Patents

Literature

32results about How to "Improve flow field characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

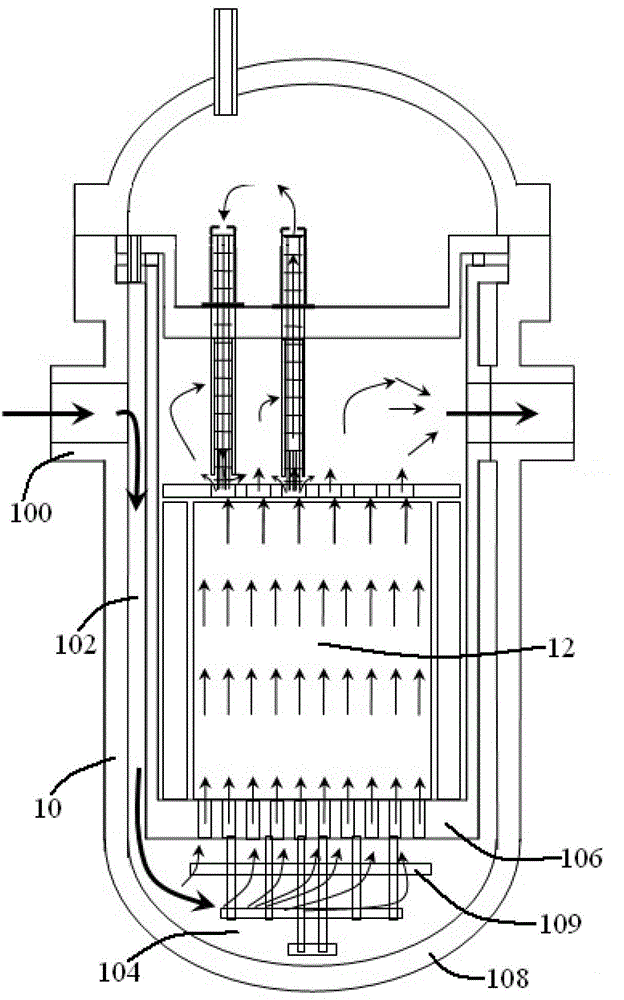

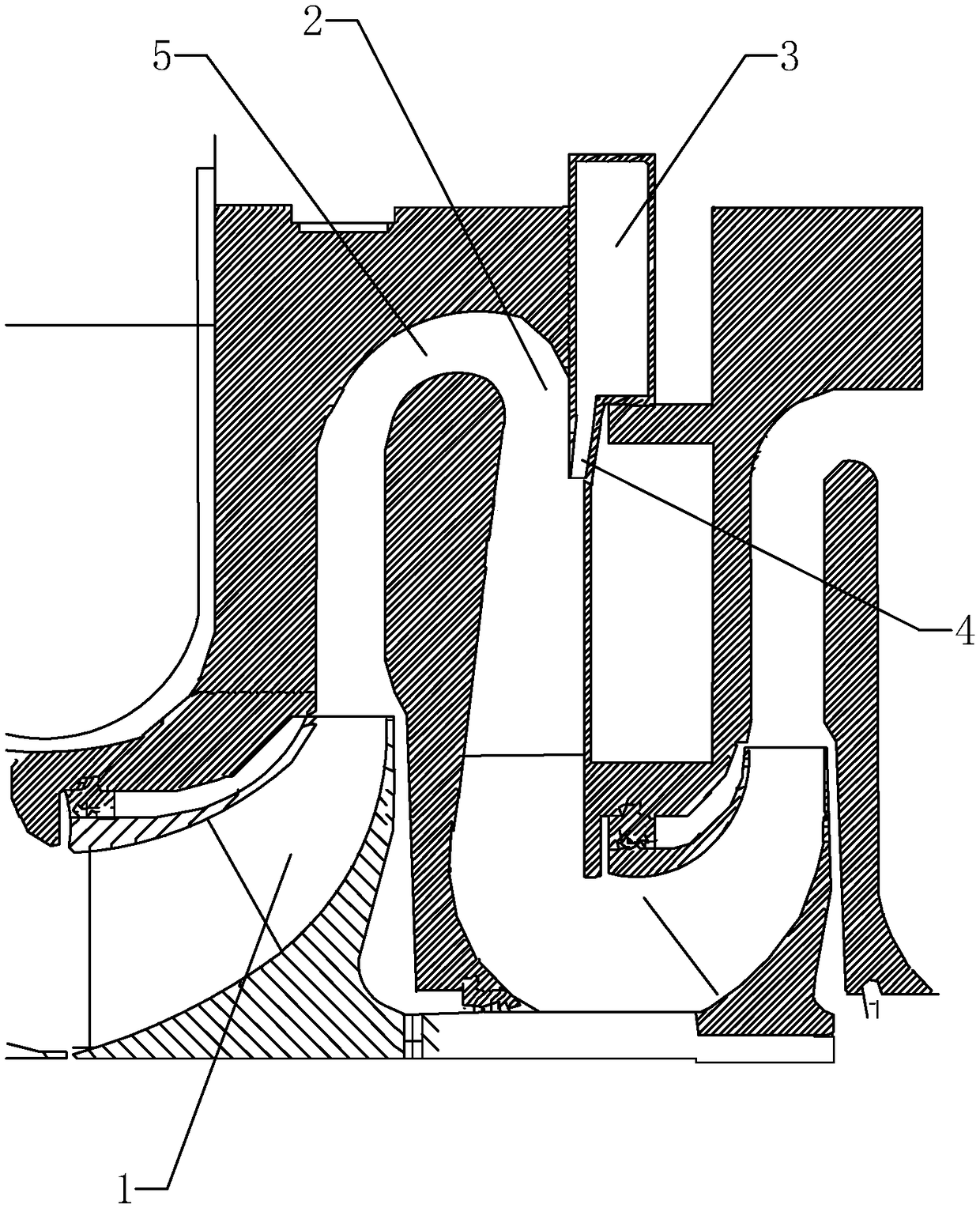

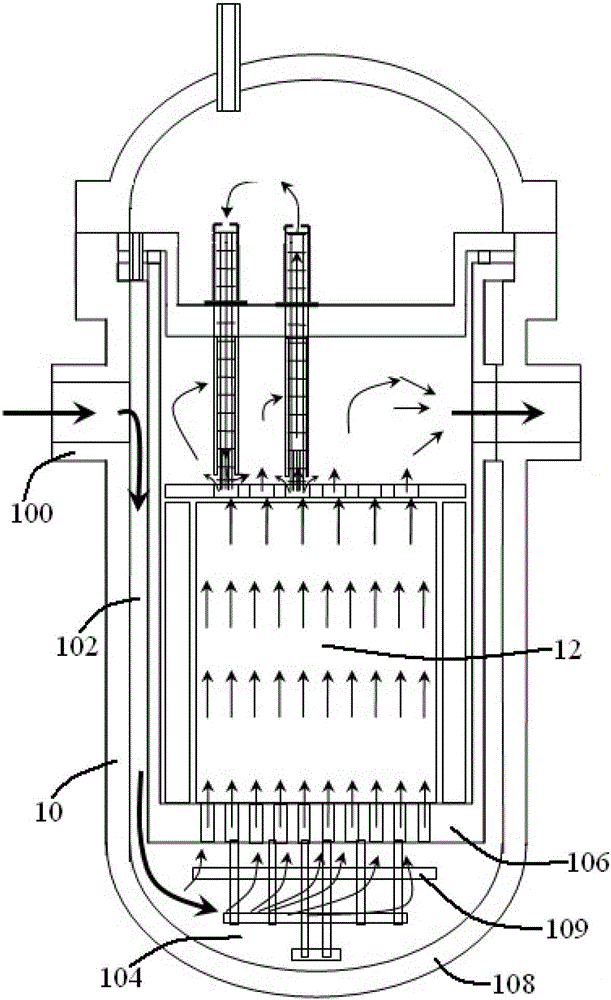

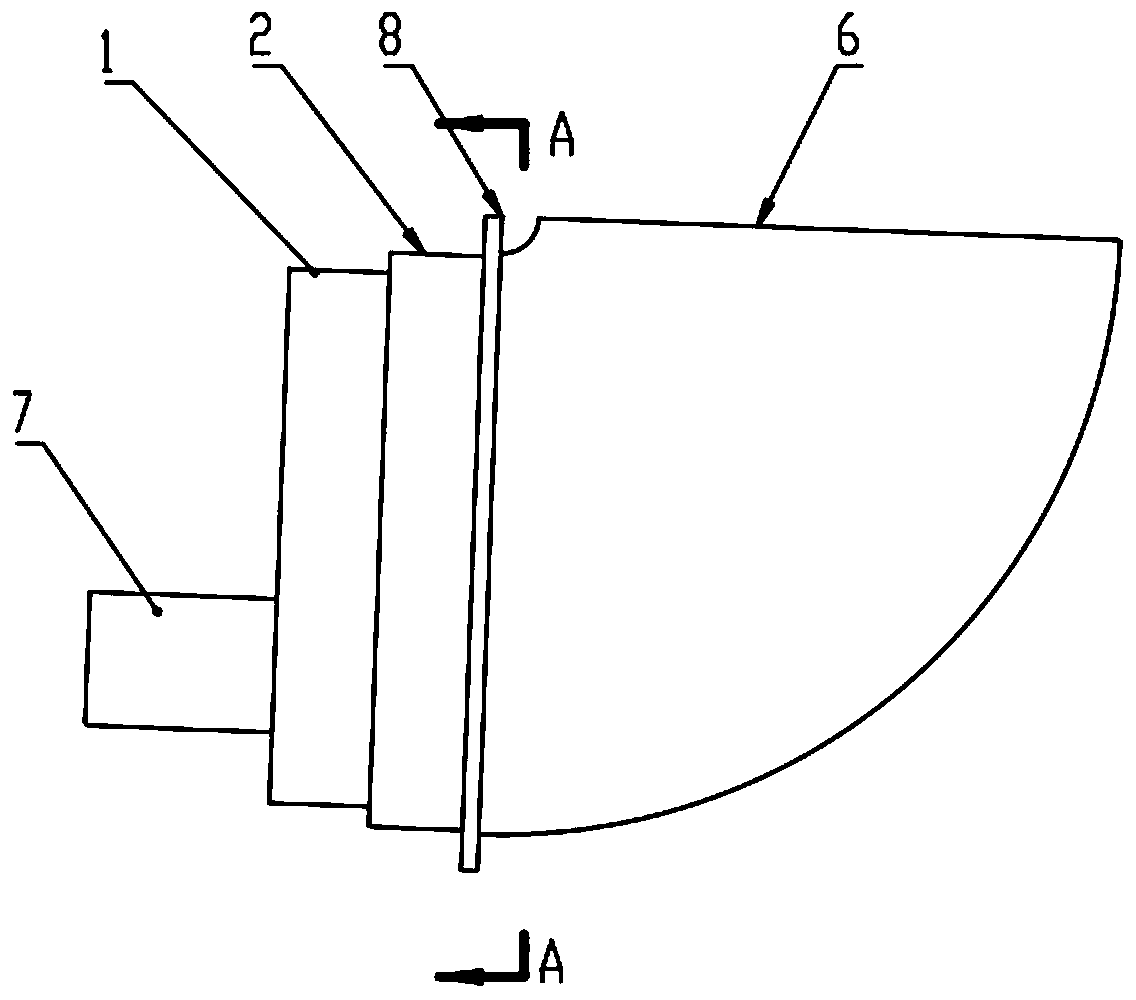

Flow distribution structure of reactor of nuclear power station

ActiveCN102800371AImprove flow field characteristicsAvoid vortex sheddingNuclear energy generationReactor fuel elementsNuclear engineeringNuclear power plant

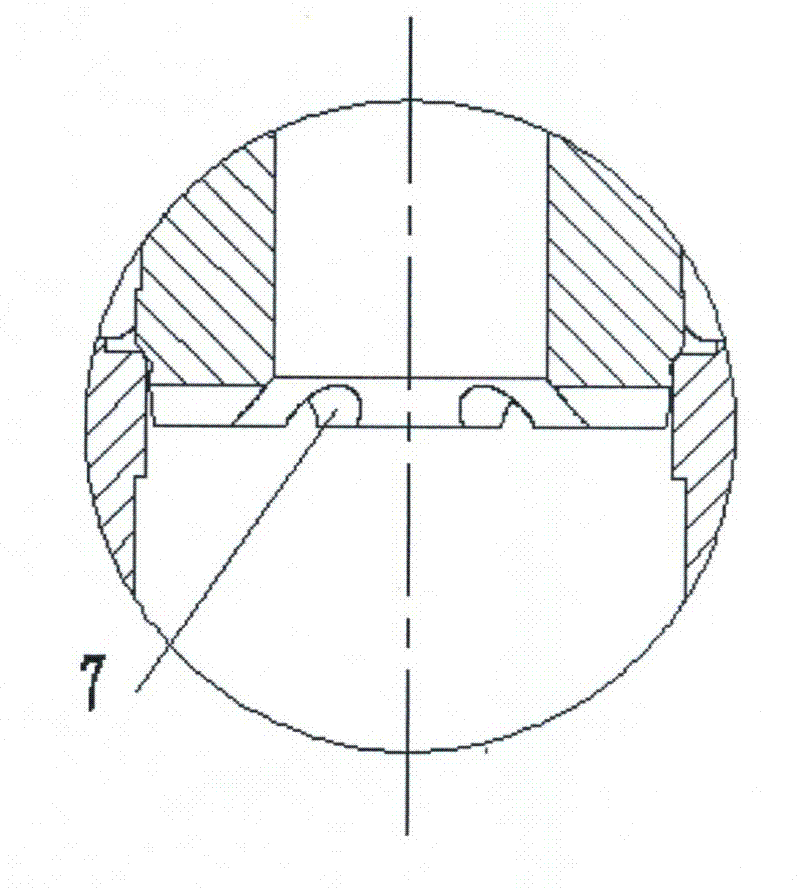

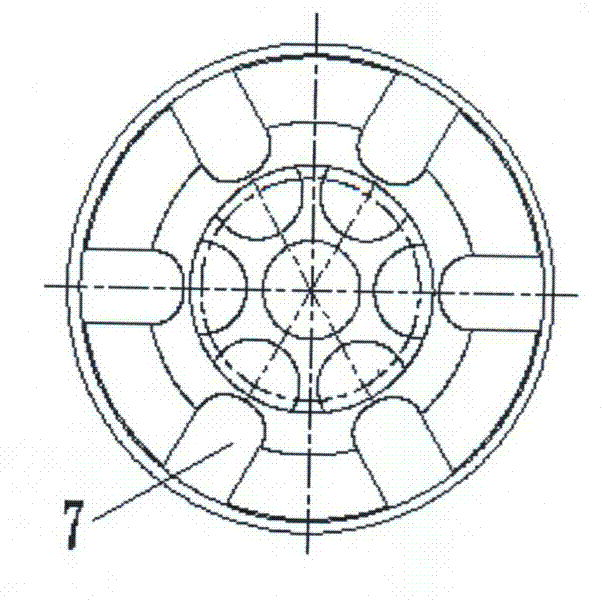

The invention discloses a flow distribution structure of a reactor of a nuclear power station. The flow distribution structure is used for distributing the flow of coolant of a cooled reactor core and comprises a reactor core lower supporting plate and an end-socket-shaped structure fixed on the reactor core lower supporting plate; and the end-socket-shaped structure comprises an end socket with drain holes. Compared with the prior art, the flow distribution structure of the reactor of the nuclear power station has the advantages that the shape of a coolant channel is changed through the end socket, so that characteristics of a flow field of a lower cavity are improved effectively, vertex shedding of reactor internals in the lower cavity is avoided, the flow of the coolant is distributed through the drain holes of the end socket, and uniformity of flow distribution of fuel assemblies entering the reactor core is perfect.

Owner:中广核工程有限公司 +1

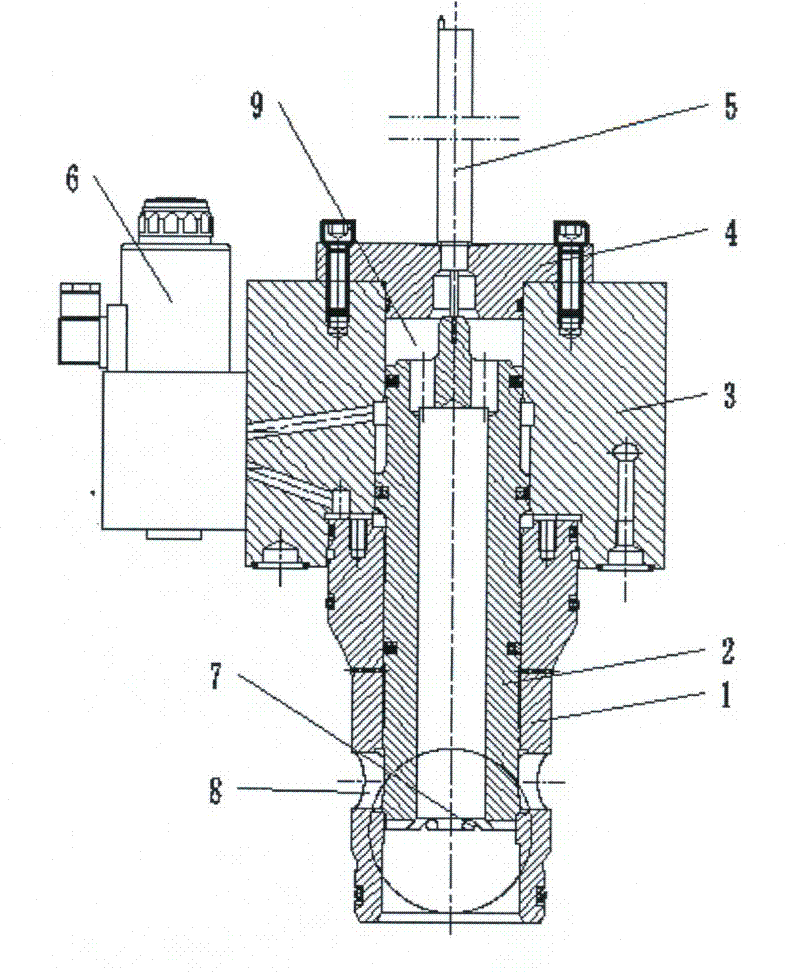

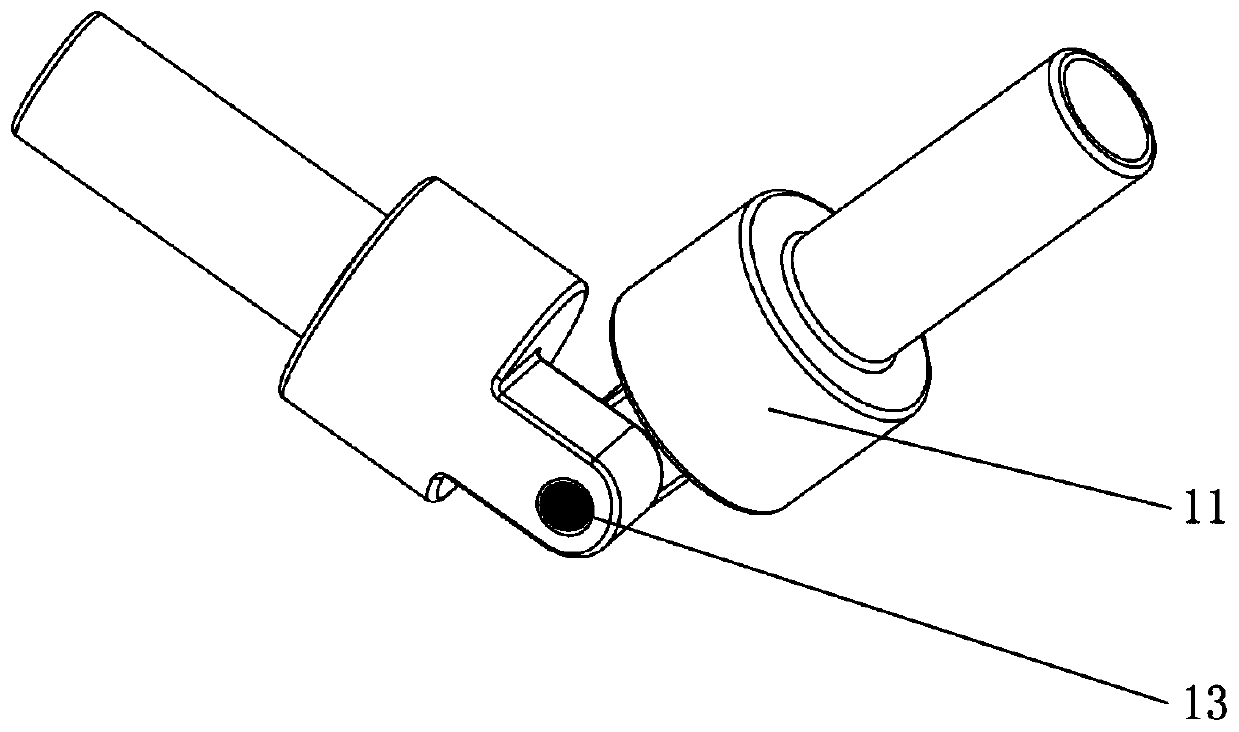

Proportional cartridge valve with variable flow gain

InactiveCN102418721AImprove linearitySmooth pressure relief controlServomotor componentsLinear controlTransducer

The invention discloses a proportional cartridge valve with variable flow gain, which comprises a valve sleeve, a hollow valve core with a damping hole, a control cover plate, a valve cover, a displacement transducer and a pilot control valve, and is characterized in that: the lower part of the hollow valve core is arranged in the valve sleeve and is linearly sealed with the valve sleeve; the upper part of the hollow valve core is matched with the control cover plate; the upper end of the control cover plate is connected with the valve cover; the displacement transducer is arranged on the valve cover; the pilot control valve is arranged on a side face of the control cover plate; a semicircular hole is machined on a port at the bottom of the valve core; and four symmetrical waist-shaped holes are machined on the valve sleeve. The invention has the advantages that: the proportional cartridge valve has small valve opening, low flow gain and high linearity, and high-precision linear control at low flow can be realized; the valve has large valve opening, high flow gain and high linearity, and high-precision linear control at high flow can be realized; and due to low flow fluctuation and low pressure shock of the valve, the service life of the valve can be prolonged.

