Ultrasonic plasma gun feeding powder internally

A technology of supersonic plasma and internal powder feeding, applied in the direction of plasma, electrical components, etc., can solve the problems of unstable jet flow, poor batch stability of coating quality, high cost, etc., and achieve low nozzle blocking rate and batch stability Good performance and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

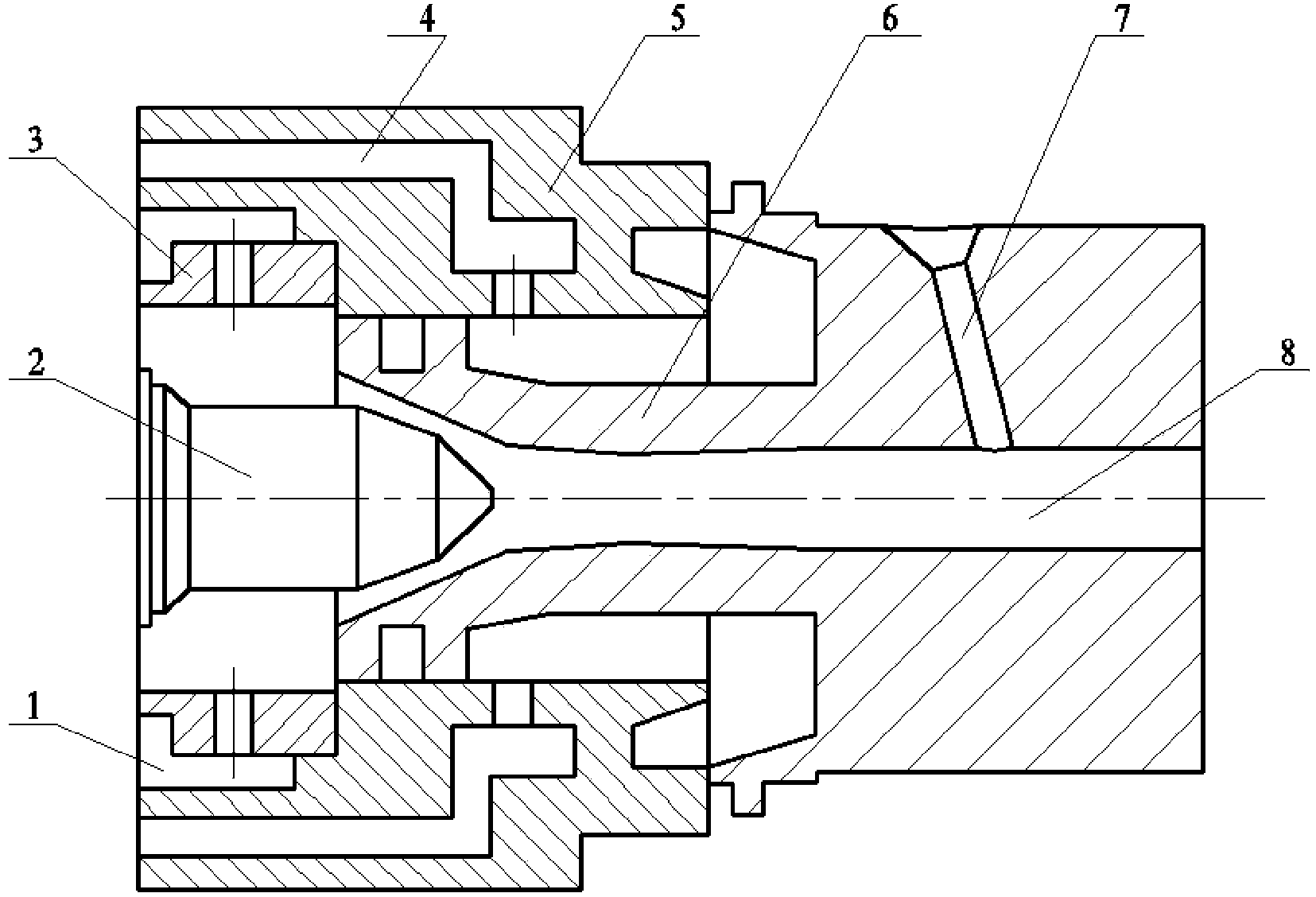

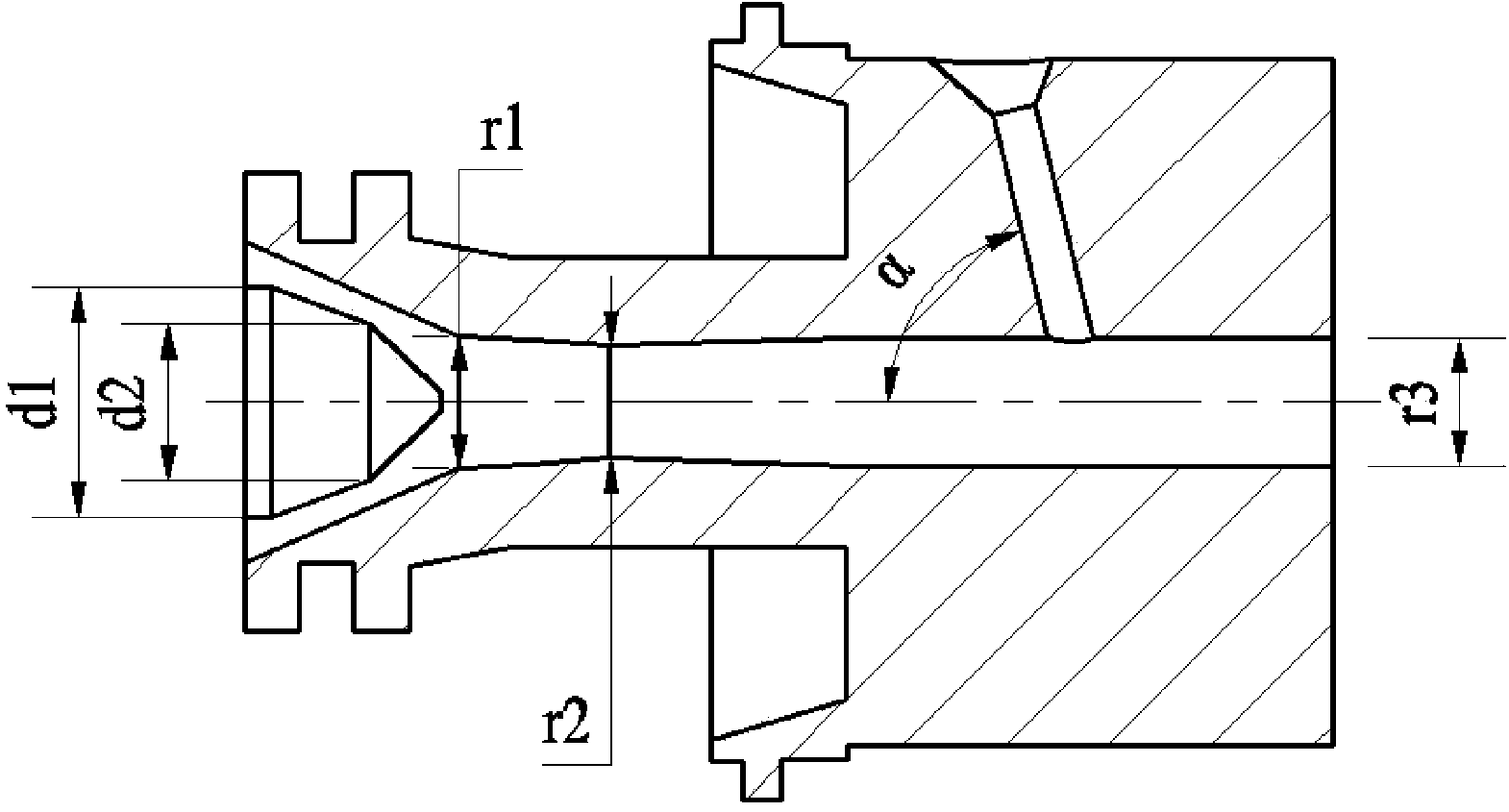

