Industrial production method for superfine high-purity alpha-alumina

An alumina, fine and high technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of unindustrial production, high cost, harsh preparation process, etc., and achieve the effect of solving the problem of particle size and purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

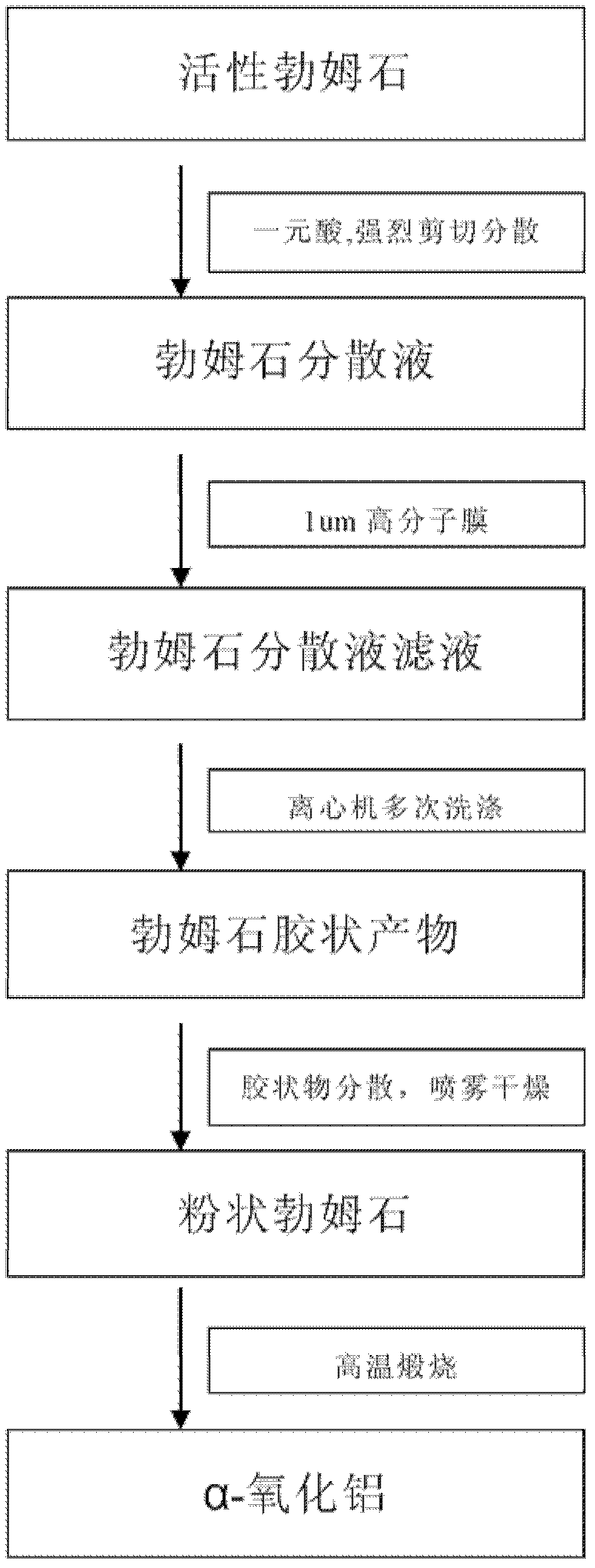

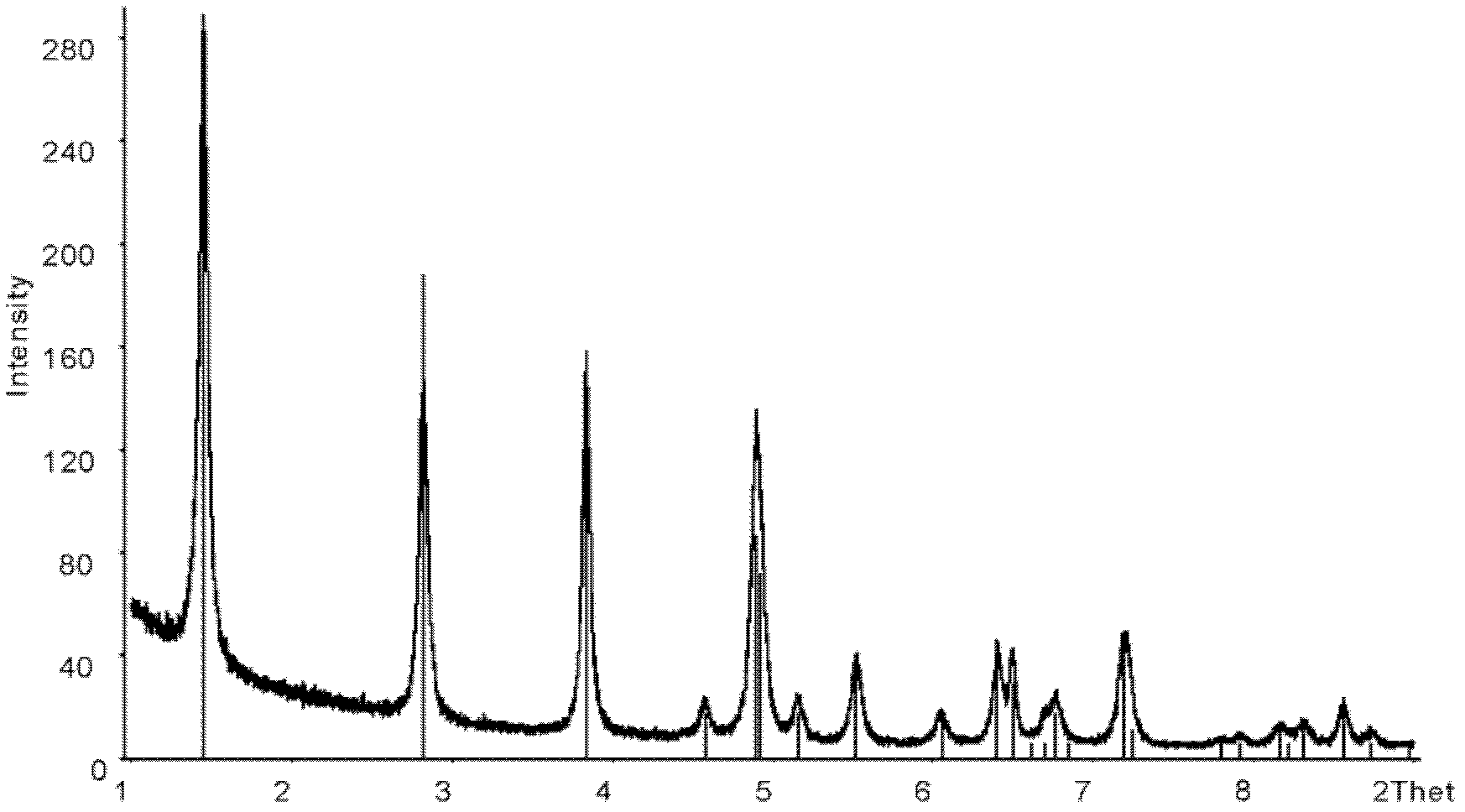

[0039] according to figure 1The process route shown prepares ultra-fine high-purity α-alumina; the XRD pattern of the boehmite raw material used is shown in figure 2 shown. In this example, the industrial production process for preparing ultrafine high-purity α-alumina includes the following steps:

[0040] 1) Add 200 kg of active boehmite (SPL powder produced by Guangzhou Huigu Chemical Co., Ltd.), 780 kg of water, and 20 kg of lactic acid in a 5-ton cylinder. At this time, the concentration of the dispersion is 20%. ;

[0041] 2) After dispersing for 2 hours with a high-speed shear disperser, add 10 kg of polyvinylpyrrolidone, and then disperse for 30 minutes. Filter the dispersion through a polymer membrane;

[0042] 3) Use an industrial centrifuge to separate the filtered liquid from solid to liquid. After the separation, put the solid into a tank, add water to disperse it, and then centrifuge it. Do this 5 times to make the conductivity of the liquid less than 2μS / c...

Embodiment 2

[0047] The basic process steps are the same as in Example 1, but the difference from Example 1 is that the water consumption of the dispersion needs to be reduced when spray drying, so that the concentration of boehmite in the dispersion becomes 5%.

Embodiment 3

[0049] The basic process steps are the same as in Example 1, but the difference from Examples 1 and 2 is that the water consumption of the dispersion needs to be further reduced when spray drying, so that the concentration of boehmite in the dispersion becomes 15%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com