Owner:YANSHAN UNIV

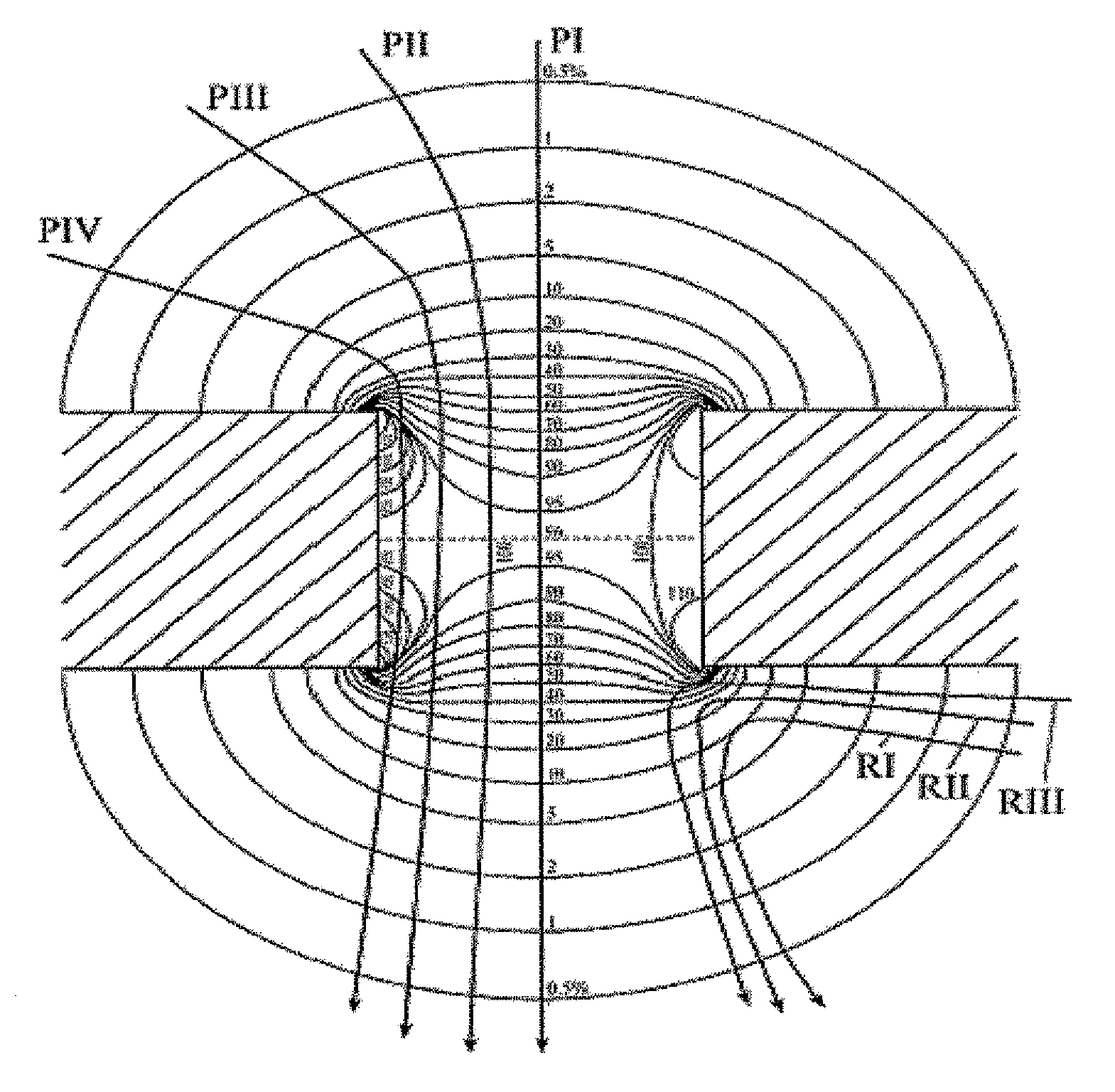

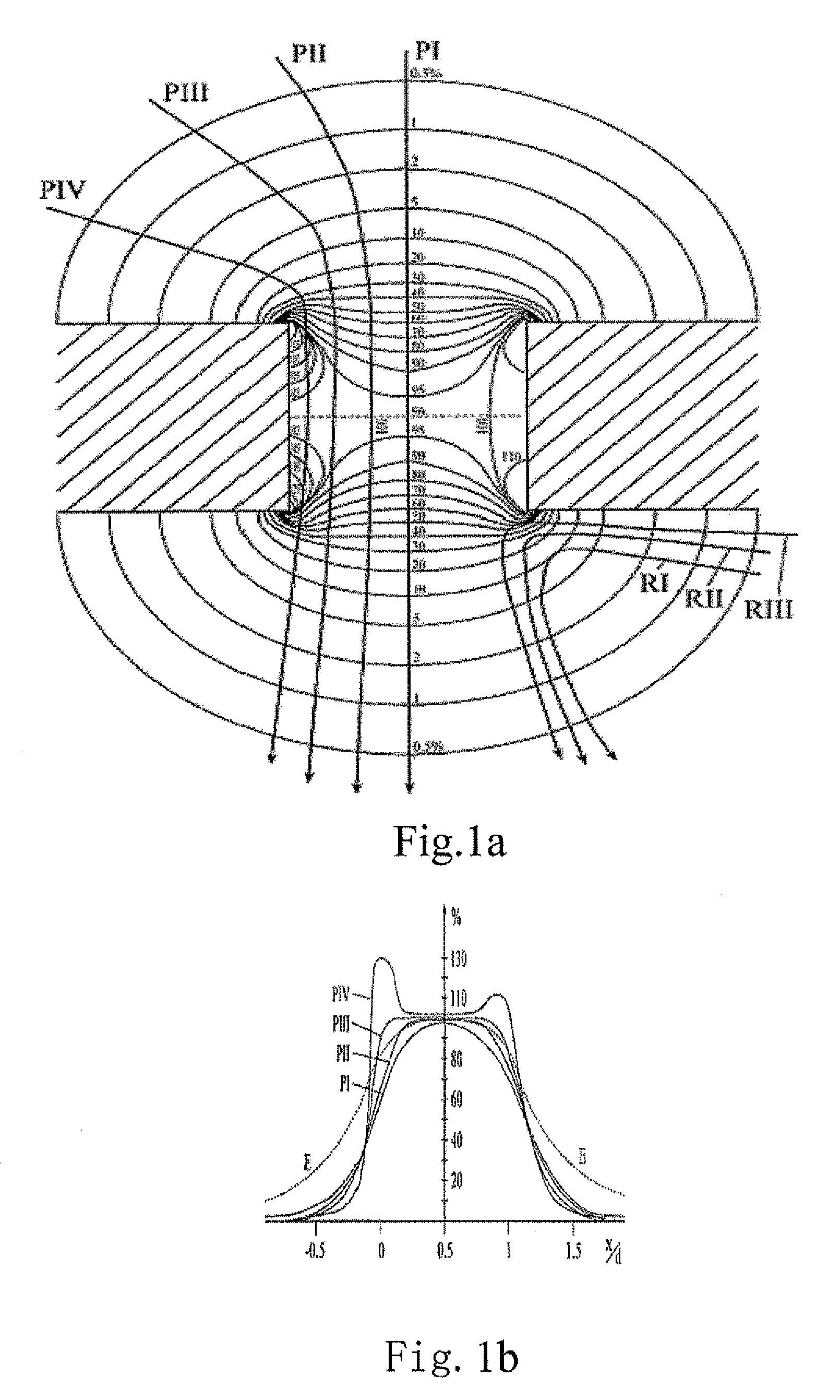

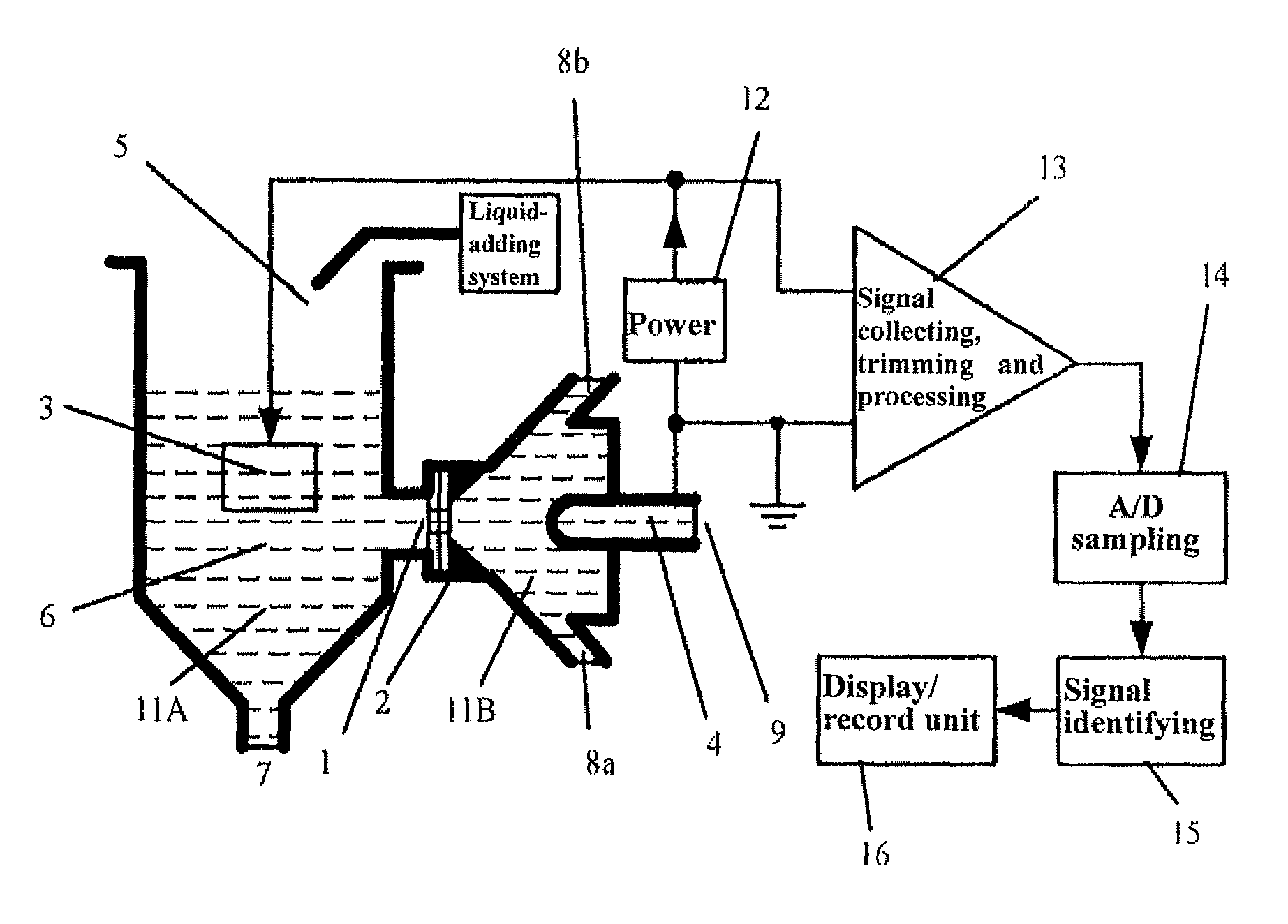

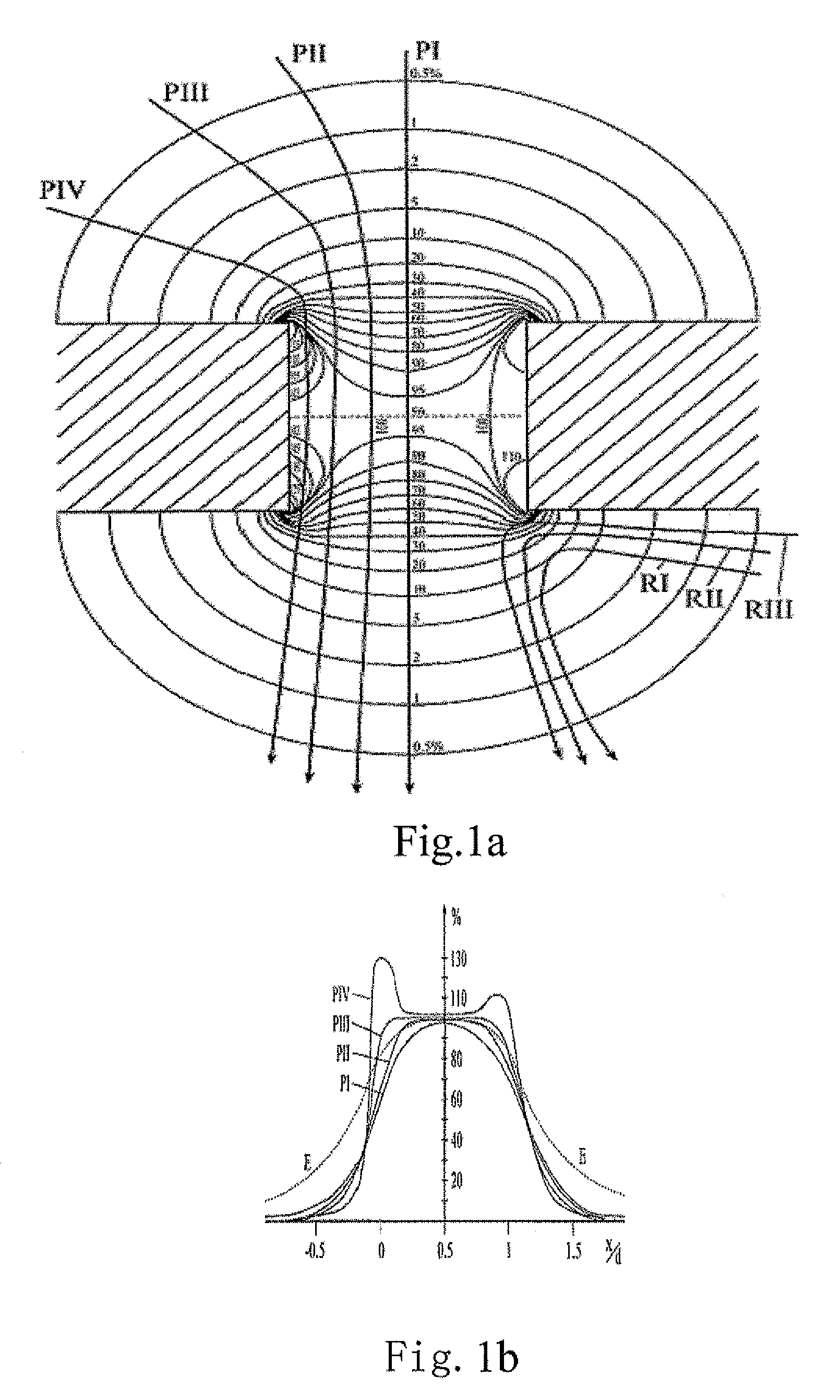

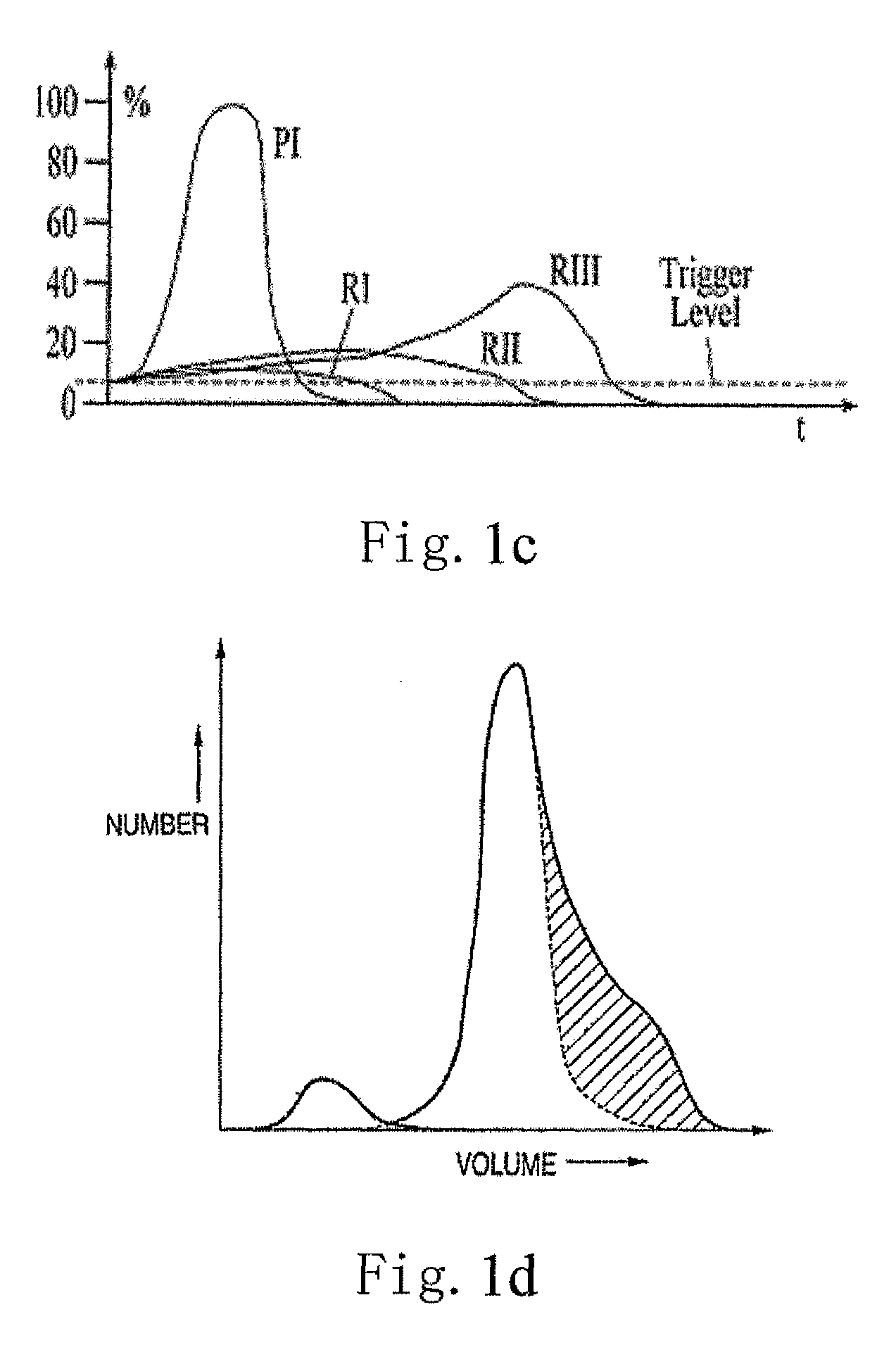

Device for determination of parameters of particles in conductive solution and microscopic hole assembly

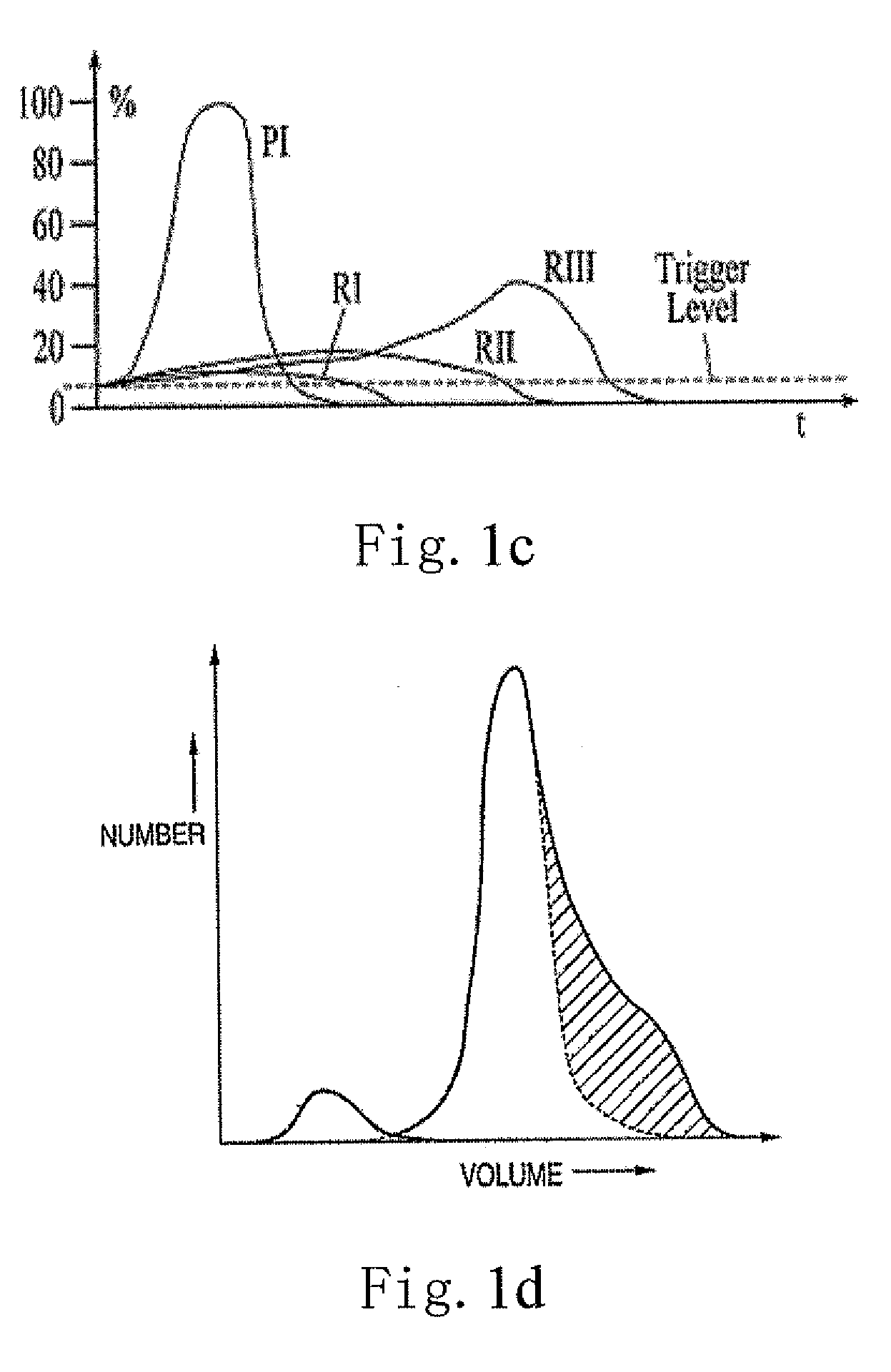

ActiveUS20080093216A1Improve signal-to-noise ratioImprove the flow fieldImmobilised enzymesBioreactor/fermenter combinationsEngineeringBiomedical engineering

The present invention discloses a device for detecting blood cells and a microscopic hole sensor assembly thereof. The device includes a microscopic hole sensor assembly positioned between a front pool and a back pool. The microscopic hole sensor assembly further includes a microscopic hole plate with a microscopic hole positioned thereon for communicating the front pool and the back pool. The end surface of the inlet is a flow-guiding surface gradually narrowing from the front pool to the back pool. The end surface of the outlet is a downstream surface gradually distending and extending towards the back pool. A straight effective orifice area is formed connecting the ends of the flow-guiding surface and the downstream surface.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

Wide-domain supersonic inlet passage based on plasma flow control

InactiveCN109606707AEnhanced leading edge shockReduce design Mach numberPower plant air intake arrangementsShock waveHigh rate

The invention relates to a wide-domain supersonic inlet passage based on plasma flow control. The wide-domain supersonic inlet passage comprises a main inlet passage body and a radome. A surface arc discharge plasma excitation device is arranged at the front end surface of the main inlet passage body. When the flight Mach number of the inlet passage is greater than a designed Mach number, the surface arc discharge plasma excitation device is started. The surface arc discharge plasma excitation device is capable of generating a high temperature plasma region in an excitation region on the curved wall of the inlet passage to form a virtual profile, thereby enhancing the virtual front edge shock wave and pushing the external pressure shock wave system of the inlet passage compression surfaceto be deflected outward; and thus the external pressure shock wave system of the inlet passage compression surface is sealed again. Therefore, the super-high rated state under the high Mach number isavoided; and the flow field characteristics of the inlet passage under the high Mach number is improved.

Owner:NANJING UNIV OF SCI & TECH

Ultrasonic plasma gun feeding powder internally

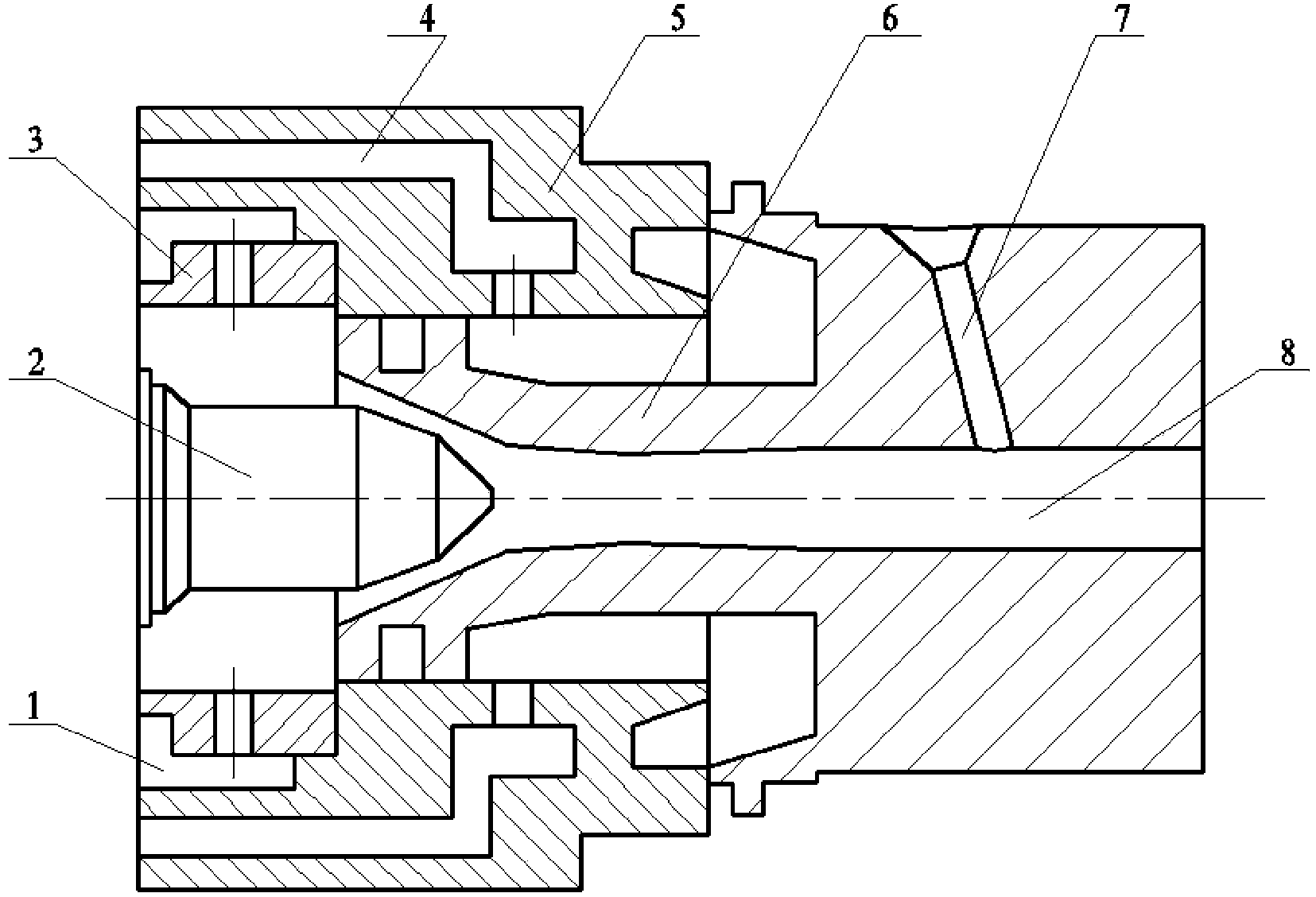

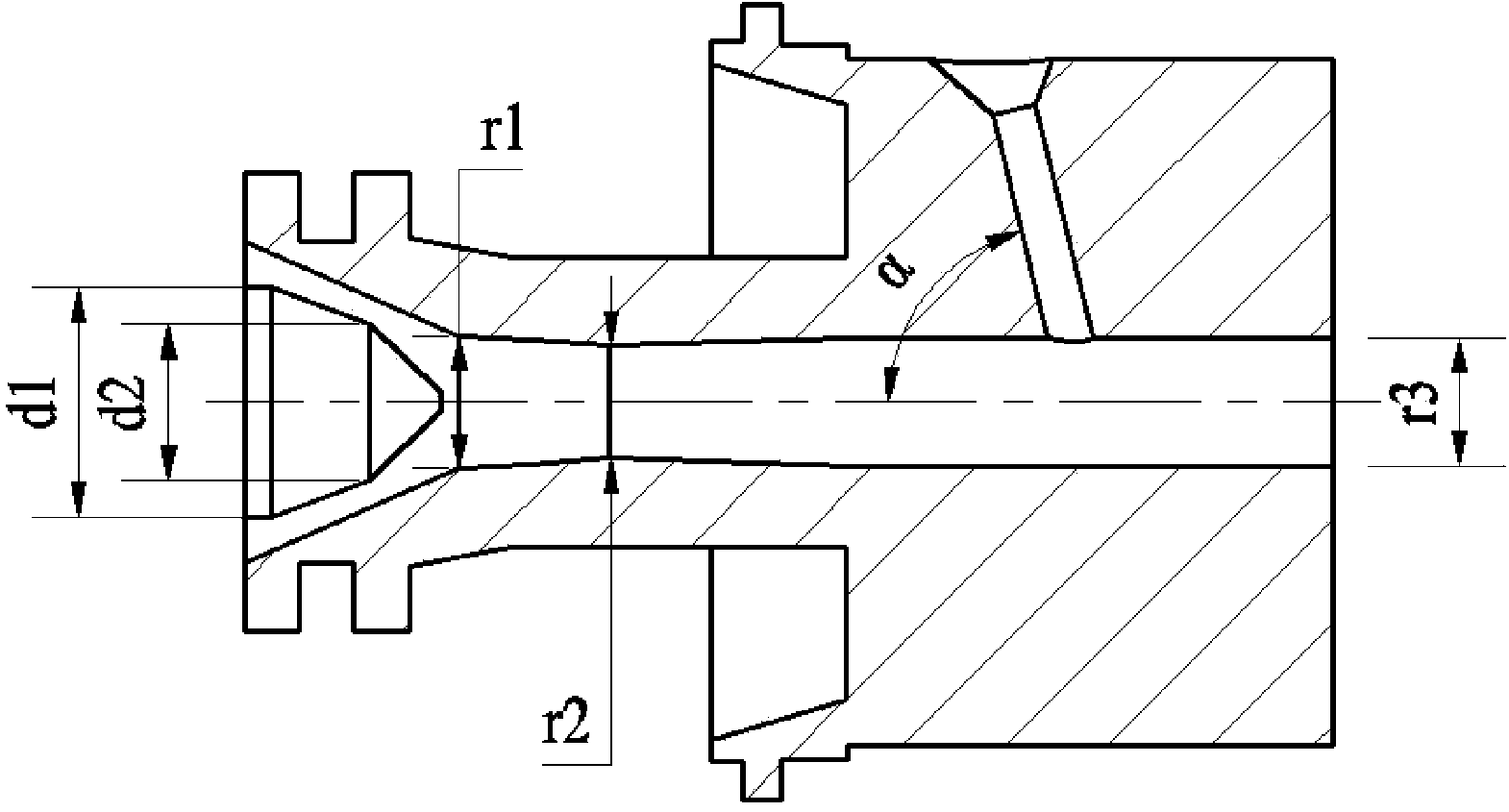

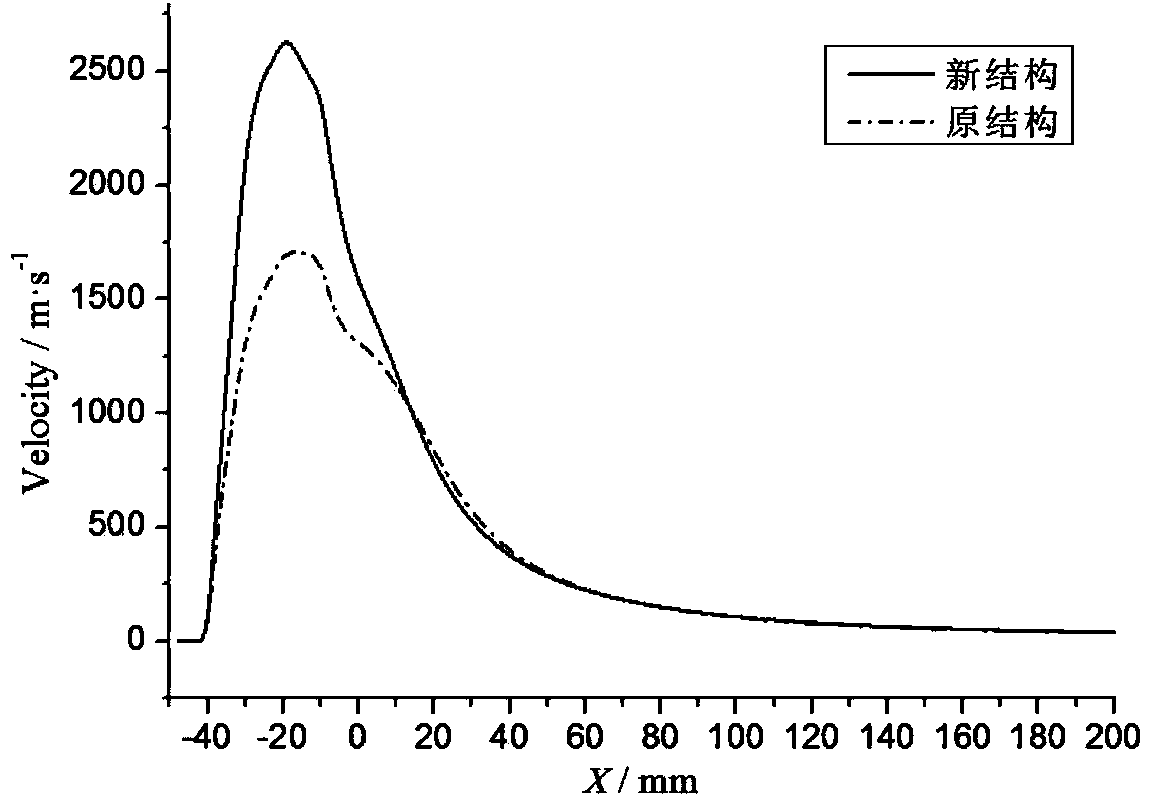

The invention discloses an ultrasonic plasma gun feeding powder internally, which is designed by adopting a parameterized structure design method in combination with a numerical simulation technique. The ultrasonic plasma gun mainly comprises a cathode, an anode, a powder feeding air flow channel, and a main air flow channel formed by matching the cathode with the anode. The mechanical compression effect of a nozzle is adjusted by changing the parameter of each pore canal in the internal compression segment and expanding segment of an anode nozzle, so that plasma jet flow in the gun is high in energy density and speed, the thermal efficiency of the gun is increased, and meanwhile the stability of arc voltage is ensured. The internal powder feeding angle is changed to an optimal position, so that heating and acceleration of sprayed powder materials are facilitated, and the problem of blocking of the gun nozzle is solved. The size of the gun is selected on the basis of an advanced computer simulation technology, so that the development period of the gun is shortened greatly, and the design cost is lowered. As proved by results, the novel gun has higher flow field characteristic than an original structure.