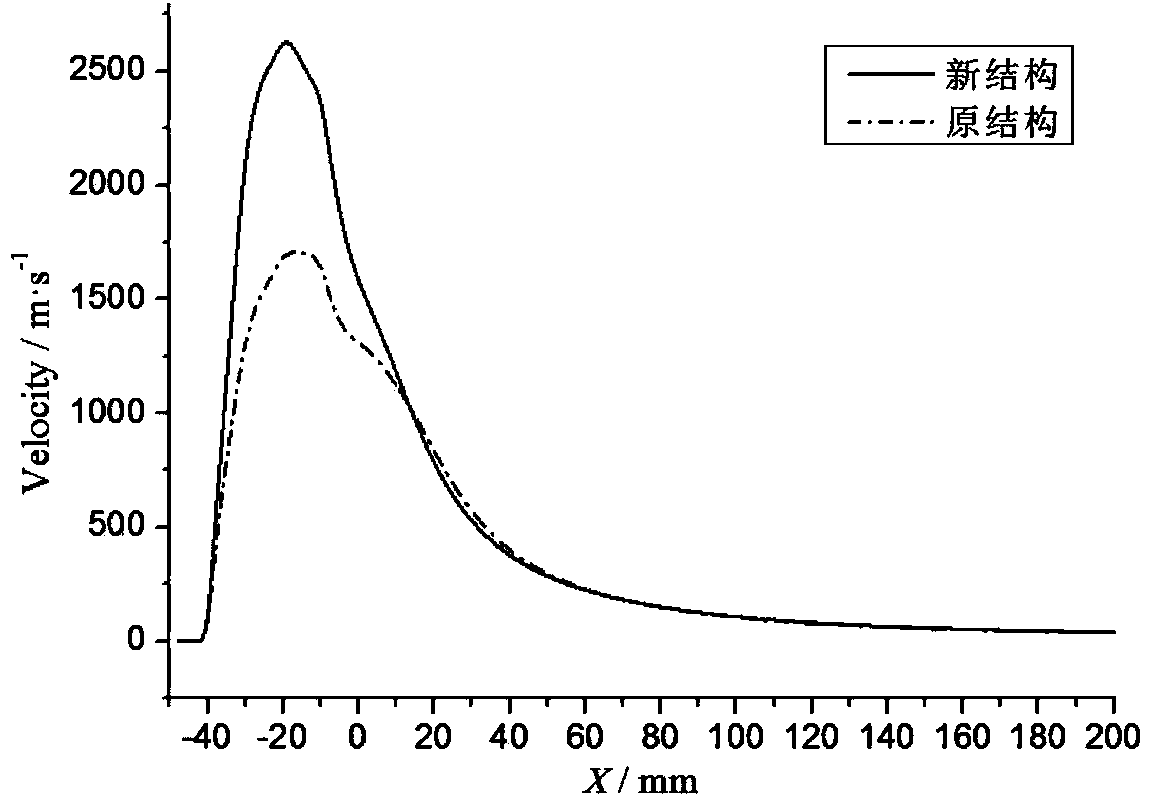

[0019] see figure 1 The present invention includes a gun body 5 and a cathode 2 installed in the gun body. The cathode 2 includes a cylindrical body and a conical front end, and one end is inserted into the gun body 5 to match the conical structure of the front end of the cathode 2. Cooperating anode 6, the anode 6 is provided with a convergent-divergent main flow channel 8, and the compression and expansion section is a Rafael curved surface, and the outer wall of the anode 6 is also provided with a delivery channel that communicates with the main flow channel 8. Powder flow channel 7, cooling water flow channel 4 and air flow channel 1 are distributed in the gun body 5, a gas distribution ring 3 is installed in the air flow channel 1, and an air inlet connected to the main air flow channel 8 is provided on the gas distribution ring 3 .

[0020] The conica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com