Wing surface fusion-type edge strips

An airfoil and edge strip technology, which is applied in the field of wing and edge deformation structure design, can solve the problem that edge strips are difficult in the design and layout of variant aircraft, the fusion of edge strips and airfoil surfaces has not been well solved, and it is easy to generate Interference and other problems, to achieve the effect of improving supersonic cruise and penetration capabilities, delaying the generation of local shock waves, and delaying airflow separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with examples, but the implementation of the present invention is not limited thereto.

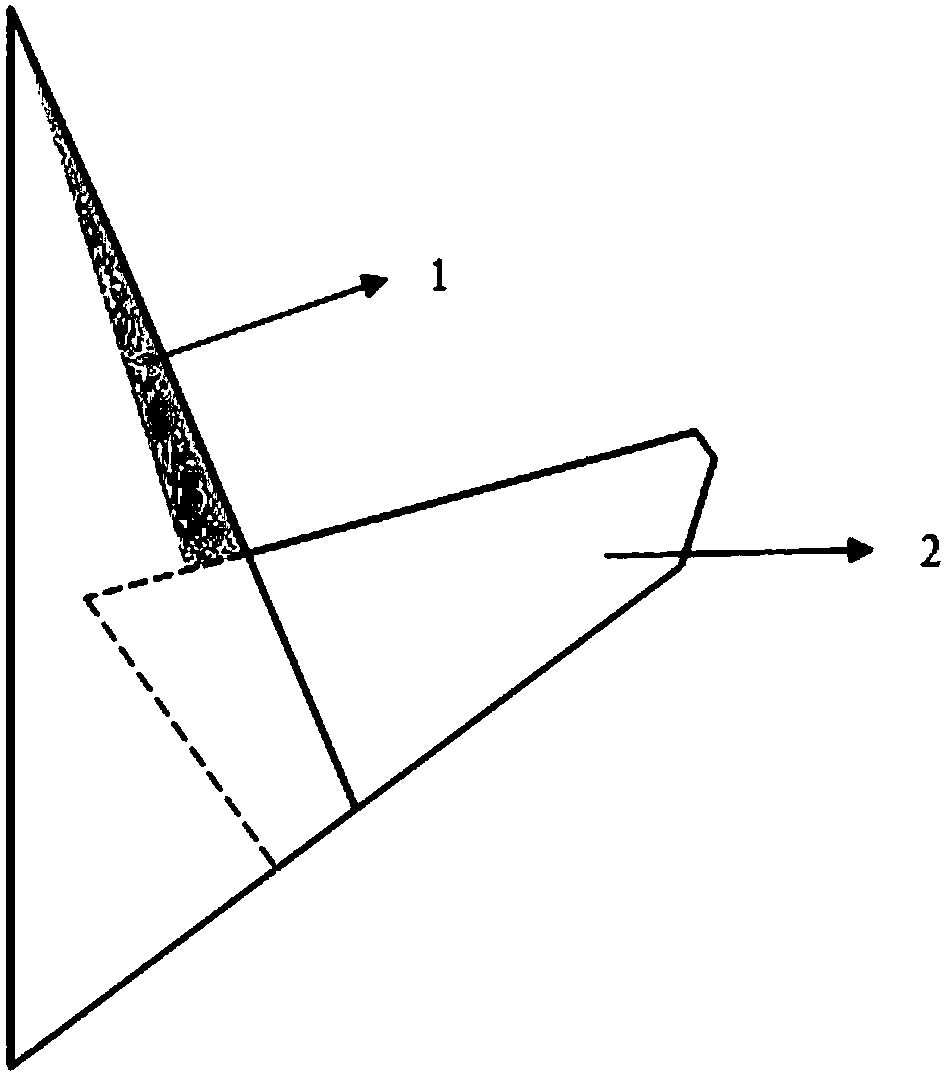

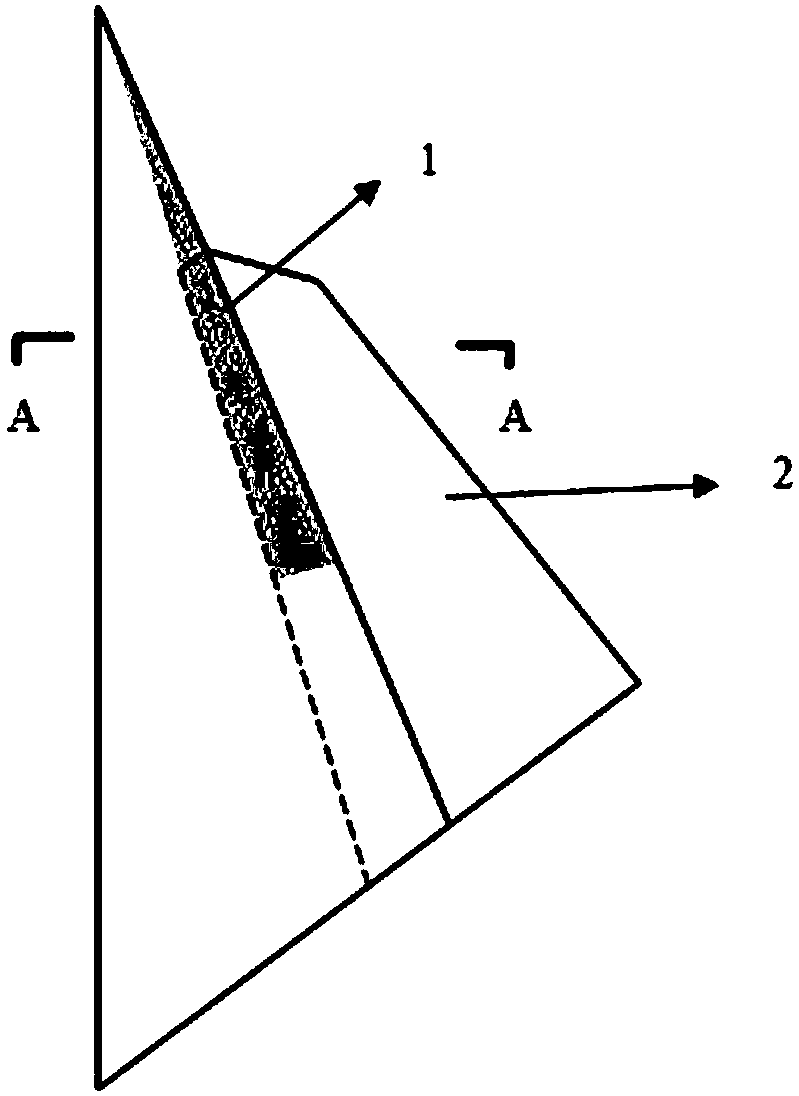

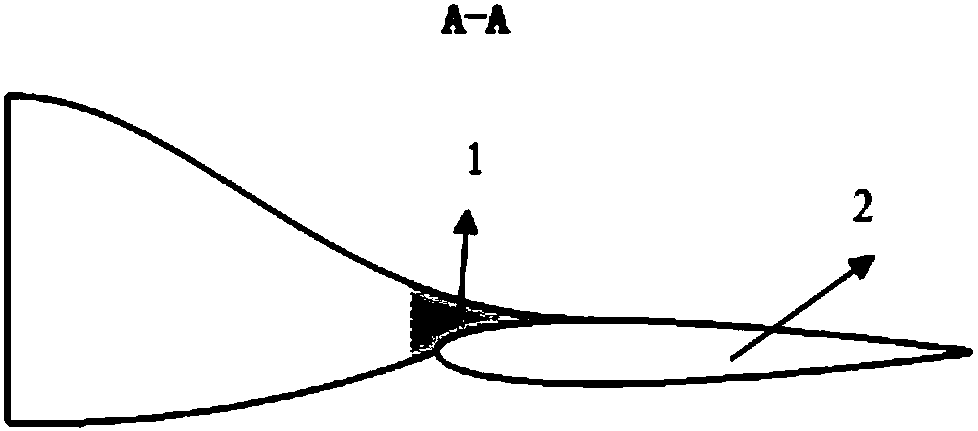

[0015] The airfoil fusion edge strip proposed by the present invention has two use states. The first state, the edge strip and the wing surface separated state, both open state (see figure 1 ). In this state, the sidebar can generate strong vortex at high angle of attack, improve the flow field characteristics of the upper airfoil, delay airflow separation, increase airfoil lift, and improve the maneuverability of the entire aircraft. The second state, the edge strip and the airfoil joint state, both closed state (see figure 2 ). In this state, the edge strips are joined with the airfoil surface, and the upper surface of the edge strips and the upper airfoil surface realize the continuous second-order curvature (see image 3 ), the separation of air flow through the upper surface is greatly reduced, effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com