Owner:XI AN JIAOTONG UNIV

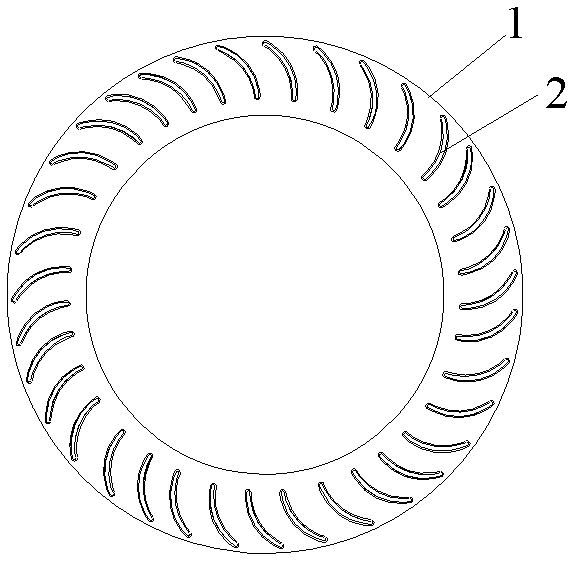

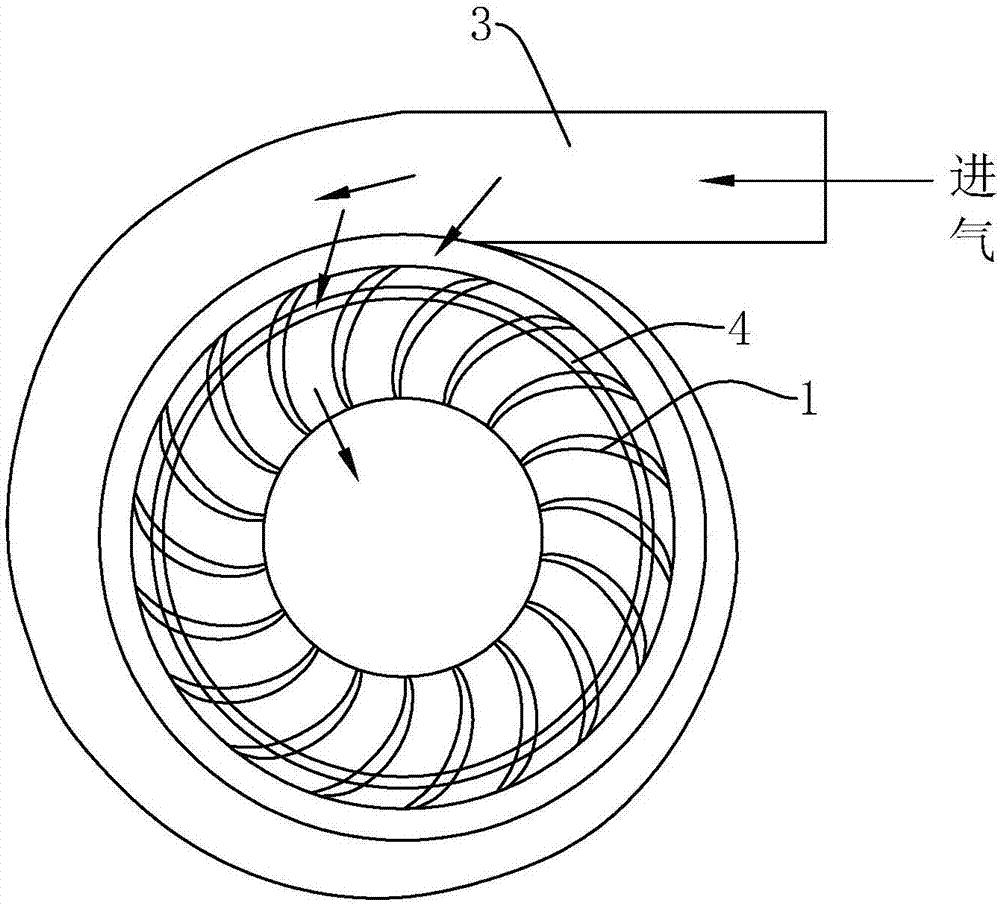

A kind of impeller structure and cross-flow fan

The invention discloses an impeller structure, which includes a fixed frame, in which at least two rows of blade groups are arranged, each row of blade groups includes a plurality of blades, and each row of blade groups is arranged around the axis of the fixed frame. The impeller structure of the present invention is provided with at least two rows of blade groups, so that the air flow is subjected to the force of the blades four times at least four times. Among the at least two rows of blade groups, the blades in the second row of blade groups play an auxiliary role and can play a role. The role of breaking the vortex and guiding the airflow, thereby reducing the eccentric vortex in the cross-flow wind wheel, thereby reducing the air volume of the secondary return flow of the cross-flow fan, increasing the outlet air volume, improving the flow field characteristics, and making the air output more uniform , At the same time, this at least two rows of blades can also break up the large vortex, thereby reducing noise. Wherein, the second row of blade sets plays a role in guiding the airflow, which can change the original flow direction of the airflow, guide the airflow to flow to the other side of the impeller and then flow out of the impeller. The invention also discloses a cross-flow fan.

Owner:GUANGDONG CHIGO AIR CONDITIONING

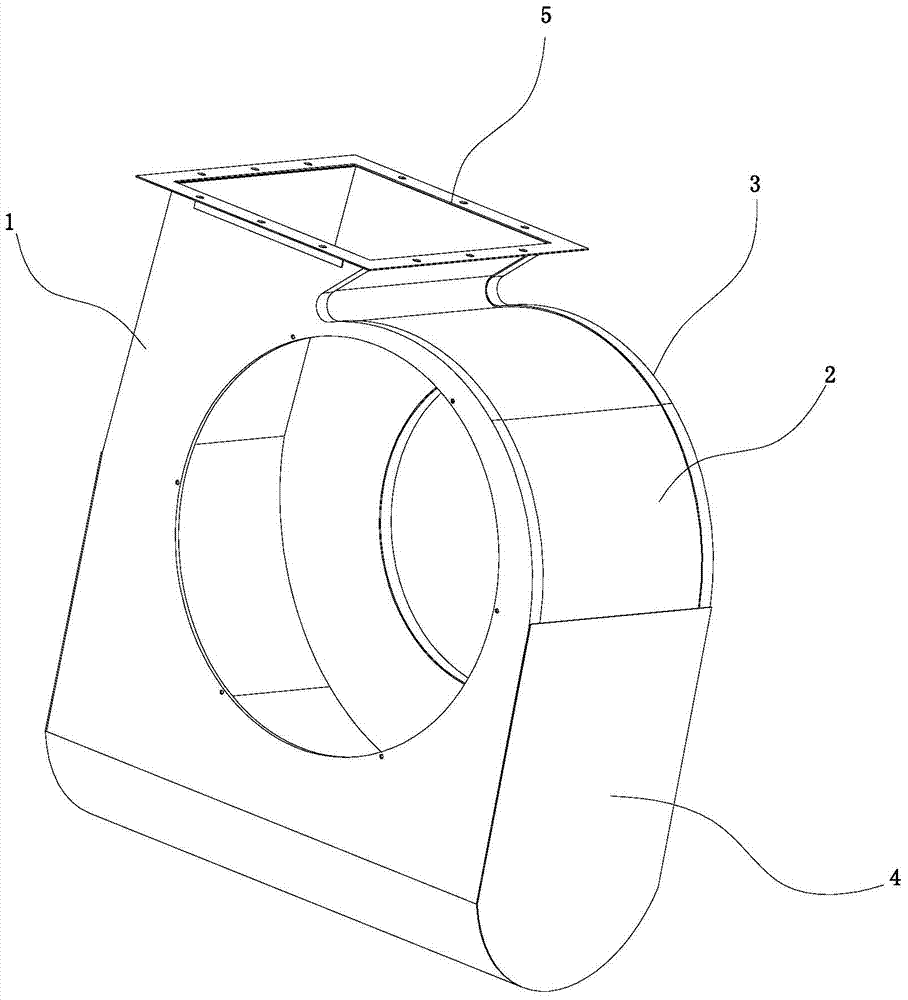

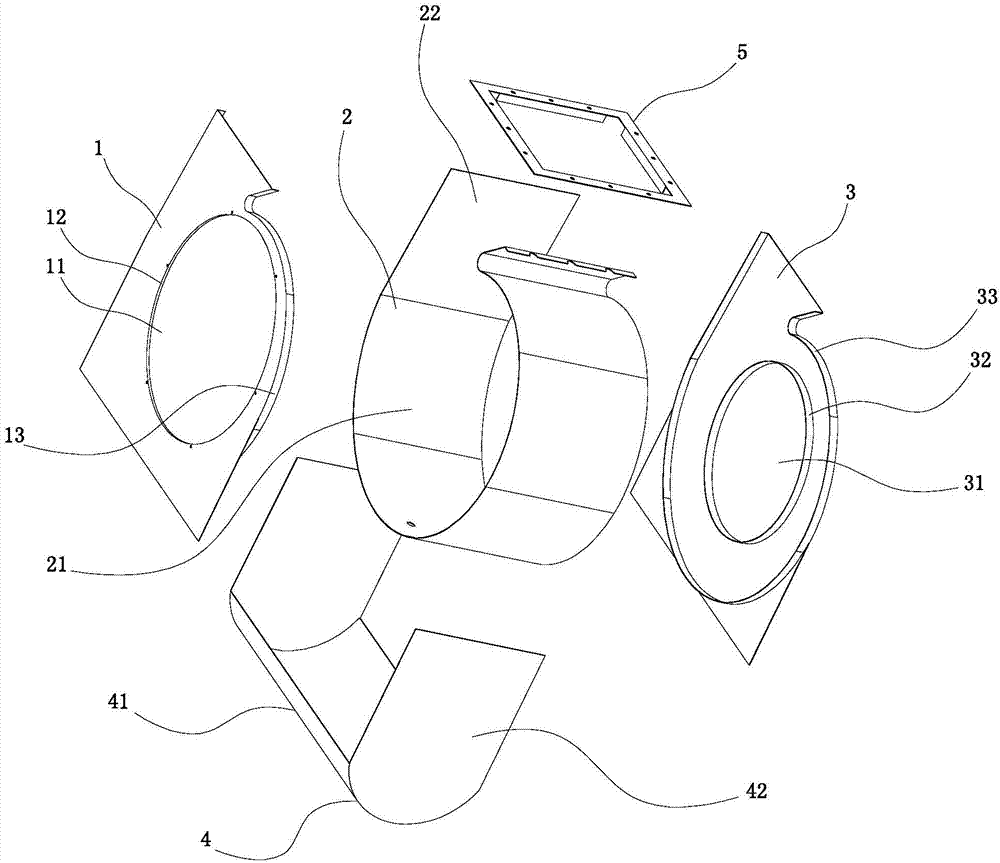

Low-noise diversion volute of range hood

InactiveCN104847698ALittle resistance lossReduce mutationDomestic stoves or rangesPump componentsLow noiseImpeller

The invention relates to a low-noise diversion volute of a range hood. The low-noise diversion volute comprises a volute body, an impeller is mounted in the volute body, and the upper outlet of the volute shell is connected with the range hood through a flange; the volute body comprises a volute plate which is enclosed to form an annular diversion space, and the inversion space is provided with a notch; volute protecting plates are respectively mounted on axial sides of the diversion space, each volute protecting plate is provided with an air inlet, and upper ends of the volute protecting plates and the notch end of the volute plate are enclosed to form an outlet; a curved-surface diversion structure is mounted on the outer side of the volute plate and comprises a diversion plate and supporting plates symmetrically located at two ends of the diversion plate, and two sides of the supporting plates and two sides of the diversion plate are respectively fixedly connected between the volute protecting plates. Airflow resistance of the range hood is effectively reduced through combination of guidance of the curved-surface diversion structure and guidance of the circular-arc surfaced volute plate, the situation of turbulent flow is improved, and flow-induced noise outside the volute and aerodynamic noise of the impeller are reduced.

Owner:中国船舶重工集团公司第七〇二研究所

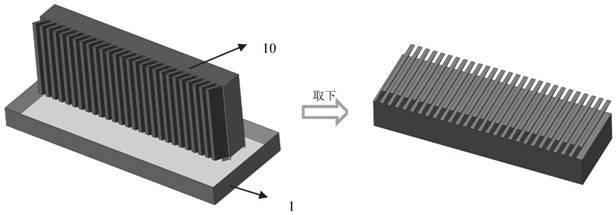

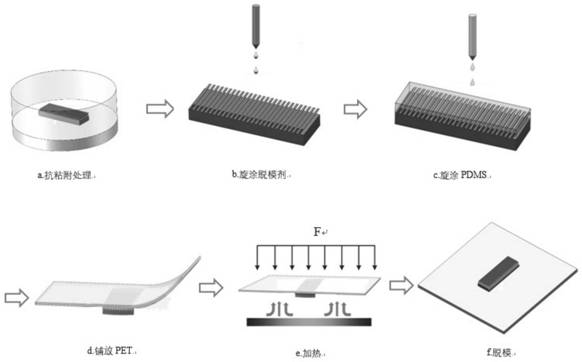

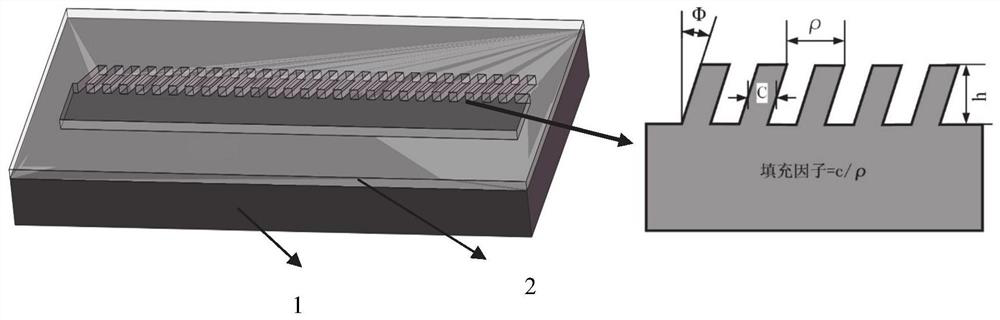

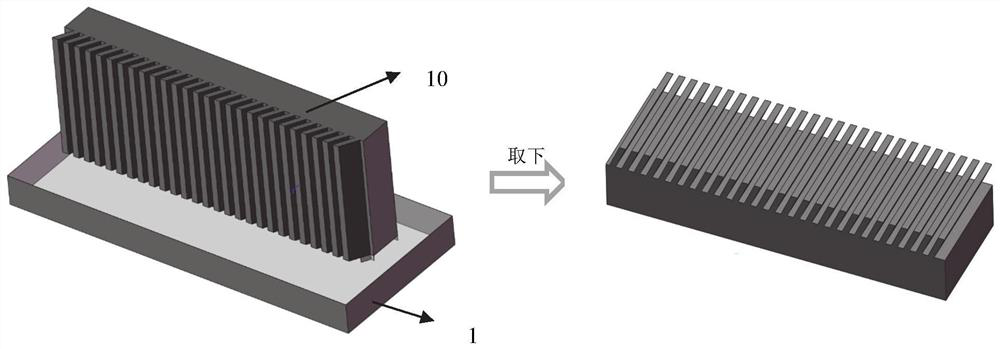

Preparation method of AR diffraction optical waveguide imprinting mold, soft mold and application

ActiveCN112026073AImprove printing accuracyMeet the precision requirementsFurnace typesElectroforming processesGratingComputer printing

The invention relates to a preparation method of an AR diffraction optical waveguide imprinting mold, a soft mold and application. The preparation method comprises the specific steps that an electroforming mask is printed on a nickel substrate through a two-photon polymerization micro-nano 3D printer; nanosecond pulse micro electroforming is utilized, electroforming is conducted on the obtained nickel substrate with the mask, and an inclined grating metal nickel mold is obtained; and the manufactured inclined grating metal nickel mold serves as a female mold, the female mold is coated with a pattern layer polymer PDMS, PET is attached to the PDMS, imprinting is conducted on the mold, uncovering type demolding is adopted, the soft mold copied at a time is obtained, the steps of PDMS coating, PET attaching, imprinting and uncovering type demolding are repeated, and finally the composite soft mold with a plurality of PDMS soft mold arrays arranged on one piece of PET is prepared. High-precision, low-cost and efficient manufacturing of the large-area AR diffraction optical waveguide imprinting mold is achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

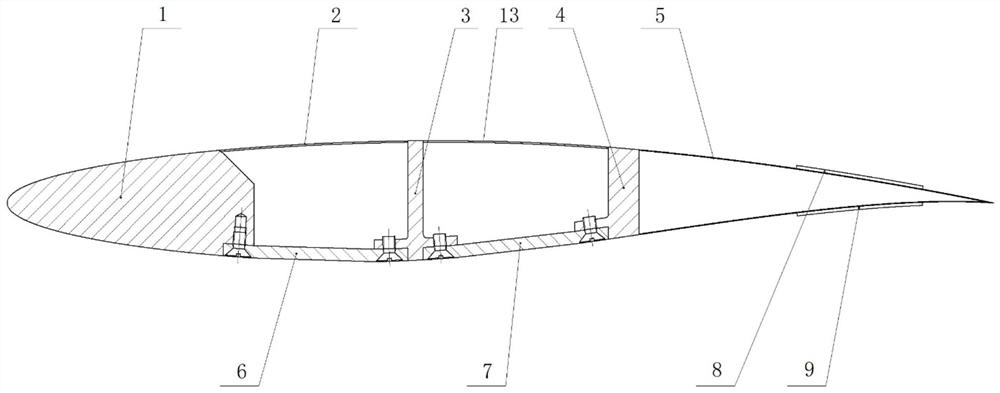

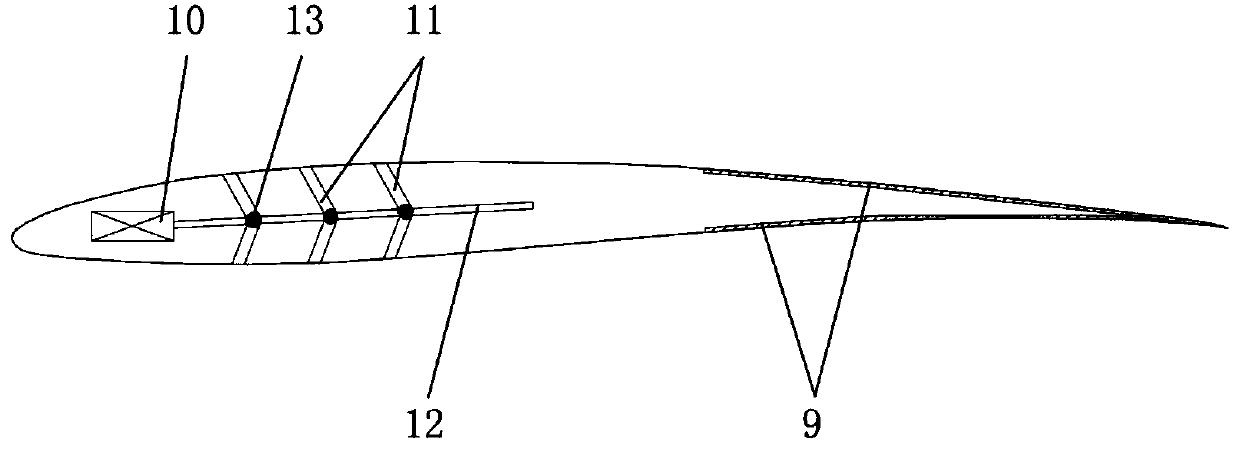

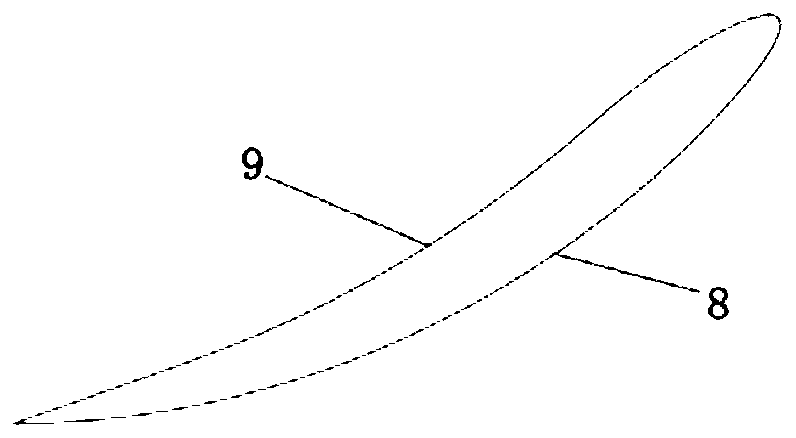

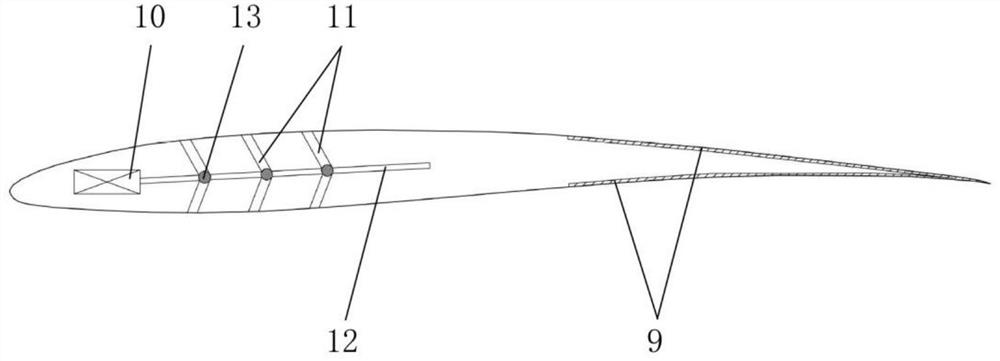

Deformable wing based on intelligent driving device

The invention discloses a deformable wing based on an intelligent driving device. A framework of the deformable wing comprises a wing leading edge, a middle partition plate, a rear partition plate andan empennage which are sequentially arranged from front to back. A front shape memory alloy driving device between the wing leading edge and the middle partition plate forms a lower surface I of thewing, and the skin I covering the wing leading edge and the middle partition plate forms an upper surface I of the wing; a rear shape memory alloy driving device between the middle partition plate andthe rear partition plate forms the lower surface II of the wing, and the skin II covering the middle partition plate and the rear partition plate forms an upper surface II of the wing; the upper surfaces and the lower surfaces of the wings are in smooth transition; the deformable wing upper surface and the deformable wing lower surface are intersected at the rear edge of the empennage; and the upper surface and the lower surface of the empennage are provided with an upper piezoelectric intelligent driving device and a lower piezoelectric intelligent driving device respectively. The deformablewing has the advantages of compact structure, few driving elements, high driving capacity and continuous deformable wing surface, and can be popularized and applied to the structural design of wing camber deformation.

Owner:中国空气动力研究与发展中心设备设计及测试技术研究所

Device for determination of parameters of particles in conductive solution and microscopic hole assembly

ActiveUS8771484B2Improve signal-to-noise ratioImprove the flow fieldImmobilised enzymesBioreactor/fermenter combinationsBiomedical engineeringEffective orifice area

The present invention discloses a device for detecting blood cells and a microscopic hole sensor assembly thereof. The device includes a microscopic hole sensor assembly positioned between a front pool and a back pool. The microscopic hole sensor assembly further includes a microscopic hole plate with a microscopic hole positioned thereon for communicating the front pool and the back pool. The end surface of the inlet is a flow-guiding surface gradually narrowing from the front pool to the back pool. The end surface of the outlet is a downstream surface gradually distending and extending towards the back pool. A straight effective orifice area is formed connecting the ends of the flow-guiding surface and the downstream surface.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

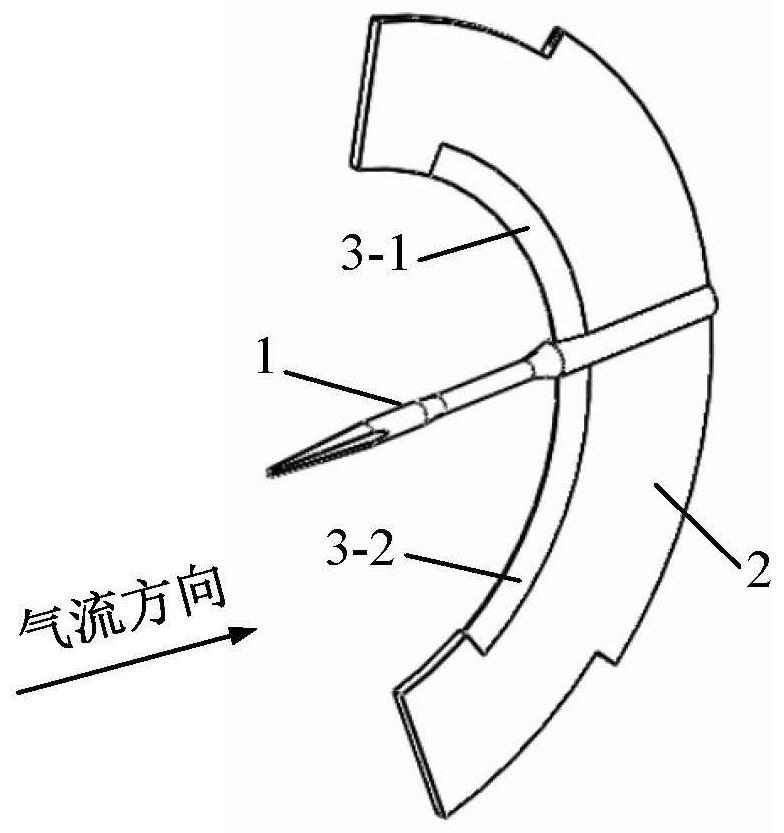

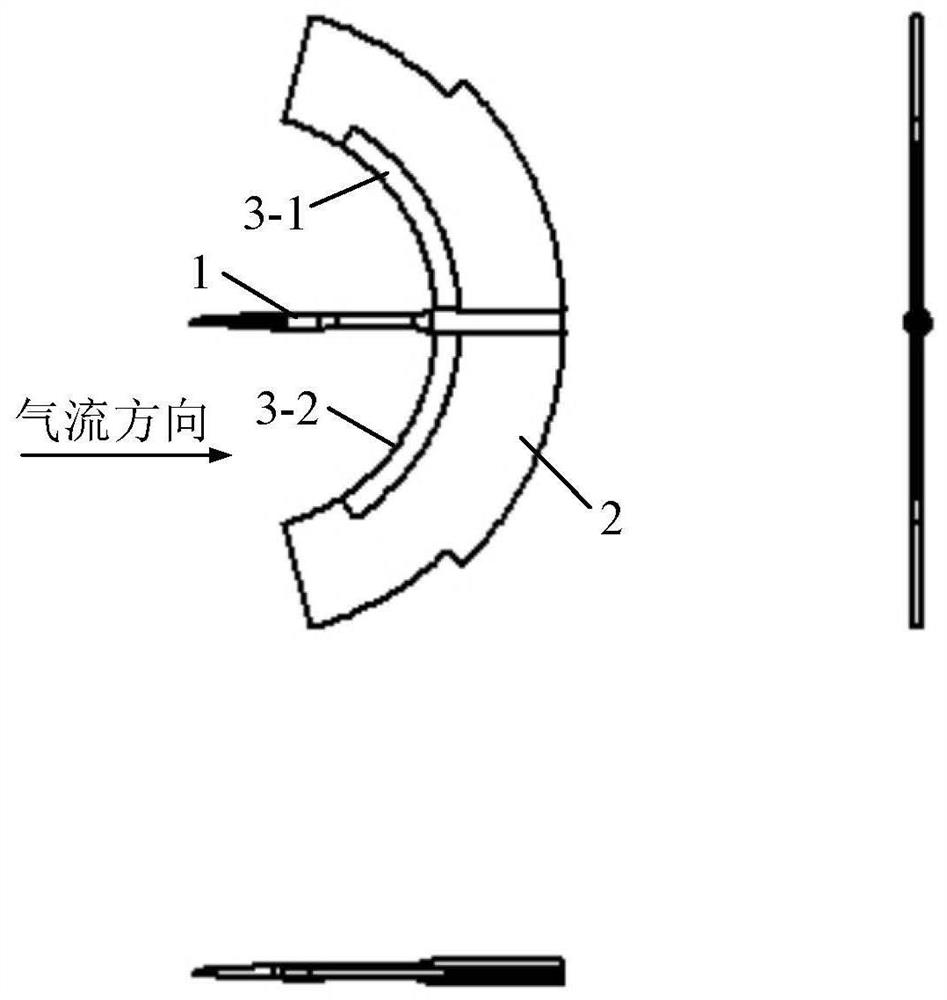

Wind tunnel test section model support structure with front edge bionic noise reduction structure

