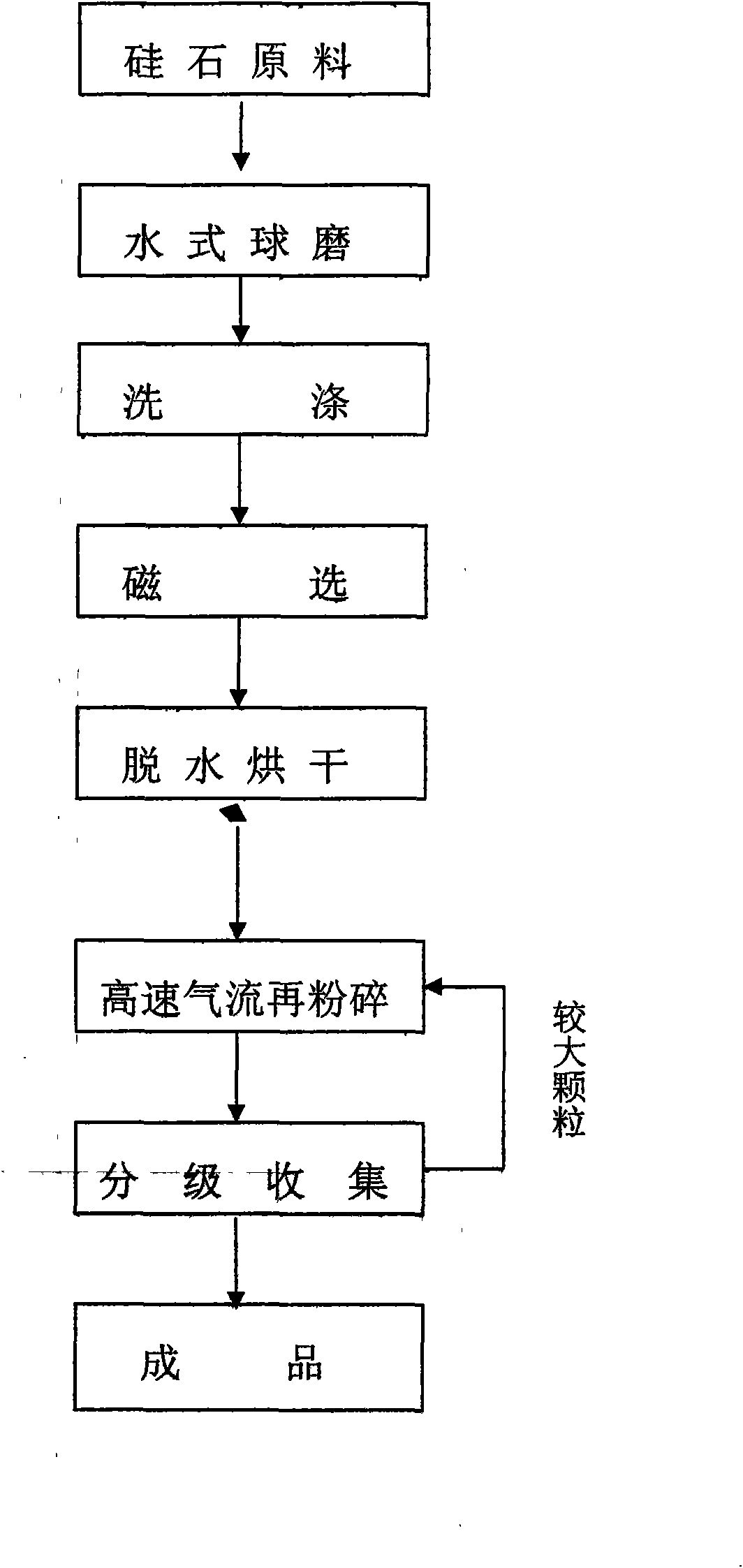

Image

Examples

Embodiment Construction

[0009] For better understanding of the present invention, below in conjunction with specific embodiment is further described:

[0010] 1. Water-type ball mill primary crushing: select high-quality silica raw materials with a silica content of more than 99.8%, first use high-pressure water to clean the dust and impurities on the surface of the raw material, and then use a water-type ball mill to crush to about 600 mesh. The technical key of this step is that the inner wall of the water ball mill and the parts in contact with the materials are all filled with silica stone plates to ensure that the materials will not be polluted by metal machinery during the crushing process.

[0011] 2. Washing and impurity removal: Pump the slurry pulverized by the ball mill into the pool with a thick slurry pump, add 5% hydrochloric acid, soak for 30 hours, then stir and rinse for 2 hours, and then wash it with deionized water.

[0012] 3. Magnetic separation and iron removal: The cleaned sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com