InactiveCN112629803AIncrease floor spaceImprove the test environmentAerodynamic testingEngineeringFront edge

The invention provides a wind tunnel test section model support structure with a front edge bionic noise reduction structure. The wind tunnel test section model support structure sequentially comprises a 10-degree cone of a model support and a bent knife tightly connected with the 10-degree cone from the upstream to the downstream of airflow. The front edge part of the bent knife structure has a certain wedge degree, and the remaining parts are equal in thickness. The bent knife is in a smooth streamline shape and is in mirror symmetry about the axis of the 10-degree cone. The bent knife structure is tightly connected with the 10-degree cone. When a wind tunnel works, airflow passes through a contraction section and enters a test section, and in the test section, the airflow firstly flows through the test model supported on the model support and then flows through the 10-degree cone and the bent knife; and then the airflow enters the wind tunnel diffusion section. The part, not connected with the 10-degree cone, of the bent blade front edge is designed to be of a sawtooth-shaped structure or a wavy structure, the two bent blade front edge structures reduce front edge interference noise by weakening the response of the bent blade to incoming flow turbulence, tail edge self-noise is restrained by influencing the stability of a boundary layer through a flow direction vortex at a wave trough, background noise of a wind tunnel test section is reduced, and the acoustic performance of the wind tunnel is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

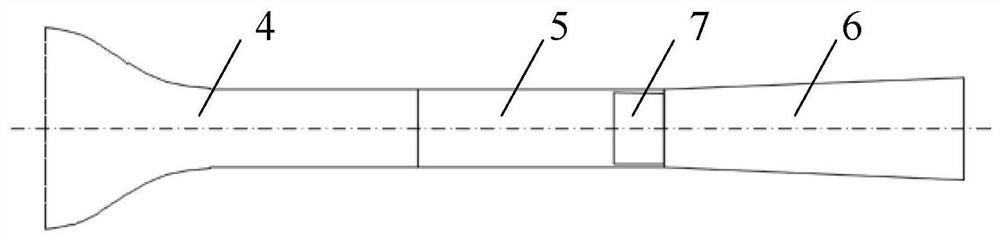

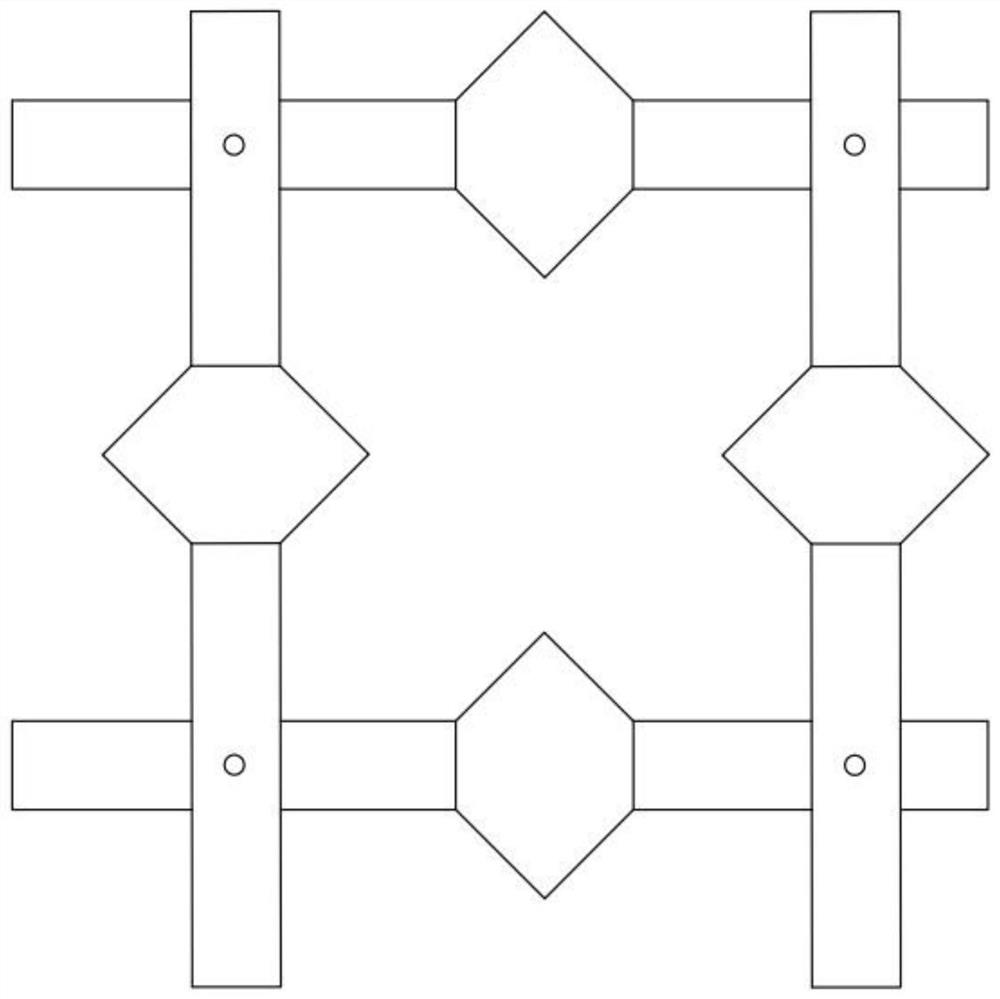

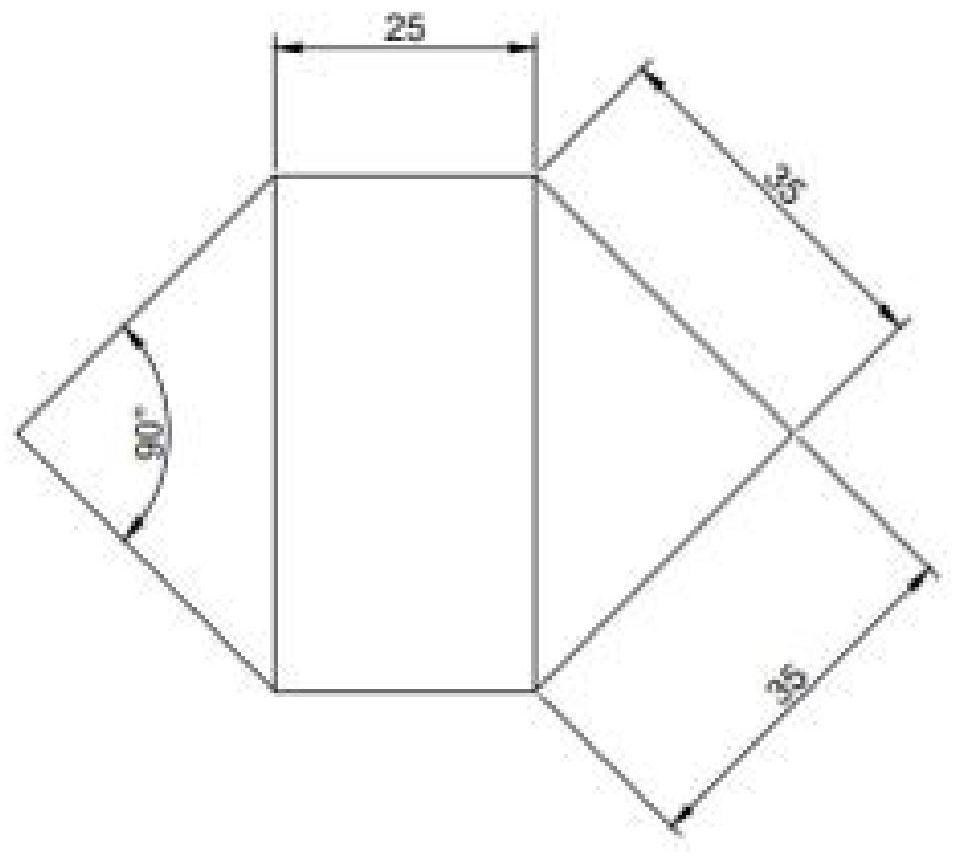

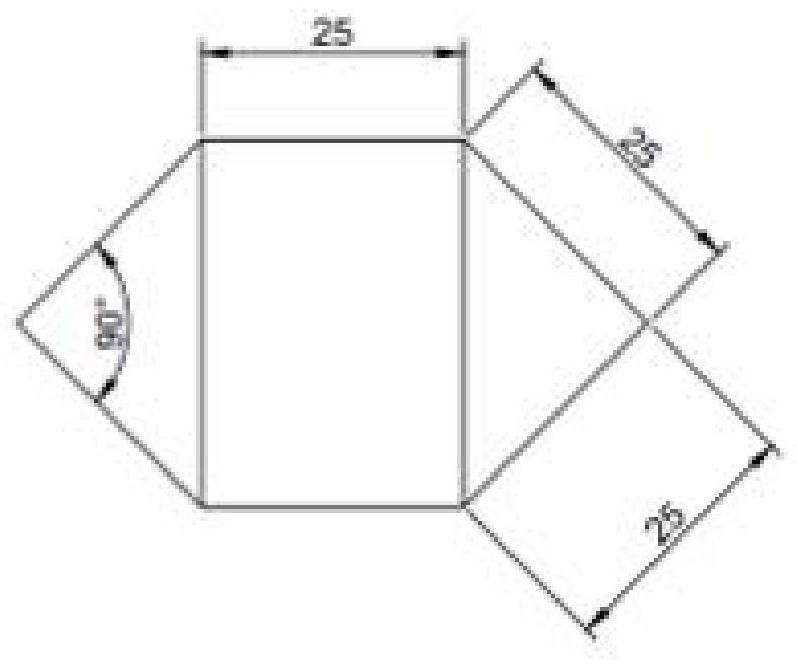

Grid for improving wind parameter characteristics of turbulence flow field in wind tunnel test

PendingCN113188750ARaise the integral scaleIncrease steady flow strengthAerodynamic testingRight triangleEngineering

The invention discloses a grid for improving wind parameter characteristics of a turbulent flow field in a wind tunnel test, and the grid improves the wind parameter characteristics of the turbulent flow field through improving the shape of a square blank, firstly, a hexagonal accessory plate is pasted at the midpoint of the lattice edge of each grid, and the hexagonal accessory plate extends towards the square blank to form a right triangle shield, and thus all the square spaces are transformed into X-shaped spaces; and secondly, an octagonal accessory plate is adhered to each grid node, so that a right-angled triangle is formed at one corner of each square space for shielding, and all the square spaces are transformed into octagonal spaces. Experiments prove that the integral scale of a turbulent flow field can be greatly improved, the steady flow intensity of a wind field is improved, the transverse uniformity and correlation are improved, and the flow field characteristics of the grid turbulent flow field are improved.

Owner:SOUTHWEST JIAOTONG UNIV

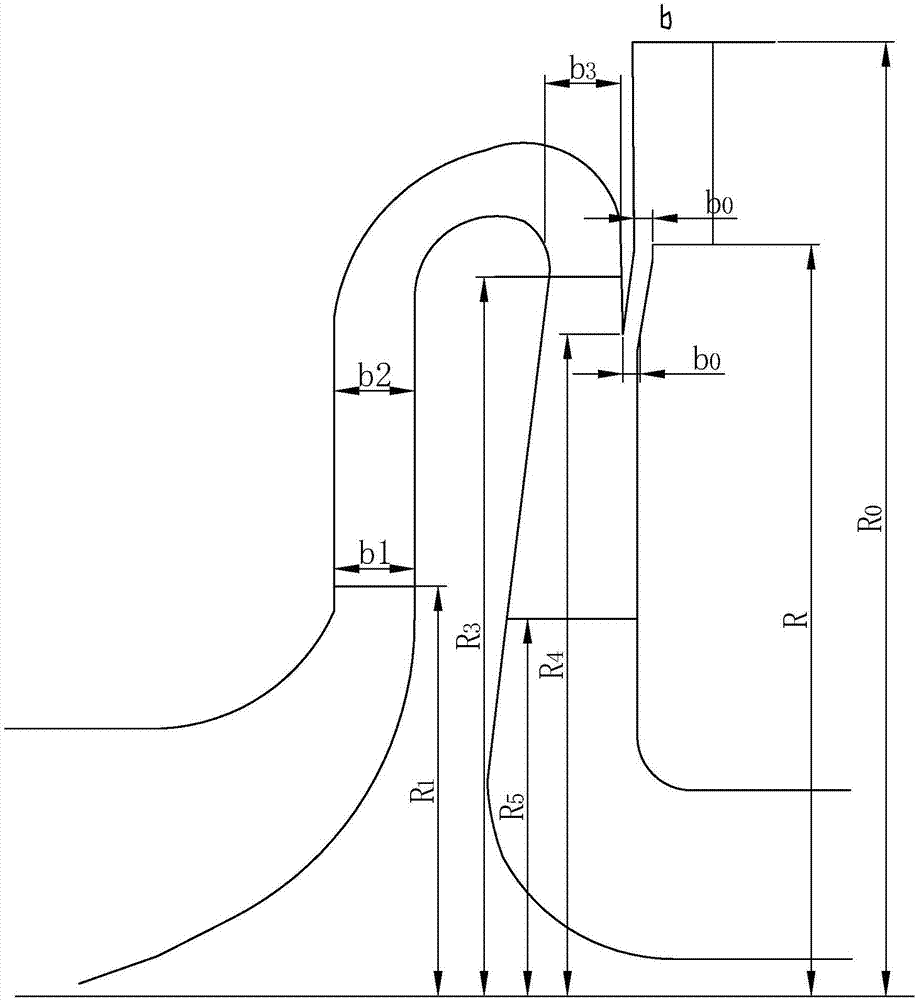

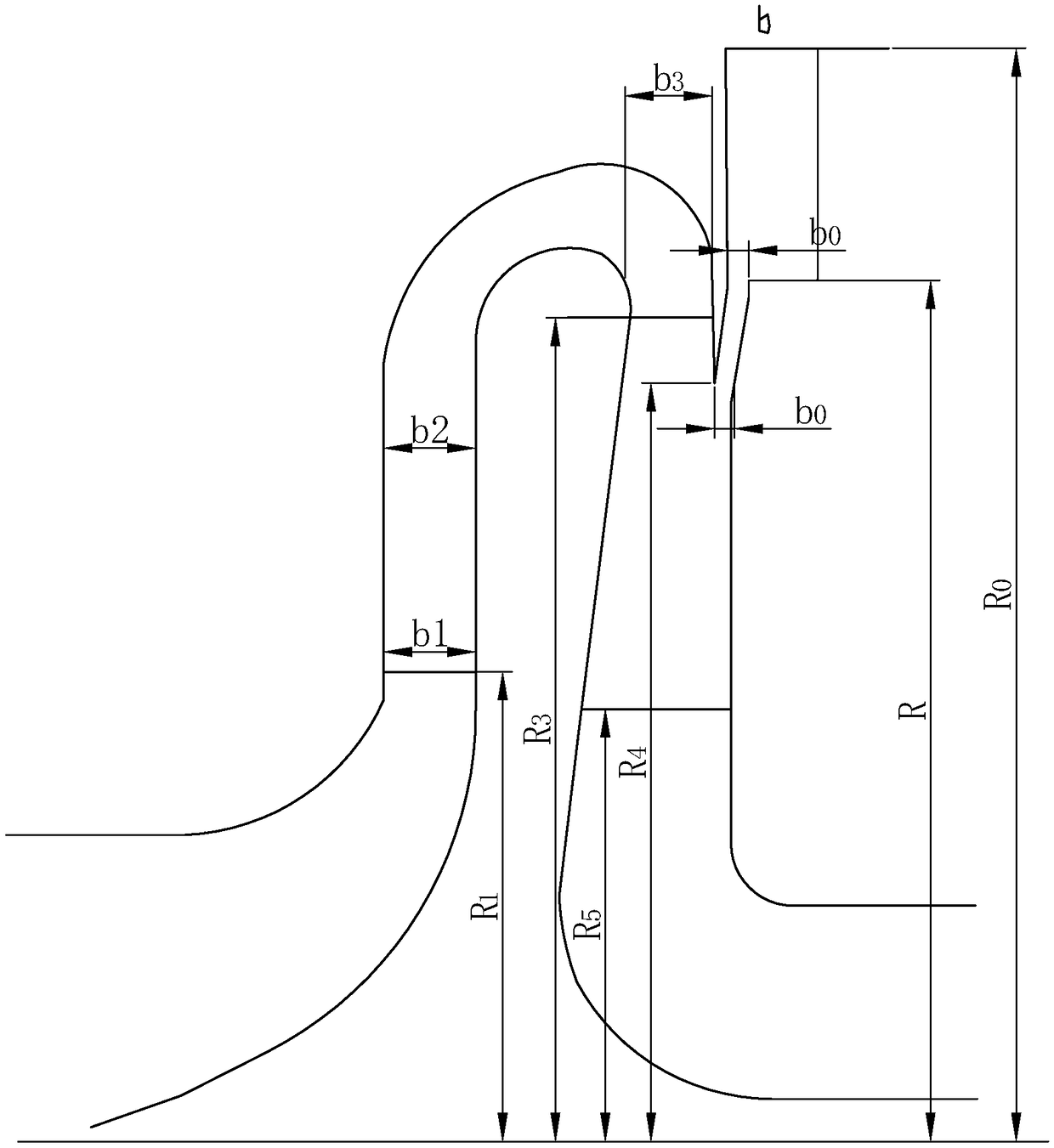

High-flow compact interstage air entraining method of centrifugal compressor

ActiveCN106870455AFlexible filling port position selectionSimple structural designGeometric CADPump componentsDesign cycleEngineering

The invention discloses a high-flow compact interstage air entraining method of a centrifugal compressor and aims to provide an air entraining design scheme which has the advantages of simplicity, high efficiency and compact size. The high-flow compact interstage air entraining method is characterized in that air entrained flow, the flow of primary air and entrained air in a backflow device and the characteristics of a flow field of an outlet of a mixed section are comprehensively analyzed, and air is entrained in the middle section of a blade of the backflow device, so that the design cycle is shortened, the production process is simplified, and materials are saved, thereby reducing the production cost of a unit.

Owner:TAIZHOU REXCHIP MECHANICAL & ELECTRICAL CO LTD

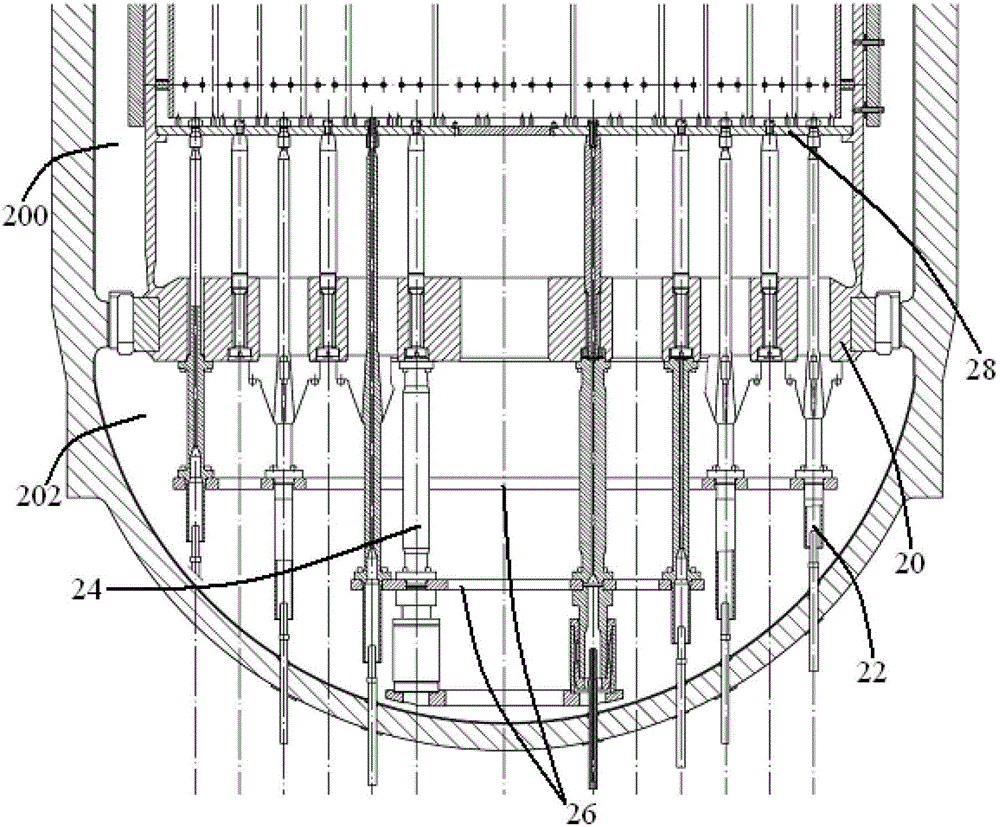

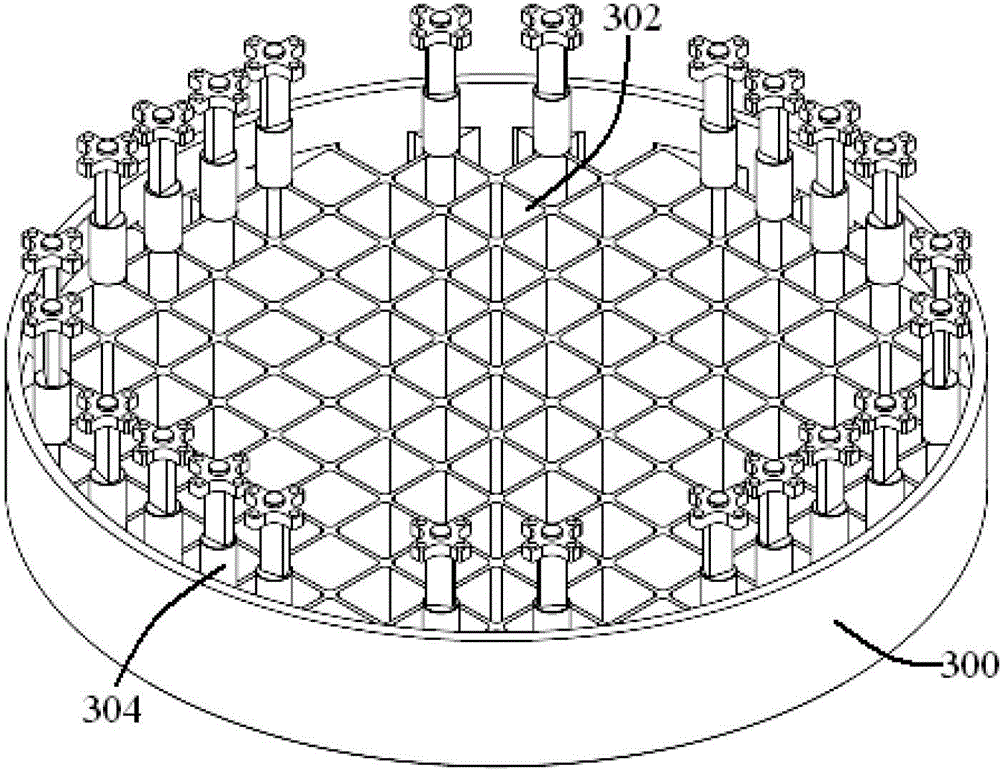

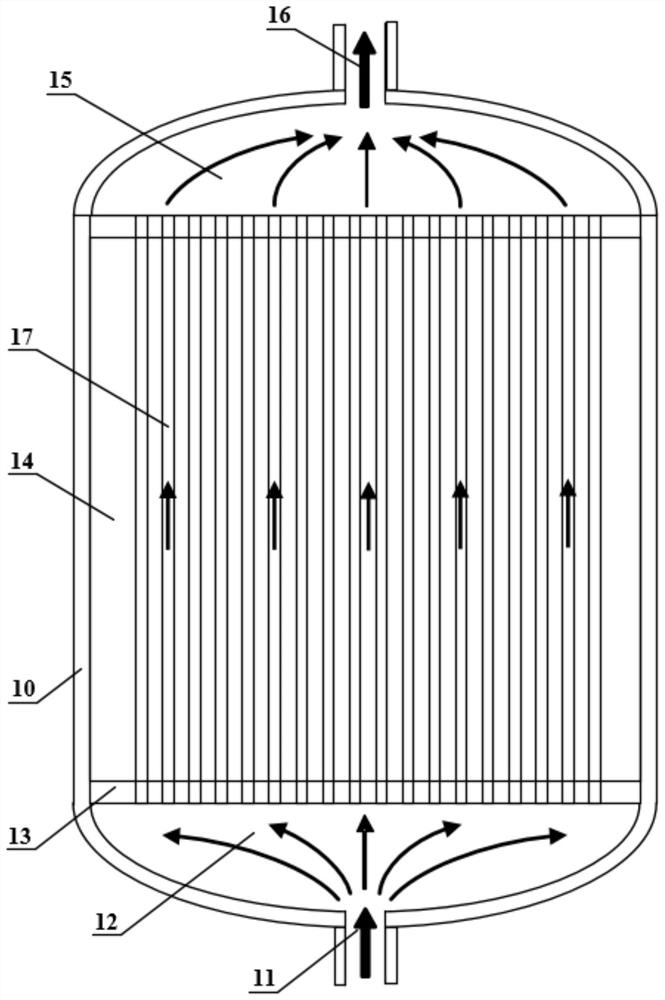

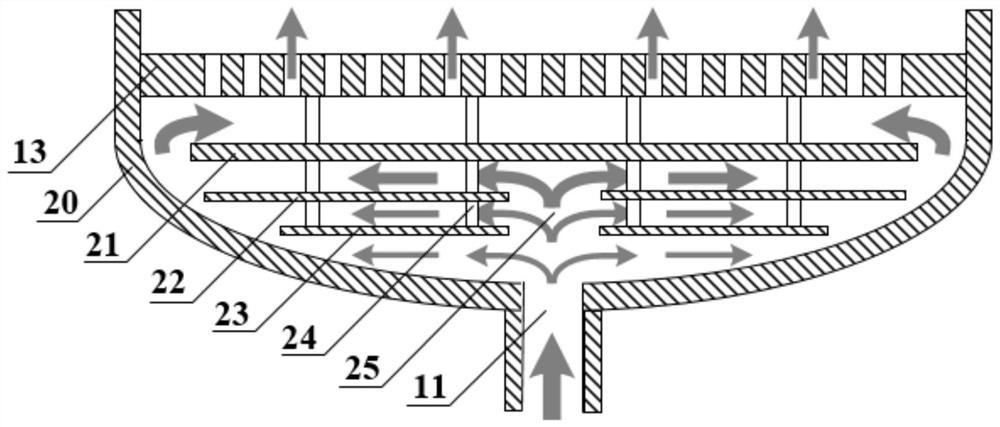

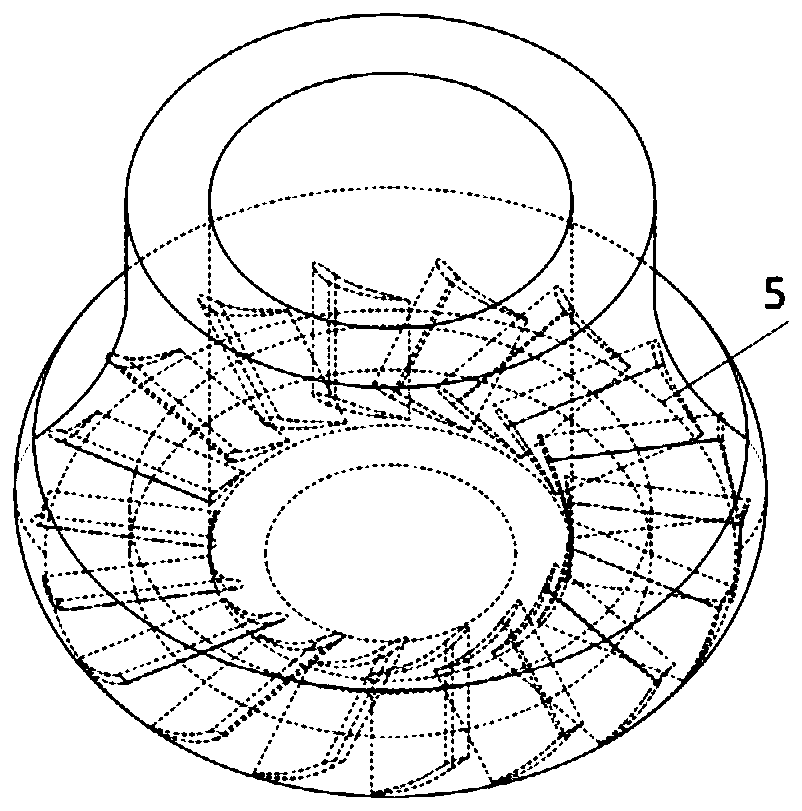

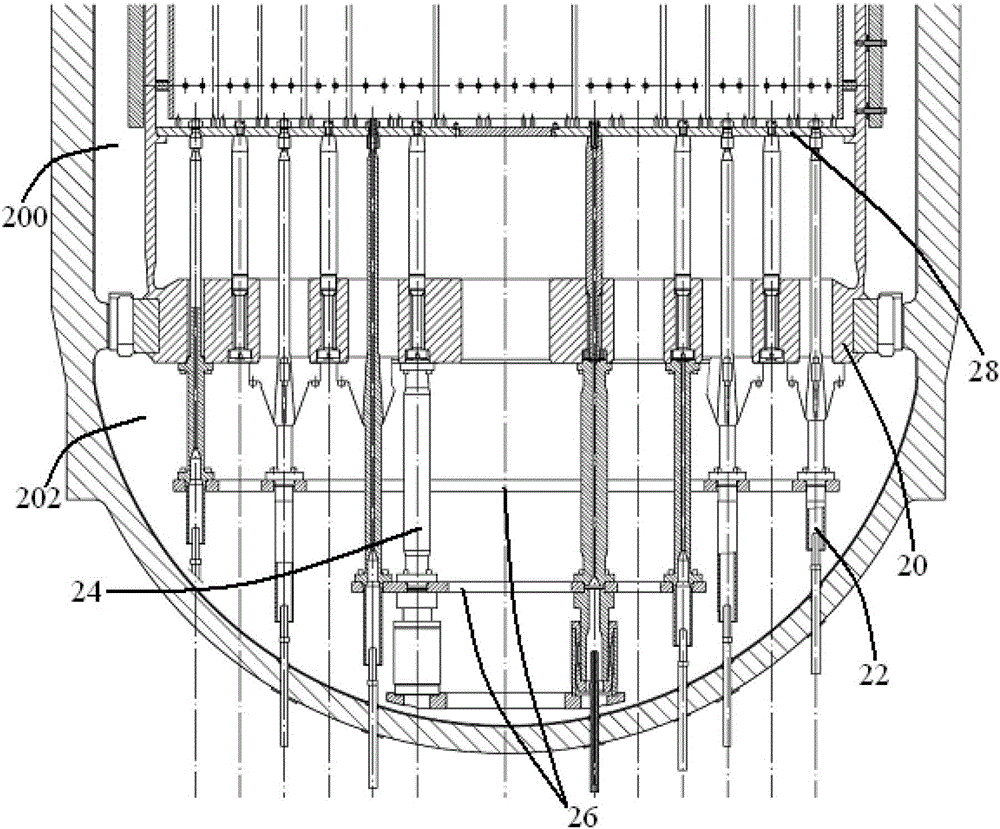

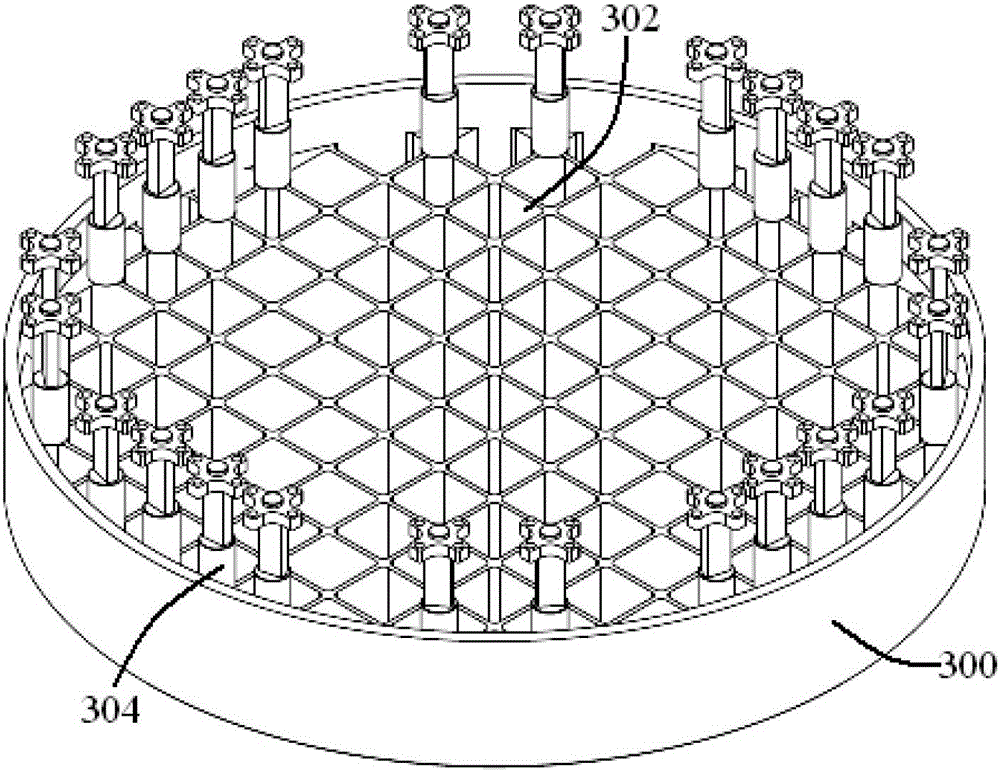

Lower chamber structure of reactor container and reactor container

ActiveCN111681786ARandom combinationImprove flow field characteristicsNuclear energy generationContainmentReactor designMechanical engineering

The invention discloses a lower chamber structure of a reactor container and the reactor container. The lower chamber structure comprises a reactor core supporting bottom plate, a reactor container lower sealing head and a reactor lower chamber inlet, a flow distribution plate circular plate is fixedly connected with a reactor core supporting bottom plate in parallel, the radial width of the flowdistribution plate circular plate is smaller than that of the reactor core supporting bottom plate, the radial width of the flow distribution plate circular plate is greater than or equal to the diameter of the circular area with the holes in the reactor core supporting bottom plate and is not in contact with the interior of the reactor container lower sealing head an inlet of the reactor lower chamber is formed in the reactor container lower seal head in the area below the flow distribution plate circular plate, the device further comprises a perforated circular plate on the flow distribution plate, and through holes are formed in the perforated circular plate on the flow distribution plate. According to the lower cavity structure, the flow field characteristic of the lower cavity is effectively improved, vortexes in the lower cavity are avoided, flow distribution is conducted on fluid in combination with the reactor core lower supporting plate, and the flow distribution of the fluidentering the reactor core reaches the design target of the reactor.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

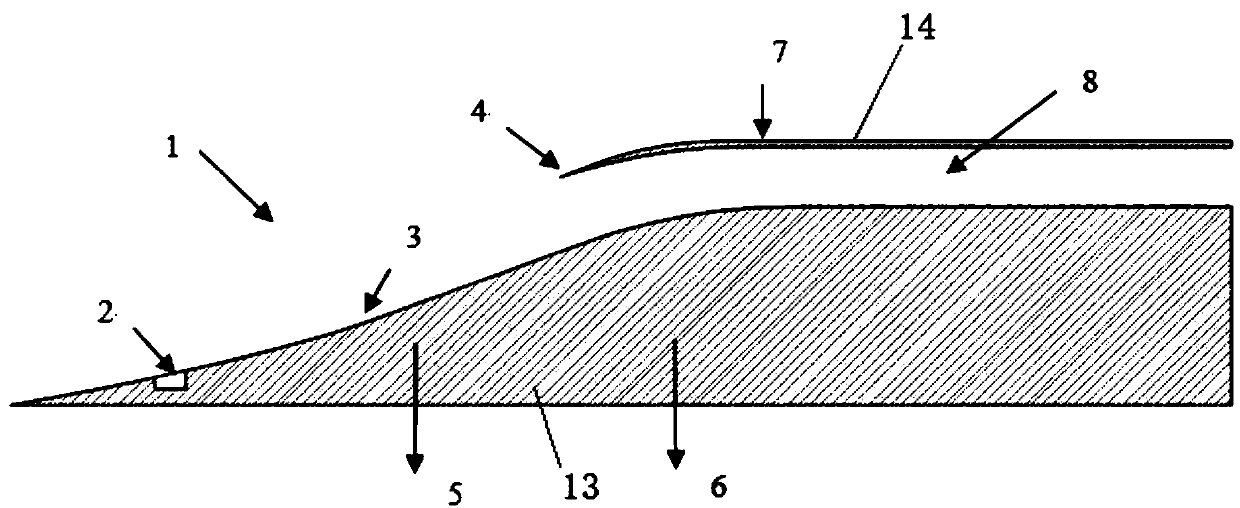

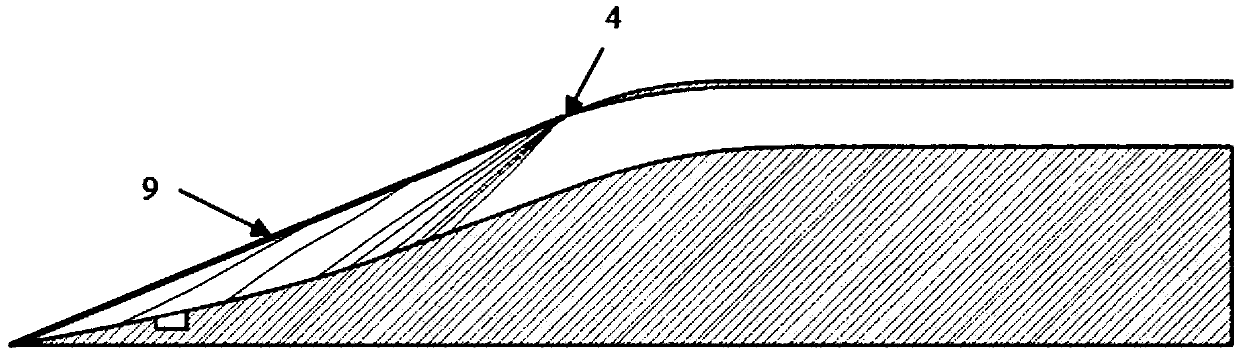

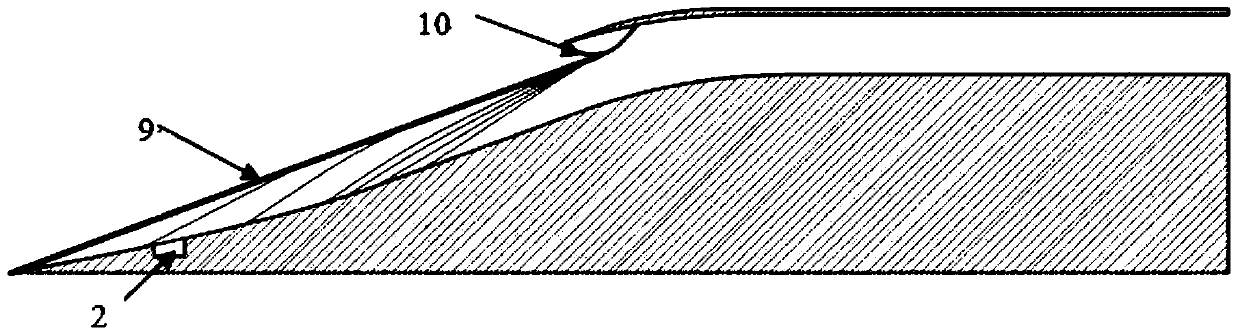

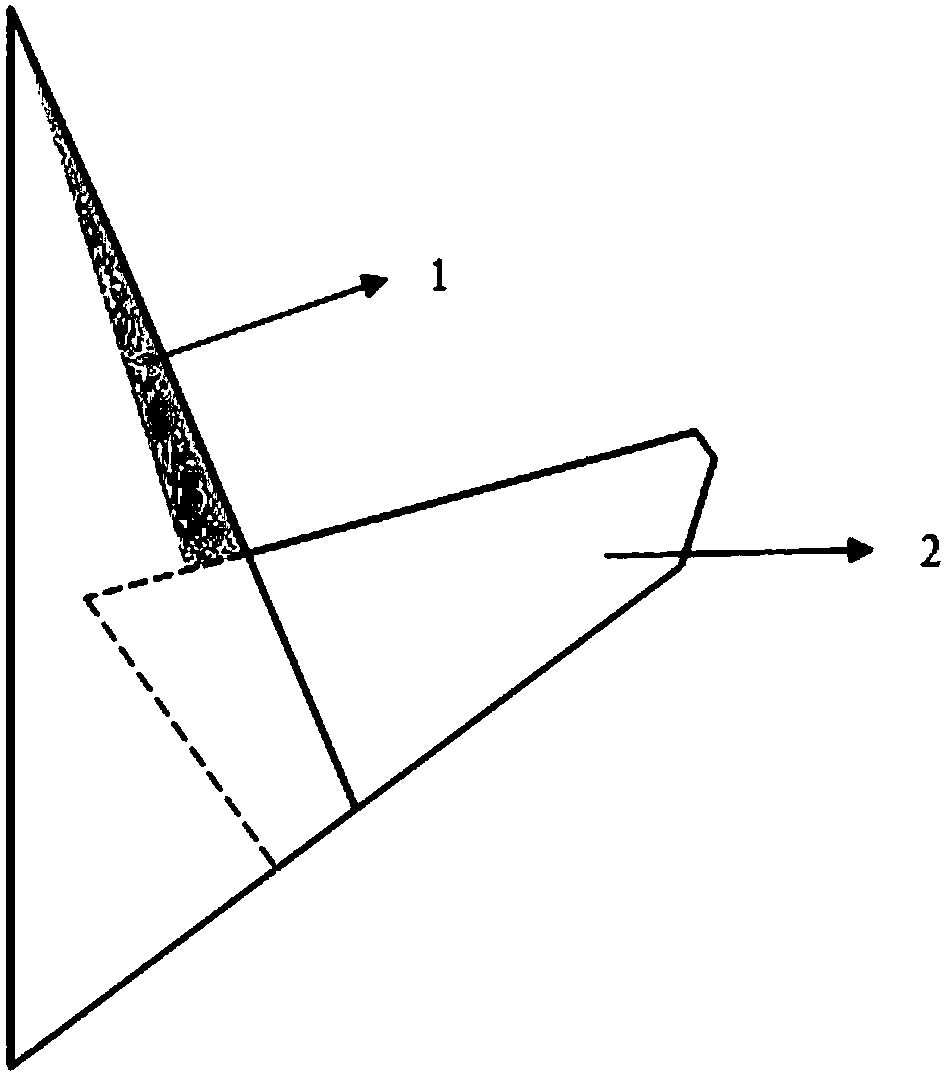

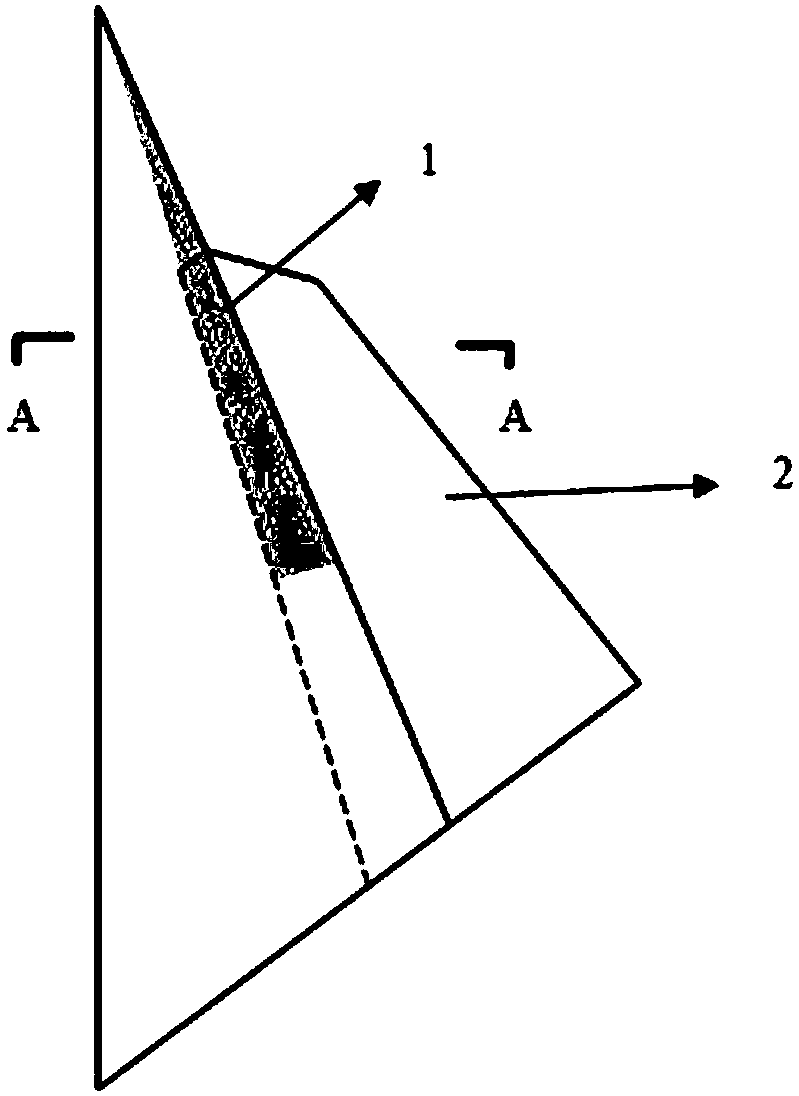

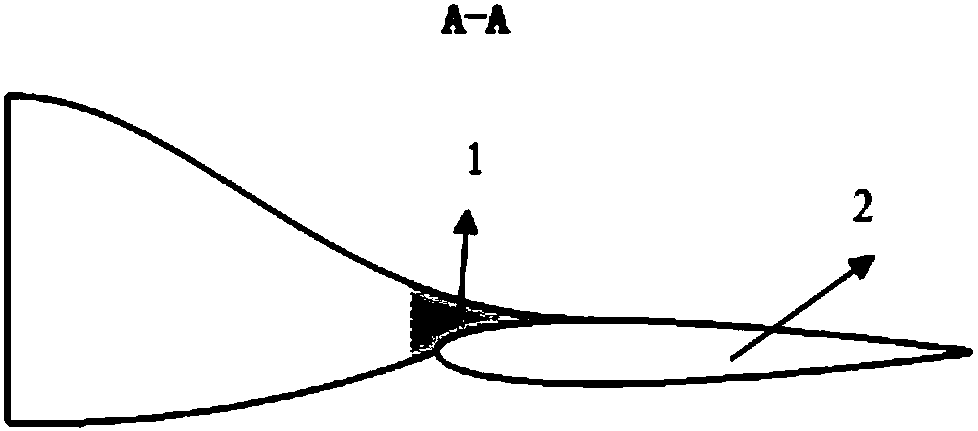

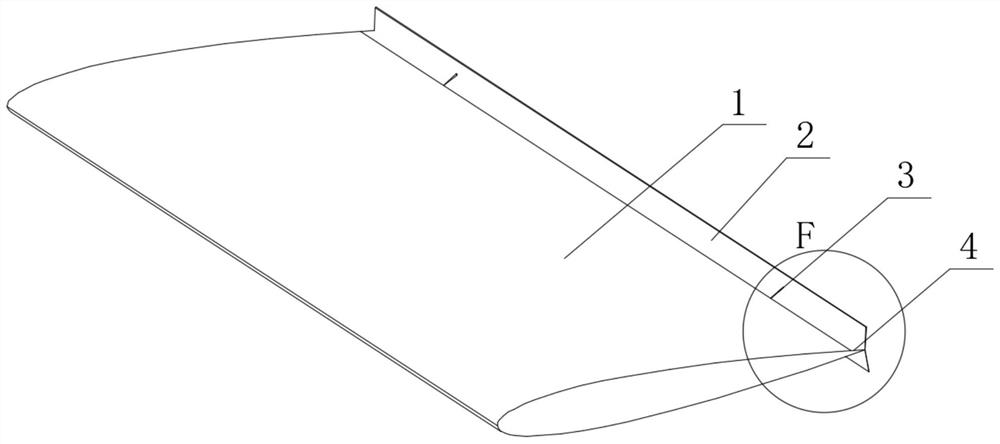

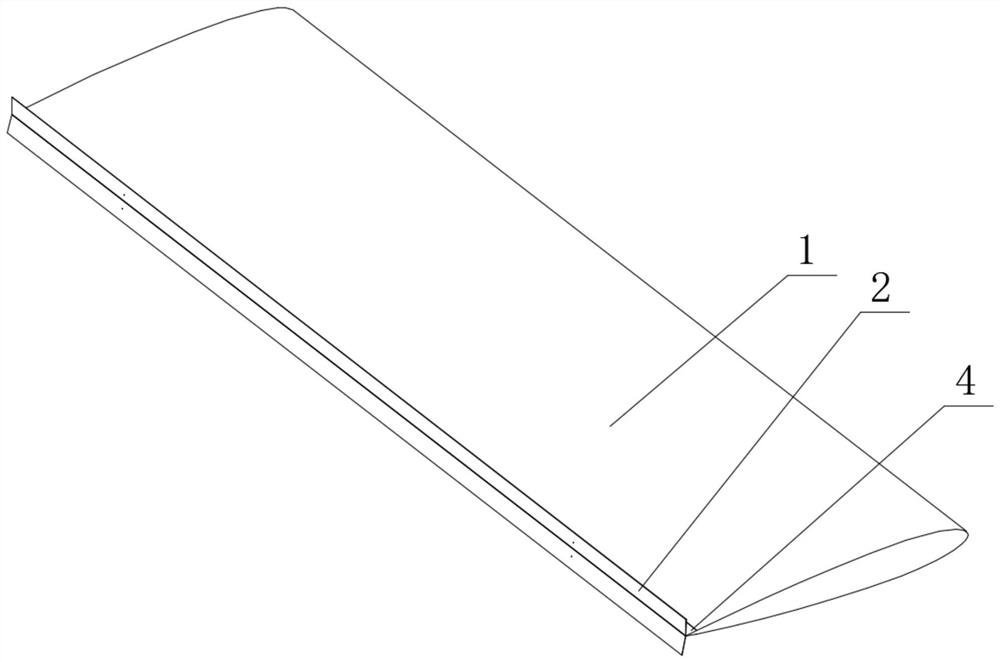

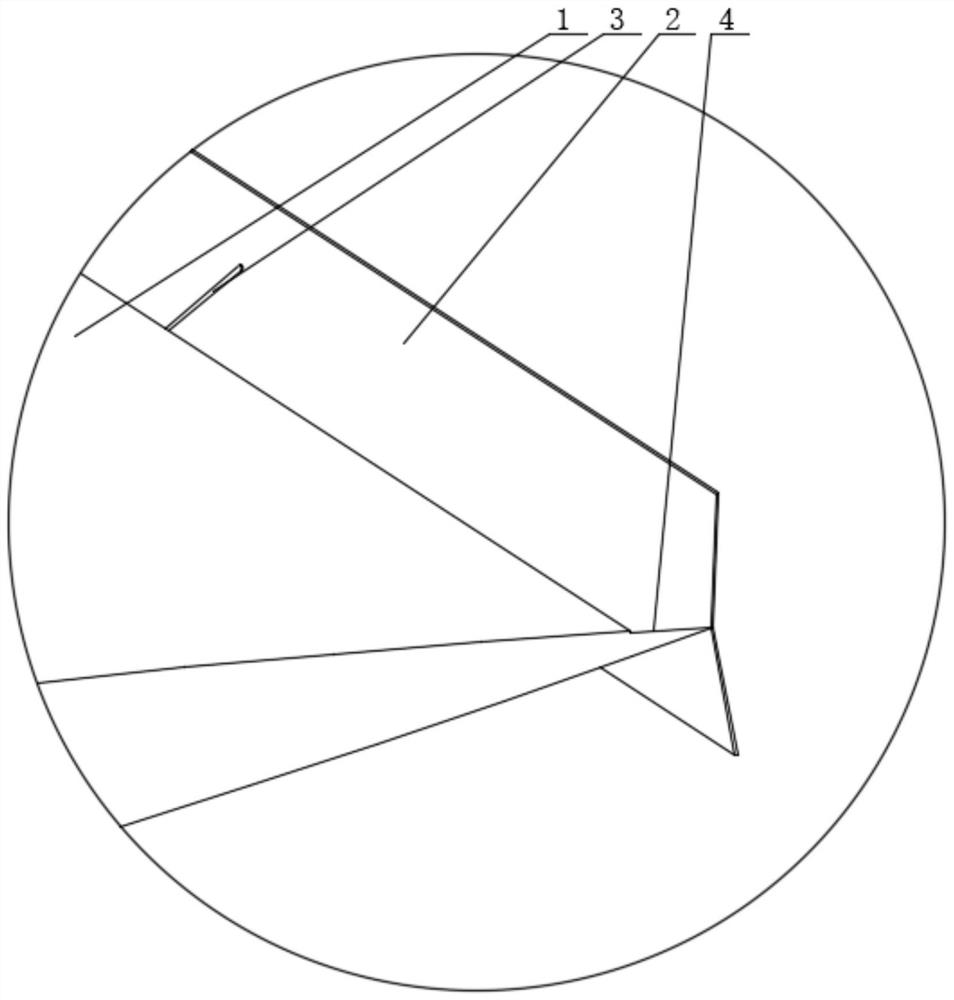

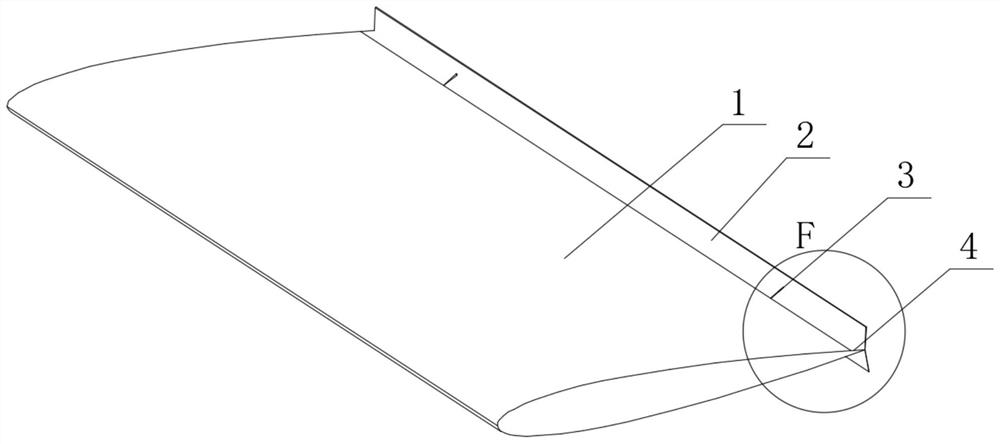

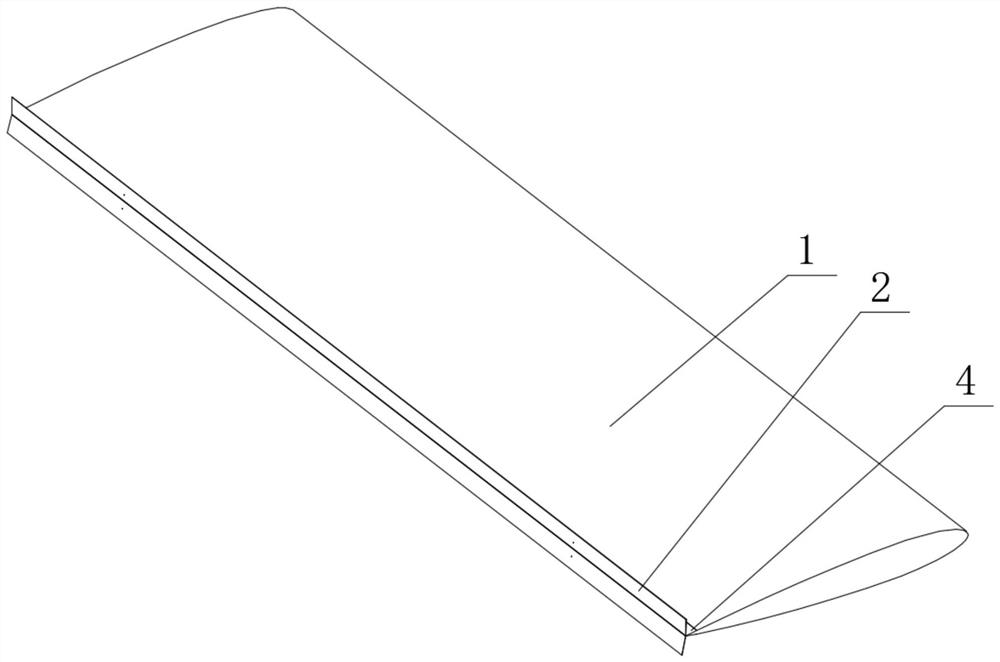

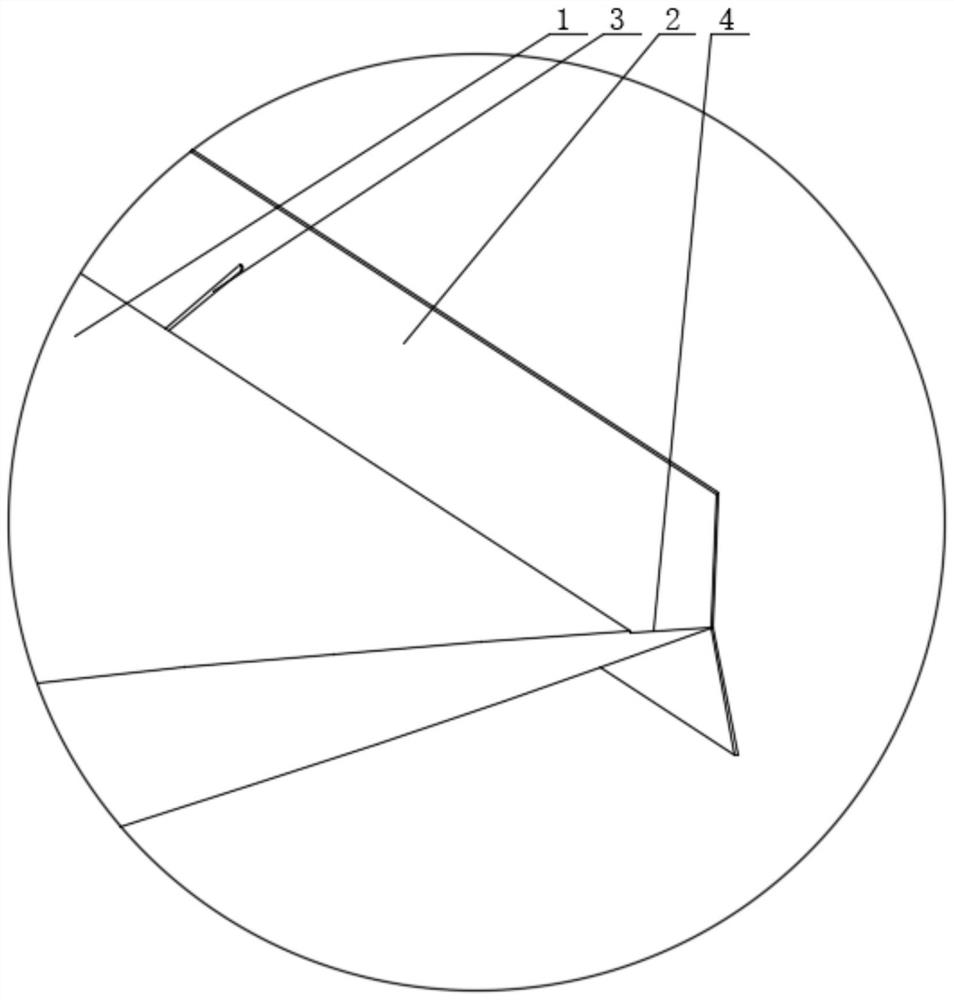

Wing surface fusion-type edge strips

PendingCN108190005AImprove flow field characteristicsImproved supersonic cruiseHeat reducing structuresSeparated stateFuselage

The invention relates to wing surface fusion-type edge strips (1) which are attached to the outer side of an aircraft fuselage and the front ends of aircraft wings (2), when the wing surfaces of the aircraft wings (2) are in an open state, the wing surface fusion-type edge strips (1) and the wing surfaces of the aircraft wings (2) are in a separated state, when the wing surfaces of the aircraft wings (2) are in a closed state, the wing surface fusion-type edge strips (1) and the wing surfaces of the aircraft wings (2) are connected, and the boundary of the connecting joint part reaches the maximum thickness of the wing profile of the upper wing surface of the aircraft wings (2), so that the upper surfaces of the fusion-type edge strips (1) and the upper wing surfaces (2) of the aircraft wings (2) form a second order curvature continuous curved surface. The wing surface fusion-type edge strips can improve the flow field characteristic of the upper wing surfaces of the wings (2), the wing surface lifting force is increased, the maneuvering ability of the whole aircraft is improved, the whole aircraft resistance is effectively reduced, the supersonic cruise lift-drag ratio of the whole aircraft is increased, and the supersonic cruise and penetration ability of the whole aircraft is effectively improved.

Owner:中国航空工业集团公司哈尔滨空气动力研究所

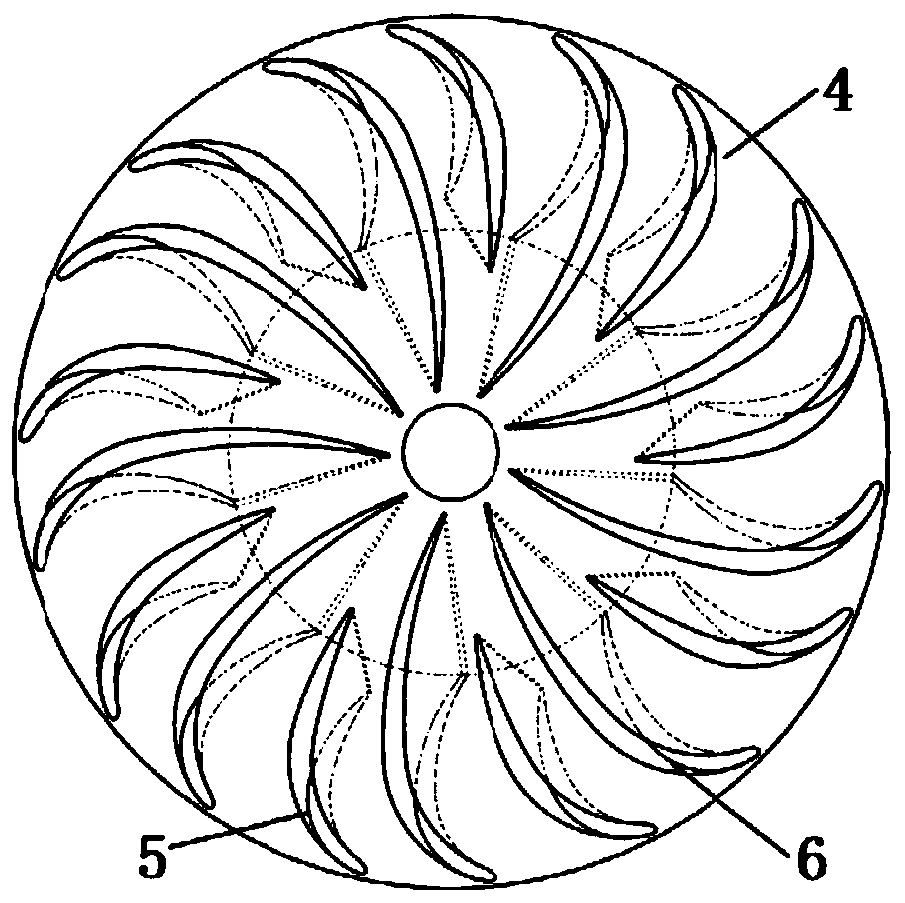

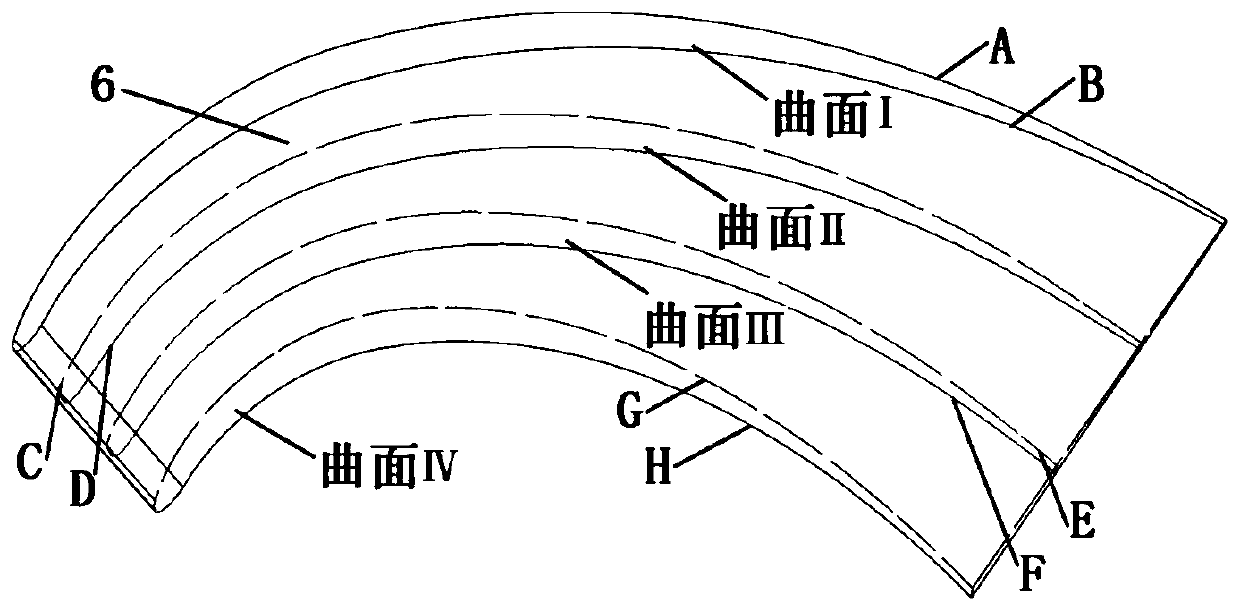

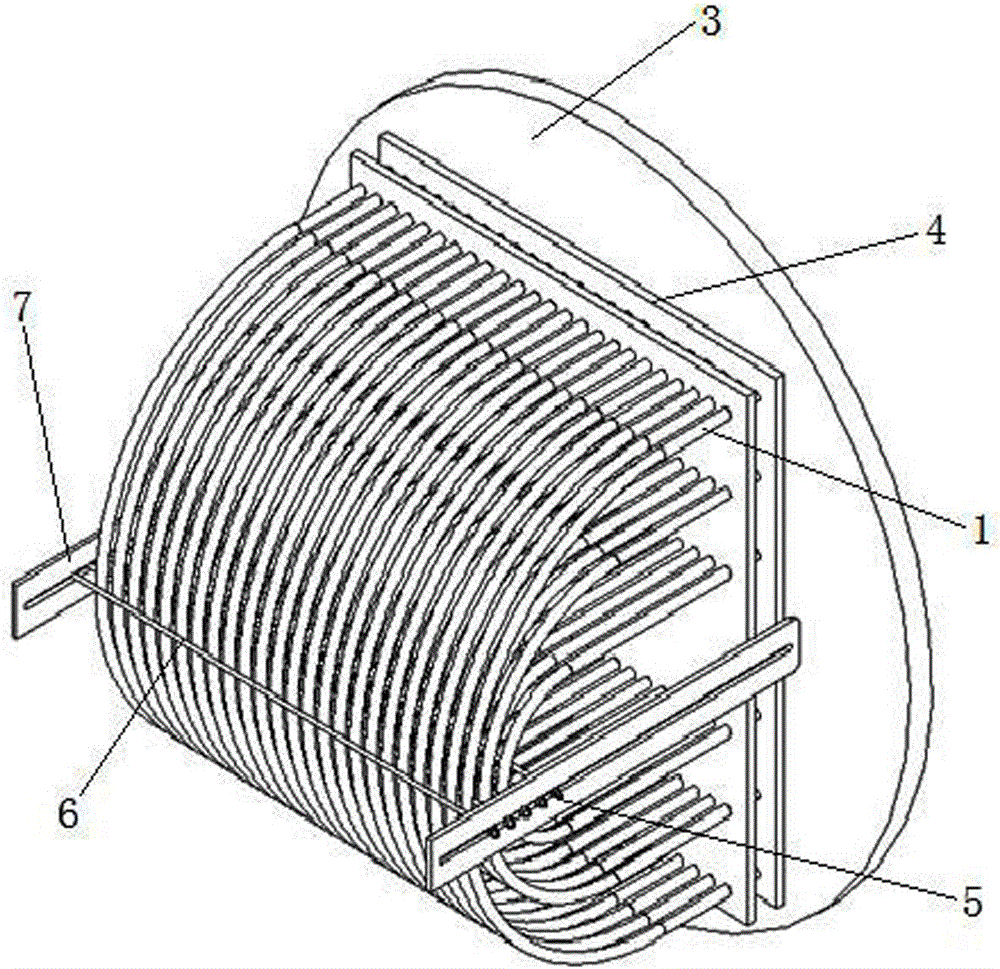

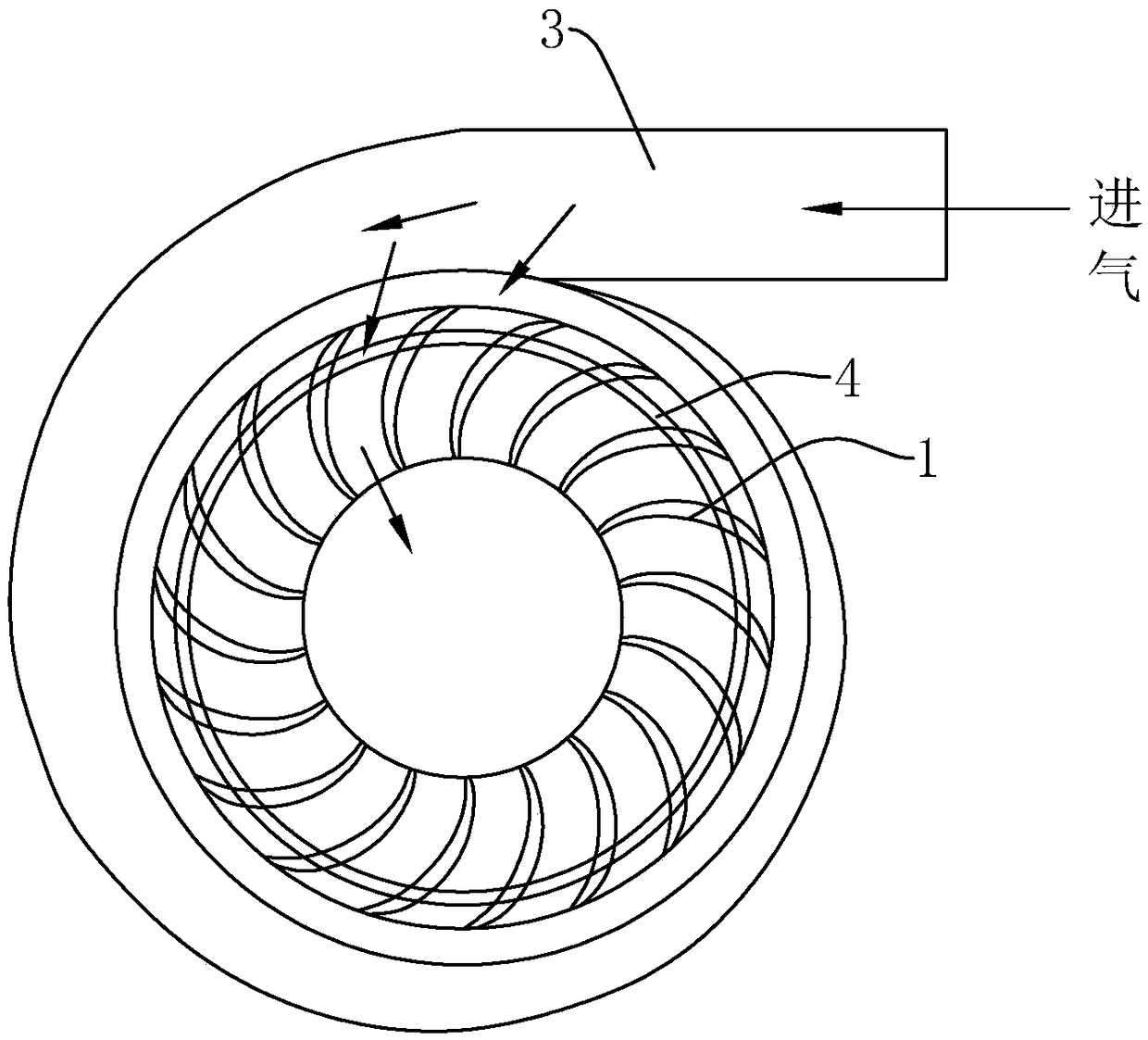

A Francis turbine with long and short blades

ActiveCN109139334BImprove flow field characteristicsImprove efficiencyHydro energy generationReaction enginesMixed flowWater turbine

The invention discloses a mixed flow type splitter blade water turbine. The overflowing area of the water turbine comprises a volute, a guide blade area, a rotating wheel and a draft tube which are connected in sequence, blades of the rotating wheel are formed by multiple long blades and short blades in a spaced manner, the length ratio of the oval cross section of the volute is the golden sectionproportion, the guide blade profile is in a negative curvature crescent shape, the blades of the rotating wheel are jointly formed by the long blades and the short blades, the inlet and outlet diameter difference ratio of the short blades and the long blades is 0.859, and rectifier plates are arranged in the conical draft tube. Efficient use of water flow energy is achieved, the running stabilityof a unit is improved while the work efficiency of the water turbine is improved, the water turbine has the wide application prospects and the popularization value, and the water turbine has the important significance in small hydropower station transformation and improving of the running stability of power plant units of the China at present.

Owner:NORTHWEST A & F UNIV

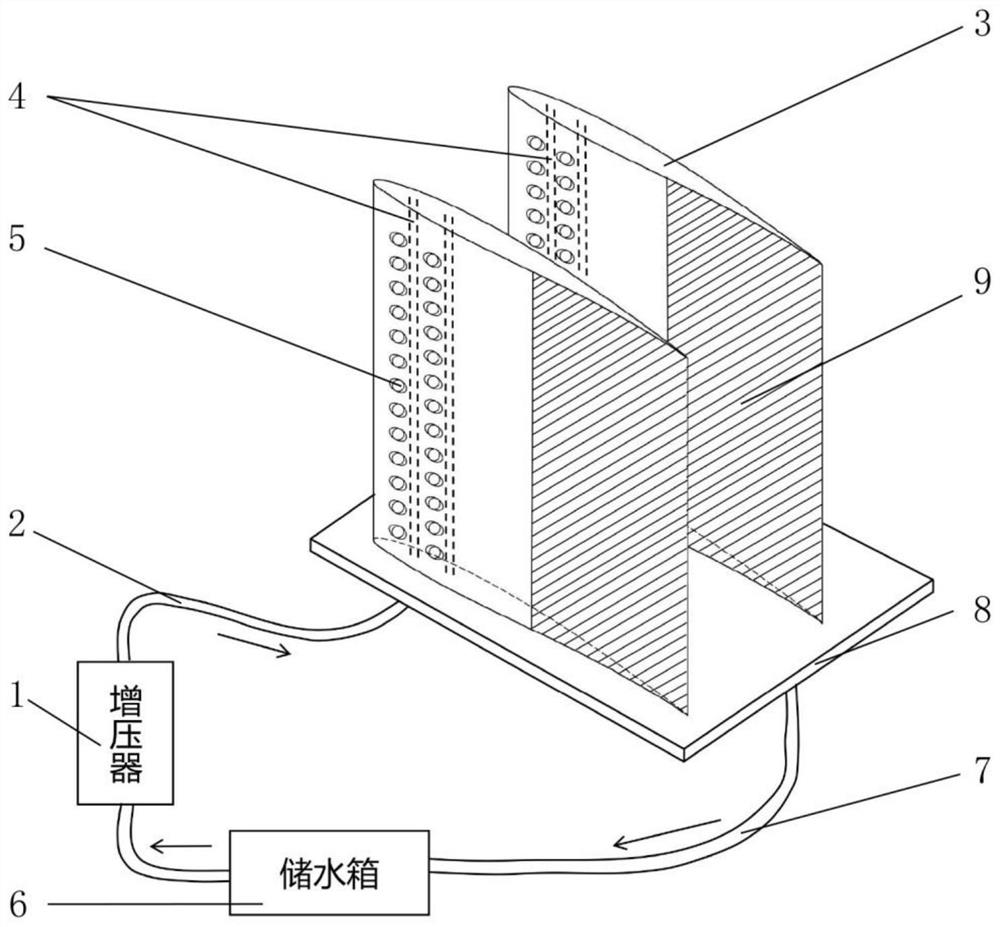

Humidifying and silencing ventilation pipeline device

ActiveCN110081580AInhibitionInhibit sheddingDucting arrangementsLighting and heating apparatusVentilation tubeWater discharge

The invention provides a humidifying and silencing ventilation pipeline device. A plurality of supporting racks are included and arranged in a ventilation pipeline. The section of each supporting rackis in a symmetric streamline shape, the head-tail direction of each supporting rack is kept to be consistent with the gas flowing direction, and gas jet flow flows towards the tails of the supportingracks from the heads of the supporting racks. An inner pipeline is arranged on the inner side of the front portion of each supporting rack, and a plurality of water spraying holes are formed in the wall faces of the two sides of the front portion of each supporting rack, wherein the inner pipeline comprises a driver, a transmission rod, a supporting pipe, an inner water conveying pipe and a rotary water spraying pipe, water can be sprayed from the positions of the water spraying holes, and the water spraying direction can be adjusted. Drying layers are arranged on the two sides of the rear portion of each supporting rack, water discharging grooves are formed in the lower positions of the drying layers, and the drying layers can absorb water of the surrounding environment and discharge water into the water discharging grooves. The water discharging grooves communicate with a water discharging pipe outside the ventilation pipeline. According to the humidifying and silencing ventilationpipeline device, on the basis of optimizing of the pipeline inner gas flow field, the humidifying noise lowering technology is utilized, spreading of noise in the ventilation pipeline is restrained, and background noise is lowered.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

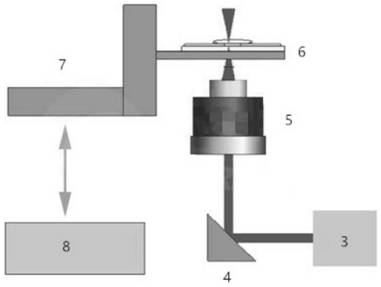

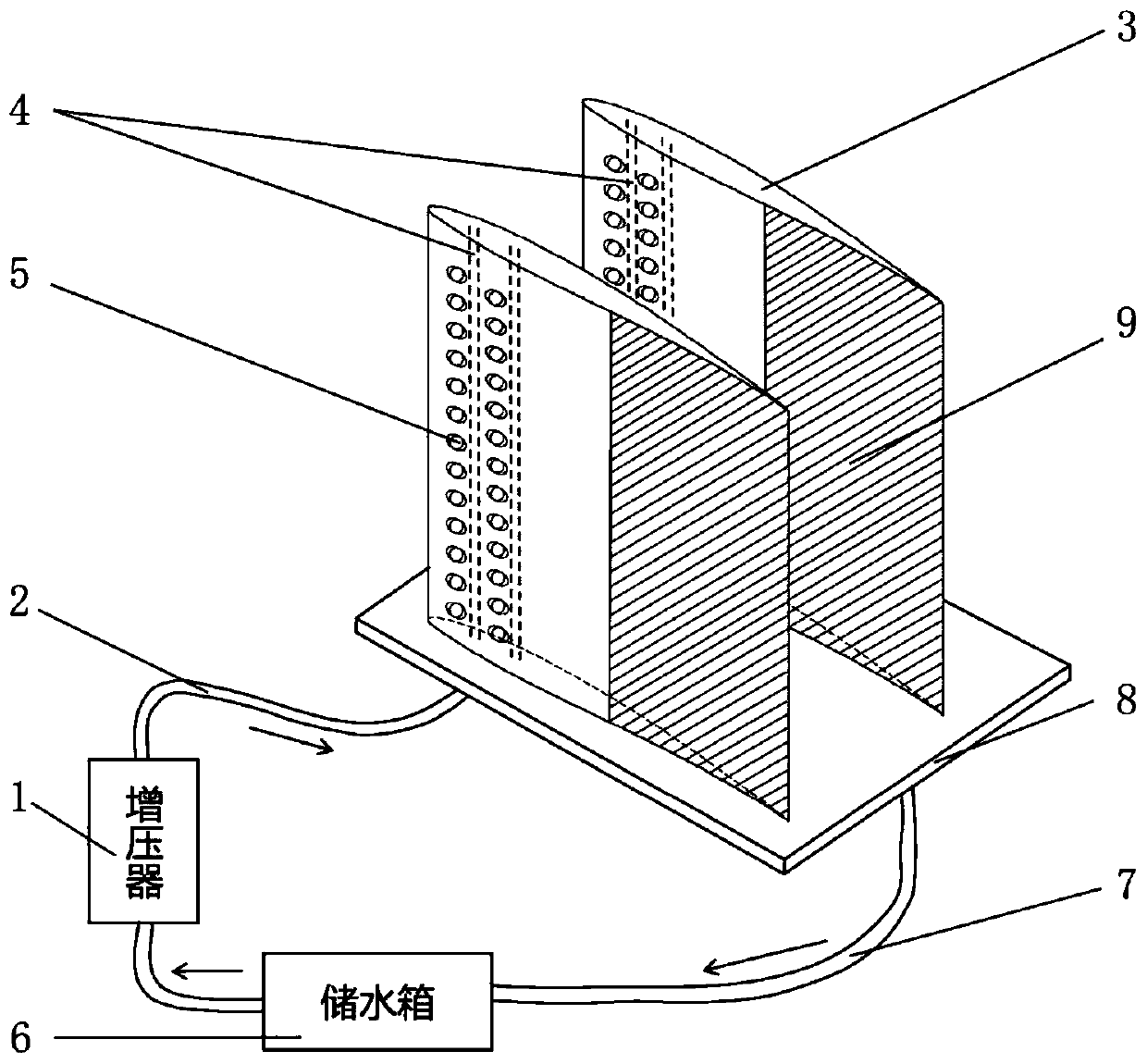

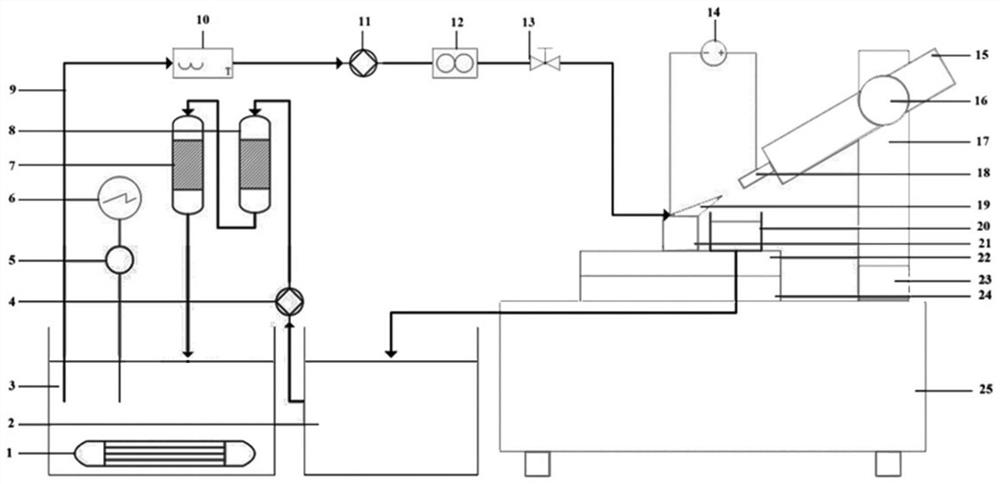

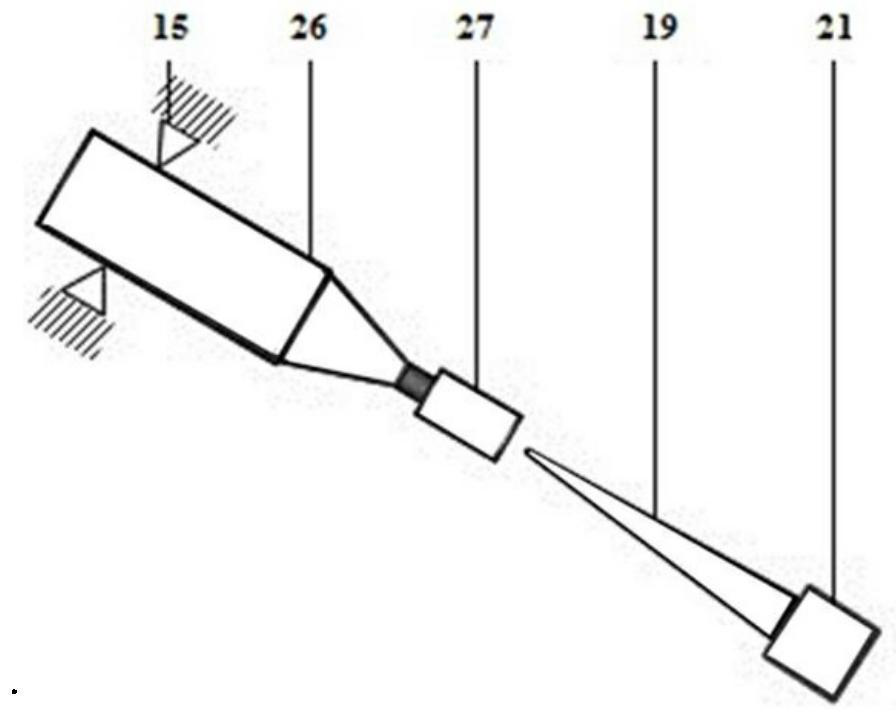

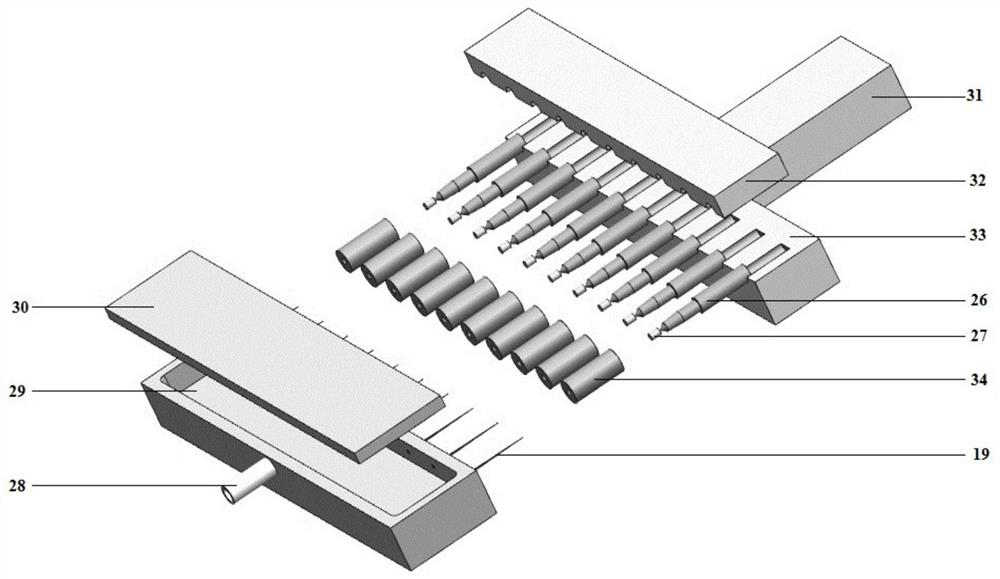

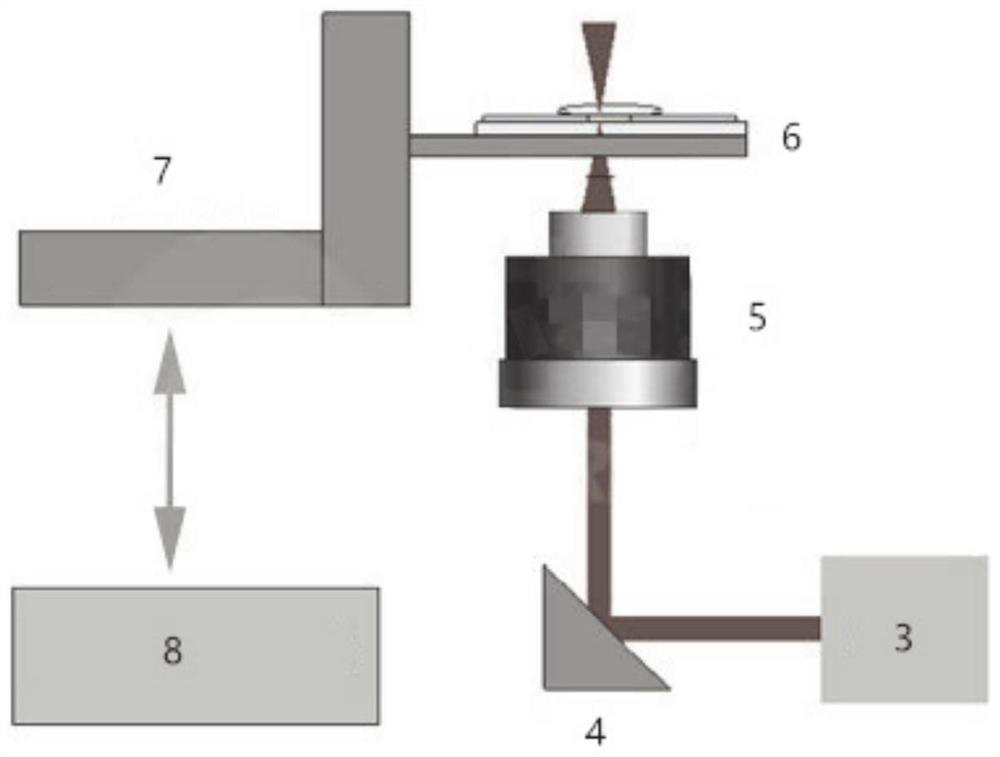

Electrolytic corrosion device for releasing metal mold cores of micro-sized shell-type parts

ActiveCN109972195BSimple structureReduce economic costsElectrolysis componentsElectrochemical machining apparatusElectrolytic agentFiltration

The invention discloses an electrolytic corrosion device for metal mold core demolding of a micro-sized shell-layer type part. The electrolytic corrosion device comprises a cathode system which can move in the X-axis direction and the Y-axis direction, an anode system which is used for positioning and clamping an anode workpiece and can move in the Z-axis direction and can do rotary movement, a flowing-speed-controllable electrolyte circulation and filtration system which is used for circulation, filtration and heating of an electrolyte, and an ion concentration online monitoring system used for monitoring metal ions of the electrolyte, during processing, the anode workpiece and a nozzle of a cathode are in an inclined state, the anode workpiece is positioned obliquely above the nozzle ofthe cathode, under the action of a direct-current pulse power supply, the corrosion voltage is controlled, a metal mold core of the micro-sized shell-layer type part is removed through electrolyte erosion corrosion, and then the shell-layer type metal part is obtained. According to the device, the defects that the common chemical corrosion is low in efficiency and heavy in pollution are overcome,the production efficiency is improved through electrolytic corrosion, and the advantage that the electrolyte can be recycled and is green and environment-friendly is achieved.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

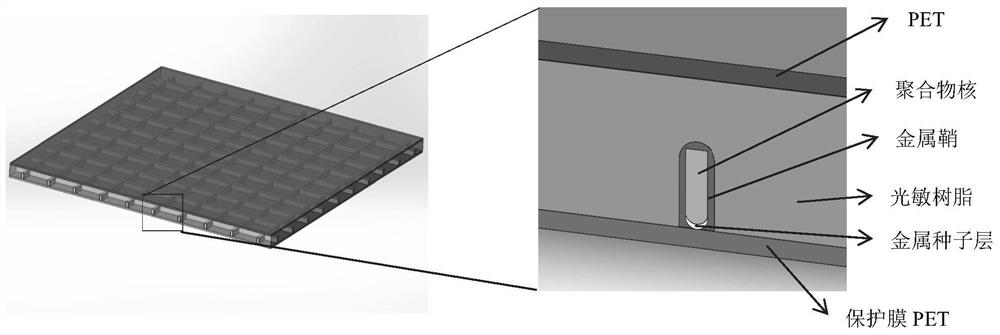

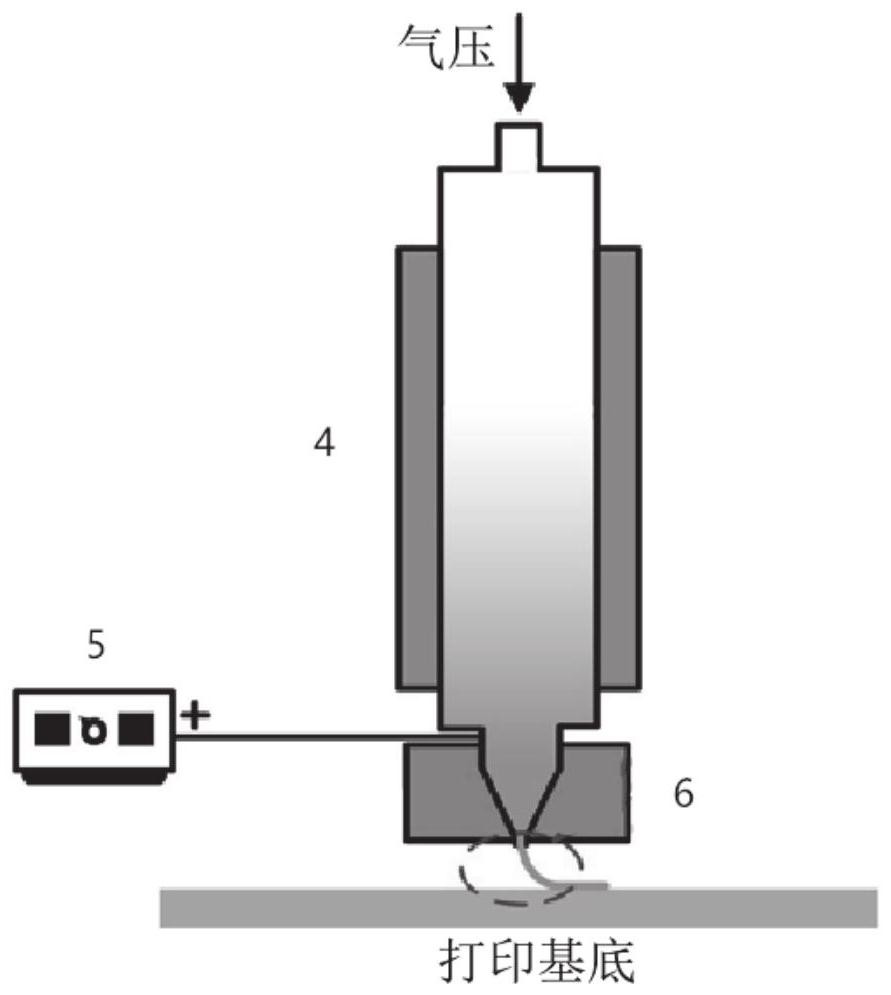

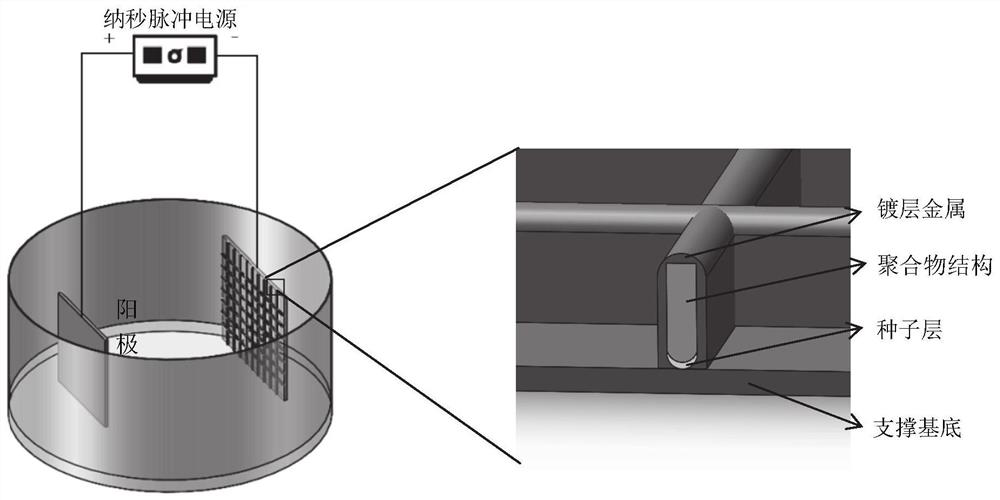

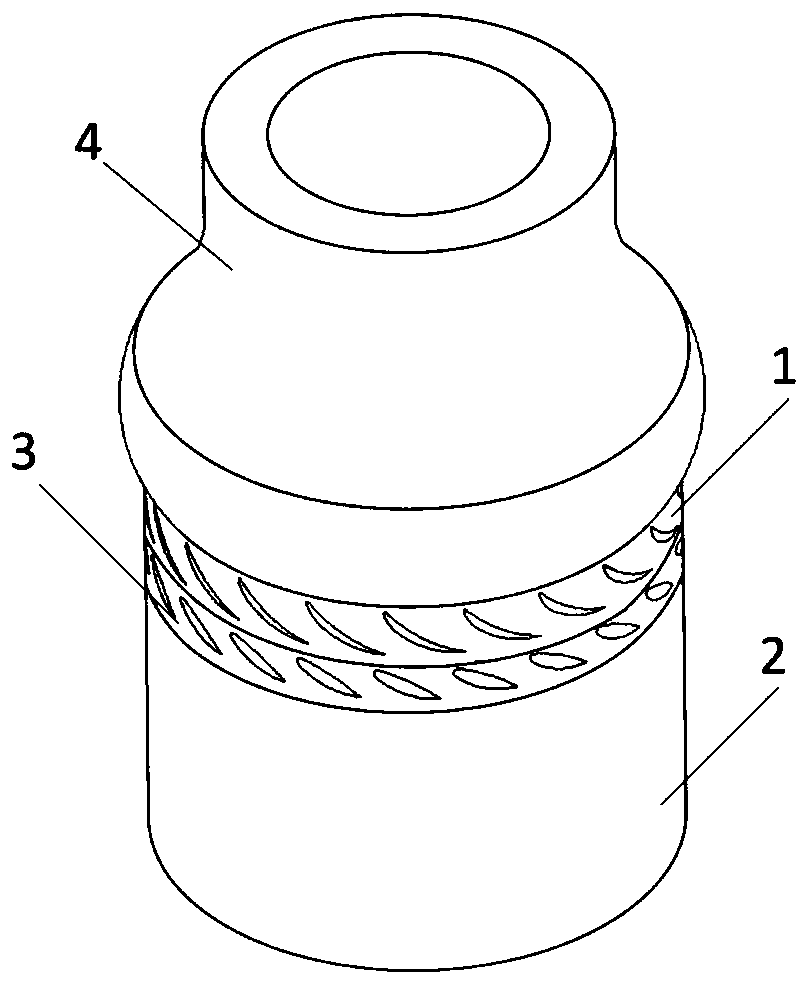

Embedded polymer/metal grid flexible transparent electrode and its preparation method and application

ActiveCN112951486BLow cost manufacturingLower node resistanceConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialMetal coatingLarge aspect ratio

The invention relates to an embedded polymer / metal grid flexible transparent electrode, a preparation method and an application. It includes a support layer, a photoresist layer, and a protective film. The photoresist layer is located between the support substrate and the protective film. The photoresist layer has a grid structure next to the protective film. The grid structure is formed by grooves. The grooves face One end of the protective film is open, the inner wall is provided with a metal coating, the inner side of the metal coating is coated with a polymer structure, the opening end of the groove is a metal seed layer, and the metal seed layer is close to the protective film. The preparation method is as follows: use the method of electric field-driven fusion jet deposition micro-nano 3D to print the grid structure, deposit the metal seed layer, transfer the polymer grid structure to the supporting substrate, deposit the metal coating by electroforming, coat the photoresist, support layer, remove the supporting base, and stick the protective film. Embedded flexible mesh transparent electrodes with high resolution, large aspect ratio, bending resistance, and high optoelectronic performance are obtained.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

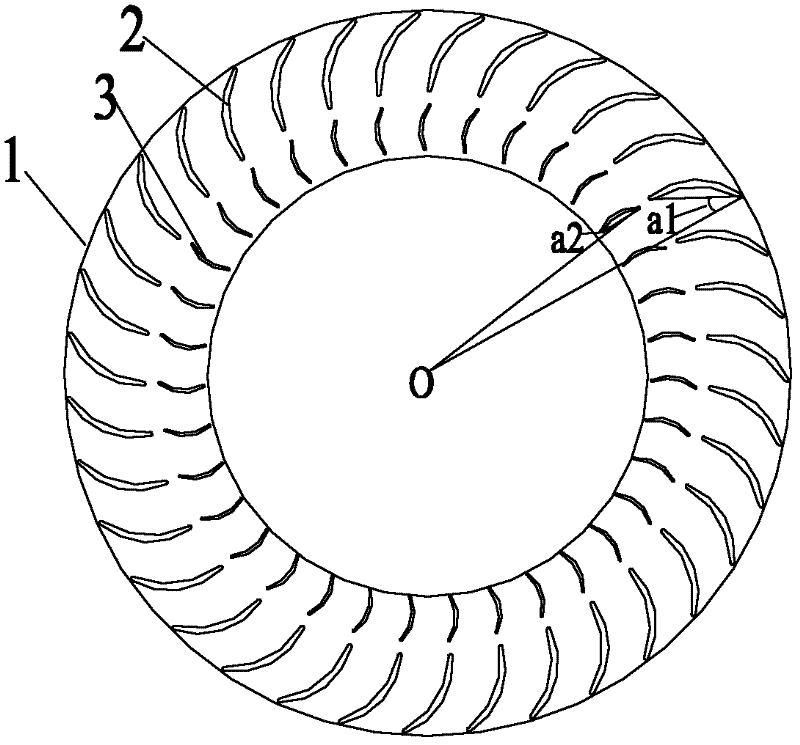

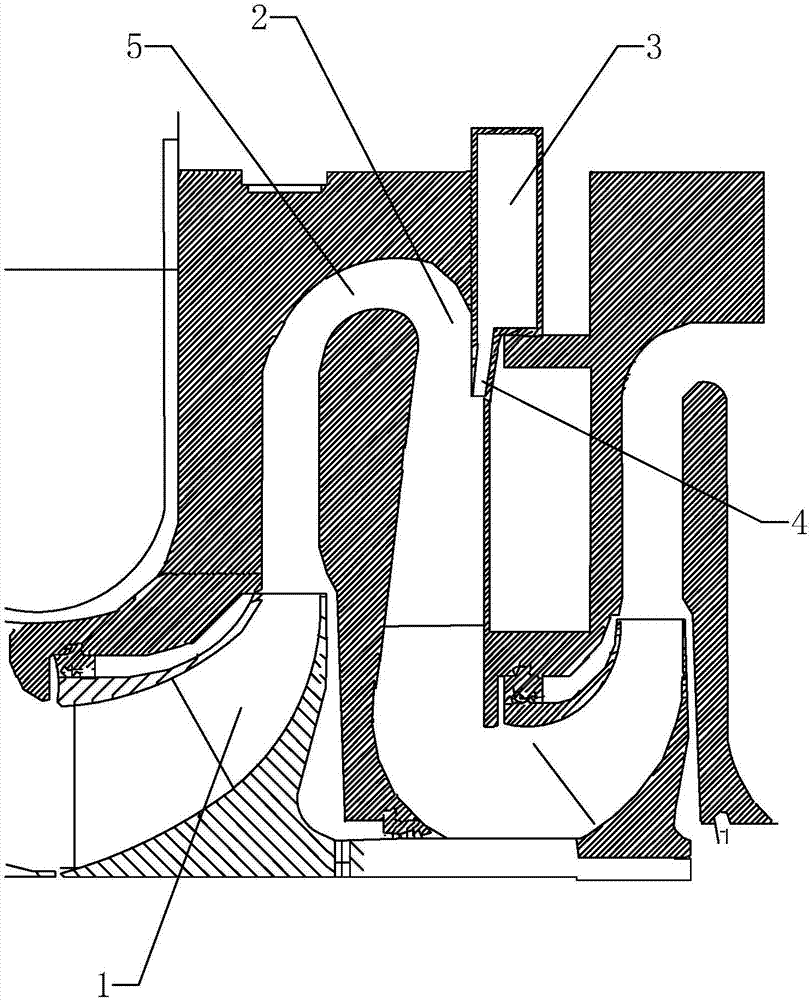

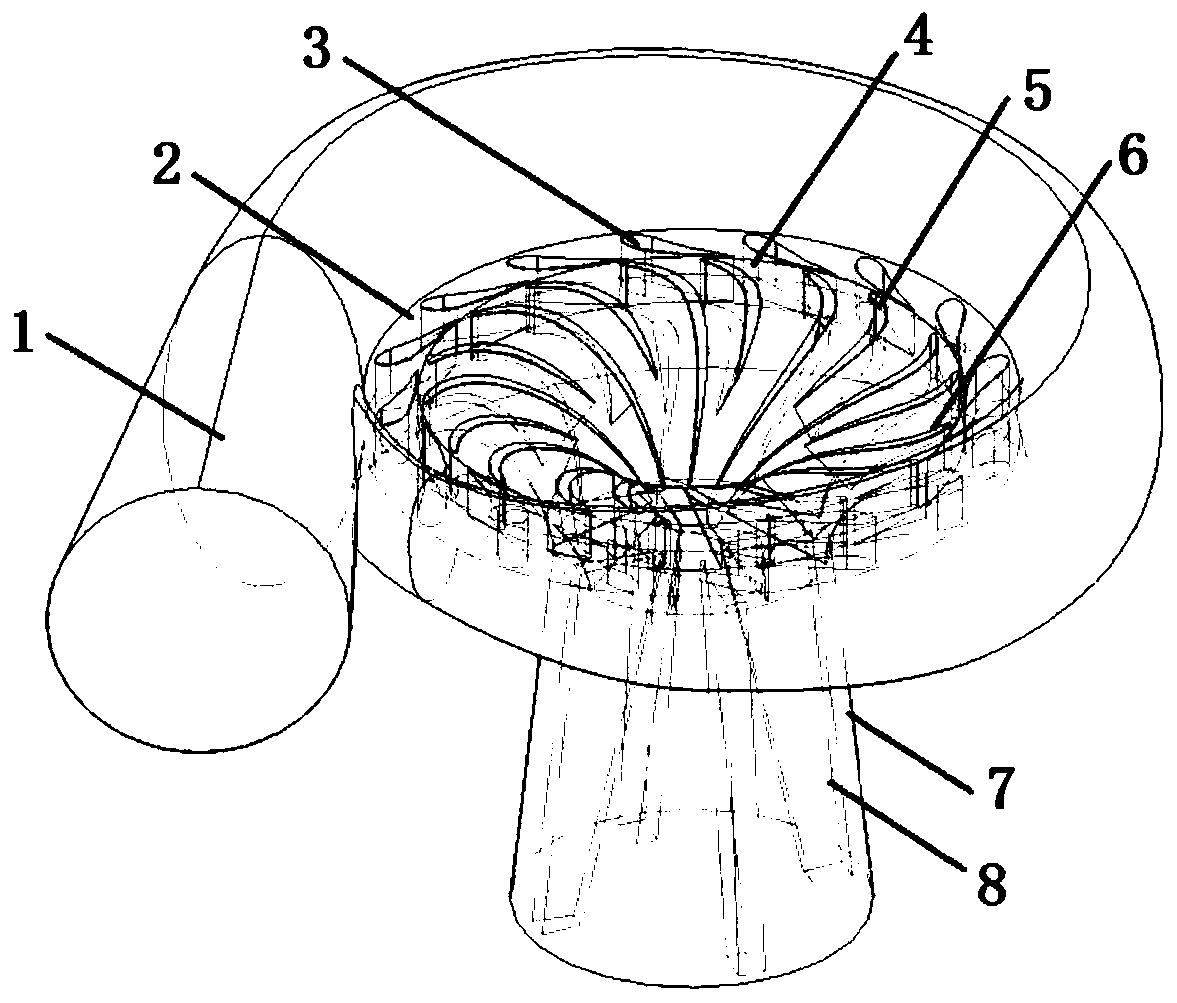

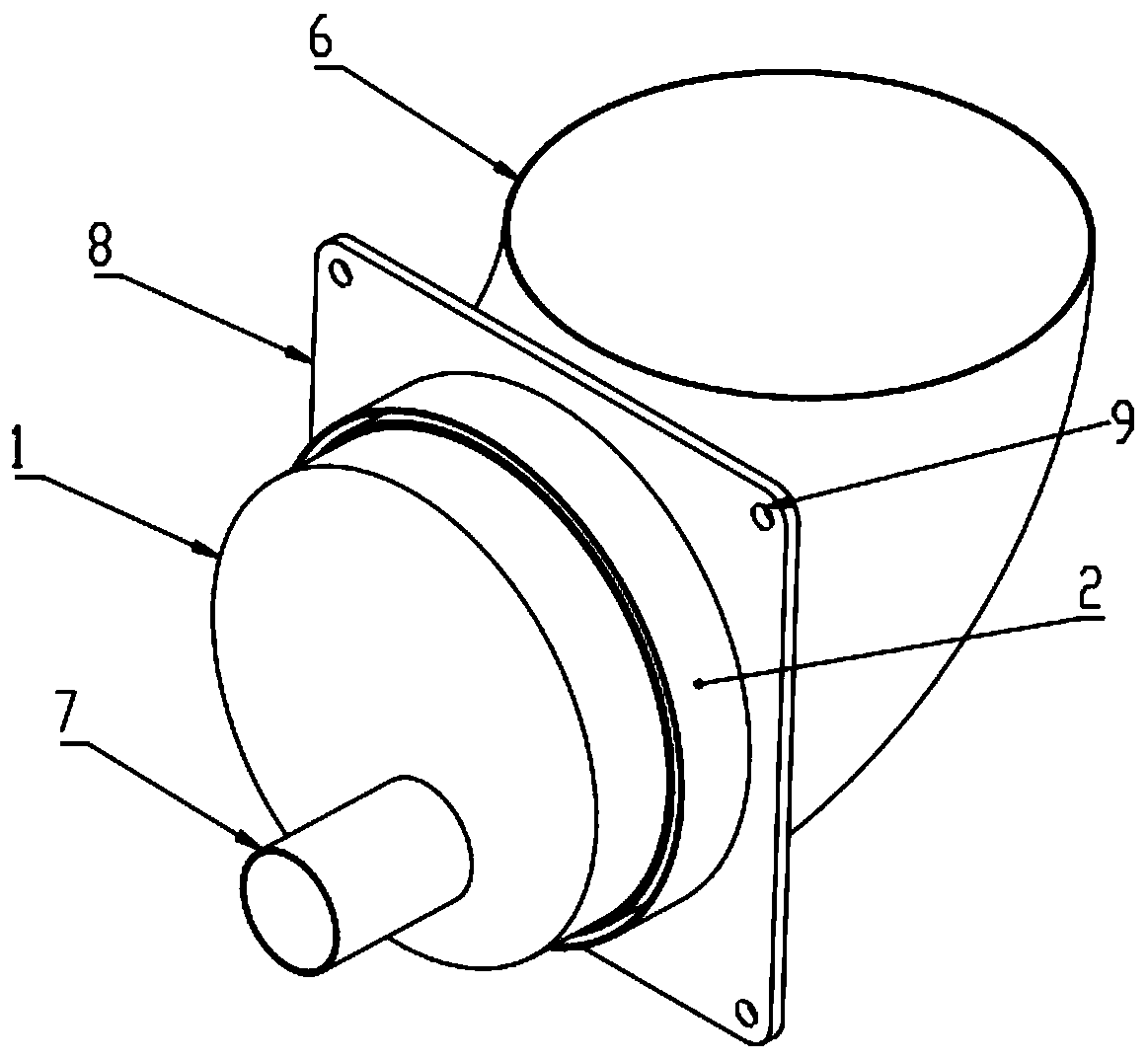

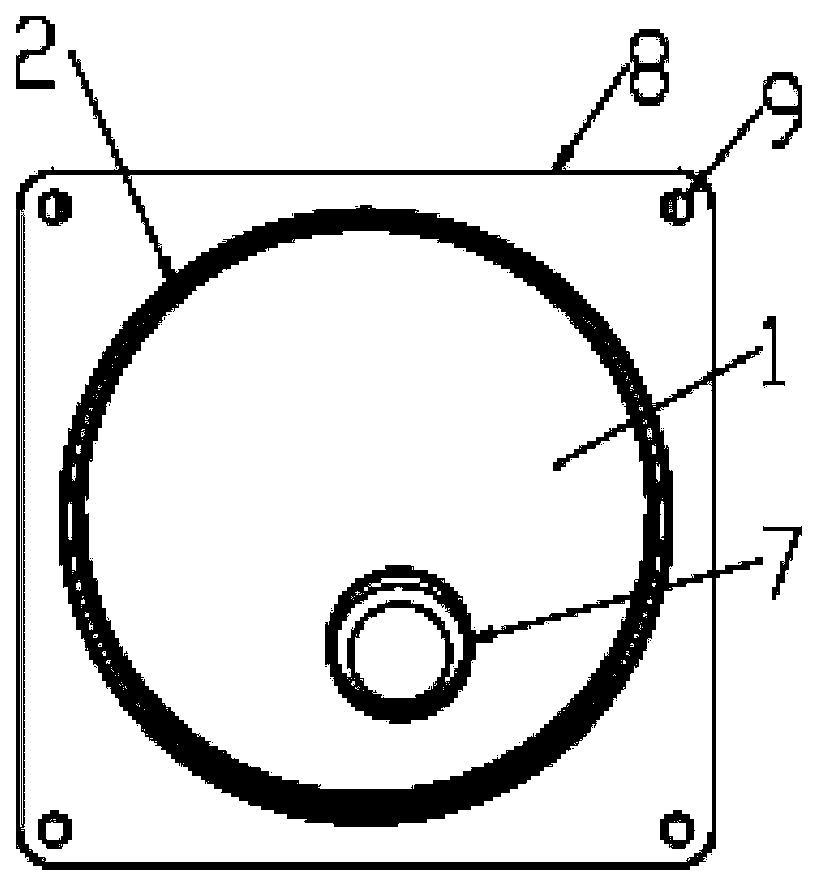

A new type of ultra-low specific speed pump-turbine

ActiveCN109798215BImprove efficiencyImprove running stabilityHydro energy generationReaction enginesWater turbineWater flow

The invention discloses a novel ultralow specific speed pump turbine. The novel ultralow specific speed pump turbine comprises a volute (4), a rotating wheel (1), a second-grade guide vane zone (3) and an exhaust water pipe (2), and water flow in a flow channel of the volute is axially input and output. The volute (4) is internally provided with multiple first-grade guide vanes (5) at the negativecurvature, and the first-grade guide vanes (5) are uniformly distributed in a single-row annular manner. The rotating wheel (1) comprises multiple rotating paddle type vanes (6). The second-grade guide vane zone (3) comprises multiple symmetrical whale-shaped movable guide vanes (7). The pump turbine can operate efficiently under two working conditions, namely power generation and water pumping;and a unit achieves good and stable performance when operating in a typical working condition transition process.

Owner:NORTHWEST A & F UNIV

A preparation method of ar diffractive optical waveguide imprint mold, soft mold and application

ActiveCN112026073BImprove printing accuracyMeet the precision requirementsFurnace typesElectroforming processesGraphicsGrating

The invention relates to a preparation method of an AR diffraction optical waveguide embossing mold, a soft mold and an application. The specific steps are: use a two-photon polymerization micro-nano 3D printer to print an electroforming mask on a nickel substrate; use nanosecond pulse micro-electroforming to electroform the obtained nickel substrate with a mask to obtain a tilted grating metal nickel mold ;Using the manufactured inclined grating metal nickel mold as the master mold, coating the graphic layer polymer PDMS on the master mold, pasting PET on the PDMS, embossing the mold, and adopting the peel-off type to obtain a one-time copy For the soft mold, repeat the steps of coating PDMS, sticking PET, embossing, and peeling off the mold, and finally make a composite soft mold in which several PDMS soft mold arrays are arranged on a PET. Realize high-precision, low-cost and high-efficiency manufacturing of large-area AR diffractive optical waveguide imprinting molds.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

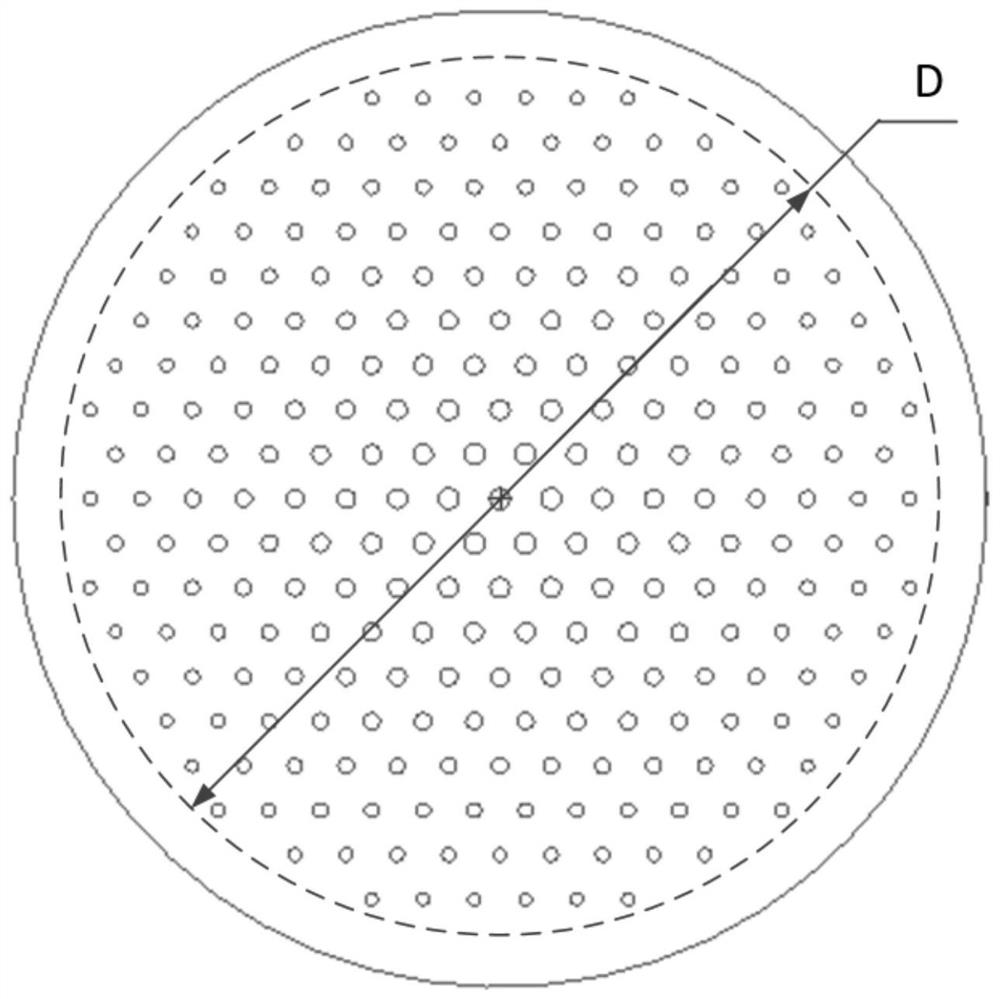

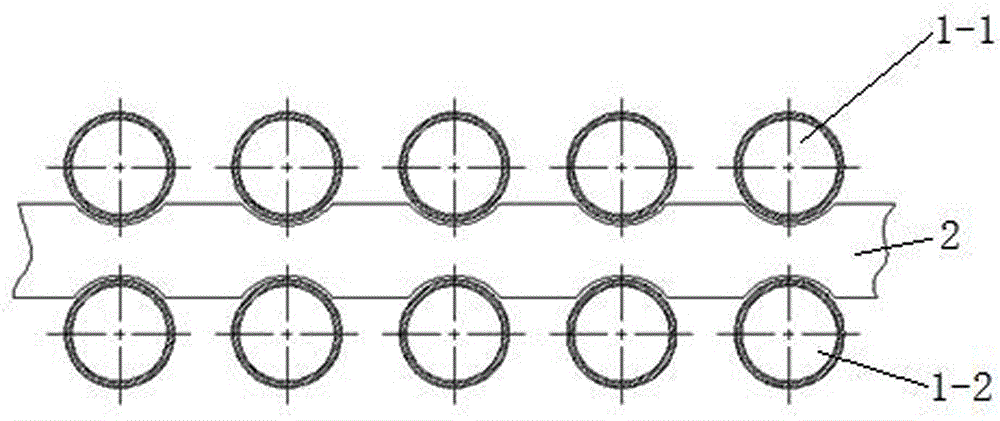

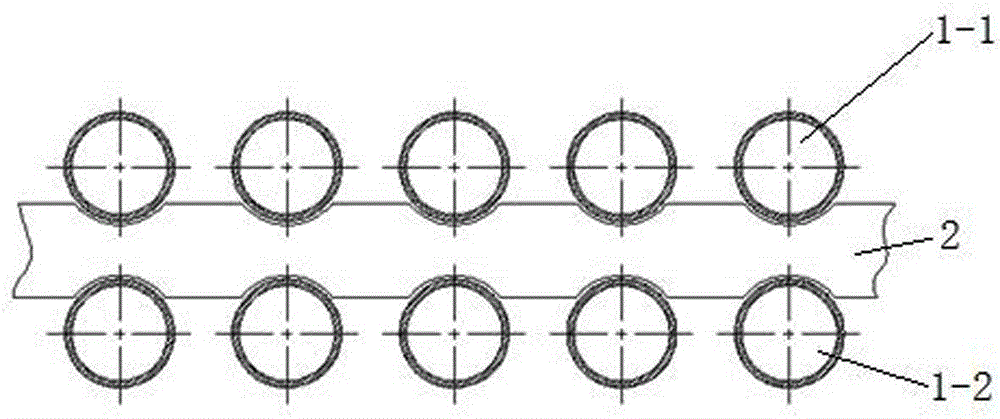

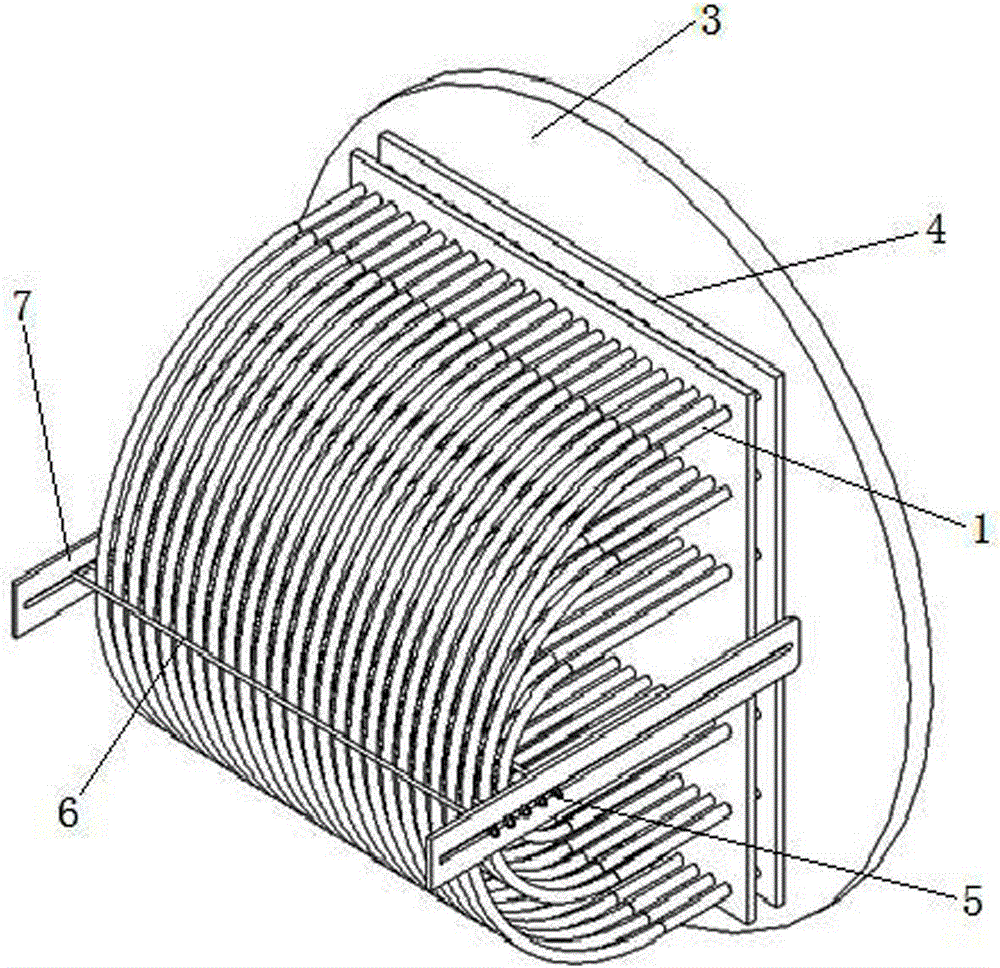

A shell-and-tube heat exchanger

ActiveCN104406431BImprove flow field characteristicsEffective limitStationary tubular conduit assembliesShell and tube heat exchangerPlate heat exchanger

The invention provides a shell and tube heat exchanger. A U-shaped heat exchange tube system arranged in n layers from the inside to the outside is arranged in the heat exchanger, the layers of the U-shaped heat exchange tubes are arranged in parallel, and two ends are fixedly connected with a tube system end tube plate. An anti-collision limit unit is arranged between the layers of the U-shaped heat exchange tubes respectively and comprises two location plates and n+1 separation rods. The two location plates are arranged on the two sides of the U-shaped heat exchange tube system, and the ends are fixedly connected with the tube system end tube plate. Installation grooves of the separation rods are formed in the corresponding positions in the two location plates which are detachably connected with the separation rods, and the separation rods are arranged before and after each layer of the U-shaped heat exchange tubes to separate the adjacent U-shaped heat exchange tubes. The shell and tube heat exchanger has the advantages that good flow field characteristics are provided, and vortexes are reduced; limit is performed effectively, and scratching of the tube walls is prevented; the requirement for assembly size is not high, and the practicality is high; the limit is flexible, cutting and tube flattening processes of tube sections are reduced, the efficiency is improved, the cost is reduced, and the cost performance is high.

Owner:DONGFANG TURBINE CO LTD

A Method for Adding Air Between Stages of a Large-Flow Compact Centrifugal Compressor

ActiveCN106870455BFlexible filling port position selectionSimple structural designGeometric CADPump componentsDesign cycleEngineering

Owner:TAIZHOU REXCHIP MECHANICAL & ELECTRICAL CO LTD

A ventilation pipeline device for humidification and noise reduction

ActiveCN110081580BReduce background noiseReduce noise hazardsDucting arrangementsLighting and heating apparatusVentilation tubeWater discharge

The invention provides a humidifying and silencing ventilation pipeline device. A plurality of supporting racks are included and arranged in a ventilation pipeline. The section of each supporting rackis in a symmetric streamline shape, the head-tail direction of each supporting rack is kept to be consistent with the gas flowing direction, and gas jet flow flows towards the tails of the supportingracks from the heads of the supporting racks. An inner pipeline is arranged on the inner side of the front portion of each supporting rack, and a plurality of water spraying holes are formed in the wall faces of the two sides of the front portion of each supporting rack, wherein the inner pipeline comprises a driver, a transmission rod, a supporting pipe, an inner water conveying pipe and a rotary water spraying pipe, water can be sprayed from the positions of the water spraying holes, and the water spraying direction can be adjusted. Drying layers are arranged on the two sides of the rear portion of each supporting rack, water discharging grooves are formed in the lower positions of the drying layers, and the drying layers can absorb water of the surrounding environment and discharge water into the water discharging grooves. The water discharging grooves communicate with a water discharging pipe outside the ventilation pipeline. According to the humidifying and silencing ventilationpipeline device, on the basis of optimizing of the pipeline inner gas flow field, the humidifying noise lowering technology is utilized, spreading of noise in the ventilation pipeline is restrained, and background noise is lowered.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Nuclear power plant reactor flow distribution structure

ActiveCN102800371BImprove distribution uniformityImprove flow field characteristicsNuclear energy generationReactor fuel elementsNuclear reactor coreNuclear reactor

The invention discloses a flow distribution structure of a reactor of a nuclear power station. The flow distribution structure is used for distributing the flow of coolant of a cooled reactor core and comprises a reactor core lower supporting plate and an end-socket-shaped structure fixed on the reactor core lower supporting plate; and the end-socket-shaped structure comprises an end socket with drain holes. Compared with the prior art, the flow distribution structure of the reactor of the nuclear power station has the advantages that the shape of a coolant channel is changed through the end socket, so that characteristics of a flow field of a lower cavity are improved effectively, vertex shedding of reactor internals in the lower cavity is avoided, the flow of the coolant is distributed through the drain holes of the end socket, and uniformity of flow distribution of fuel assemblies entering the reactor core is perfect.

Owner:中广核工程有限公司 +1

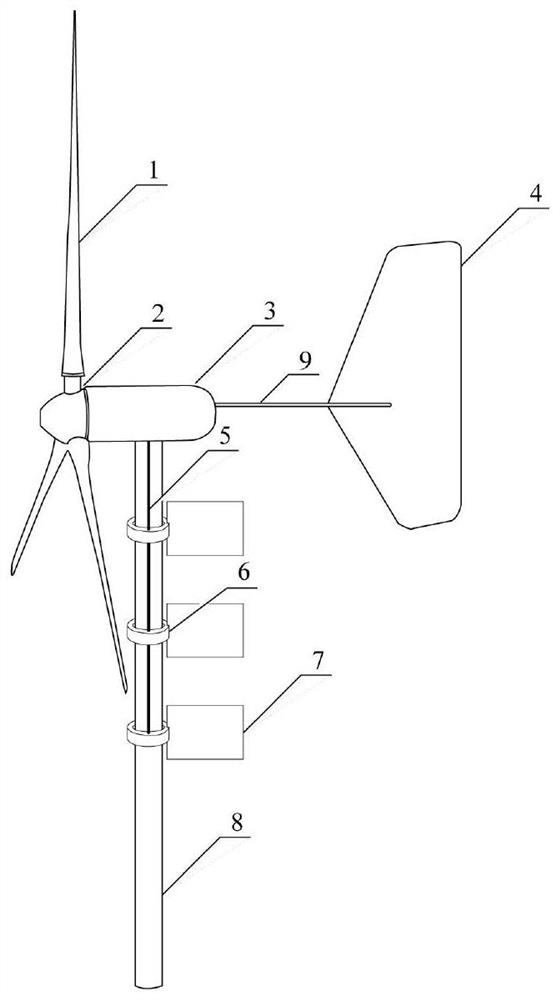

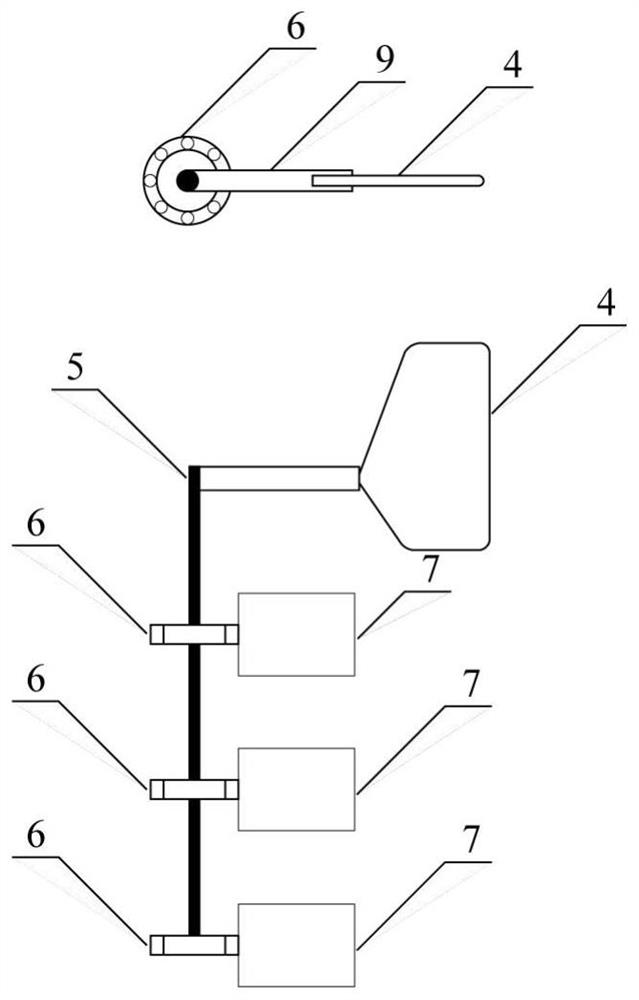

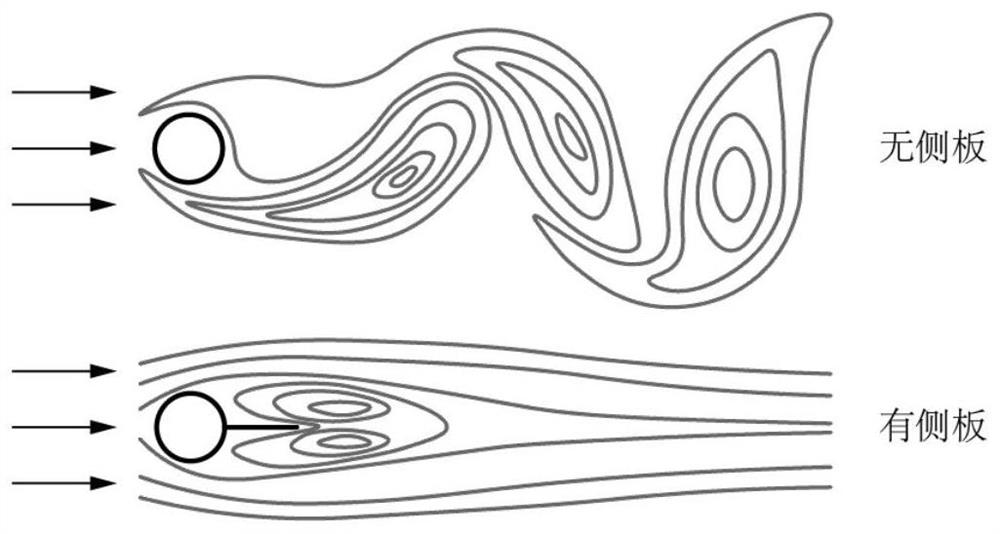

Novel self-adaptive vortex suppression control wind turbine tower structure

PendingCN114738199AImprove flow field characteristicsImprove stabilityEngine fuctionsWind motor supports/mountsExternal energyNacelle

The invention discloses a novel self-adaptive vortex suppression control wind turbine tower structure. The novel self-adaptive vortex suppression control wind turbine tower structure comprises a tower, a cabin fixedly connected with the tower, a hub arranged on the cabin, blades fixedly connected to the hub, a plurality of bearings connected to the tower in a sleeving mode and side plates fixedly connected to the bearings. The tower is fixedly connected with two oppositely-arranged connecting rods, the connecting rods extend into the cabin, and the ends, located in the cabin, of the connecting rods are fixedly connected with tail vanes. According to the invention, the generation of the periodic Karman vortex street is limited, resonance is avoided, the stability of the tower is enhanced, external energy input is not needed, the structure is simple, and the method is simple and feasible.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

A new type of flapping wing propulsion device and its working process

ActiveCN113665807BBoost feature improvementsIncrease pressure differencePropulsion based emission reductionOrnithoptersFlapping wingClassical mechanics

A novel flapping wing propulsion device and its working process include a flapping wing main body, a pair of tail sealing plates are hinged at the trailing edge of the flapping wing main body, and a step is respectively provided on the upper surface and the lower surface of the tail part of the flapping wing main body, and forms a step. A plurality of retracting rods are installed between the stepped surface, the tail sealing plate and the stepped surface, and the movements of the retracting rods control the opening and closing of the tail sealing plate. The tail sealing plate can be adaptively adjusted according to the movement position of the flapping wing. On the one hand, the existence of the tail sealing plate greatly increases the pressure difference between the upper and lower surfaces of the flapping wing, and the corresponding lift is also significantly increased. There is an angle of attack in the horizontal direction, so the component force of the lift force increased in the vertical direction in the horizontal direction is also increased, so the propulsion characteristics of the flapping wing are improved; The flow field characteristics are improved, the flow separation at the trailing edge of the flapping wing is gradually slowed down, the energy dissipation is reduced, and the system input power is greatly reduced.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

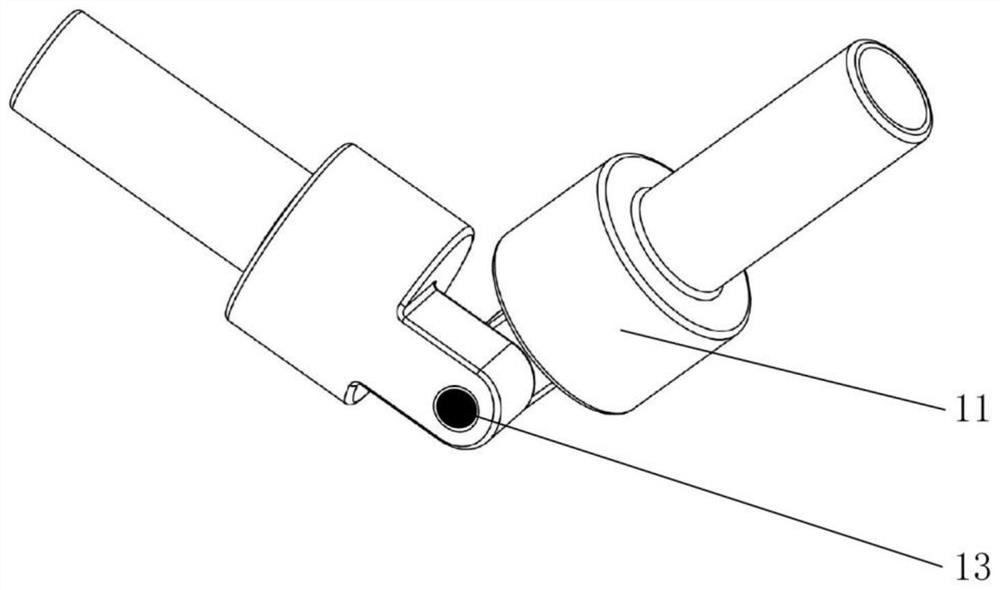

Durable anti-smell-returning range hood check valve

InactiveCN110274060AExcellent mechanical propertiesGuaranteed automatic graceful shutdownCheck valvesPipe-jointsEngineeringCheck valve

The invention aims to provides a durable anti-smell-returning range hood check valve. The durable anti-smell-returning range hood check valve comprises a valve body and a valve plate; a lampblack inlet is arranged in front of the valve body; a bent pipe is connected behind the valve body; the valve plate is mounted in the valve body through a valve shaft; and a moment center change device is mounted on the leeside of the valve plate. The moment center change device is adopted to improve mechanical performances of the valve plate to meet resistance suffered by the valve plate after attachment of oil stains. The device can automatically change the mechanical performances according to an opening angle of the valve plate to meet different requirements of startup and stop of a range hood and opening and closing of the valve plate. The durable anti-smell-returning range hood check valve is simple in structure and high in adaptability. Each improvement for the mechanical performances of the range hood check valve at present is only to increase a counterweight of the valve plate, although the normal automatic closing of the valve plate can be guaranteed after attachment of the oil stains, meanwhile, the valve plate opening resistance is generated, so that the valve plate is possibly not opened after startup of the range hood, and lampblack is stopped to flow back to a kitchen.

Owner:HARBIN ENG UNIV

Novel flapping wing propelling device and working process

ActiveCN113665807ABoost feature improvementsIncrease pressure differencePropulsion based emission reductionOrnithoptersFlapping wingEngineering

The invention discloses a novel flapping wing propelling device and a working process. The device comprises a flapping wing body, a pair of tail sealing plates are hinged to the tail edge of the flapping wing body, the upper surface and the lower surface of the tail of the flapping wing body are each provided with a step, a step surface is formed, a plurality of telescopic rods are installed between the tail sealing plates and the step surfaces, and the telescopic rod acts to control opening and closing of the tail sealing plate. The tail sealing plate can be adaptively adjusted according to the movement position of the flapping wing, on one hand, the pressure difference between the upper surface and the lower surface of the flapping wing is greatly increased, and the corresponding lift force is obviously increased, so that the component force of the lift force increased in the vertical direction in the horizontal direction is also increased, and the propulsion characteristic of the flapping wing is improved; and on the other hand, due to the existence of the tail sealing plate, the flow field characteristics around and at the tail part of the flapping wing are improved, the flow separation at the tail edge of the flapping wing is gradually slowed down, the energy dissipation is reduced, and the input power of the system is greatly reduced.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Shell and tube heat exchanger

ActiveCN104406431AImprove flow field characteristicsEffective limitStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

The invention provides a shell and tube heat exchanger. A U-shaped heat exchange tube system arranged in n layers from the inside to the outside is arranged in the heat exchanger, the layers of the U-shaped heat exchange tubes are arranged in parallel, and two ends are fixedly connected with a tube system end tube plate. An anti-collision limit unit is arranged between the layers of the U-shaped heat exchange tubes respectively and comprises two location plates and n+1 separation rods. The two location plates are arranged on the two sides of the U-shaped heat exchange tube system, and the ends are fixedly connected with the tube system end tube plate. Installation grooves of the separation rods are formed in the corresponding positions in the two location plates which are detachably connected with the separation rods, and the separation rods are arranged before and after each layer of the U-shaped heat exchange tubes to separate the adjacent U-shaped heat exchange tubes. The shell and tube heat exchanger has the advantages that good flow field characteristics are provided, and vortexes are reduced; limit is performed effectively, and scratching of the tube walls is prevented; the requirement for assembly size is not high, and the practicality is high; the limit is flexible, cutting and tube flattening processes of tube sections are reduced, the efficiency is improved, the cost is reduced, and the cost performance is high.

Owner:DONGFANG TURBINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com